Overview

Selecting industrial axial fans effectively necessitates a focus on three pivotal steps:

- Determining airflow requirements

- Evaluating static pressure needs

- Considering size and mounting options

Understanding these criteria is essential for ensuring optimal fan performance and efficiency, as they directly influence cooling and ventilation capabilities across various industrial applications. By meticulously assessing these factors, one can guarantee that the selected fan meets the specific demands of the environment, thereby enhancing operational effectiveness.

Introduction

Selecting the right industrial axial fan is pivotal for enhancing operational efficiency and minimizing energy consumption across various applications. In an era where sustainability and energy savings are paramount, it is essential for engineers and facility managers to grasp the distinct features and performance metrics of axial fans.

Nevertheless, the process of identifying the most suitable fan is often fraught with challenges—ranging from inadequate airflow to excessive noise levels. Therefore, what criteria should be prioritized to ensure optimal performance while effectively navigating these complexities?

Understand Axial Fans: Definition and Key Features

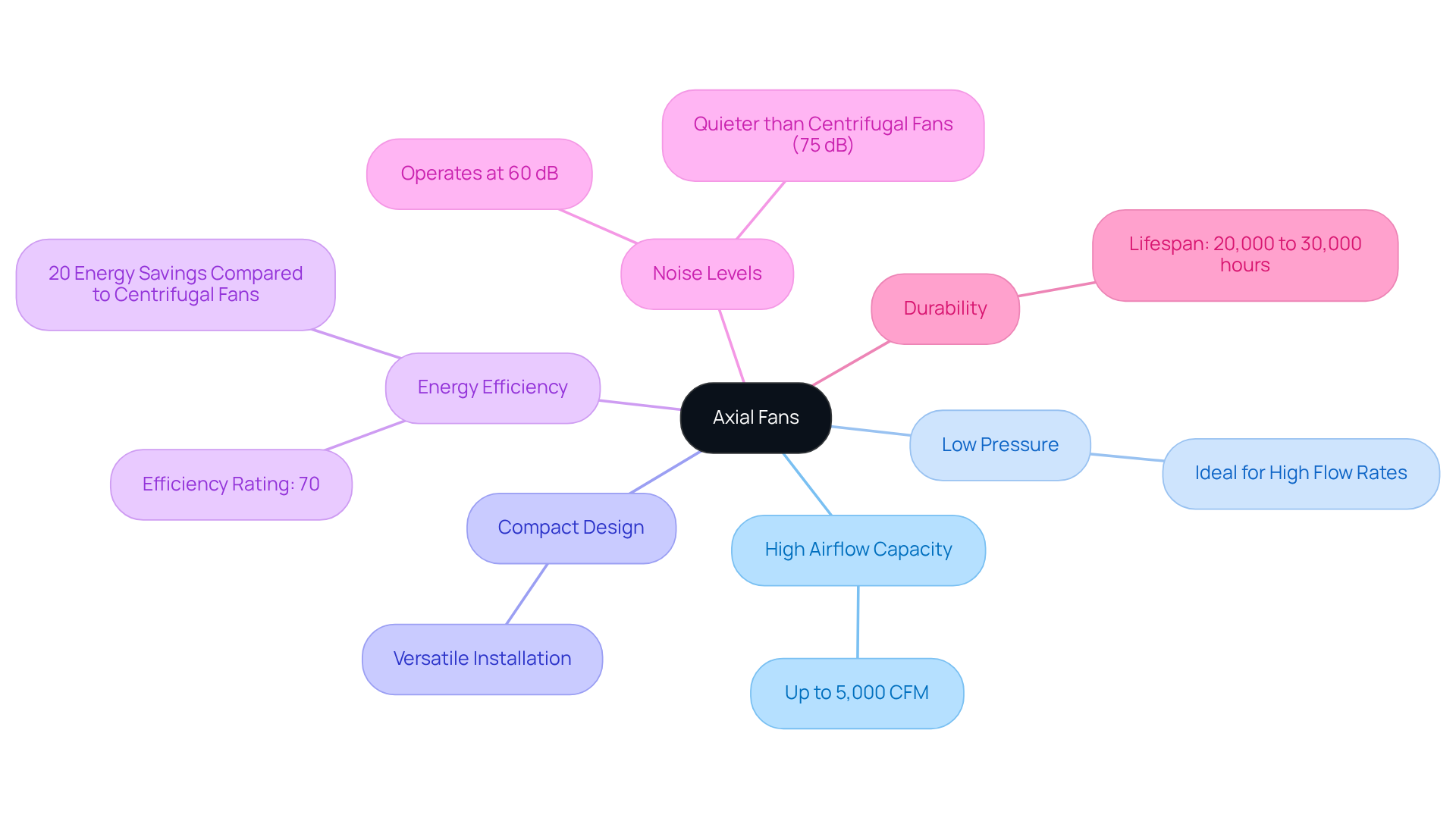

Axial blowers are sophisticated mechanical devices engineered to move air or gas parallel to the rotating axis. They are characterized by their propeller-like blades, which draw air in and discharge it in the same direction. The key features of axial fans include:

- High Airflow Capacity: Capable of moving up to 5,000 cubic feet of air per minute (CFM), axial fans excel in cooling and ventilation applications. This makes them ideal for environments that require substantial air movement.

