Overview

The article addresses the critical relationship between air flow and pressure, underscoring its importance for engineers tasked with designing efficient cooling systems and managing air movement across diverse applications. By elucidating this relationship, which is governed by principles such as Bernoulli’s principle, the article empowers engineers to enhance system performance and energy efficiency. It emphasizes the necessity of accurately assessing both static and dynamic pressures—elements that are vital in contexts including HVAC systems and electronic cooling solutions. Understanding these dynamics not only optimizes operational effectiveness but also drives energy conservation, making it imperative for engineers to integrate this knowledge into their designs.

Introduction

Understanding the intricate relationship between air flow and pressure is crucial for engineers addressing the challenges of efficient system design. Air movement is measured in cubic feet per minute (CFM), while pressure is quantified in pounds per square inch (psi). Mastering these concepts can lead to significant advancements in cooling systems and the performance of electronic devices.

However, the inverse relationship between static force and air flow raises critical questions:

- How can engineers optimize their designs to effectively balance these forces?

- What practical strategies can be employed to enhance system efficiency?

These inquiries underscore the necessity for a deeper exploration of the dynamics at play.

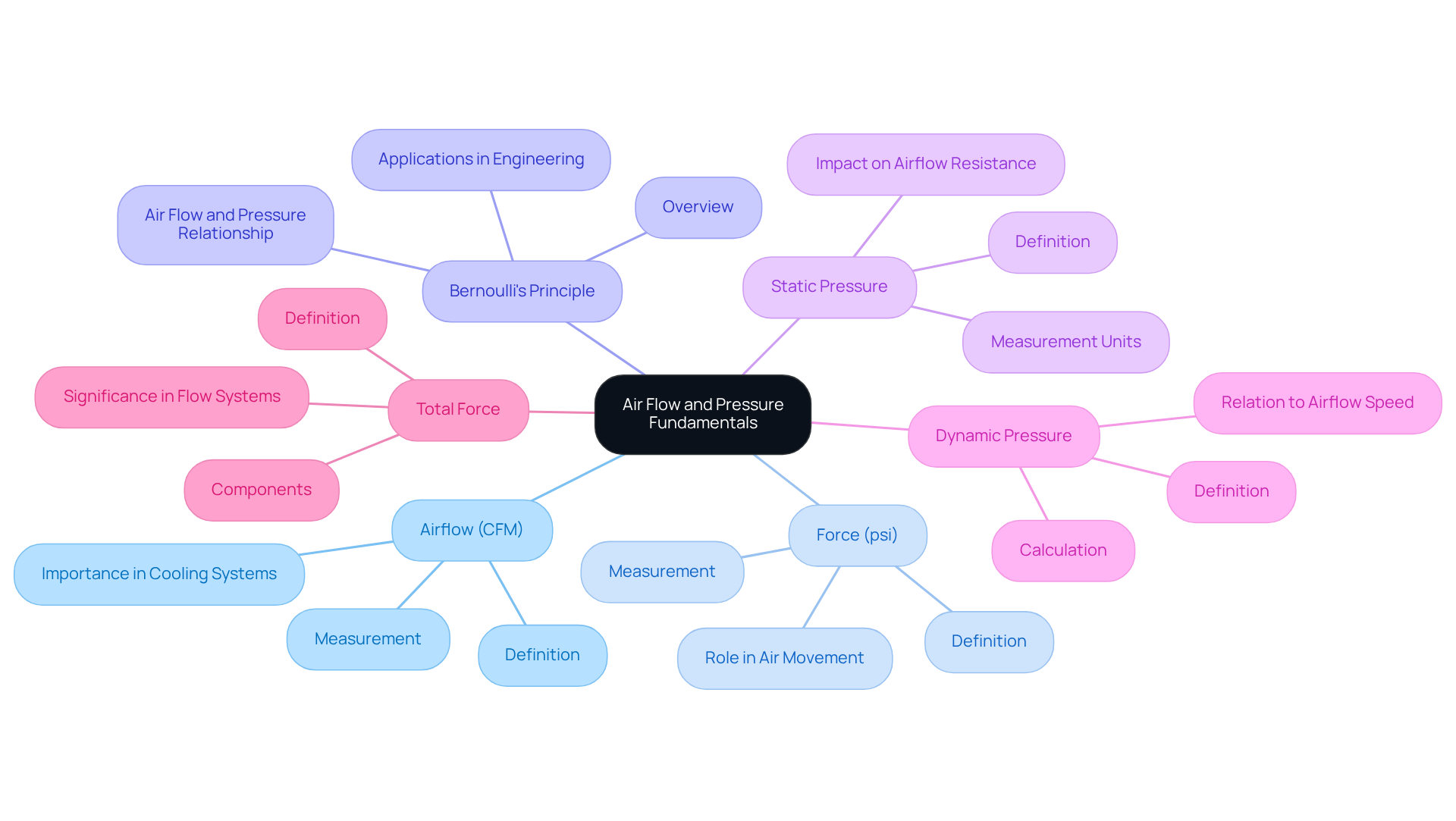

Clarify Air Flow and Pressure Fundamentals

