Overview

Master server liquid cooling encompasses a range of methods, including:

- Direct-to-chip cooling

- Immersion cooling

- Rear-door heat exchangers

Each of these techniques is meticulously designed to enhance thermal management in high-density computing environments. These advanced cooling solutions not only improve energy efficiency but also significantly reduce operational costs through effective heat dissipation and lower Power Usage Effectiveness (PUE). As data centers confront escalating heat densities, the implementation of these strategies becomes essential, driving the need for innovative thermal management solutions.

Introduction

Liquid cooling systems are transforming the management of heat in data centers, especially in an era where high-density computing has become the standard. By harnessing the exceptional thermal conductivity of liquids, these systems not only enhance performance but also significantly lower energy consumption. This presents a compelling opportunity for organizations aiming to optimize their infrastructure.

However, the transition to liquid cooling is fraught with challenges. How can data centers effectively implement and maintain these advanced systems while ensuring maximum efficiency and sustainability?

Understand Liquid Cooling Fundamentals

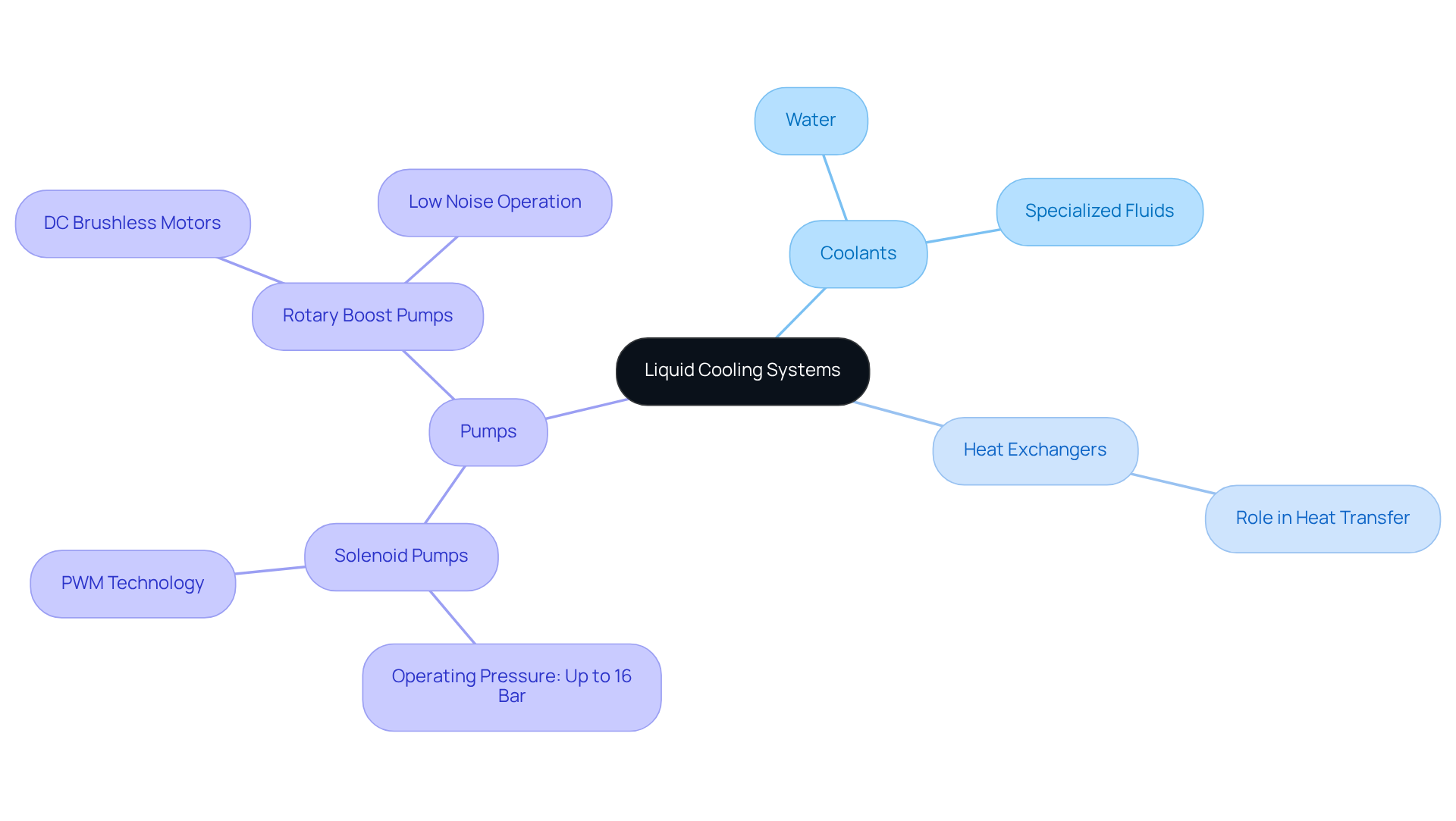

Liquid cooling systems operate on the principle of thermal transfer through liquids, which outperform air due to their superior thermal conductivity. This technology addresses the critical need for in high-density computing environments. Key components of liquid cooling systems include:

- Coolants: These are typically water or specialized fluids that effectively absorb heat, ensuring optimal performance.

- Heat Exchangers: These devices are essential for transferring heat from the coolant to the external environment, facilitating efficient thermal management.

- Pumps: Integral to the system, pumps circulate the coolant throughout the network. Advanced technologies, such as solenoid pumps capable of operating up to 16 Bar and rotary boost pumps with DC brushless motors, play a pivotal role in these systems. These pumps provide precision control through PWM technology and are designed for low noise operation, making them particularly suitable for high-density computing applications.

A thorough understanding of these components is crucial for recognizing their collaborative function in maintaining optimal temperatures within server liquid cooling systems. By implementing server liquid cooling for temperature regulation, organizations can achieve lower temperatures and enhanced efficiency, positioning themselves favorably in the realm of high-density computing.

Explore Liquid Cooling Methods and Technologies

