Overview

This article serves as a comprehensive guide for readers faced with the decision between PWM (Pulse Width Modulation) and DC (Direct Current) fans for their projects. It delineates the key differences and respective advantages of each type.

- PWM fans stand out due to their superior energy efficiency, precise control, and quieter operation, rendering them ideal for high-performance applications.

- Conversely, DC fans present a more cost-effective solution and are simpler to install, making them suitable for basic cooling needs.

By understanding these distinctions, readers can make informed choices that align with their project requirements.

Introduction

Understanding the nuances of cooling solutions is essential for anyone involved in electronics, whether for a high-performance gaming rig or a cost-effective home project. The choice between PWM and DC fans significantly impacts energy efficiency, noise levels, and overall system performance. As engineers weigh their options, a pivotal question arises: how does one determine the best fan type for their specific needs? This article delves into the critical differences, advantages, and applications of PWM and DC fans, providing a comprehensive checklist to guide informed decisions in cooling technology.

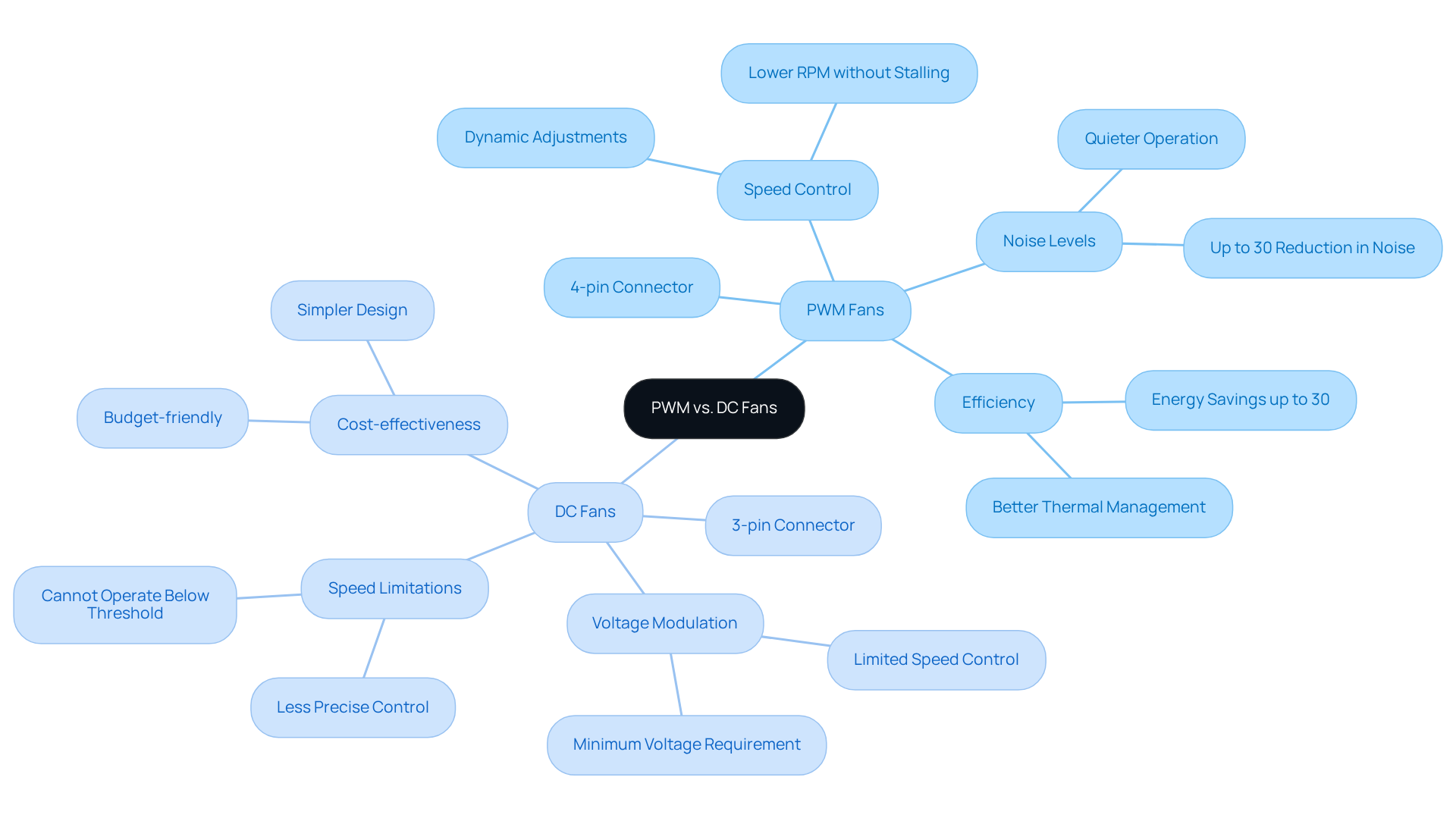

Identify Key Differences Between PWM and DC Fans

PWM or DC blowers: These advanced devices utilize a 4-pin connector, where the fourth pin transmits a PWM signal to enable precise control of rotation. Capable of operating at significantly lower speeds, they can achieve reductions of up to 40% of their rated capacity, making them particularly suitable for applications that demand meticulous temperature regulation. The efficiency of devices using PWM or DC shines in environments where noise reduction is critical; they can operate silently at reduced RPMs, eliminating the risk of stalling.

DC devices, which are often referred to as PWM or DC devices, are typically outfitted with a 3-pin connector and function by modulating the voltage supplied to them, ranging from 0 to 12 volts. This operational method limits their ability to achieve minimal velocities, as they generally cannot operate below a certain threshold. While these devices are often simpler and more cost-effective, they fall short in delivering the that PWM or DC technology provides.

Key Takeaway: PWM or DC units excel in providing superior control over rotation and energy efficiency, which makes them the preferred choice for high-performance applications. In contrast, while DC devices are more straightforward and budget-friendly, they may not meet the demands of systems requiring advanced thermal management solutions.