- Low Pressure: Operating typically at low static pressures, these ventilators are well-suited for applications demanding high flow rates without significant resistance, thereby enhancing their effectiveness across various settings.

- Compact Design: Their streamlined construction allows for installation in tight spaces, providing versatility throughout different industrial environments that often require industrial axial fans.

- Energy Efficiency: Energy efficiency is demonstrated by industrial axial fans, which have an efficiency rating of approximately 70%, converting a significant portion of input power into useful airflow. This efficiency can lead to energy savings of up to 20% compared to centrifugal blowers, establishing them as a cost-effective option for continuous operation.

- Noise Levels: Axial types generally operate at a lower audible noise level of 60 dB, making them quieter than centrifugal models, which can reach sound levels of up to 75 dB.

- Durability: The lifespan of industrial axial fans is projected to range between 20,000 to 30,000 hours, offering long-term value and dependability.

In 2025, the emphasis on energy efficiency in rotating devices continues to grow, driven by sustainability initiatives and regulations. The global ventilation market is expected to expand with a CAGR of 5.98% until 2029, indicating a rising demand for effective airflow solutions. Engineers are increasingly recognizing the importance of selecting high-efficiency devices to enhance performance while reducing operational expenses. Real-world applications demonstrate that industrial axial fans effectively manage low-pressure environments, ensuring reliable airflow across various industrial settings. Nonetheless, challenges such as balancing efficiency with noise levels and compliance with environmental regulations persist in the market. Understanding these characteristics will empower you to determine if a fan aligns with your .

