Overview

The key distinctions between IP69 and IP69K are rooted in their testing criteria and their suitability for specific applications. Notably, IP69K offers superior protection against high-pressure, high-temperature environments. While both ratings provide strong defense against dust and moisture, IP69K is specifically engineered for industries that mandate rigorous sanitation and cleaning protocols. It is imperative for engineers to select the appropriate rating based on their operational requirements, ensuring optimal performance and compliance.

Introduction

Understanding the nuances of Ingress Protection (IP) ratings is crucial for engineers tasked with selecting equipment for challenging environments. Among these ratings, IP69 and IP69K stand out due to their robust protection against dust and high-pressure water. This makes them essential for industries such as food processing and pharmaceuticals.

However, a key question arises: how do these two ratings differ in their testing standards and applications, and which one is the optimal choice for specific operational needs?

Exploring these distinctions will clarify their individual benefits and guide engineers in making informed decisions that enhance both safety and efficiency.

Understanding Ingress Protection Ratings

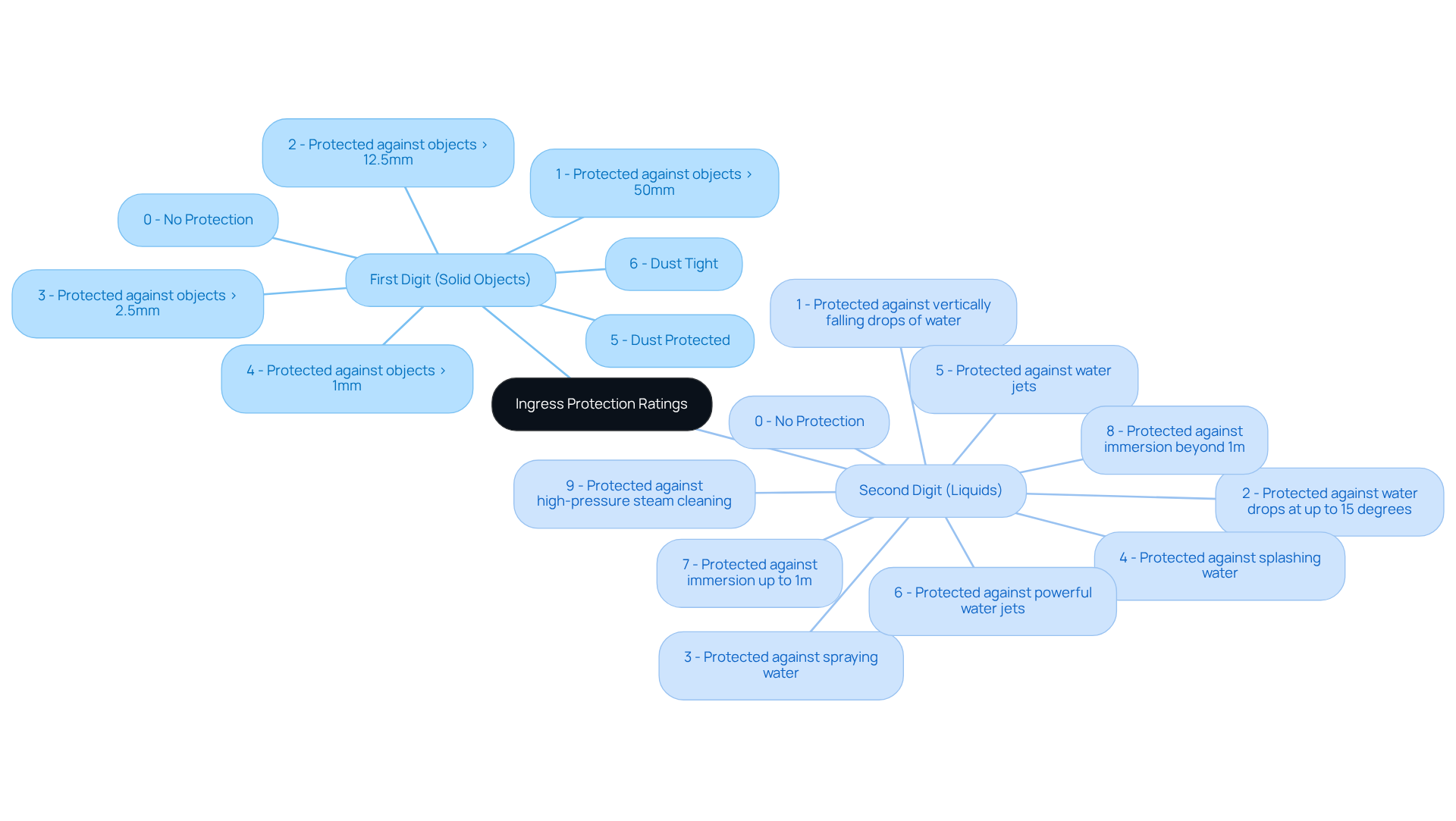

Ingress Protection (IP) classifications represent standardized categories that convey the level of defense provided by an enclosure against the ingress of solid objects and liquids. These evaluations are stipulated by the International Electrotechnical Commission (IEC) under standard IEC 60529. Each IP classification consists of two digits:

- The first digit (ranging from 0 to 6) indicates defense against solid objects.

- The second digit (ranging from 0 to 9) denotes defense against liquids.

Higher numbers signify enhanced safety levels, underscoring the necessity for engineers to understand these ratings when selecting components for environments potentially exposed to dust, water, or other contaminants.

Products such as Gagner-Toomey Associates‘ IP67-rated fiber assemblies—including patchcords, jumpers, and specialty breakout cables—are meticulously engineered to endure challenging conditions, thereby ensuring reliable performance in demanding applications. These fiber assemblies can be seamlessly integrated into advanced electronic systems, making them an operating in environments where moisture and particulate matter pose significant concerns.

Defining IP69 and IP69K: Key Features and Applications

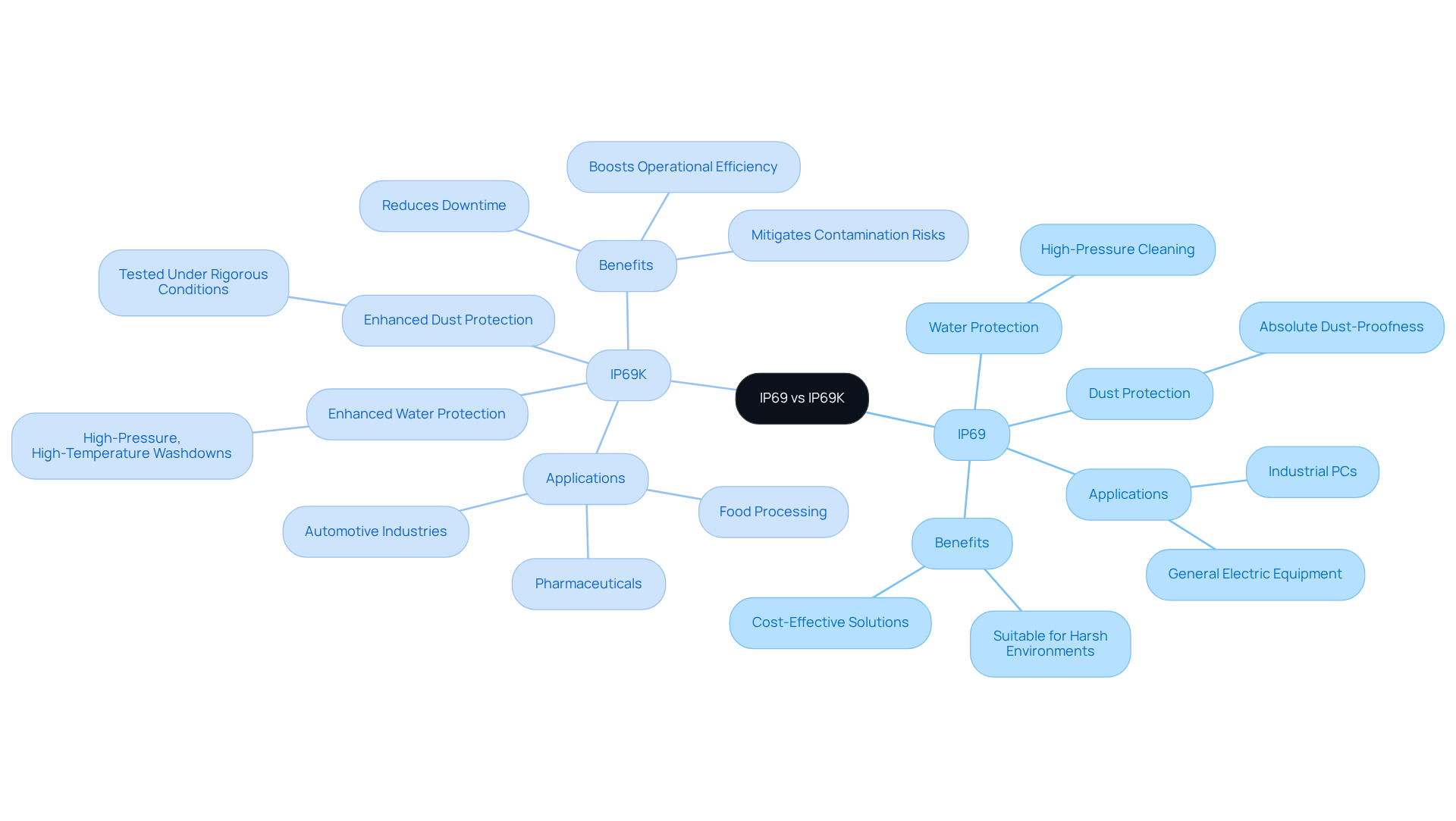

When comparing IP69 vs IP69K, it is clear that IP69 is characterized by providing complete protection against dust and high-pressure water jets, making it suitable for devices operating in harsh environmental conditions. This classification is particularly relevant in industrial applications where equipment frequently encounters cleaning processes or exposure to dust and moisture.

Furthermore, the classification enhances this protection by indicating that devices can withstand high-pressure, high-temperature washdowns, commonly utilized in sectors such as food processing, pharmaceuticals, and automotive industries. The ‘K’ in the rating indicates that the device has been tested under more rigorous conditions, ensuring it meets the demands of environments requiring strict sanitation and cleaning protocols, which is an important distinction in the discussion of IP69 vs IP69K.

Originally designed for road vehicles, this rating has been widely adopted in the food and beverage sector, where compliance with hygiene regulations is critical. The importance of robust sanitation measures is highlighted by the fact that approximately 48 million people in the U.S. suffer from foodborne illnesses each year.

When comparing IP69 vs IP69K, it is clear that IP69K-rated products are engineered to , significantly mitigating the risk of contamination and enhancing operational efficiency. Manufacturers have noted that equipment with high-level protection not only elevates plant sanitation but also boosts efficiency and reduces downtime, establishing it as a standard in environments where cleanliness is paramount.

Additionally, the stringent testing protocols that certain products undergo—featuring high-pressure and high-temperature scenarios—validate their reliability in demanding applications.

