Overview

The article titled “10 Essential Insights for Effective Fan Engineering” presents crucial principles and strategies that significantly enhance the design and performance of fan systems. It underscores the critical role of:

- Thermal design

- System impedance

- Airflow measurement

Alongside innovative technologies such as:

- Sensors

- Speed control methods

These elements collectively contribute to improved efficiency and reliability in fan engineering applications, making it essential reading for professionals in the field.

Introduction

In the rapidly evolving landscape of fan engineering, the integration of advanced cooling solutions and innovative design principles is more crucial than ever. As industries strive for enhanced efficiency and reliability, understanding the intricate dynamics of thermal management, airflow, and system impedance becomes essential for engineers.

However, with the myriad of technologies and strategies available, professionals must effectively navigate these complexities to optimize performance. This article delves into ten essential insights that illuminate best practices for fan engineering and address the pressing challenges in achieving superior thermal management and operational efficiency.

Gagner-Toomey Associates: Innovative Cooling Solutions for Fan Engineering

Gagner-Toomey Associates stands at the forefront of delivering innovative cooling solutions specifically designed for the electronics industry. As the largest producer of both standard and custom air-movers globally, their expertise encompasses cutting-edge technologies such as vapor chambers and liquid cooling solutions, which are crucial for optimizing thermal management in fan applications. Their comprehensive product range, which includes:

- DC input tube axial fans

- Centrifugal blowers

- Miniature blower solutions

ensures that engineers are equipped with the latest advancements in cooling technology—essential for enhancing fan efficiency and reliability across various applications. Recent innovations in cooling technologies, including the incorporation of phase change materials and advanced thermal interface materials, empower engineers to effectively address complex thermal challenges.

The successful applications of vapor chambers in fan engineering have resulted in significant enhancements in heat dissipation, showcasing the transformative potential of innovative cooling solutions for the reliability and efficiency of products in the electronics sector. Moreover, Gagner-Toomey’s unwavering commitment to quality is reinforced by the certifications held by their partners, such as AS9100 and ISO 9001, guaranteeing that the cooling solutions provided adhere to stringent industry standards. This holistic approach not only boosts the performance of cooling systems but also significantly of electronic devices.

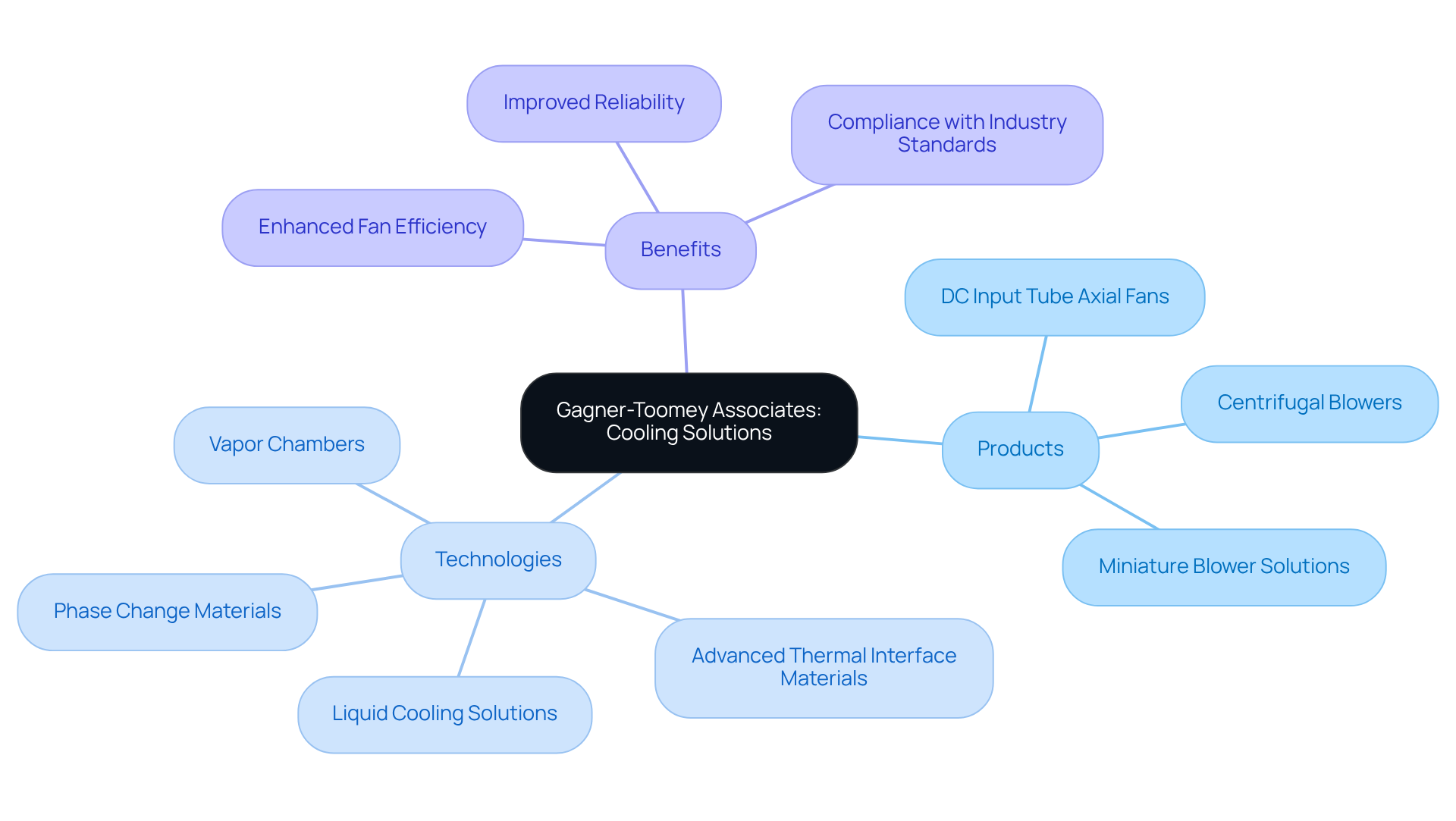

Thermal Design: Key Principles for Effective Fan Engineering

In fan engineering, efficient thermal design is paramount, emphasizing critical aspects such as heat transfer, fluid dynamics, and material selection. The following key principles are essential:

- Heat Transfer: A thorough understanding of conduction, convection, and radiation is crucial for effectively managing heat dissipation.

- Airflow Dynamics: Designing for optimal airflow paths is vital, as it minimizes resistance and significantly enhances cooling efficiency.

- Material Selection: The choice of materials with appropriate thermal conductivity can profoundly influence performance. Engineers must also consider the integration of heat sinks and fans to maximize cooling efficiency. By prioritizing these principles, professionals can achieve superior thermal management in their designs by utilizing fan engineering.