Identify Key Selection Criteria for Axial Fans

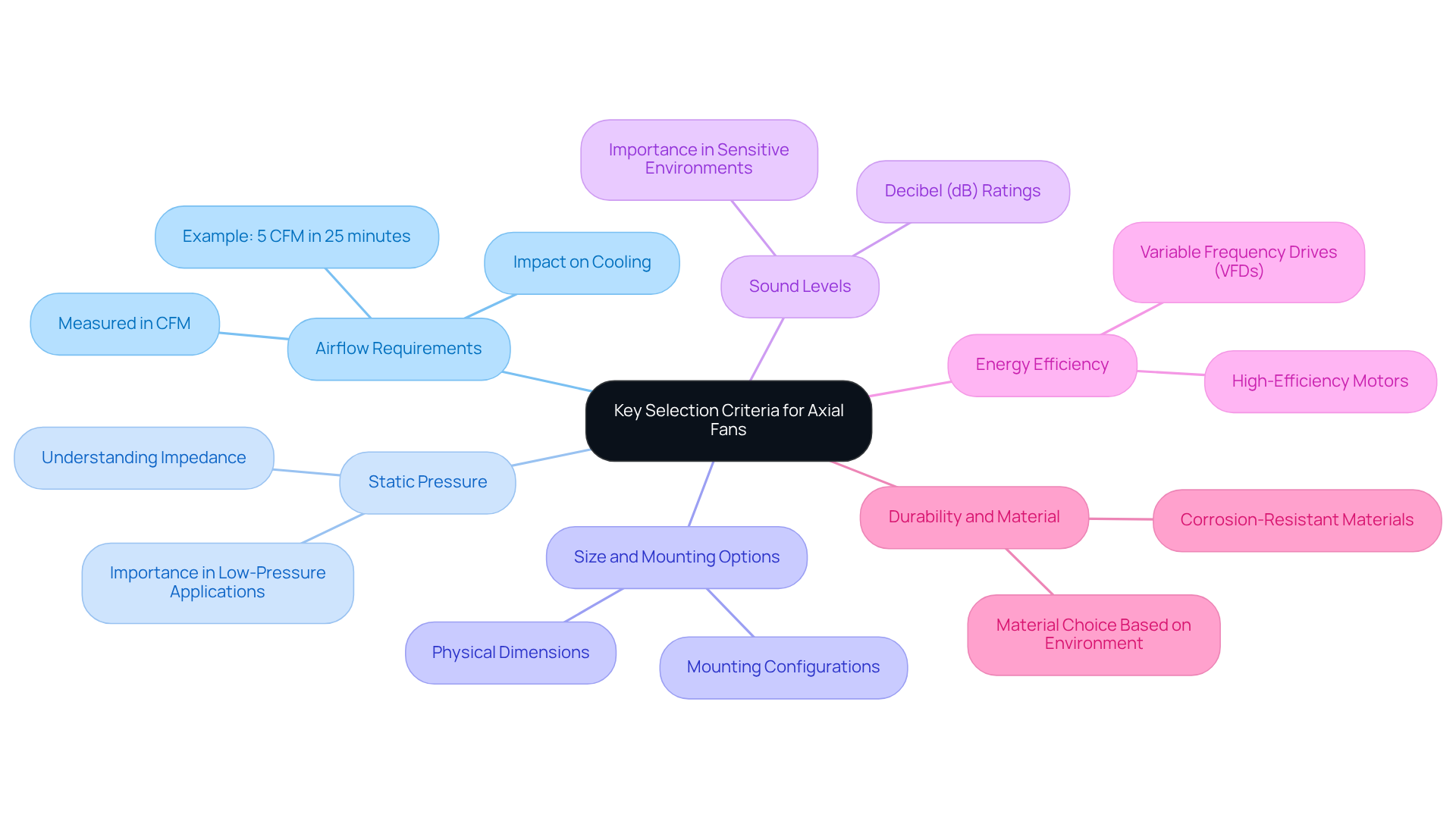

When selecting an axial fan, several key criteria must be considered to ensure optimal performance and efficiency:

- Airflow Requirements: It is essential to accurately determine the required airflow in cubic feet per minute (CFM) for your application. This measurement is crucial for guaranteeing sufficient cooling or ventilation, particularly in electronics cooling, where the movement of air directly impacts system performance. For instance, a fan generating 5 CFM will take approximately 25 minutes to ventilate a 5 ft x 5 ft x 5 ft enclosure, providing practical context for your ventilation needs.

- Static Pressure: Evaluating the static pressure requirements of your system is vital. Understanding the pressure drop within your system is imperative, as industrial axial fans excel in low-pressure applications. Additionally, the concept of impedance should be considered, as it significantly influences the actual airflow and static pressure in your application.

- Size and Mounting Options: Assessing the physical dimensions of the fan alongside available mounting configurations is crucial. Ensuring the fan fits within the designated space and can be securely installed is vital for effective operation.

- Sound Levels: It is important to consider the acceptable sound levels for your application. Numerous industrial axial fans are designed for silent functioning, which is particularly crucial in environments where sound sensitivity is a priority. Choosing fans based on their decibel (dB) rating can assist in meeting noise level standards.

- Energy Efficiency: Prioritizing devices that offer energy-efficient operation can significantly reduce operational costs. Look for energy ratings and specifications that indicate power consumption, as high-efficiency motors can lead to substantial energy cost savings over time. Furthermore, variable frequency drives (VFDs) allow users to adjust fan speed based on demand, enhancing energy efficiency further.

- Durability and Material: Examining the materials used in the fan’s construction is essential. For harsh environments, fans made from corrosion-resistant materials, such as stainless steel or coated aluminum, are preferable to ensure longevity and reliability.

By thoroughly assessing these criteria, you can effectively narrow down your options and select the most suitable industrial axial fans tailored to your specific needs, thereby enhancing both performance and efficiency in your applications.