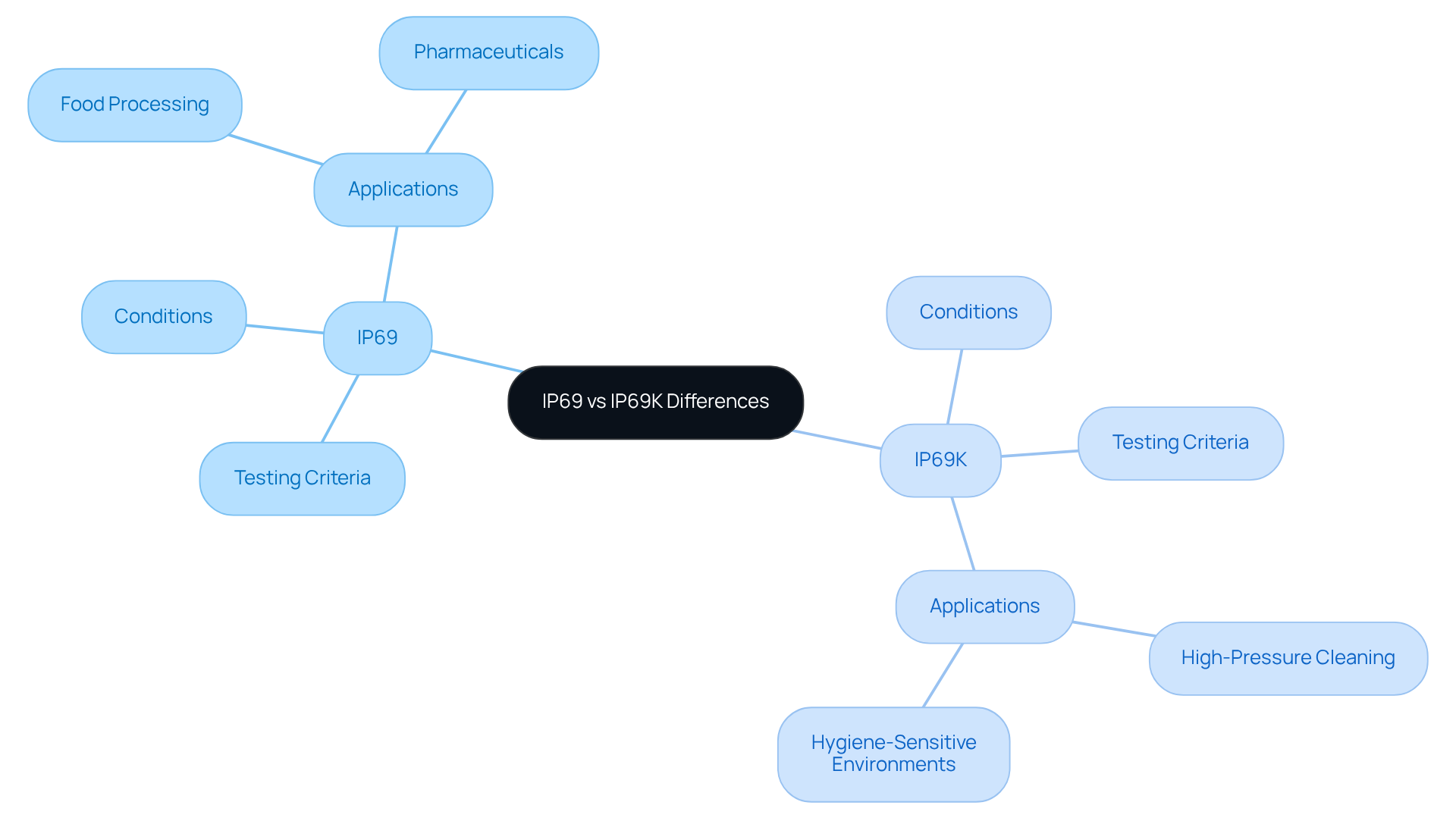

Comparing IP69 and IP69K: Differences in Protection Standards

The primary distinction between IP69 vs IP69K revolves around their testing criteria and the specific conditions they are designed to withstand. The assessment of IP69 vs IP69K is conducted according to IEC guidelines, which prioritize safety against both dust and high-pressure water jets. Conversely, the rating undergoes testing under ISO standards, incorporating additional requirements for high-temperature water exposure, especially when comparing IP69 vs IP69K.

Although both ratings offer robust protection against dust and moisture, the specific rating is tailored for applications necessitating routine high-pressure cleaning. This makes it particularly , where hygiene is paramount. This distinction is vital for engineers as they determine the appropriate equipment for their particular applications.