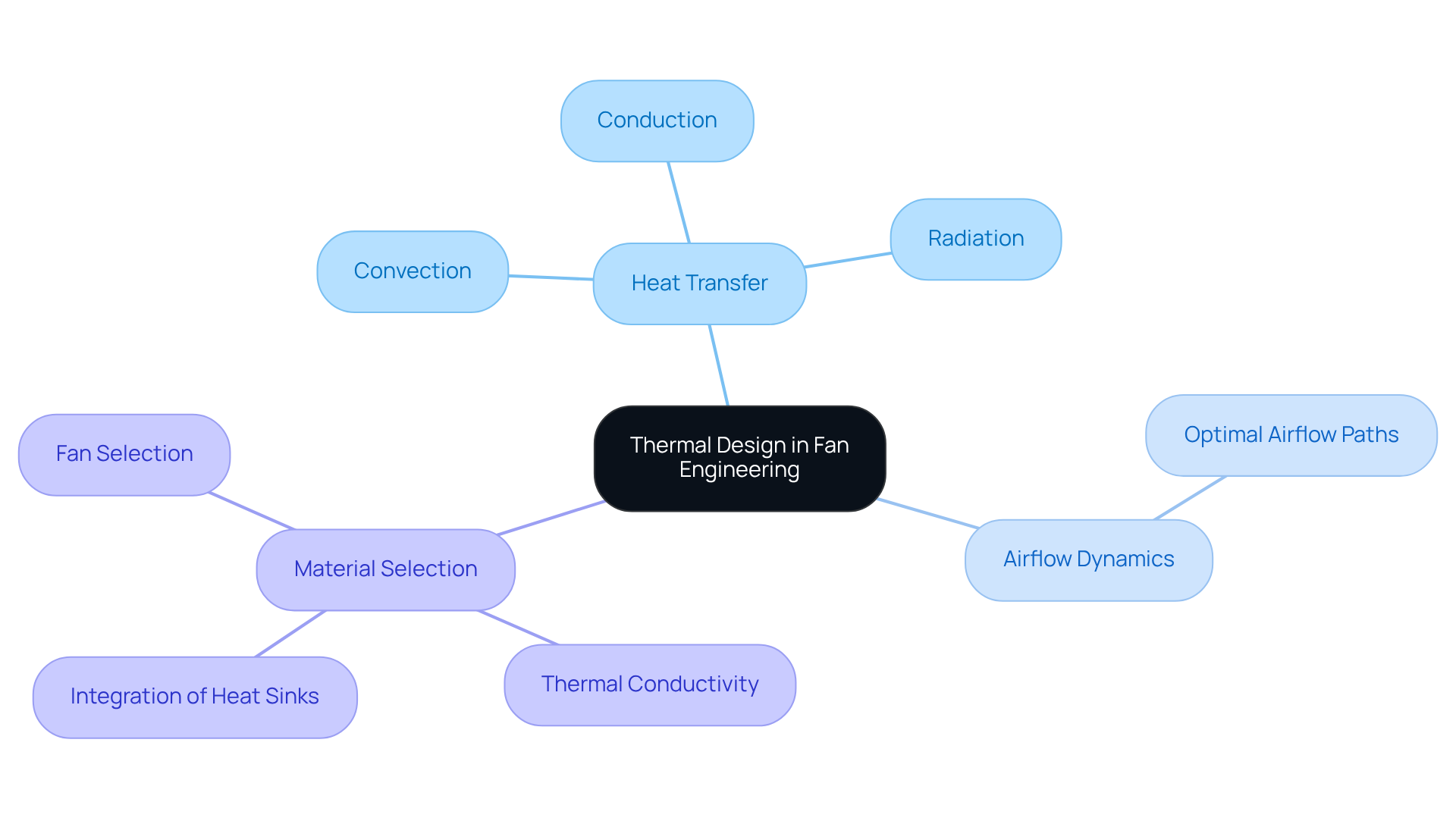

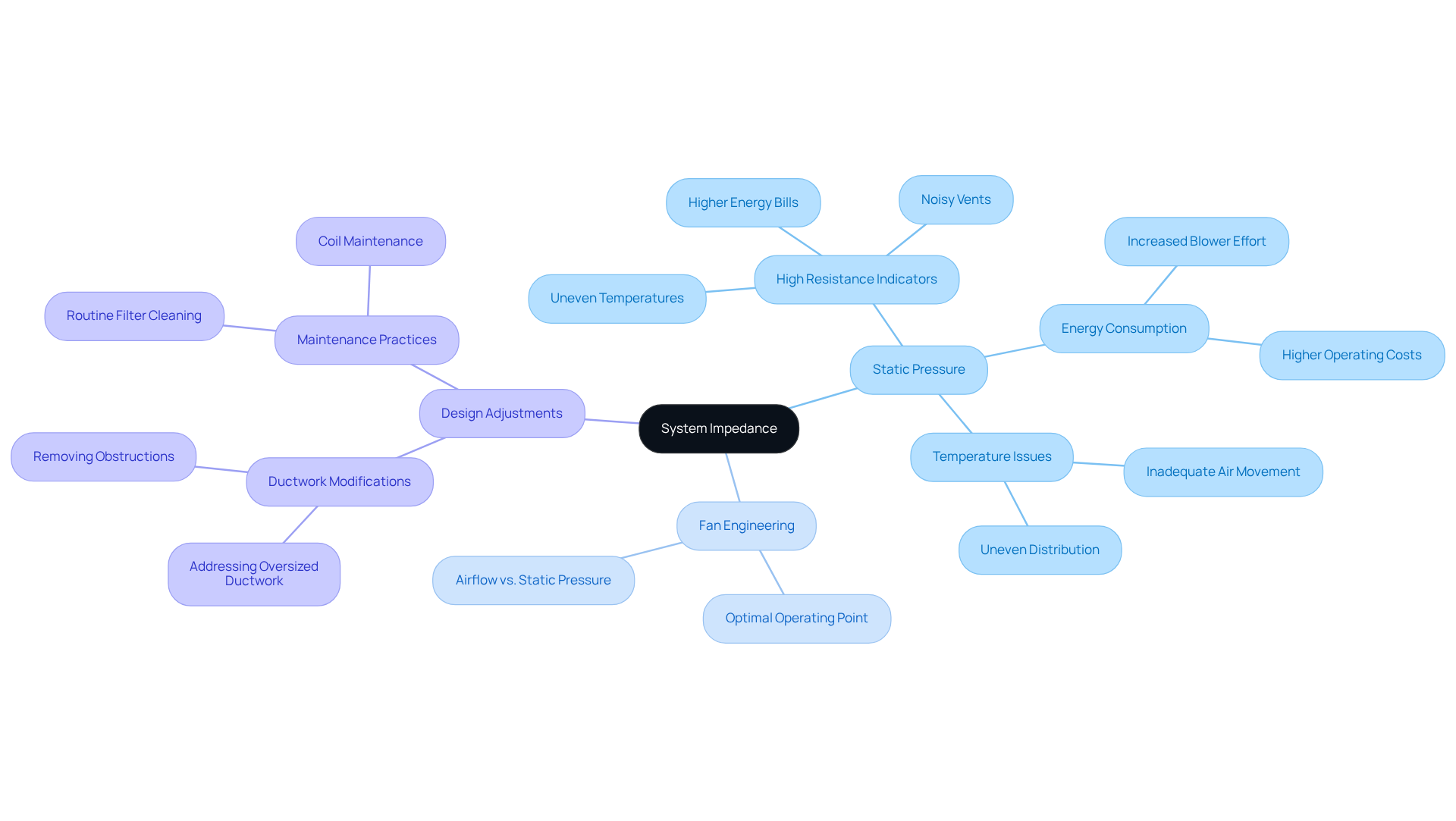

System Impedance: Understanding Its Impact on Fan Performance

Impedance refers to the resistance encountered by air movement in fan engineering setups, and understanding its impact is crucial for improving fan efficiency. Key considerations include:

- Static Pressure: Elevated static pressure often indicates increased resistance within the system, which can negatively affect airflow rates. For instance, high static pressure compels the blower to exert more effort, leading to higher energy consumption and costs. Indicators of static pressure issues include uneven temperatures, escalated energy expenses, and noisy vents—critical signs for engineers to diagnose potential fan engineering problems.