Address Common Challenges and Solutions in Axial Fan Selection

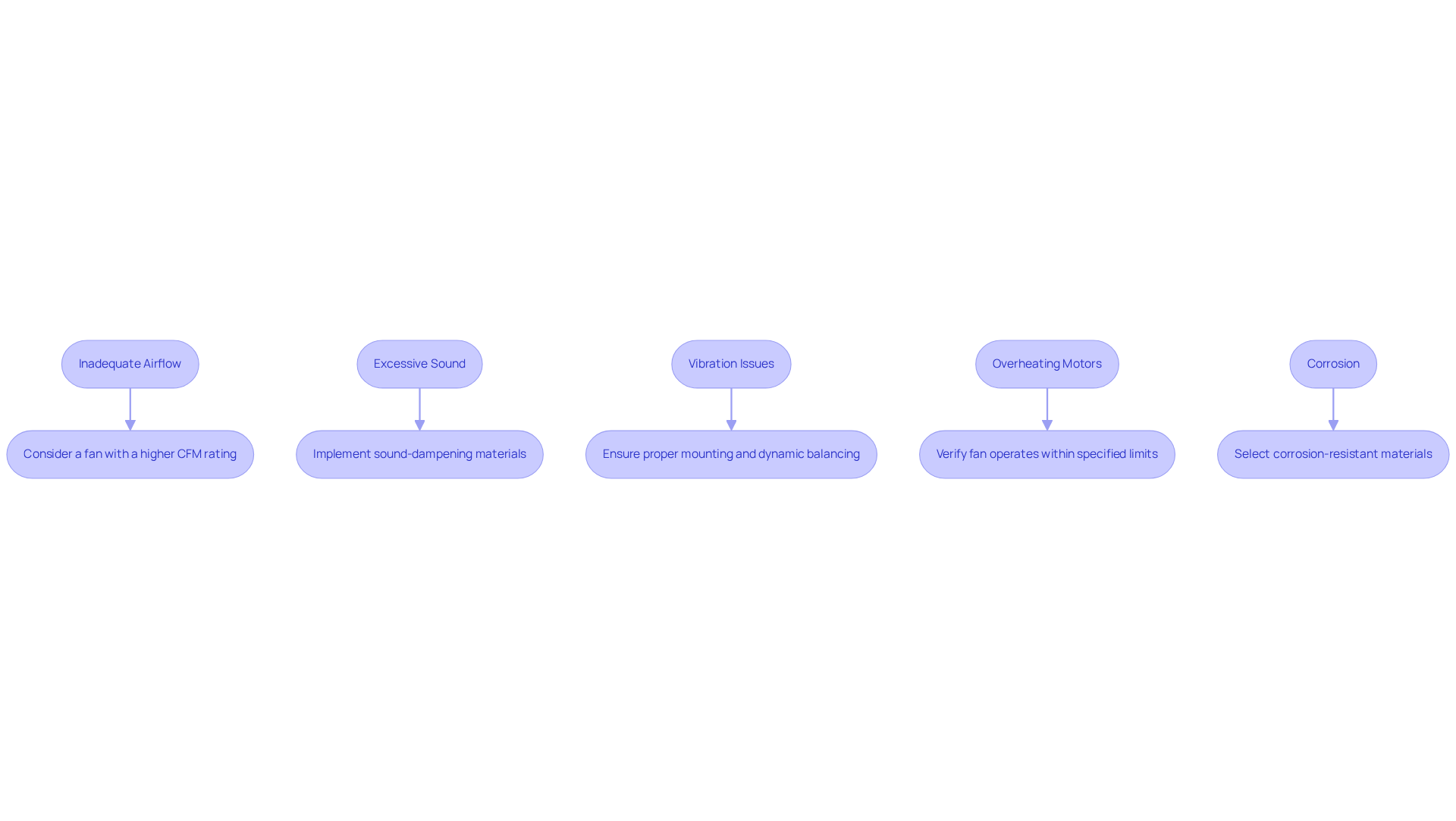

Selecting the right industrial axial fans presents several challenges that require careful consideration. Common issues include inadequate airflow, excessive sound, vibration problems, overheating motors, and corrosion. Addressing these challenges effectively can lead to optimal performance and longevity of the fan.