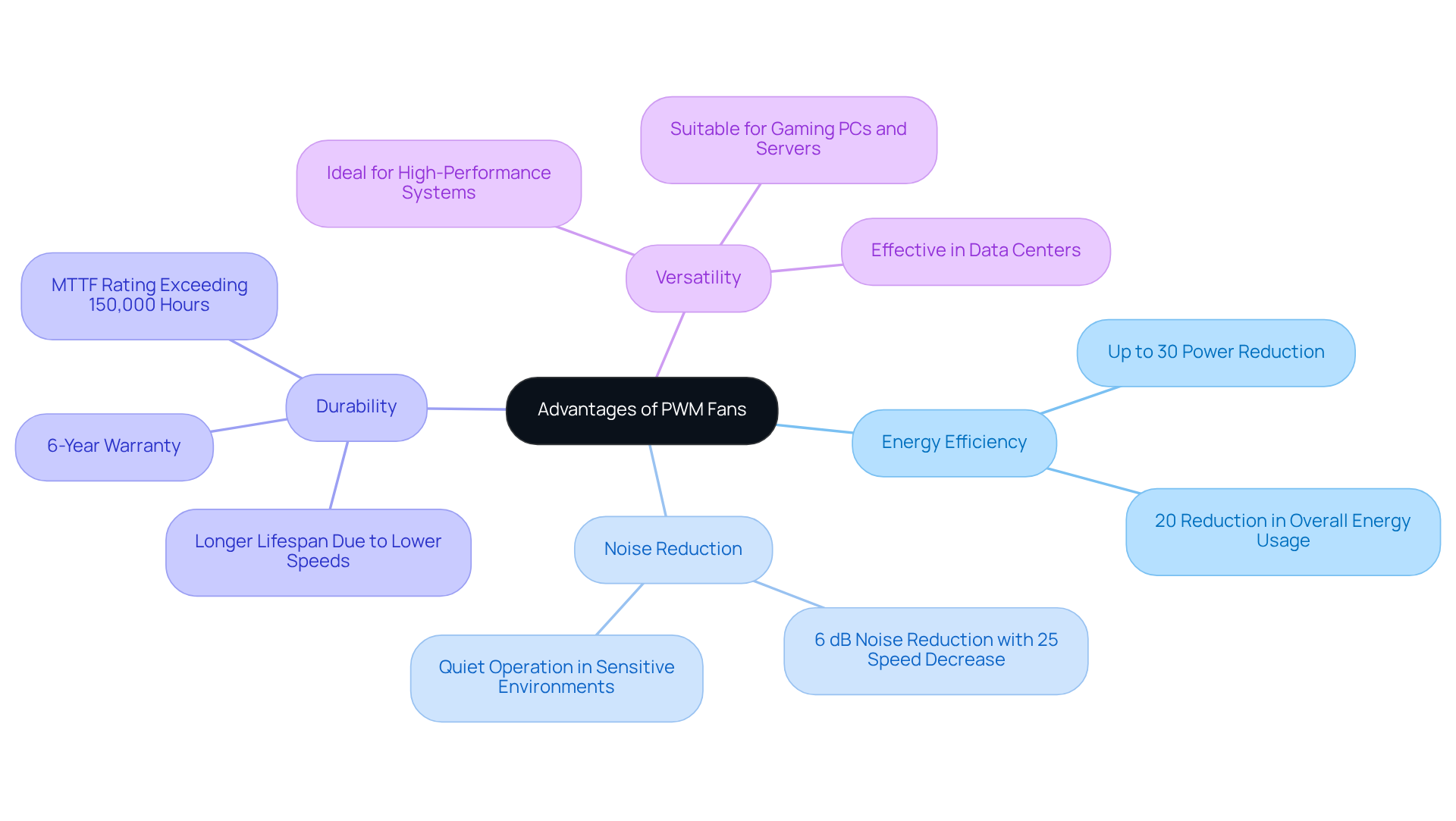

Evaluate Advantages of PWM Fans for Enhanced Performance

PWM cooling devices offer significant advantages in energy efficiency, dynamically adjusting their operational rates based on thermal conditions. This capability can lead to of up to 30% compared to traditional units that use PWM or DC. Such adaptability not only improves cooling performance but also meets the increasing demand for sustainable engineering solutions in electronics.

In terms of noise reduction, PWM devices excel by operating more quietly at lower levels, making them particularly suitable for noise-sensitive environments such as home theaters or serene office spaces. For example, a 25% reduction in fan operation can lead to a noise decrease of approximately 6 dB, a considerable improvement in maintaining a comfortable acoustic atmosphere. This reduction is especially evident in models like the Pure Wings 3 and Shadow Wings 2, specifically designed for quiet operation.

Moreover, the durability of PWM devices is exceptional; they generally feature a longer lifespan due to reduced wear from operating at lower speeds. A mere 10 °C decrease in motor temperature can nearly double the motor’s lifespan, with certain PWM devices providing warranties of up to 6 years, underscoring their reliability and longevity. Notably, Noctua products boast an MTTF rating exceeding 150,000 hours, further emphasizing their long-term performance.

These devices are versatile and ideal for high-performance systems that necessitate precise cooling control, such as gaming PCs and servers. Data centers transitioning to PWM or DC technology have reported efficiency improvements in temperature control of up to 30%, as evidenced by multiple case studies, showcasing the practical benefits of employing PWM or DC devices in demanding applications.

Assess Benefits of DC Fans for Cost-Effective Solutions

DC enthusiasts typically offer a more economical alternative to models that use PWM or DC, making them an attractive choice for budget-conscious projects. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers for temperature regulation, presents an extensive range of DC input units optimized for performance, efficiency, and low noise, ensuring engineers have access to reliable solutions.

The design of devices using PWM or DC incorporates fewer components, which simplifies installation and integration into existing systems. This ease of installation is particularly advantageous in confined spaces, where the low-profile design of models like the WhisperValue® DC Fan allows for versatile placement in both ceilings and walls.

Many applications require only basic cooling functions, and devices using PWM or DC deliver sufficient airflow without the complexity of advanced control features. For example, the WhisperValue® DC Fan operates efficiently at customizable airflow levels of 30-70 CFM for continuous operation and can boost to 80 or 100 CFM when activated, addressing diverse ventilation needs.

DC enthusiasts are prevalent across various devices, facilitating easy sourcing for engineers. Their compatibility with standard installations further enhances their appeal, as evidenced by the successful integration of Snap-Fan products in commercial greenhouses and residential settings.