- Fan Engineering: Engineers must conduct thorough analyses of fan curves to identify the optimal operating point where the fan matches the system impedance. This ensures that the fan , enhancing circulation while minimizing energy usage. The interplay between airflow and static pressure is vital; as static pressure increases, airflow typically diminishes, necessitating a careful equilibrium. As Jouviane Alexandre notes, “High static pressure indicates your HVAC setup is facing excessive resistance.”

- Design Adjustments: Alterations to ductwork and fan positioning can significantly mitigate impedance, thereby improving overall system performance. For example, addressing issues such as oversized ductwork or obstructions can alleviate static pressure challenges, resulting in better circulation and energy efficiency. Routine maintenance, including filter and coil cleaning, is also essential to avert static pressure imbalances that can disrupt air movement. A case study on the implications of oversized ductwork illustrates that such conditions can lead to inadequate air movement and uneven temperature distribution throughout the residence.

By comprehending and managing system impedance, engineers can enhance fan engineering to ensure effective flow rates and energy efficiency across various applications.

Airflow and Pressure Measurement: Essential Metrics for Fan Efficiency

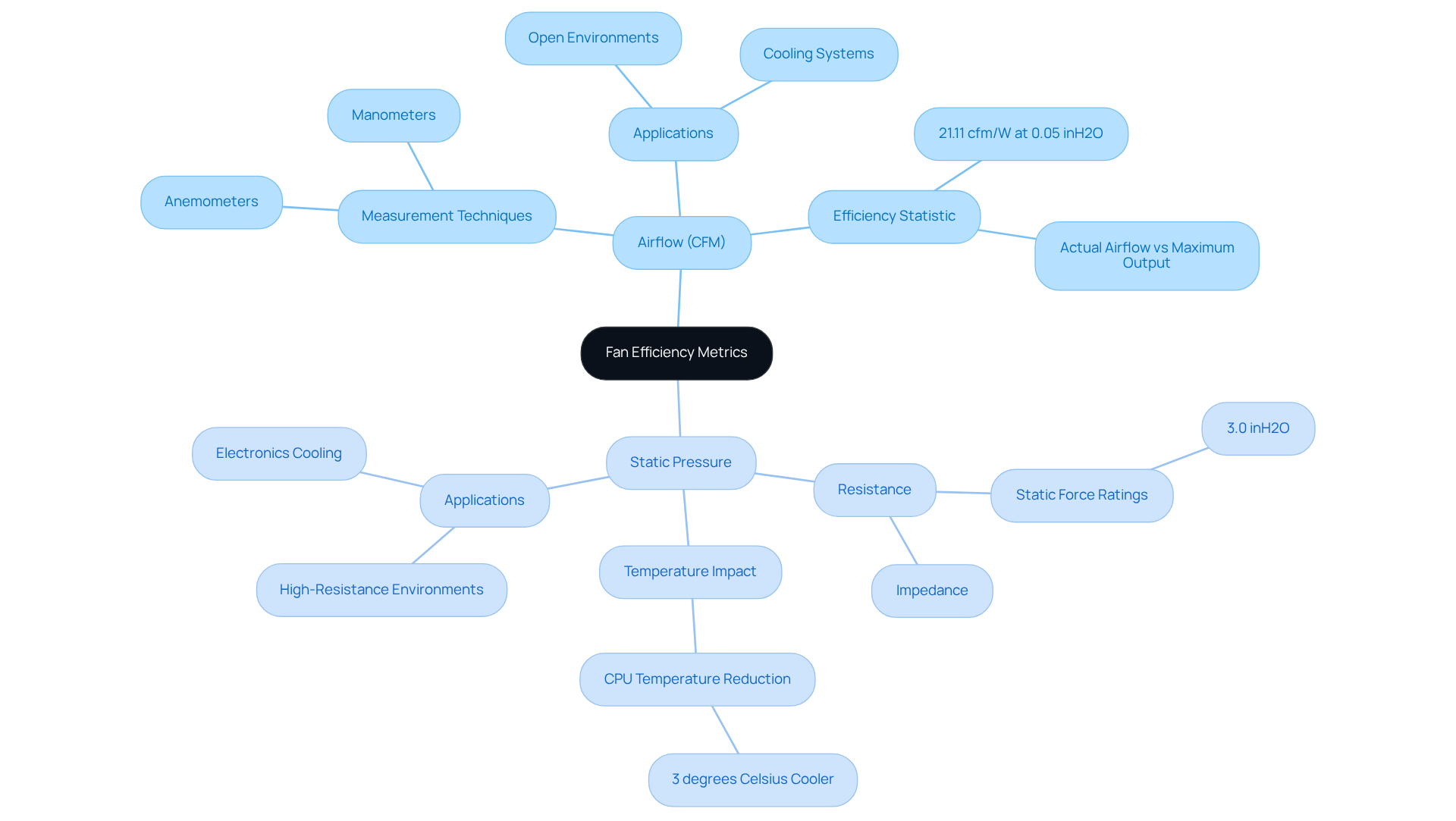

Assessing air movement and static pressure is essential for determining the efficiency of fan engineering. Key metrics include:

- Airflow (CFM): Quantified in cubic feet per minute (CFM), this metric represents the volume of air a fan can move. In many applications, actual airflow often reaches about half of the fan’s maximum output, making accurate measurement essential. At a constant force of 0.05 inH2O, the efficiency statistic indicates 21.11 cfm/W, underscoring the need for appropriate fan selection.

- Static Pressure: Measured in inches of water gauge (in. wg), static pressure indicates the resistance the fan must overcome to effectively move air through the system. Static pressure blowers typically achieve force ratings around 3.0 inH2O, which is crucial for applications with significant resistance. Notably, static pressure fans maintain CPU temperatures 3 degrees Celsius cooler than ventilation fans in a radiator setup.

- Measurement Techniques: Utilize anemometers for accurate air current measurement and manometers for static pressure evaluation. These tools ensure accurate data collection, which is critical for optimizing fan performance in various environments.