- Inadequate Airflow: Insufficient airflow from the selected fan necessitates a reassessment of airflow requirements. Consider a fan with a higher CFM rating to meet operational needs. Real-world examples illustrate that inadequate airflow can result in overheating and operational inefficiencies, underscoring the necessity of informed fan selection. Notably, the global axial fan market is projected to grow to $4,381.46 million by 2032, highlighting the importance of making educated choices in this expanding market.

- Excessive Sound: If sound levels exceed expectations, it is crucial to review the fan’s specifications for sound ratings. Implementing sound-dampening materials or opting for fans designed for quieter operation can mitigate this issue. Engineers have noted that addressing sound concerns often involves selecting fans engineered for reduced noise or utilizing vibration-dampening mounts. An engineer’s insight reinforces this point: “Choosing the right fan design can significantly reduce noise levels and improve overall system performance.”

- Vibration Issues: Excessive vibration may indicate misalignment or imbalance within the fan. Proper mounting and ensuring that the blades are free from obstructions are essential steps. Regular inspections and dynamic balancing services can substantially decrease vibrations, thereby enhancing operational efficiency.

- Overheating Motors: In instances of motor overheating, it is essential to verify that the fan operates within its specified limits. Adequate ventilation around the motor is critical, and considering a fan with a higher power rating may be necessary. Regular maintenance, including cleaning and inspecting the fan, plays a vital role in preventing overheating and airflow obstructions.

- Corrosion and Material Degradation: In environments characterized by high humidity or corrosive substances, selecting fans constructed from corrosion-resistant materials, such as stainless steel or coated aluminum, is advisable. This choice significantly , as corrosion can compromise structural integrity over time. A case study on material selection emphasizes that appropriate materials can prevent degradation and ensure longevity in challenging environments.

By recognizing these challenges and their corresponding solutions, along with implementing regular maintenance practices, you can make informed decisions that ensure optimal performance from your industrial axial fans.

Conclusion

Selecting the right industrial axial fans is crucial for optimizing airflow and ensuring efficient operation across various applications. This guide outlines essential steps to effectively choose axial fans by understanding their defining characteristics, identifying key selection criteria, and addressing common challenges encountered during the selection process.

The article delves into the fundamental features of axial fans, highlighting their high airflow capacity, energy efficiency, and compact design. It emphasizes the importance of assessing airflow requirements, static pressure, size, sound levels, and durability when making a selection. Furthermore, it addresses potential issues such as inadequate airflow, excessive noise, and material corrosion, providing practical solutions to enhance fan performance and longevity.

Ultimately, making informed decisions about axial fan selection not only improves operational efficiency but also contributes to energy savings and sustainability in industrial environments. By applying the insights and best practices discussed, engineers and decision-makers can ensure they choose the most suitable axial fans for their specific needs, paving the way for optimal performance and reliability in their operations.

Frequently Asked Questions

What are axial fans?

Axial fans are mechanical devices designed to move air or gas parallel to the rotating axis, characterized by propeller-like blades that draw air in and discharge it in the same direction.

What are the key features of axial fans?

Key features include high airflow capacity (up to 5,000 CFM), low operating pressure, compact design for installation in tight spaces, energy efficiency (approximately 70% efficiency), low noise levels (around 60 dB), and durability with a lifespan of 20,000 to 30,000 hours.

How much air can axial fans move?

Axial fans can move up to 5,000 cubic feet of air per minute (CFM), making them suitable for cooling and ventilation applications.

What is the energy efficiency of industrial axial fans?

Industrial axial fans have an efficiency rating of approximately 70%, which can lead to energy savings of up to 20% compared to centrifugal blowers.

How do axial fans compare to centrifugal models in terms of noise levels?

Axial fans generally operate at a lower noise level of about 60 dB, while centrifugal models can reach sound levels of up to 75 dB.

What is the expected lifespan of industrial axial fans?

The lifespan of industrial axial fans is projected to range between 20,000 to 30,000 hours.

What trends are affecting the axial fan market?

The emphasis on energy efficiency continues to grow due to sustainability initiatives and regulations, with the global ventilation market expected to expand at a CAGR of 5.98% until 2029.

What challenges do axial fans face in the market?

Challenges include balancing efficiency with noise levels and compliance with environmental regulations.