The overall cost-effectiveness of units, whether PWM or DC, is underscored by their long-term reliability and reduced maintenance requirements. With for motors and three years for other components, users can anticipate a robust return on investment, reinforcing the value of selecting DC fans for both new projects and retrofits. Gagner-Toomey Associates distinguishes itself as a leading supplier of innovative temperature control solutions, delivering comprehensive air-movers and thermal management for electronics and beyond.

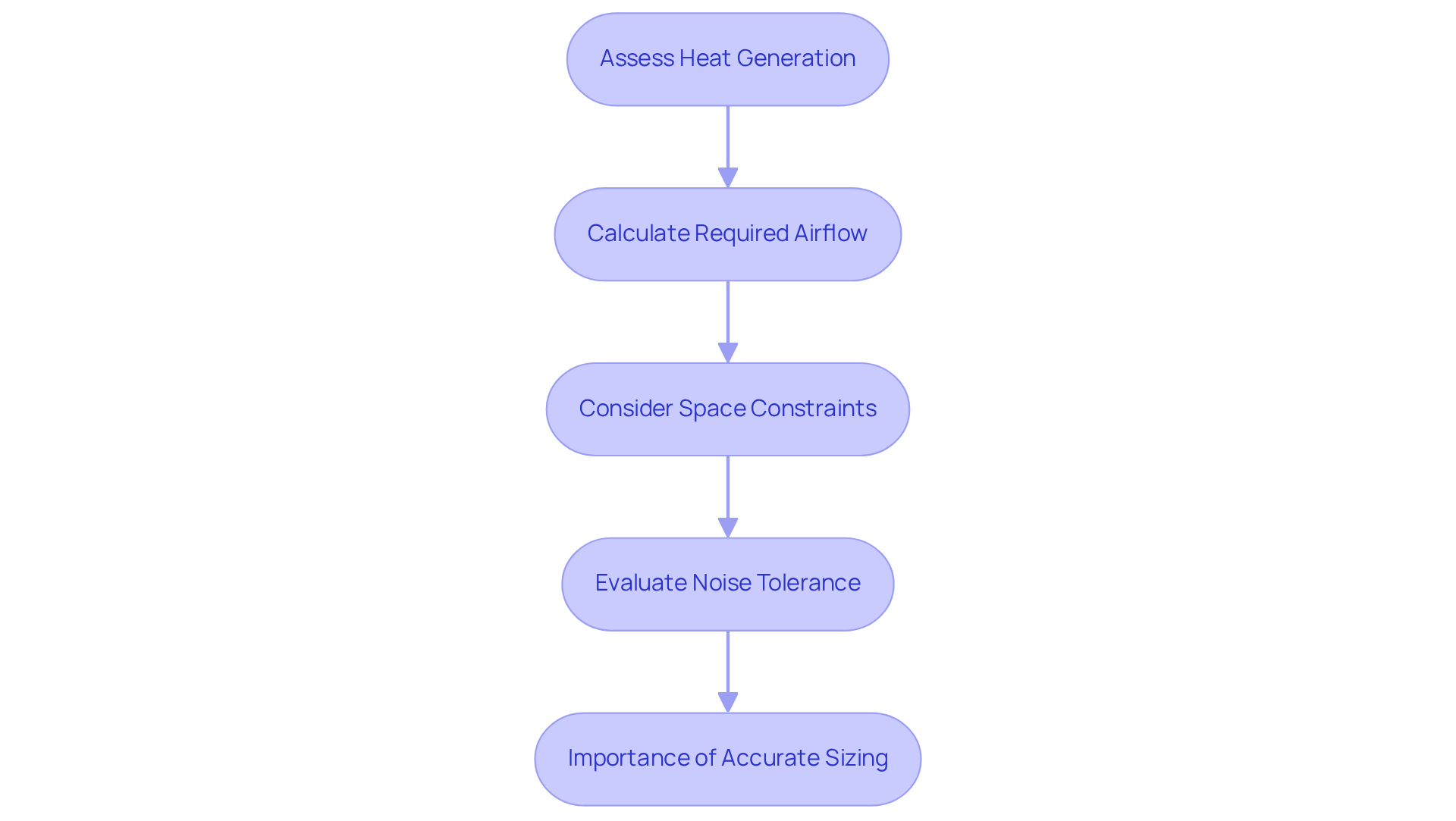

Determine Your Specific Cooling Requirements and Applications

- Assess Heat Generation: Begin by identifying the heat output of the components that require temperature regulation. Understanding the of your components is crucial, as excessive heat can lead to performance degradation or failure.