Comprehending these metrics enables engineers to apply fan engineering to choose the suitable fan for particular uses, balancing ventilation requirements against resistance factors. For instance, in high-resistance environments, static pressure fans excel, while airflow fans are better suited for open spaces requiring high CFM ratings. As Johann Tang noted, “When air flow increases, static pressure decreases; and when static pressure increases, air flow decreases.” By leveraging these measurement techniques and insights, engineers can enhance the reliability and efficiency of their cooling systems with fan engineering. Furthermore, citing the case study ‘Understanding Air Flow vs Static Pressure’ underscores the significance of these concepts for proper fan selection, while the case study ‘Effects of Accessories on Fan Efficiency’ illustrates how accessories can influence effectiveness.

Acoustic Noise Measurement: Reducing Sound in Fan Applications

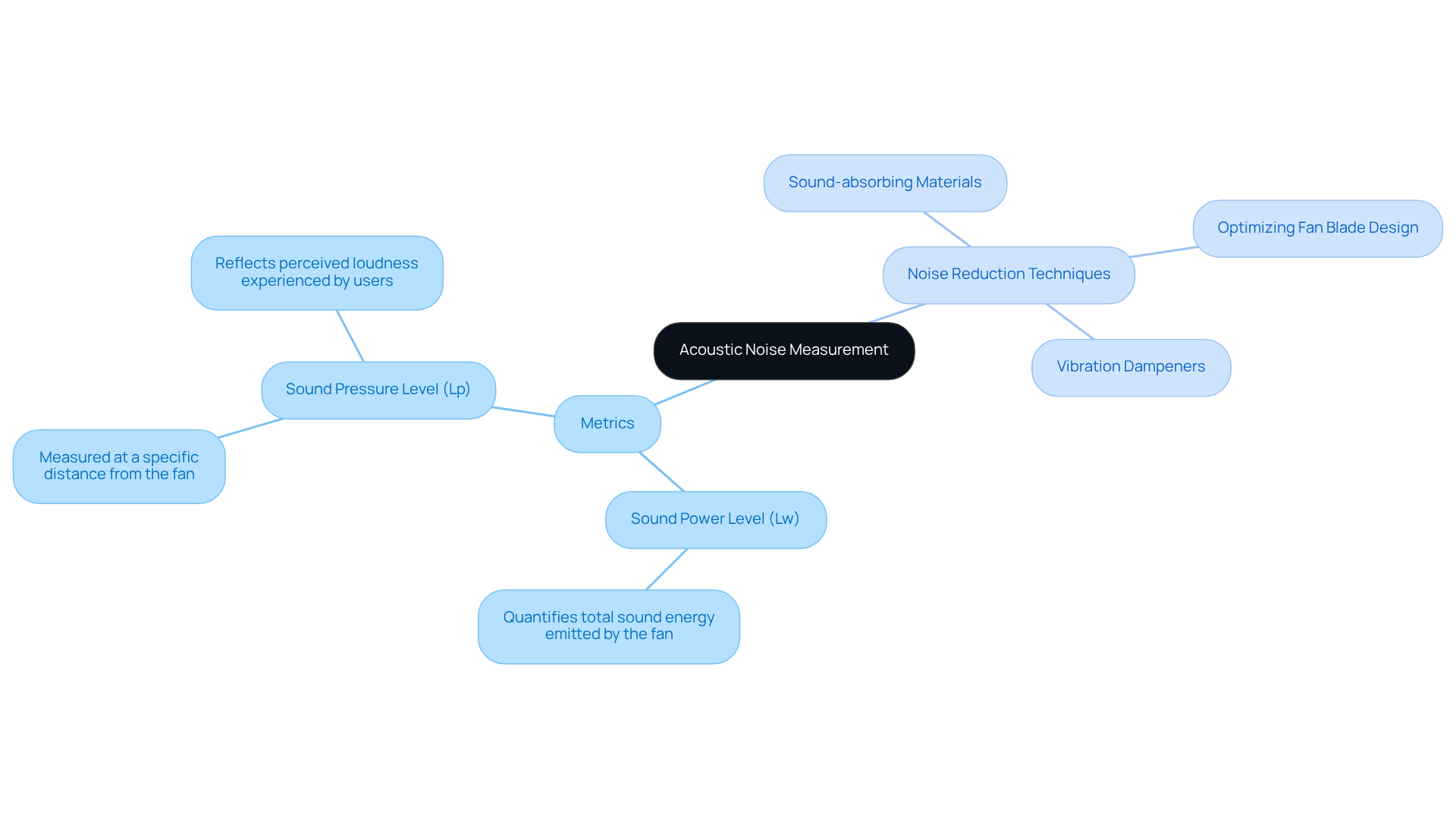

In fan engineering, acoustic noise measurement is crucial for ensuring that fan applications comply with noise regulations and meet user expectations. This section outlines key strategies to achieve effective noise management:

- Sound Power Level (Lw): This metric quantifies the total sound energy emitted by the fan, providing a foundational understanding of its acoustic output.

- Sound Pressure Level (Lp): Measured at a specific distance from the fan, this metric reflects the perceived loudness, offering insight into how the sound is experienced by users in real-world scenarios.

- Noise Reduction Techniques: Implementing sound-absorbing materials, optimizing fan blade design, and utilizing vibration dampeners can significantly reduce noise levels, enhancing overall performance and user satisfaction.

By employing these strategies in fan engineering, engineers can effectively address noise concerns, ensuring compliance with regulations while enhancing the user experience.