Liquid cooling methods are becoming increasingly vital in modern data centers, with several technologies currently in use:

- Direct-to-Chip Cooling: This method places cold plates directly on CPUs and GPUs, facilitating efficient heat transfer. It is especially beneficial as it focuses on specific elements, resulting in quicker thermal dissipation and lower energy usage. Direct-to-chip temperature regulation can dissipate more heat with less energy compared to conventional air systems, significantly reducing Power Usage Effectiveness (PUE), often achieving ratings below 1.2. The optimal rating for PUE is 1.0, while the mean is approximately 1.8, emphasizing the efficiency of this temperature regulation method. As technology analyst Christopher Tozzi notes, ‘server liquid cooling has entered prime time and is a major element of the rapidly expanding data center fluid temperature regulation market.’

- Server Liquid Cooling: This method involves immersing servers in a thermally conductive liquid, which provides outstanding thermal dissipation. Server liquid cooling is gaining traction for immersion temperature regulation due to its ability to handle the rising heat densities of modern IT infrastructure, particularly in AI and high-performance computing environments. This method of server liquid cooling can lead to longer-lasting equipment and potential power savings, with some implementations achieving . Furthermore, implementing immersion technology can lead to a 15% reduction in power consumption, enabling more IT equipment.

- Rear-Door Heat Exchangers: These units are installed on the back of server racks, reducing the temperature of the air as it leaves the servers. While they are less invasive than other methods, they still contribute to improved energy efficiency and can be a practical solution for existing setups.

Current trends show that 6.5% of IT professionals would depend exclusively on immersion methods, while 7% would utilize a combination of direct-to-chip and immersion techniques. Each temperature regulation technique, like server liquid cooling, provides unique benefits, such as improved energy efficiency and lowered noise levels. However, it is essential to evaluate these technologies based on specific operational requirements and the unique demands of the data center environment. Challenges related to fluid refrigeration, such as maintenance difficulties and high implementation expenses, should also be taken into account. Furthermore, understanding the competitive landscape, including companies like Zutacore and Liquidstack, can provide valuable context for making informed decisions. Lastly, environmental concerns associated with specific temperature regulation technologies are becoming more pertinent for organizations dedicated to sustainability.

