Overview

Selecting a powerful fan in electronics is crucial for optimal performance. To achieve this, it is essential to:

- Identify application requirements

- Evaluate fan specifications

- Implement best practices for integration and maintenance

Key factors to consider include:

- Airflow needs

- Static pressure

- Environmental considerations

Furthermore, proper installation and regular maintenance are necessary to ensure the longevity of the fan system. By understanding these practices, professionals can make informed decisions that lead to enhanced efficiency and reliability in their electronic applications.

Introduction

Selecting the right fan for electronic applications is a critical decision that can significantly impact both performance and longevity. Given the vast array of options available, understanding specific requirements—such as airflow, static pressure, and environmental factors—becomes essential for engineers aiming to optimize cooling solutions. The challenge lies in navigating intricate specifications, ensuring that the chosen fan not only meets technical demands but also integrates seamlessly into existing systems.

What key practices can guide this selection process and enhance the reliability of electronic systems?

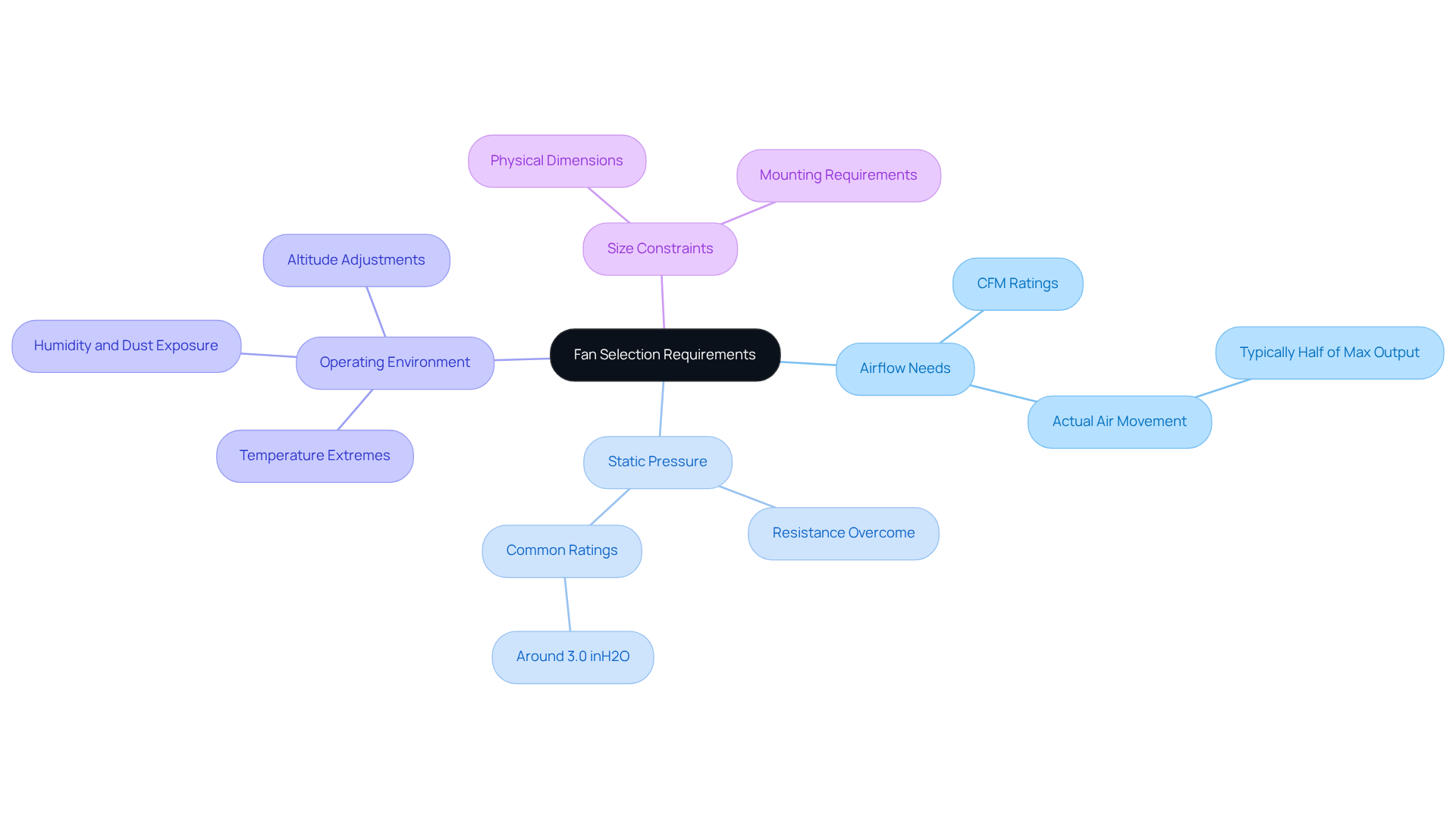

Identify Application Requirements for Fan Selection

Choosing the appropriate big powerful fan for electronic applications requires a thorough evaluation of specific needs, particularly in light of the innovative cooling solutions offered by a leading supplier in this field. Key factors to consider include:

- Airflow Needs: It is essential to accurately determine the volume of air required to maintain optimal temperatures for electronic components, typically measured in cubic feet per minute (CFM). Gagner-Toomey’s ventilation fans frequently achieve impressive ratings, often exceeding 100 CFM. However, it is crucial to recognize that the actual movement of air in forced air cooling applications typically reaches about half of the fan’s maximum output, which is vital for effective cooling.