Fan Sensors: Enhancing Performance Monitoring and Control

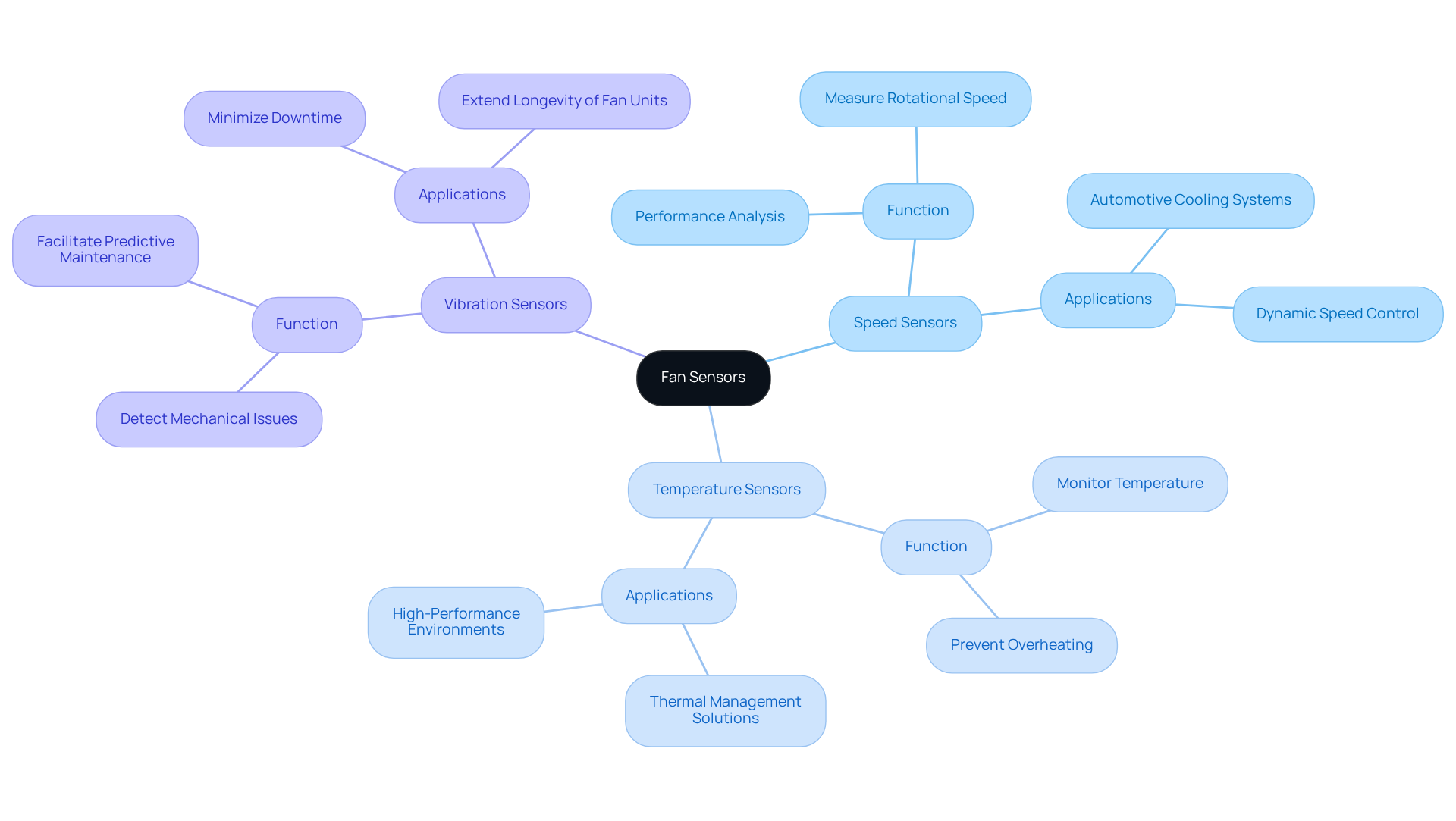

In fan engineering, fan sensors play a pivotal role in enhancing fan efficiency and ensuring reliability across a range of applications. The primary types of sensors include:

- Speed Sensors: These devices measure the rotational speed of the fan, providing critical data for performance analysis and enabling necessary adjustments to maintain optimal operation. Recent advancements in speed sensor technology have significantly improved accuracy and response times, thereby enhancing overall system efficiency. Gagner-Toomey Associates offers a diverse array of DC input Tube Axial units and Centrifugal Blowers, available in sizes from 15 to 280mm and 15 to 225mm respectively, which can be integrated with these sensors for improved performance.

- Temperature Sensors: Continuously monitoring temperature, these sensors help prevent overheating, ensuring that fans operate within safe limits. The incorporation of temperature sensors has been shown to considerably bolster the durability and dependability of cooling solutions, particularly in high-performance environments. Gagner-Toomey’s extensive portfolio includes thermal management solutions such as CPU coolers and custom cooling solutions that leverage temperature monitoring for optimal operation.

- Vibration Sensors: These sensors detect vibrations that may indicate mechanical issues, facilitating predictive maintenance. By identifying potential issues early, engineers can minimize downtime and extend the longevity of fan units. Gagner-Toomey’s innovative designs, including miniature blower solutions starting from 15x3mm, are particularly suited for applications where space is limited, yet reliability is paramount.

The impact of temperature sensors on fan functionality is substantial, with research indicating that setups equipped with these sensors can reduce overheating occurrences by as much as 40%. Moreover, the adoption of smart fan technology, which utilizes advanced sensors, has surged by over 30% in the past year, reflecting a growing trend towards more intelligent and efficient cooling solutions.

Real-world applications of speed sensors are apparent in automotive cooling systems, where precise speed control is essential for managing heat generated by high-performance engines. These sensors enable to fan speed based on real-time temperature data, ensuring optimal thermal management. Gagner-Toomey’s broad product line of fans and blowers is designed to meet these demanding requirements.

As the cooling fan market is projected to expand considerably, approaching $30 billion by 2035, fan engineering will focus on the role of sensors in enhancing fan efficiency, remaining a central concern for engineers seeking innovative solutions in the electronics sector.

