Overview

This article delves into the principles and mechanics of thermoelectric cooling systems, elucidating how these systems harness the Peltier effect for effective temperature regulation without the need for moving parts or harmful refrigerants. It meticulously details the operational mechanics and key components, while also examining the advantages of such systems, including their compact size and environmental friendliness.

However, it does not shy away from discussing the drawbacks, such as lower efficiency and higher costs. This comprehensive analysis underscores the critical balance that engineers must navigate in their applications, ensuring informed decision-making in the deployment of thermoelectric cooling technologies.

Introduction

The realm of temperature control is undergoing a significant transformation, propelled by the demand for more efficient and sustainable solutions. Thermoelectric cooling systems, which utilize the Peltier effect, present a compelling alternative to conventional refrigeration methods by offering precise temperature regulation without relying on moving parts or harmful refrigerants.

As industries increasingly embrace this technology, critical questions emerge: what are the genuine advantages and limitations of thermoelectric cooling?

This article explores the principles, mechanics, and practical applications of these innovative systems, uncovering the complexities that engineers must navigate to fully leverage their potential.

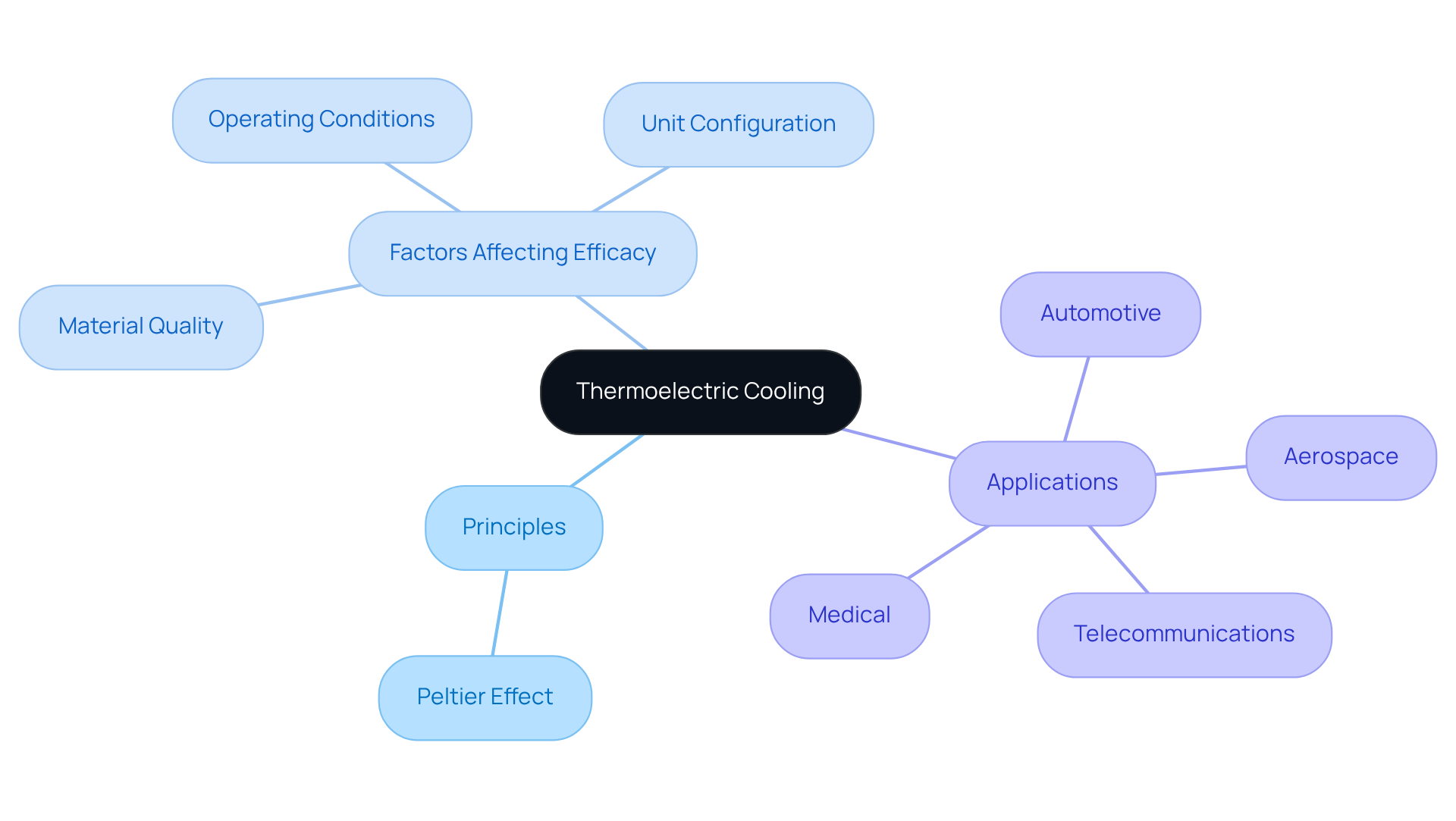

Define Thermoelectric Cooling and Its Principles

Thermal refrigeration represents a sophisticated solid-state technology that employs the to facilitate temperature transfer within these modules. Upon the application of (DC), electrons navigate through the semiconductor material, absorbing heat on the cold side—commonly known as the ‘freezer side’—and dissipating it on the hot side. This mechanism enables precise , independent of moving components or refrigerants, thereby positioning the thermoelectric cooling system as a sustainable alternative to traditional .