- Static Pressure: Evaluate the resistance the fan must overcome to sustain air movement, particularly in systems with filters or ductwork. Static pressure ratings around 3.0 inH2O are common for static pressure units, which excel in overcoming resistance but generally exhibit lower airflow ratings compared to conventional models. This trade-off is a critical consideration when selecting the appropriate fan from their extensive portfolio of DC input Tube Axial fans and Centrifugal Blowers, which range in sizes from 15 to 280mm and 15 to 225mm, respectively.

- Operating Environment: Consider environmental factors such as temperature extremes, humidity, and exposure to dust or corrosive elements, all of which can significantly affect fan performance and longevity. The company provides designed to withstand diverse operating conditions, ensuring reliability. Additionally, adjustments for density changes due to temperature and altitude must be made to static pressure before selecting a fan or blower to guarantee accurate performance assessments.

- Size Constraints: Confirm that the fan fits within the physical dimensions of the setup, accounting for any mounting requirements. The company offers a broad range of products, including miniature blower and fan solutions for consumer applications and compact cooling, making it essential to choose a model that accommodates the specific spatial limitations of the project.

By clearly defining these parameters and leveraging innovative cooling solutions, engineers can effectively narrow down their options and select a big powerful fan that meets the specific requirements of their project, ultimately enhancing the reliability and efficiency of electronic systems. As Jeff Smoot from CUI Inc. notes, “The choice of fan, particularly for an enclosed PCB, can have a significant impact on the overall lifespan of a system.