Speed Control: Techniques for Optimizing Fan Operation

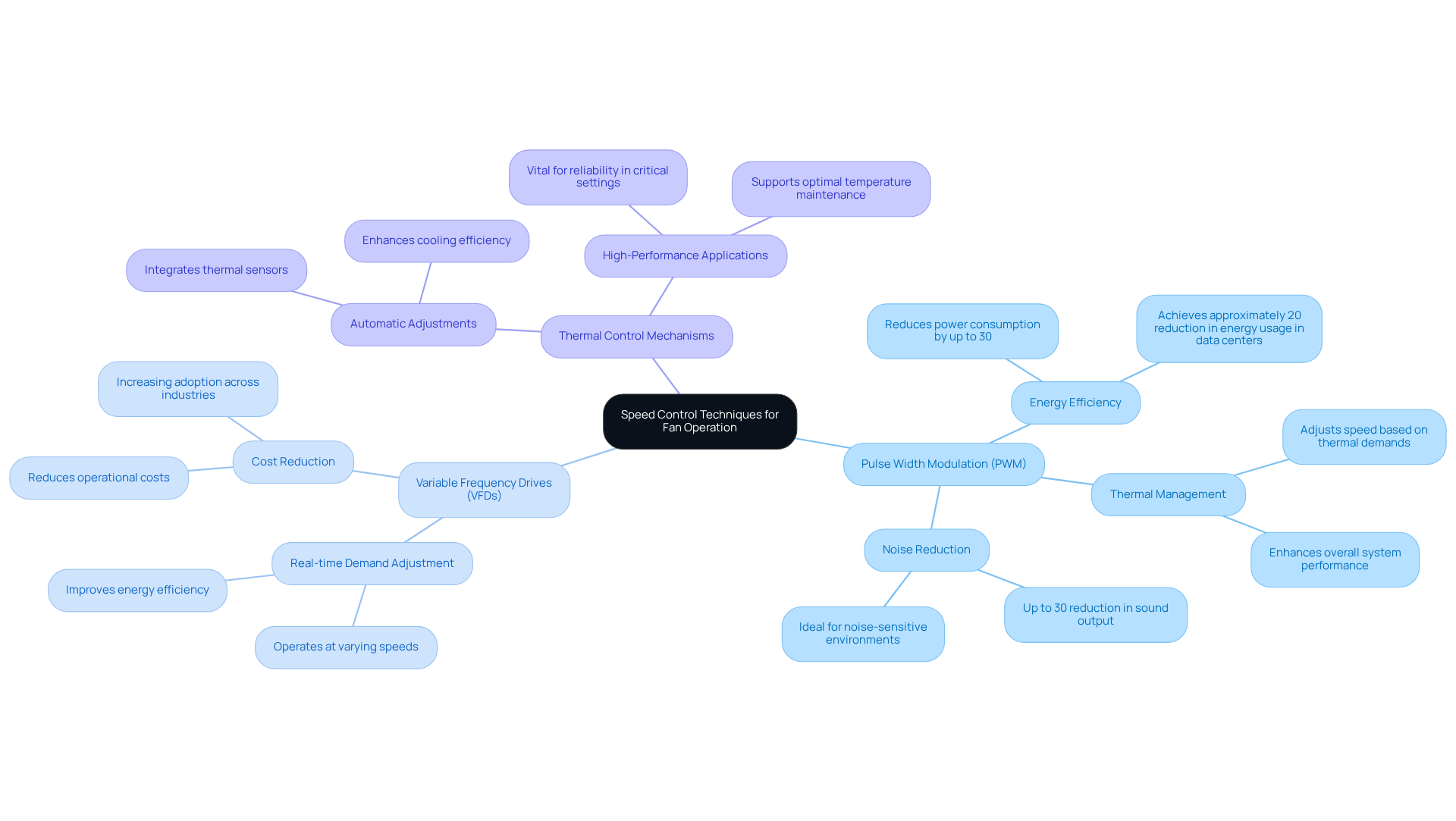

Effective speed control techniques in fan engineering significantly enhance performance and energy efficiency. The primary methods to achieve this include:

- Pulse Width Modulation (PWM): This technique precisely adjusts the voltage supplied to the fan, enabling accurate speed control. PWM units can lower power usage by as much as 30% compared to conventional models while preserving similar temperature regulation efficiency and minimizing heat production. This makes them ideal for situations that demand .

- Variable Frequency Drives (VFDs): VFDs allow fans to operate at varying speeds based on real-time demand, improving energy efficiency and reducing operational costs. Their adoption is on the rise as industries aim to enhance energy use in fan engineering setups. Recent statistics indicate a growing trend in fan engineering through VFD implementation across various sectors, reinforcing their importance in modern engineering practices.

- Thermal Control Mechanisms: By integrating thermal sensors with fan controls, these mechanisms enable automatic adjustments according to temperature variations, thereby enhancing cooling efficiency. This adaptability is vital in high-performance settings, where sustaining optimal temperatures is essential for reliability. As noted by David Hanrahan, the adaptability of PWM devices provides more comprehensive thermal-management solutions, enhancing overall system performance.

Recent advancements in PWM technology have led to enhanced thermal management solutions, with applications ranging from data centers to industrial settings. For instance, data centers utilizing PWM technology have reported approximately 20% reductions in overall energy usage, demonstrating the effectiveness of these innovations in real-world scenarios. Additionally, case studies highlight the significant role of PWM fans in improving energy efficiency and operational effectiveness, particularly in environments where precise temperature control is critical. As industries continue to prioritize energy efficiency and sustainability, the importance of fan engineering, particularly the role of PWM and VFDs in fan operation, is expected to grow, reinforcing their significance in modern engineering practices.

Fan Laws: Fundamental Principles for Performance Analysis

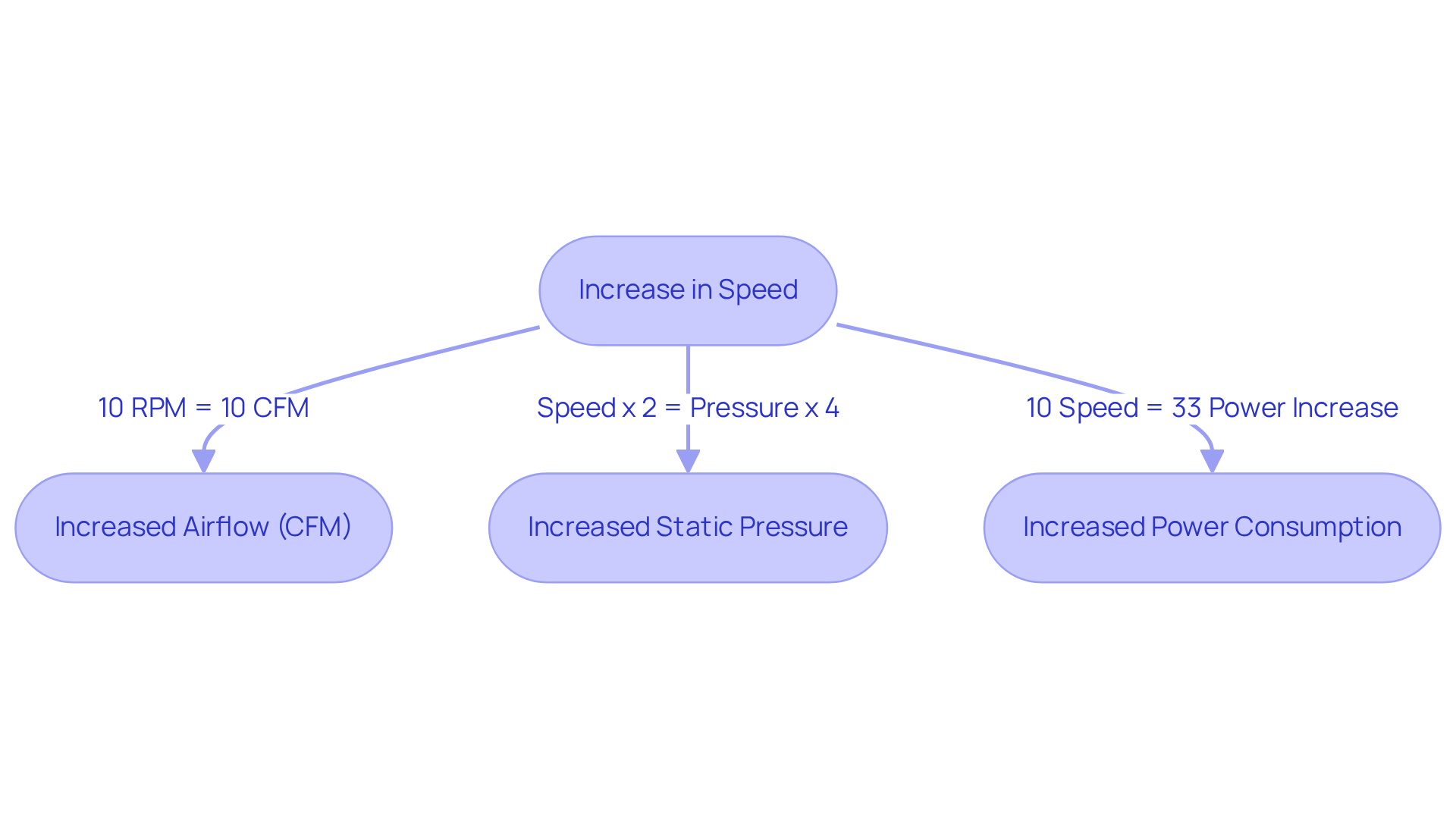

Understanding is essential for grasping the relationships between fan speed, air movement, pressure, and power consumption. These principles provide crucial insights into fan performance:

- Fan Law 1: Airflow, measured in cubic feet per minute (CFM), is directly proportional to revolutions per minute (RPM). Thus, a 10% increase in RPM yields a corresponding 10% increase in airflow.