Airflow, quantified in cubic feet per minute (CFM), signifies the movement of air, whereas force denotes the strength exerted by air per unit area, typically measured in pounds per square inch (psi). The interaction between these two variables is governed by fundamental principles of fluid dynamics, particularly the air flow and pressure relationship outlined by Bernoulli’s principle. This principle asserts that an increase in fluid velocity corresponds to a decrease in force, emphasizing the air flow and pressure relationship, which is a crucial concept for engineers designing efficient cooling systems and regulating movement in electronic devices.

Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers for cooling, offers an extensive product line of DC input Tube Axial fans and Centrifugal Blowers. These products are optimized for performance, efficiency, and low noise, with IP protection available upon request. Understanding the dynamics of air movement and the is essential when choosing from their extensive range of products, which includes dimensions from 15mm to 910mm, catering to diverse applications in electronics, automotive, telecom, and beyond.

Key concepts include:

- Static Pressure: The pressure exerted by air within a duct when stationary, vital for assessing airflow resistance, especially in systems utilizing Gagner-Toomey’s innovative cooling solutions.

- Dynamic Pressure: Associated with the movement of air, calculated based on the speed of the airflow.

- Total Force: The aggregate of static and dynamic force, encapsulating the total energy within the flow system.

Grasping these principles empowers engineers to accurately predict the air flow and pressure relationship across various systems, leading to more effective designs and enhanced performance. Recent studies underscore the importance of measuring force in psi to refine cooling solutions, further emphasizing the relevance of these concepts in practical applications, particularly when leveraging Gagner-Toomey’s advanced thermal management solutions.