Choosing the Right Rating: Implications for Engineers

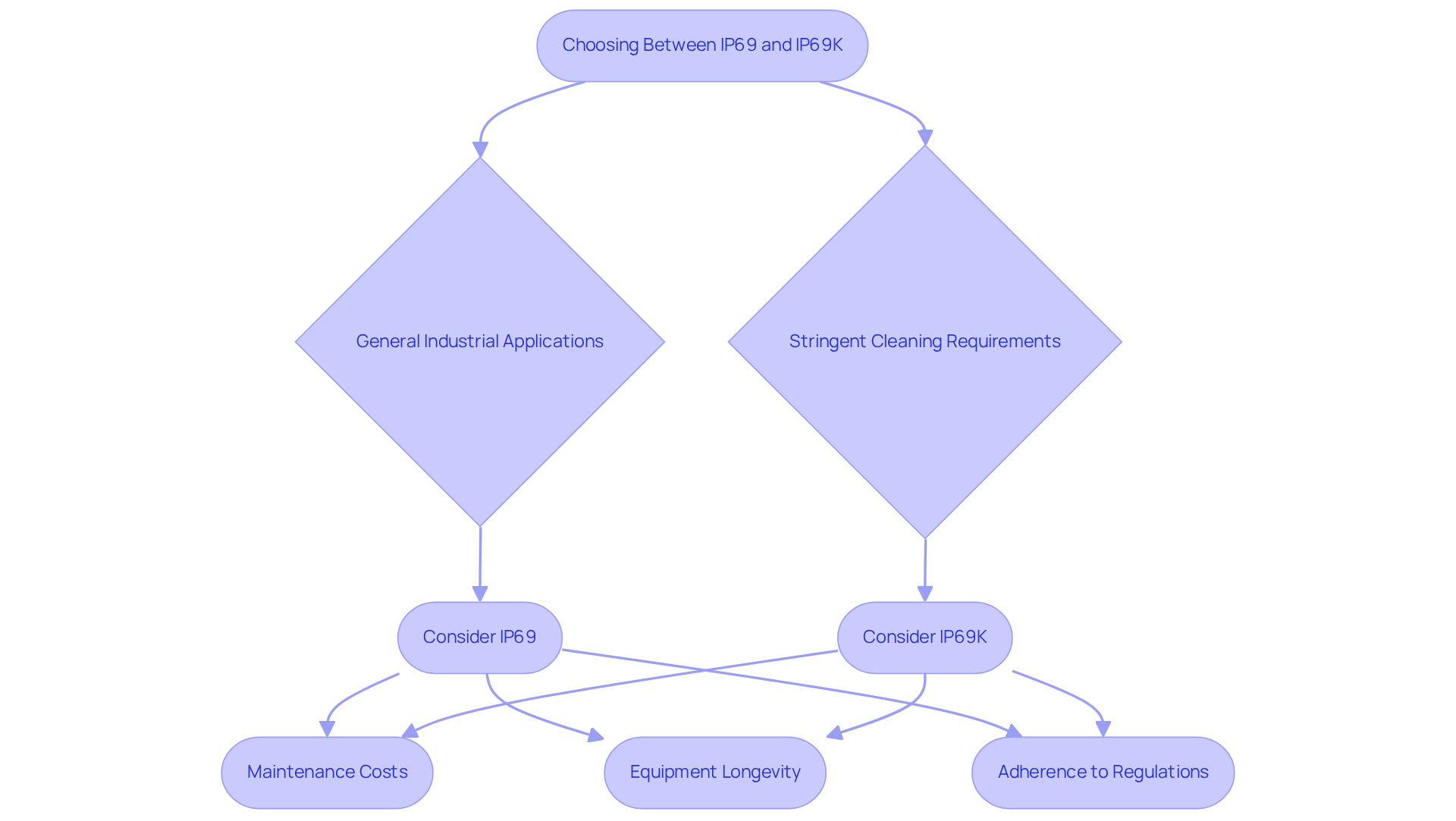

When selecting between IP69 vs IP69K and other alternatives, engineers must carefully consider the their equipment will face. For general industrial applications where dust and occasional water exposure pose challenges, IP69 may be adequate. However, in sectors demanding stringent cleaning and sanitation protocols, such as food and beverage processing or pharmaceuticals, the discussion of IP69 vs IP69K reveals that IP69K emerges as the superior choice due to its enhanced protection against high-pressure, high-temperature washdowns.

Furthermore, it is essential for engineers to assess the long-term implications of their decision, including:

- Maintenance costs

- Equipment longevity

- Adherence to industry regulations

Ultimately, making the right choice can profoundly influence operational efficiency and product reliability.

Conclusion

Understanding the distinctions between IP69 and IP69K is crucial for engineers tasked with selecting equipment for environments subject to stringent cleanliness and protection requirements. While both ratings provide robust defenses against dust and moisture, IP69K stands out due to its enhanced testing criteria, which includes high-pressure and high-temperature conditions. This makes it particularly suitable for industries such as food processing and pharmaceuticals, where sanitation is not just important but mandated.

The choice between IP69 and IP69K should be informed by the specific environmental challenges faced by the equipment. Key factors such as maintenance costs, equipment longevity, and regulatory compliance play a significant role in this decision-making process. By understanding these ratings and their implications, engineers can ensure optimal operational efficiency and reliability in their applications.