- Fan Law 2: Static pressure varies with the square of the speed. Therefore, when the speed is doubled, static pressure increases by a factor of four.

- Fan Law 3: Power consumption is affected by the cube of the speed. A 10% increase in speed leads to a significant 33% rise in power consumption.

These laws not only highlight the intricate dynamics of fan engineering but also underscore the importance of precise adjustments in fan systems to optimize their performance and efficiency.

Fan Life and Reliability: Ensuring Long-Term Performance

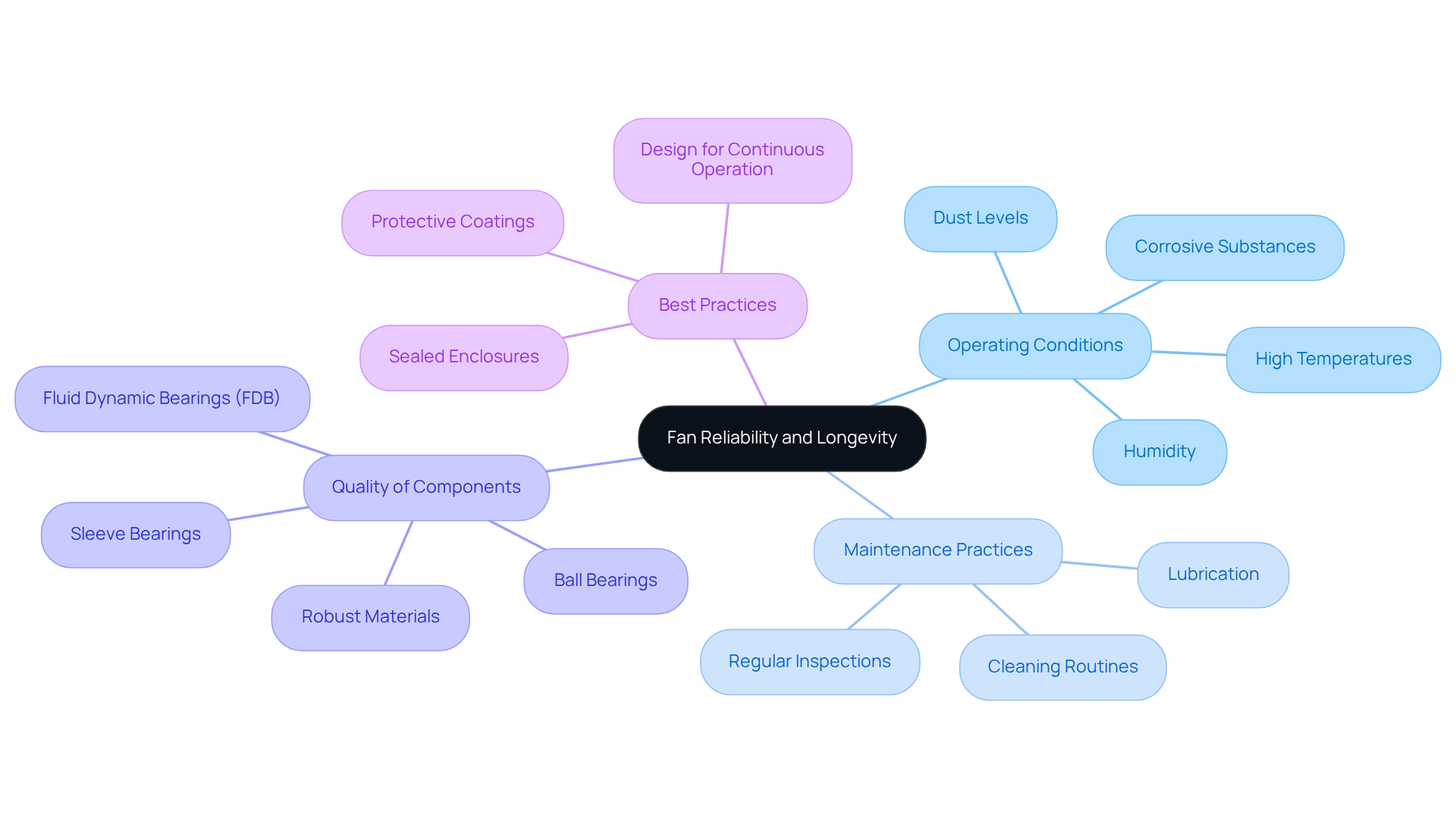

Ensuring the long-lasting efficiency of blowers necessitates a comprehensive understanding of fan engineering and the factors that influence their reliability. Key considerations include:

- Operating Conditions: High temperatures, humidity, dust levels, and exposure to corrosive substances significantly shorten fan life. It is essential to select devices specifically rated for these environmental conditions to sustain optimal functionality in fan engineering.

- Maintenance Practices: Regular inspections, lubrication, and cleaning routines are vital in preventing premature failures. Consistent upkeep is particularly crucial for devices involved in fan engineering that operate under high-duty cycles, as insufficient rest intervals can lead to increased wear and tear.

In fan engineering, the longevity of a fan is heavily influenced by the . Employing high-quality bearings, such as ball bearings or fluid dynamic bearings (FDB), is crucial in fan engineering to enhance reliability and lifespan. Conversely, sleeve bearings, while more economical, typically offer shorter service lives. Additionally, utilizing robust materials and dependable components in fan engineering is critical for ensuring long-lasting functionality.

Case studies demonstrate that fan engineering significantly influences the impact of operating conditions on fan lifespan. For example, excessive heat, humidity, and exposure to dust or corrosive substances can accelerate wear, leading to diminished efficiency. In fan engineering, selecting units designed for high-temperature environments can mitigate these risks, thereby ensuring improved functionality and durability.

Best practices for longevity highlight the importance of fan engineering in designing blowers for durability, especially in sensitive systems. Fan engineering for continuous operation with minimal performance degradation is essential in applications where reliability is paramount. Furthermore, incorporating protective coatings and sealed enclosures is advisable for devices in challenging conditions, further enhancing durability.