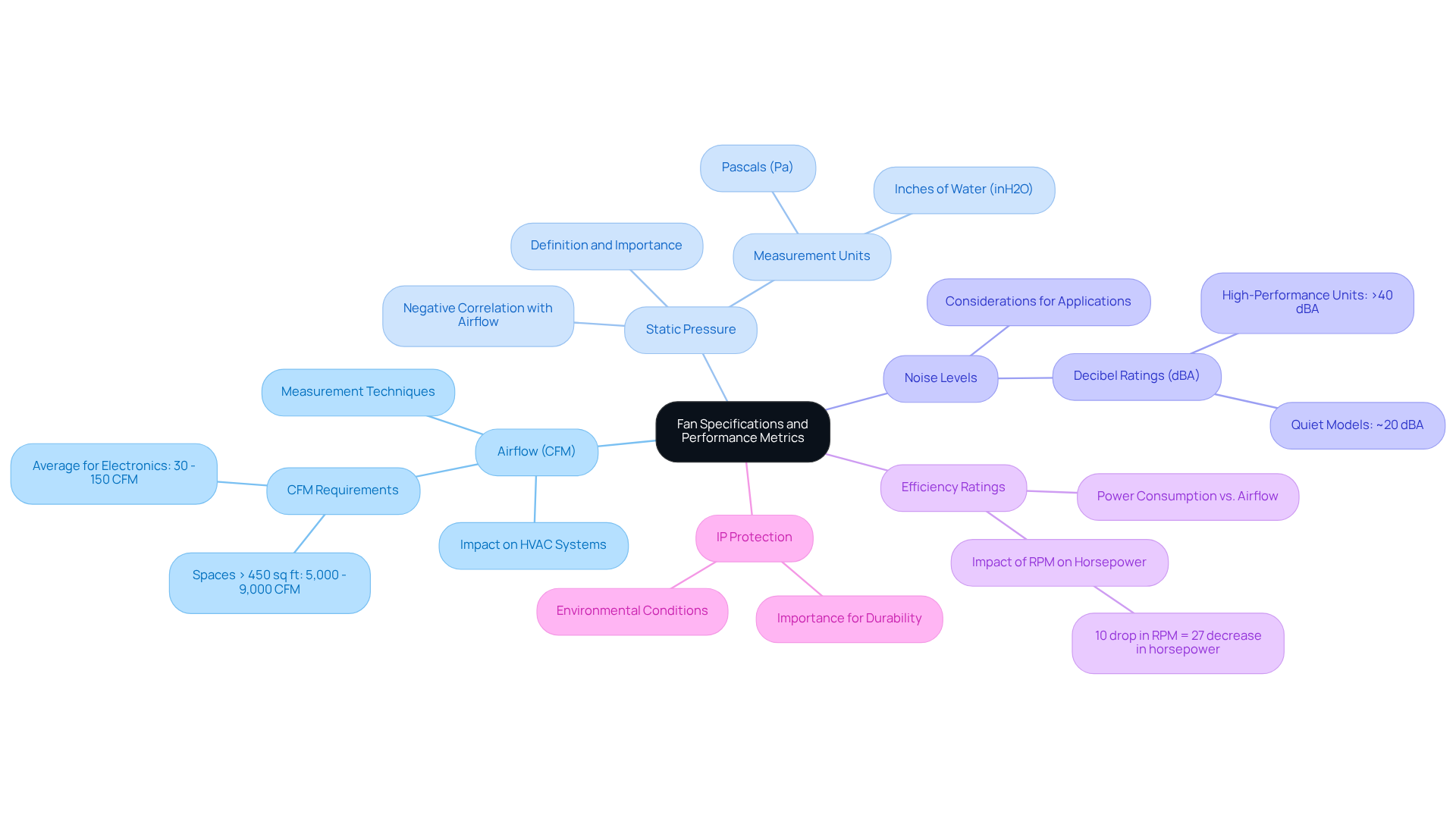

Evaluate Fan Specifications and Performance Metrics

Once project requirements are established, the next step is to assess the specifications and performance metrics of potential fans from the world’s largest manufacturer of standard and custom air-movers. Key metrics to consider include:

- Airflow (CFM): It is crucial to ensure the fan can provide sufficient airflow to meet the cooling requirements of the system, particularly for electronics and automotive applications. Gagner-Toomey Associates offers a wide variety of ventilation ratings for different fan sizes, guaranteeing choices for numerous uses.

- Static Pressure: Seek fans that can sustain the movement of air against the system’s resistance, a vital consideration in confined areas, which are common in various industrial contexts. Understanding the is essential, as increased static pressure frequently results in diminished air circulation.

- Noise Levels: Assess the decibel (dBA) rating of the fan, particularly for applications where noise is a concern, such as in residential or office environments. Noise levels can vary significantly, with quiet models operating around 20 dBA and high-performance units exceeding 40 dBA.

- Efficiency Ratings: Consider the fan’s power consumption relative to its airflow output, as higher efficiency can lead to lower operational costs, aligning with energy efficiency goals. A 10% drop in RPM can lead to a significant 27% decrease in horsepower, underscoring the importance of selecting efficient fans.

- IP Protection: Numerous models from the firm come with IP protection, which is essential for guaranteeing durability and reliability in diverse environmental conditions.