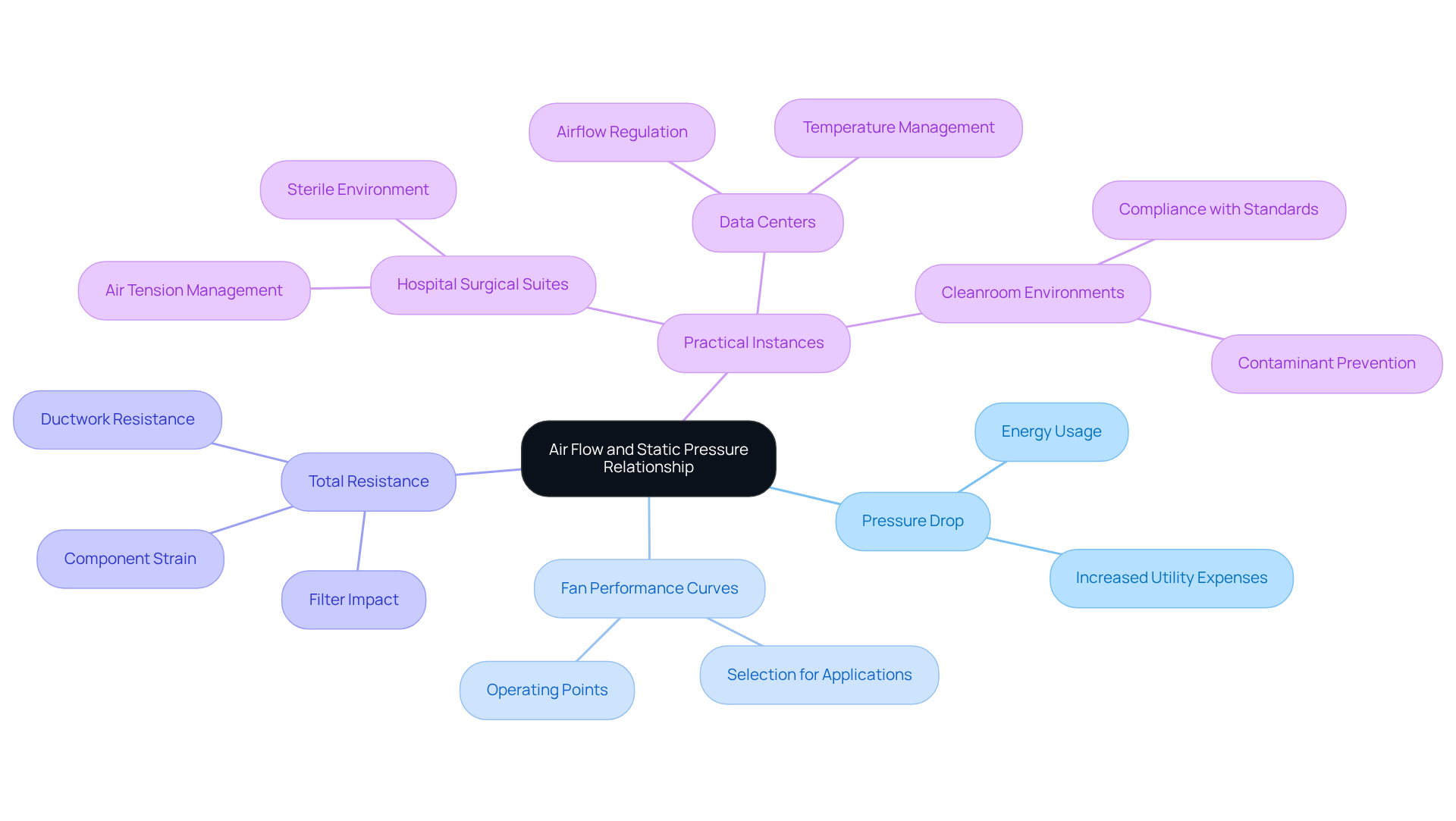

Explore the Air Flow and Static Pressure Relationship

The air flow and pressure relationship demonstrates that the connection between air movement and fixed force is fundamentally inversely related; as fixed force increases, air movement generally decreases, and conversely, the opposite holds true. This dynamic is essential in applications such as and electronic cooling solutions.

Key considerations include:

- Pressure Drop: As air travels through ductwork, it faces resistance, leading to a drop in static pressure that can significantly affect the overall airflow rate. Research indicates that limited ventilation forces HVAC systems to operate more intensively, consequently increasing energy usage and utility expenses. For instance, higher fixed force can lead to increased energy consumption and costs due to reduced motor efficiency.

- Fan performance curves illustrate the air flow and pressure relationship by showing how fans operate at specific points based on air movement and resistance. Comprehending these curves is crucial for engineers to select the appropriate fan for their specific application, thereby ensuring efficient operation.

- The total resistance within a system—including ductwork, filters, and various components—directly affects the air flow and pressure relationship, which in turn influences the movement of air. Engineers must take these factors into account during the design phase to achieve optimal performance. For example, in cleanroom environments, maintaining elevated atmospheric conditions is vital to prevent contaminants from entering, thus ensuring compliance with industry standards.

- Practical instances underscore the effects of force drop on the air flow and pressure relationship in electronic cooling systems. In data centers, precise fixed airflow regulation is crucial for managing air movement, temperature, and humidity, all of which are essential for optimal server performance. Similarly, in hospital surgical suites, elevated air tension is critical to ensure a sterile environment during operations, as demonstrated in the case study on Air Tension Management in Hospital Surgical Suites.