Implement Liquid Cooling Systems in Server Environments

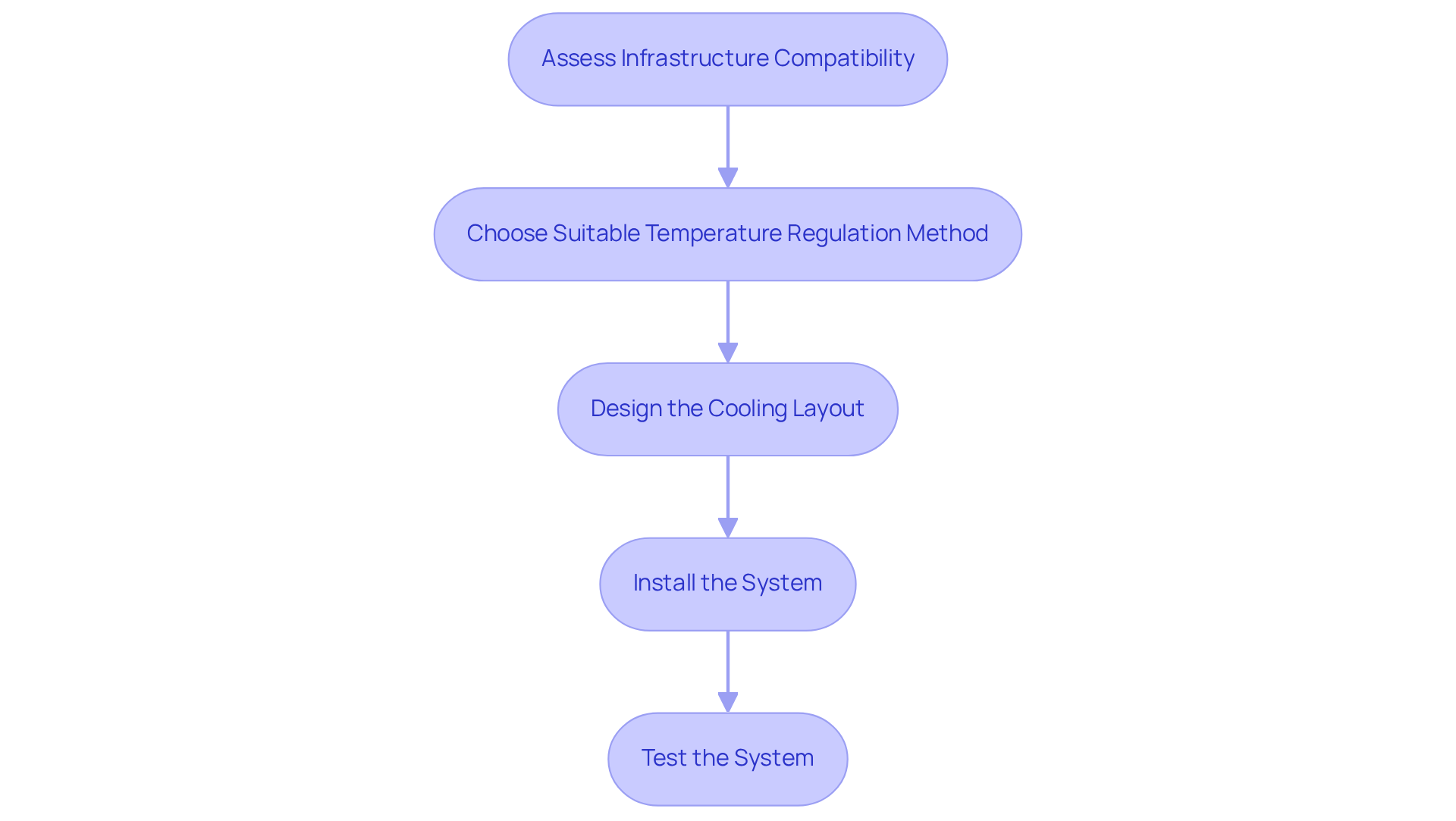

Introducing fluid temperature regulation mechanisms in server settings necessitates a methodical strategy to ensure effectiveness and compatibility. The essential steps are as follows:

- Assess Infrastructure Compatibility: Evaluate current server racks and components to confirm they can accommodate server liquid cooling setups. This evaluation is crucial, as approximately 30% of power usage in data centers is associated with climate control mechanisms, making compatibility a significant factor in energy efficiency.

- Choose the Suitable Temperature Regulation Method: Select a temperature regulation technique that aligns with your specific needs and the layout of your facility. Direct-to-chip temperature regulation is increasingly favored due to its effectiveness in addressing thermal sources, requiring less power than traditional methods.