Ultimately, the selection of the appropriate IP rating is not merely a technical decision but a strategic one that can impact the overall performance and safety of systems in demanding environments. Engineers are encouraged to thoroughly evaluate their specific needs and the standards that best align with their operational goals, ensuring that their equipment can withstand the rigors of its intended application.

Frequently Asked Questions

What do Ingress Protection (IP) ratings represent?

Ingress Protection (IP) ratings represent standardized categories that indicate the level of defense an enclosure provides against the ingress of solid objects and liquids.

Who establishes the standards for IP ratings?

The standards for IP ratings are established by the International Electrotechnical Commission (IEC) under standard IEC 60529.

How is an IP classification structured?

An IP classification consists of two digits: the first digit (ranging from 0 to 6) indicates defense against solid objects, and the second digit (ranging from 0 to 9) denotes defense against liquids.

What do higher IP rating numbers signify?

Higher IP rating numbers signify enhanced safety levels, indicating better protection against dust and moisture.

Why is it important for engineers to understand IP ratings?

It is important for engineers to understand IP ratings when selecting components for environments that may be exposed to dust, water, or other contaminants, ensuring the reliability of the products.

Can you provide an example of a product with a specific IP rating?

An example of a product with a specific IP rating is Gagner-Toomey Associates’ IP67-rated fiber assemblies, which include patchcords, jumpers, and specialty breakout cables.

What environments are IP67-rated fiber assemblies suitable for?

IP67-rated fiber assemblies are suitable for challenging environments where moisture and particulate matter pose significant concerns, ensuring reliable performance in demanding applications.