- Calculate Required Airflow: Utilize established formulas or online calculators to determine the necessary airflow for maintaining optimal temperatures. A common approach involves calculating the required cubic feet per minute (CFM) based on the heat output in watts, using the formula: CFM = (Heat Load in Watts) / (Temperature Rise in °F x 1.08). This calculation ensures that the temperature regulation system is adequately sized to handle the thermal load.

- Consider Space Constraints: Evaluate the physical space available for fan installation, as this significantly influences the choice of fan size and type. In settings with restricted space, compact ventilators or specialized cooling solutions may be necessary to ensure effective airflow without compromising performance.

- Evaluate Noise Tolerance: Determine the acceptable noise levels in the environment where the fan will operate. This evaluation is crucial for guiding the selection between devices that use PWM or DC. PWM or DC fans typically offer quieter operation at lower speeds, making them suitable for noise-sensitive applications, while PWM or DC fans may provide higher airflow at the cost of increased noise.

- Importance of Accurate Sizing: Accurate sizing and load calculations are vital for maintaining consistent indoor temperatures. HVAC systems typically endure from 10 to 20 years, and appropriate temperature control solutions can greatly improve their lifespan and efficiency.

By systematically addressing these factors, engineers can make informed decisions that optimize temperature management and enhance the reliability of electronic systems. As Johann Tang, a Product Specialist at Oriental Motor USA Corp., noted, “A deeper understanding is necessary to determine how the fan will actually perform in a real-life scenario.” Additionally, the implementation of the Varistar LHX+ air-water heat exchanger serves as a prime example of effective cooling solutions in technologically advanced applications.

Conclusion

Selecting the appropriate fan technology for a project is essential for optimizing performance and efficiency. This article has examined the differences between PWM (Pulse Width Modulation) and DC (Direct Current) fans, emphasizing how PWM fans deliver superior control, energy efficiency, and quieter operation, making them particularly suited for high-performance applications. Conversely, DC fans offer a more economical solution that simplifies installation and meets basic cooling needs, albeit without the advanced control features characteristic of PWM systems.

Key insights highlight the benefits of PWM fans, including:

- Their adaptability to thermal conditions

- Substantial noise reduction

- Enhanced durability—all crucial for environments that demand precise temperature management

In contrast, DC fans present budget-friendly options that provide adequate performance for less demanding applications, proving advantageous for projects with limited resources or simpler cooling requirements.

Ultimately, grasping the specific cooling needs and constraints of a project is paramount. By assessing factors such as heat generation, required airflow, and noise tolerance, engineers can make informed choices between PWM and DC fans. This meticulous evaluation not only bolsters the reliability of electronic systems but also aligns with sustainable engineering practices. Embracing the right fan technology can lead to enhanced performance, longevity, and overall satisfaction in any project.

Frequently Asked Questions

What is the main difference between PWM and DC fans?

The main difference is that PWM fans utilize a 4-pin connector and can receive a PWM signal for precise control of rotation, allowing them to operate at significantly lower speeds, while DC fans typically have a 3-pin connector and modulate voltage between 0 to 12 volts, limiting their ability to achieve minimal velocities.

What advantages do PWM fans offer?

PWM fans offer superior control over rotation and energy efficiency, allowing for reductions in speed of up to 40% of their rated capacity, which is ideal for applications requiring meticulous temperature regulation and noise reduction.

How do DC fans operate?

DC fans operate by modulating the voltage supplied to them, which ranges from 0 to 12 volts. However, they generally cannot operate below a certain threshold, limiting their performance in low-speed applications.

Are PWM fans quieter than DC fans?

Yes, PWM fans can operate silently at reduced RPMs, making them suitable for environments where noise reduction is critical.

What are the cost implications of PWM vs. DC fans?

DC fans are often simpler and more cost-effective compared to PWM fans, which offer advanced control and efficiency but may come at a higher price.

In what scenarios are PWM fans preferred over DC fans?

PWM fans are preferred in high-performance applications that demand advanced thermal management solutions and precise control of rotation, whereas DC fans may not meet these demands.