By meticulously analyzing these relationships, engineers can refine their designs for enhanced efficiency and effectiveness, ultimately contributing to improved indoor comfort and system longevity. Moreover, maintaining adequate stationary force extends the HVAC system’s lifespan, while excessive force can lead to increased noise levels and stress on system components.

Apply Concepts through Practical Calculations and Examples

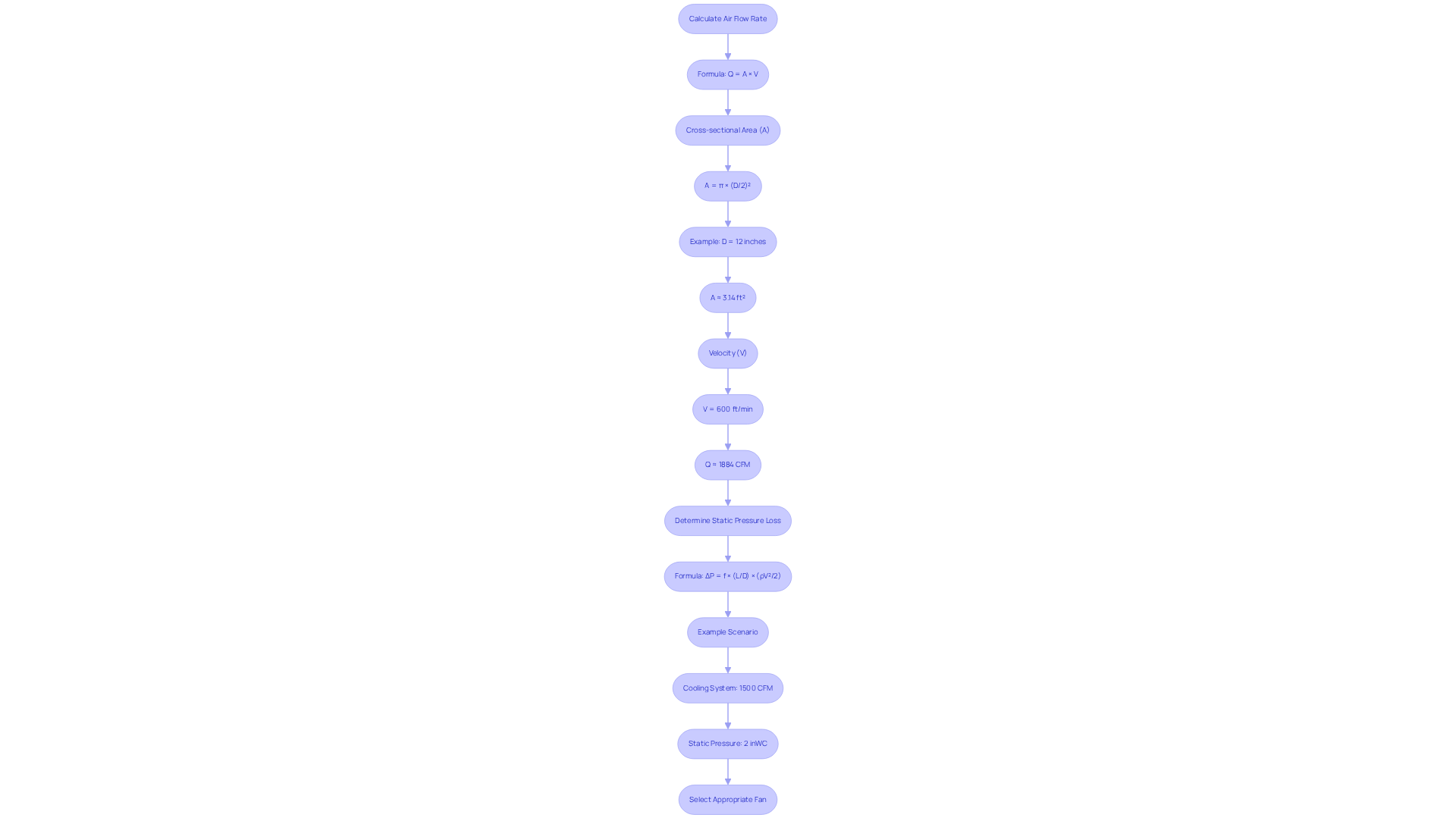

To effectively apply the , engineers must engage in several critical calculations and examples that enhance their understanding and design capabilities.