By carefully analyzing these specifications, engineers can select a fan that not only meets performance needs but also benefits from Gagner-Toomey Associates’ commitment to optimized performance, efficiency, and low noise.

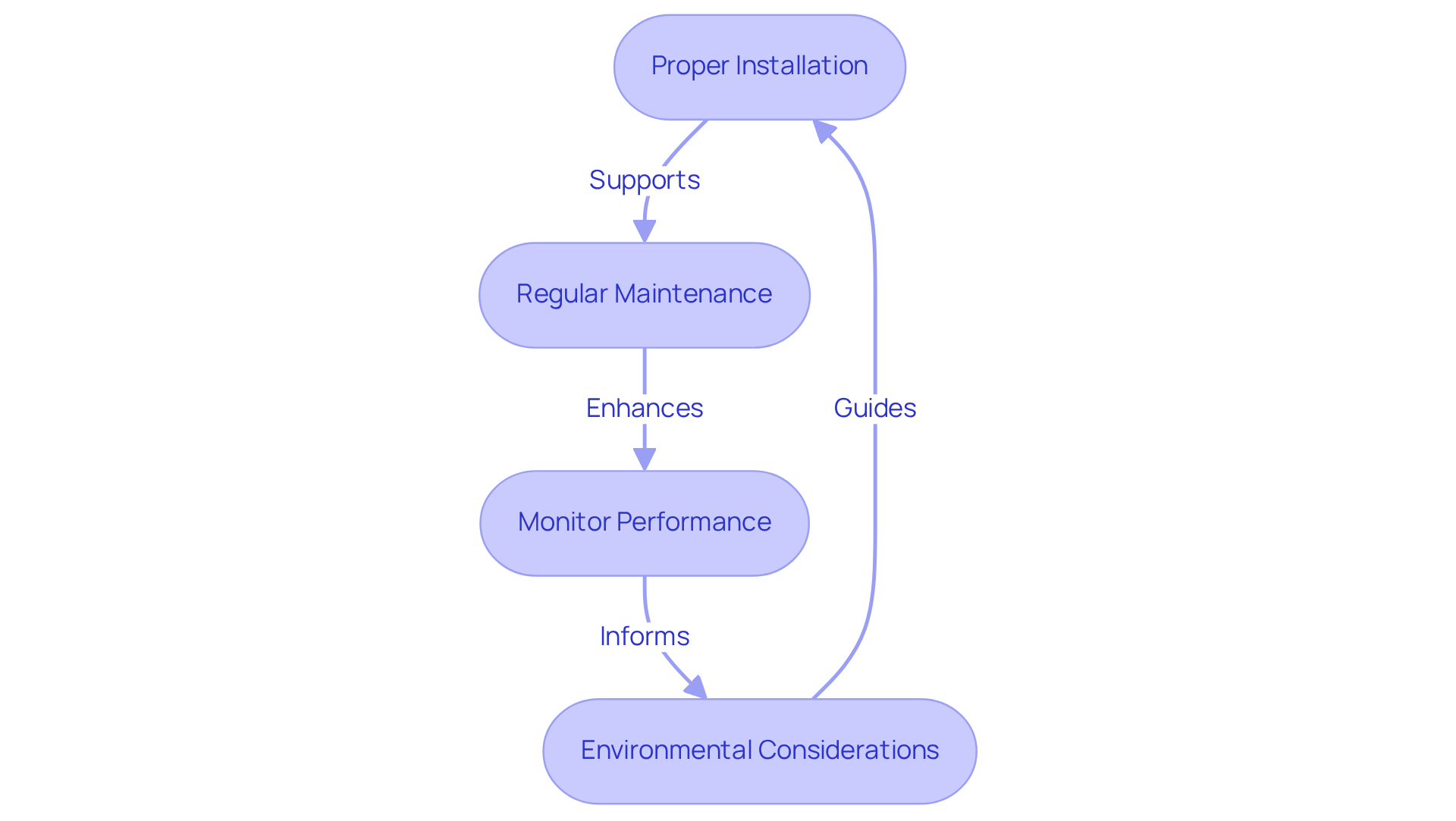

Implement Best Practices for Fan Integration and Maintenance

To maximize the effectiveness of the selected fan, adhering to best practices for integration and maintenance is essential:

- Proper Installation: It is crucial to install the fan according to the manufacturer’s guidelines, ensuring correct orientation and secure mounting. This minimizes vibration and noise, which can adversely affect performance. Incorrectly installed ventilators can result in inefficiencies and operational halts, leading to increased energy usage.