Multiple Fan Use: Strategies for Effective System Design

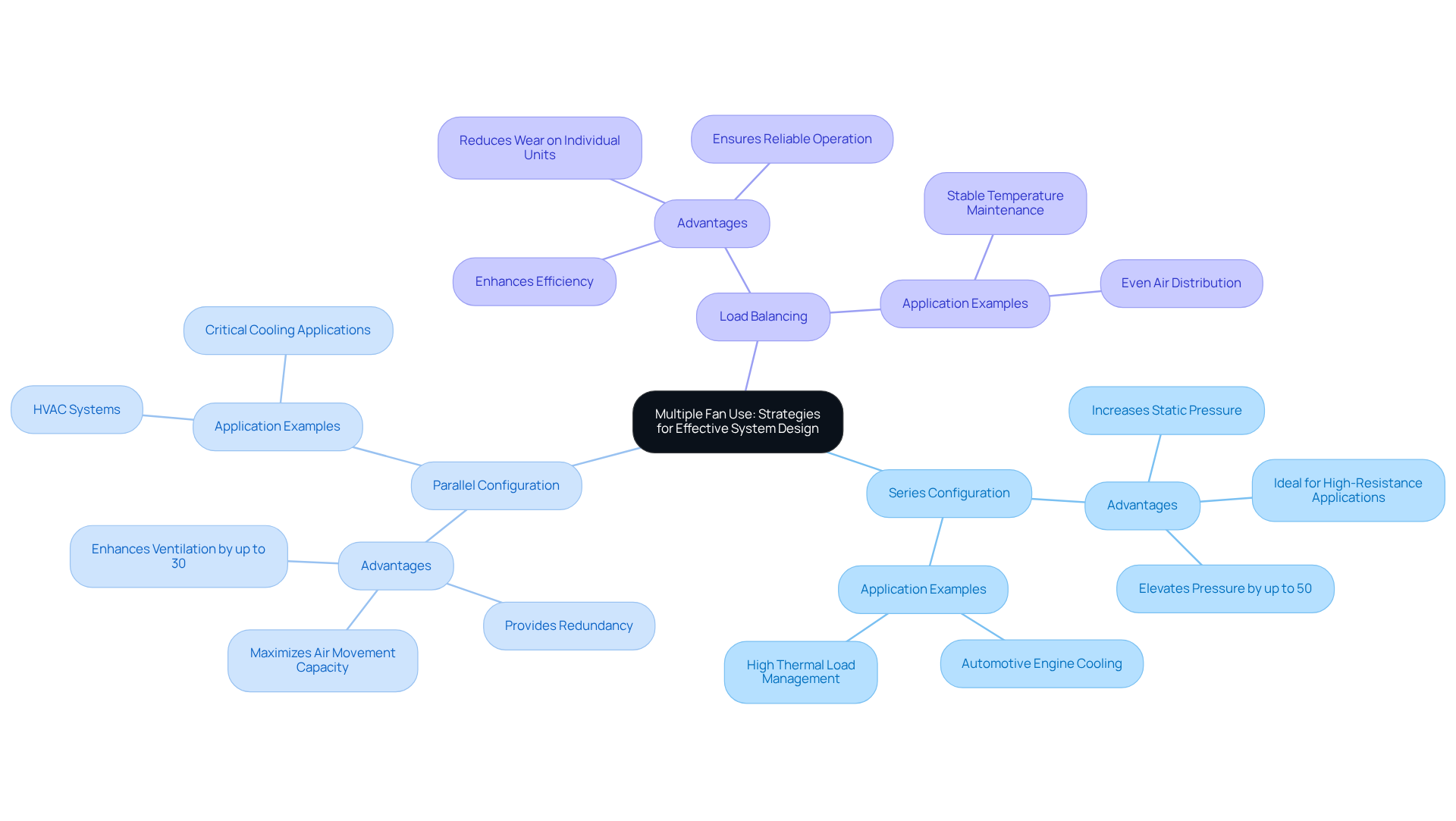

Creating systems with multiple ventilators significantly enhances the effectiveness of fan engineering in circulation and cooling. Key strategies include:

- Series Configuration: Arranging fans in series increases static pressure, making this setup ideal for high-resistance applications. This configuration proves particularly advantageous in scenarios where air movement must navigate considerable barriers, such as filters or heat exchangers. Studies indicate that series configurations can elevate pressure by up to 50%, ensuring optimal performance in demanding environments.

- Parallel Configuration: Utilizing fans in parallel maximizes air movement capacity, making it suitable for applications requiring high volume. This configuration provides redundancy; if one fan malfunctions, others can sustain circulation, which is essential in . Expert opinions suggest that parallel configurations can enhance ventilation by up to 30% compared to single fan arrangements, rendering them a preferred choice in numerous industrial applications.

- Load Balancing: Distributing ventilation demands among multiple fans not only enhances efficiency but also reduces wear on individual units, thereby extending their lifespan and ensuring reliable operation. By implementing load balancing techniques, setups can achieve a more even distribution of air, which is crucial for maintaining stable temperatures throughout components.

Real-world examples underscore the effectiveness of these configurations. For instance, in automotive applications, series fan arrangements are frequently employed in engine cooling mechanisms to manage high thermal loads, while parallel configurations are favored in HVAC setups for their ability to sustain airflow during peak demand.

Recent advancements in fan technology highlight the significance of these configurations, with industry leaders advocating for designs that prioritize both efficiency and reliability. As the demand for effective cooling solutions continues to escalate, comprehending the advantages of series versus parallel fan configurations in fan engineering will be essential for engineers striving to optimize system performance.

Conclusion

Innovative fan engineering is crucial for enhancing efficiency and reliability across diverse applications, particularly in the electronics sector. By harnessing advanced cooling technologies, such as those offered by Gagner-Toomey Associates, engineers can refine thermal management strategies that are essential for sustaining optimal performance. The integration of cutting-edge materials and techniques not only tackles thermal challenges but also significantly elevates the reliability of electronic devices.

Key insights from this exploration underscore the necessity of grasping fundamental principles including:

- Thermal design

- System impedance

- Airflow measurement

Each of these components plays a pivotal role in ensuring effective fan operation, while advancements in sensor technology and speed control methods further bolster performance monitoring and energy efficiency. Furthermore, the implementation of suitable configurations—whether through series or parallel fan setups—facilitates enhanced circulation and cooling, addressing the specific demands of various environments.

As industries continue to evolve, the importance of effective fan engineering becomes increasingly evident. Engineers are urged to embrace these insights and best practices to propel innovation and sustainability in their designs. By prioritizing advanced cooling solutions and comprehending the foundational principles of fan performance, the engineering community can guarantee that future systems are not only efficient but also reliable, paving the way for superior performance across multiple applications.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative cooling solutions for the electronics industry, focusing on both standard and custom air-movers.

What types of products does Gagner-Toomey offer?

Gagner-Toomey offers a comprehensive range of products including DC input tube axial fans, centrifugal blowers, and miniature blower solutions.

What innovative technologies are utilized in their cooling solutions?

Their cooling solutions incorporate advanced technologies such as vapor chambers and liquid cooling solutions, as well as phase change materials and advanced thermal interface materials.

How do vapor chambers contribute to fan engineering?

Vapor chambers enhance heat dissipation, significantly improving the reliability and efficiency of products in the electronics sector.

What certifications do Gagner-Toomey’s partners hold?

Gagner-Toomey’s partners hold certifications such as AS9100 and ISO 9001, ensuring adherence to stringent industry standards.

What are the key principles of effective thermal design in fan engineering?

The key principles include understanding heat transfer (conduction, convection, radiation), optimizing airflow dynamics, and selecting appropriate materials for thermal conductivity.

What is system impedance in fan engineering?

System impedance refers to the resistance encountered by air movement in fan setups, which affects fan efficiency and airflow rates.

How does static pressure relate to fan performance?

Elevated static pressure indicates increased resistance, which can lead to higher energy consumption and reduced airflow rates, impacting overall fan efficiency.

What are some indicators of static pressure issues?

Indicators include uneven temperatures, increased energy expenses, and noisy vents.

How can engineers mitigate impedance in fan systems?

Engineers can mitigate impedance by making design adjustments to ductwork and fan positioning, as well as performing routine maintenance such as filter and coil cleaning.