Calculating Air Flow Rate: The air flow rate (Q) is determined using the formula: Q = A × V, where A represents the cross-sectional area of the duct (in square feet) and V denotes the velocity of the air (in feet per minute). For instance, in a duct with a diameter of 12 inches, the area can be computed as:

A = π × (D/2)² = π × (1)² ≈ 3.14 ft²

If the air velocity is 600 feet per minute, then

Q = 3.14 × 600 ≈ 1884 CFM

Determining Static Pressure Loss: Engineers can ascertain the static pressure loss in a duct using the Darcy-Weisbach equation:

ΔP = f × (L/D) × (ρV²/2)

In this equation, ΔP signifies the pressure loss, f is the friction factor, L is the duct length, D is the diameter, ρ represents the air density, and V is the velocity. This calculation is essential for understanding the air flow and pressure relationship, especially in terms of the force lost due to friction within the duct system.

Example Scenario: Consider a cooling system in an electronic device requiring an air flow of 1500 CFM. If the static pressure at the fan outlet measures at 2 inches of water column (inWC), engineers can leverage this data to select an appropriate fan capable of sustaining the desired air flow against the static pressure.

By practicing these calculations, engineers can significantly enhance their design capabilities, ensuring that their systems operate efficiently and effectively.

Conclusion

Mastering the intricate relationship between air flow and pressure is essential for engineers aiming to optimize their designs and enhance system performance. Understanding the interaction between these two variables not only facilitates the creation of efficient cooling systems but also plays a pivotal role across various applications in multiple industries. By grasping the principles of fluid dynamics, engineers can make informed decisions that lead to improved functionality and energy efficiency in their projects.

Key insights from the article underscore the significance of:

- Static and dynamic pressures

- The impact of pressure drop on air flow rates

- The necessity of precise calculations for effective system design

A comprehensive understanding of these concepts enables engineers to anticipate challenges and refine their approaches, particularly in critical environments such as data centers and surgical suites, where air quality and temperature control are paramount.

Ultimately, mastering the relationship between air flow and pressure transcends academic exercise; it is a practical necessity that can significantly influence the success of engineering projects. Engineers are encouraged to apply these principles in their designs, ensuring that both air flow and pressure dynamics are considered to achieve optimal performance and sustainability in their systems.

Frequently Asked Questions

What is airflow and how is it measured?

Airflow signifies the movement of air and is quantified in cubic feet per minute (CFM).

What does force refer to in the context of air movement?

Force refers to the strength exerted by air per unit area, typically measured in pounds per square inch (psi).

How are airflow and pressure related?

The interaction between airflow and pressure is governed by fluid dynamics principles, particularly Bernoulli’s principle, which states that an increase in fluid velocity corresponds to a decrease in force.

Why is understanding airflow and pressure important for engineers?

Understanding these concepts is crucial for engineers when designing efficient cooling systems and regulating movement in electronic devices.

What types of products does Gagner-Toomey Associates manufacture?

Gagner-Toomey Associates manufactures standard and custom air-movers for cooling, including DC input Tube Axial fans and Centrifugal Blowers.

What are some features of Gagner-Toomey’s products?

Their products are optimized for performance, efficiency, and low noise, with IP protection available upon request.

What is static pressure and why is it important?

Static pressure is the pressure exerted by air within a duct when stationary, and it is vital for assessing airflow resistance in cooling systems.

What is dynamic pressure?

Dynamic pressure is associated with the movement of air and is calculated based on the speed of the airflow.

What is total force in the context of airflow?

Total force is the aggregate of static and dynamic force, representing the total energy within the flow system.

How can understanding airflow and pressure principles improve system design?

Grasping these principles allows engineers to accurately predict airflow and pressure relationships, leading to more effective designs and enhanced performance in various applications.