- Regular Maintenance: Scheduling routine inspections and cleaning is vital to prevent dust buildup, which can hinder ventilation and elevate noise levels. Utilizing compressed air to is a recommended practice. Routine upkeep is essential, as it can prolong the longevity of blowers and associated equipment, ultimately lowering operational expenses. Preventive maintenance can decrease the likelihood of unplanned outages by up to 66%, and cooling system maintenance accounts for 75% of the unit’s total cost of ownership (TCO), emphasizing the financial implications of these practices.

- Monitor Performance: Implementing monitoring systems to track key performance metrics such as airflow and noise levels over time is critical. This proactive approach allows for early detection of potential issues, facilitating timely interventions. Utilizing AI-driven platforms to analyze sensor data can identify patterns that precede failures, enhancing reliability. As noted by industry experts, predictive maintenance offers a proactive approach to managing fan performance for long-term reliability and efficiency.

- Environmental Considerations: For devices functioning in harsh conditions, considering additional protective measures such as enclosures or filters is necessary. Industrial fans operate continuously in environments filled with dust, moisture, or extreme temperatures, making these measures critical for prolonging the fan’s lifespan and maintaining optimal performance.

By following these practices, engineers can ensure that their cooling solutions remain effective and reliable throughout their operational life, ultimately contributing to improved energy efficiency and reduced total cost of ownership.

Conclusion

Selecting the appropriate big powerful fan for electronic applications is a pivotal task that can profoundly affect the performance and longevity of electronic systems. By comprehensively understanding the specific requirements of the application, engineers are positioned to make informed decisions that significantly enhance cooling efficiency and reliability.

This article underscores essential practices for fan selection, including:

- Identification of airflow needs

- Evaluation of static pressure

- Consideration of the operating environment

- Assurance of size compatibility

It highlights the necessity of assessing fan specifications such as:

- Airflow rates

- Noise levels

- Efficiency ratings

- IP protection

to identify a suitable model. Moreover, the implementation of best practices for installation, maintenance, and performance monitoring is critical for optimizing the effectiveness of the selected fan.

Ultimately, the judicious selection of fans and adherence to maintenance practices can yield improved energy efficiency and reduced operational costs. By prioritizing these considerations, engineers not only ensure optimal cooling solutions but also contribute to the overall reliability and performance of electronic systems, paving the way for innovative advancements in technology.

Frequently Asked Questions

What factors should be considered when selecting a fan for electronic applications?

Key factors include airflow needs, static pressure, operating environment, and size constraints.

How is airflow measured, and what is a typical rating for ventilation fans?

Airflow is measured in cubic feet per minute (CFM), with Gagner-Toomey’s ventilation fans often exceeding 100 CFM.

What is the significance of static pressure in fan selection?

Static pressure indicates the resistance a fan must overcome to maintain air movement, especially in systems with filters or ductwork. Common static pressure ratings are around 3.0 inH2O.

How does the operating environment affect fan performance?

Environmental factors like temperature extremes, humidity, and exposure to dust or corrosive elements can impact fan performance and longevity.

Why is it important to consider size constraints when choosing a fan?

It is essential to ensure the fan fits within the physical dimensions of the setup and meets any mounting requirements.

What types of fans does the company offer for different applications?

The company offers a range of products, including DC input Tube Axial fans and Centrifugal Blowers in various sizes, as well as miniature blower and fan solutions for compact applications.

How can engineers effectively narrow down fan options for their projects?

By clearly defining parameters such as airflow needs, static pressure, operating environment, and size constraints, engineers can select a fan that meets their project requirements.

What impact does the choice of fan have on electronic systems?

The choice of fan can significantly influence the overall lifespan and reliability of electronic systems, particularly for enclosed PCBs.