- Design the Cooling Layout: Strategically plan the routing of pipes and the placement of exchangers to optimize coolant flow and system efficiency. Engaging design partners early in this phase can ensure that the cooling components align with operational needs, thereby avoiding costly retrofitting later on.

- Install the System: Execute the installation of pumps, heat exchangers, and piping with care, ensuring all connections are secure to prevent leaks. Routine inspections of critical components, such as Coolant Distribution Units (CDUs) and in-rack manifolds, are vital to maintain system integrity and performance.

- Test the System: Conduct comprehensive testing to verify that the system operates as intended before going live. This includes assessing , such as reductions in Power Usage Effectiveness (PUE), which are essential for confirming performance improvements.

By following these steps, organizations can effectively transition to server liquid cooling, significantly enhancing their data center’s performance and sustainability.

Maintain and Optimize Liquid Cooling Solutions

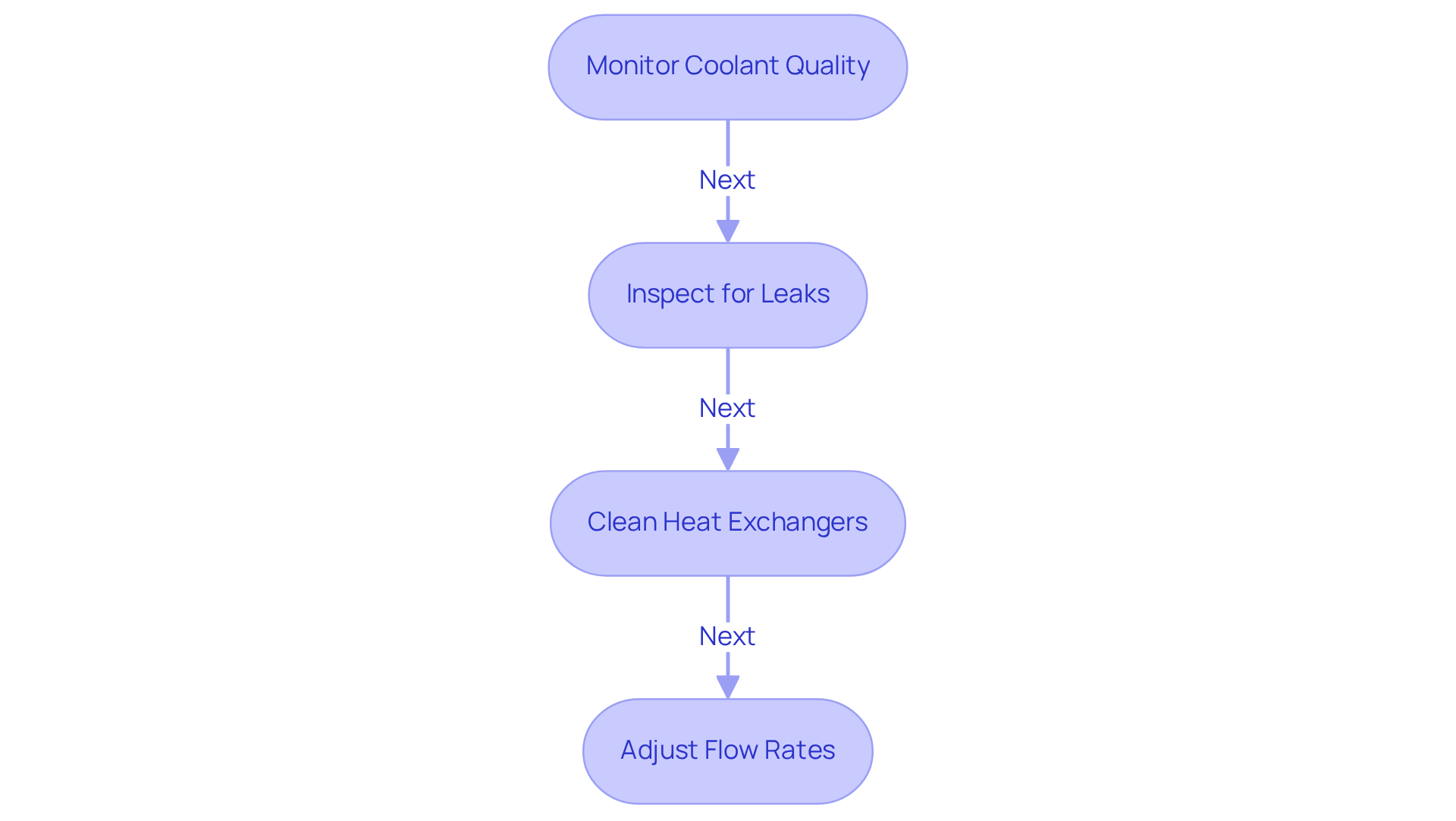

To effectively maintain and optimize liquid cooling solutions, it is essential to consider the following best practices:

- Regularly Monitor Coolant Quality: Implement routine checks for contamination and ensure timely replacement of coolant to facilitate efficient heat transfer. Monitoring coolant quality is crucial, as it directly impacts performance and longevity. Routine upkeep is vital to prevent algae accumulation or rust in fluid refrigeration setups.

- Inspect for Leaks: Conduct frequent inspections of all connections and components to identify any signs of leaks. Statistics indicate that leaks are a common issue in liquid cooling setups, with early detection being critical to avoid failures and costly damages.

- Clean Heat Exchangers: Ensure heat exchangers remain free from debris and buildup to sustain optimal heat transfer efficiency. Regular cleaning is instrumental in maintaining overall performance and preventing overheating.

- Adjust Flow Rates: Fine-tune pump speeds and flow rates based on performance data to enhance temperature management. Effective flow rate management can significantly improve the efficiency of the refrigeration setup.

As Sarah Jones from Dell Technologies notes, “Liquid refrigeration arises as a persuasive solution to the issue of contemporary datacenter infrastructure temperature management.” By implementing these maintenance practices, data centers can ensure their liquid cooling systems operate at peak efficiency, ultimately leading to enhanced performance and reduced operational costs.

Conclusion

Implementing master server liquid cooling systems represents a transformative approach to managing heat in high-density computing environments. This technology not only enhances cooling efficiency but also positions organizations to excel in the competitive landscape of modern data centers. By leveraging the superior thermal conductivity of liquids, businesses can achieve optimal temperature regulation, resulting in improved performance and energy savings.

The discussion highlights various liquid cooling methods—including direct-to-chip cooling, server immersion, and rear-door heat exchangers—each offering unique advantages tailored to specific operational needs. Key implementation steps include:

- Assessing infrastructure compatibility

- Designing an effective cooling layout

These steps are essential for ensuring a successful transition. Furthermore, maintaining and optimizing these systems through regular monitoring, leak inspections, and flow rate adjustments is vital for sustaining performance and minimizing operational costs.

In a world increasingly reliant on high-performance computing, the significance of effective liquid cooling cannot be overstated. Organizations are encouraged to explore these advanced cooling solutions and consider their long-term benefits, which include reduced energy consumption and enhanced equipment longevity. Embracing liquid cooling technologies not only addresses current challenges but also paves the way for sustainable growth in the data center sector.

Frequently Asked Questions

What is the principle behind liquid cooling systems?

Liquid cooling systems operate on the principle of thermal transfer through liquids, which have superior thermal conductivity compared to air, making them more effective for temperature regulation in high-density computing environments.

What are the key components of liquid cooling systems?

The key components include coolants (typically water or specialized fluids), heat exchangers (for transferring heat to the external environment), and pumps (which circulate the coolant throughout the system).

What role do coolants play in liquid cooling systems?

Coolants absorb heat effectively, ensuring optimal performance by maintaining lower temperatures within the system.

How do heat exchangers function in liquid cooling systems?

Heat exchangers transfer heat from the coolant to the external environment, facilitating efficient thermal management.

What types of pumps are used in liquid cooling systems?

Advanced technologies such as solenoid pumps, which can operate up to 16 Bar, and rotary boost pumps with DC brushless motors are used. These pumps provide precision control through PWM technology and are designed for low noise operation.

Why is understanding the components of liquid cooling systems important?

A thorough understanding of the components is crucial for recognizing how they work together to maintain optimal temperatures within server liquid cooling systems.

What benefits do organizations gain from implementing server liquid cooling?

By implementing server liquid cooling, organizations can achieve lower temperatures and enhanced efficiency, which positions them favorably in the realm of high-density computing.