The efficacy of hinges on several factors, including:

- Material quality

- The configuration of the thermal-electric unit

- Specific operating conditions

Recent studies indicate that advancements in materials science, particularly the development of , are expected to yield significant improvements in efficiency.

The practical applications of the Peltier effect are extensive, encompassing sectors such as:

- Automotive

- Aerospace

- Telecommunications

- Medical fields

For instance, TECs are increasingly utilized for , medical devices, and food storage solutions, underscoring their versatility and effectiveness. Industry leaders emphasize the importance of to enhance performance and broaden application ranges, thereby reinforcing the relevance of the Peltier effect in modern refrigeration technologies.

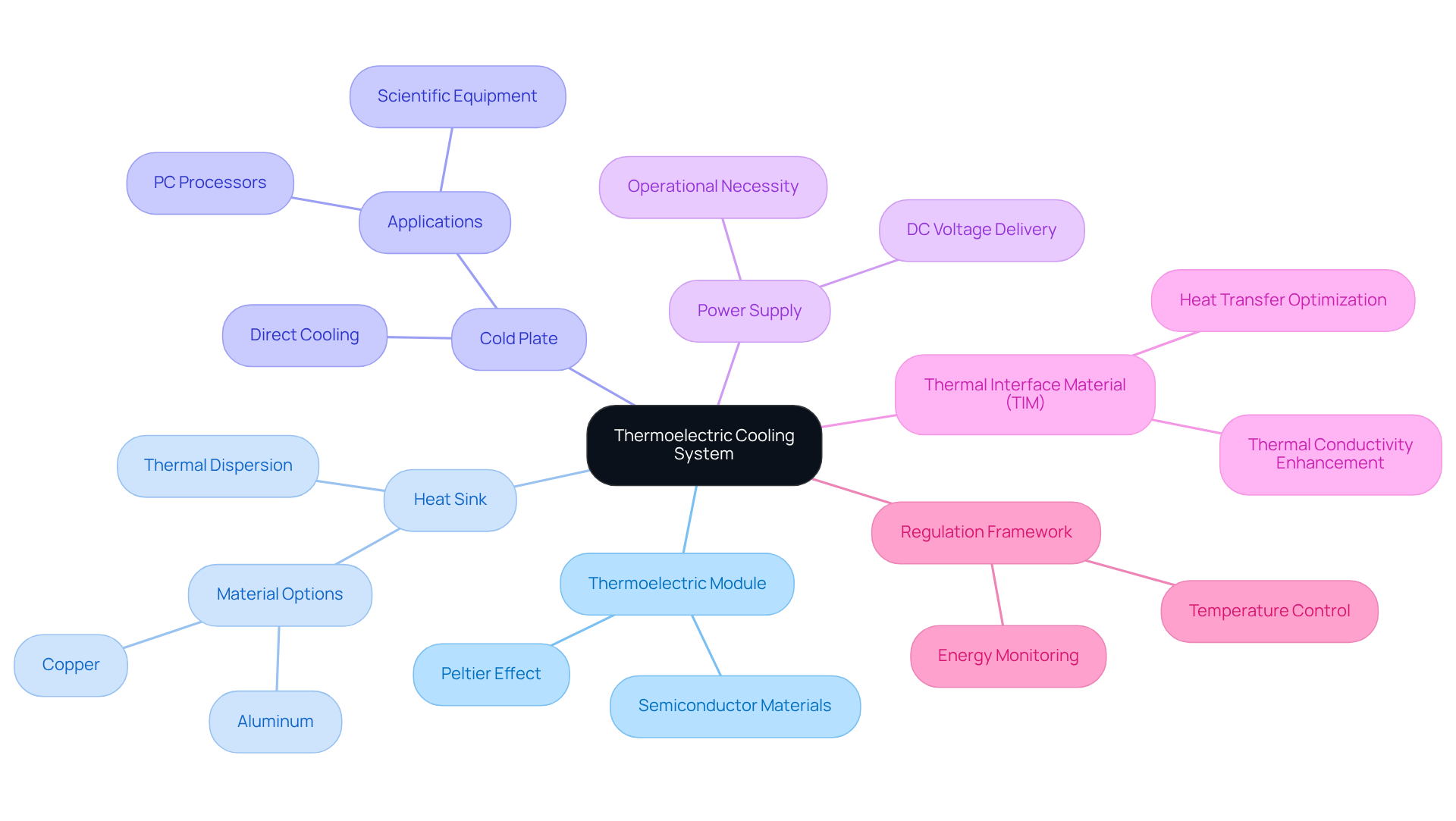

Identify Key Components of Thermoelectric Cooling Systems

A comprises several essential components that collaboratively achieve efficient cooling:

- : The core of the system, this module leverages the Peltier effect to generate a temperature differential. It consists of p-type and n-type semiconductor materials that facilitate thermal transfer.

- Heat Sink: Attached to the warm side of the energy conversion module, the heat sink disperses warmth absorbed from the cool side into the surroundings, ensuring effective thermal control. offers a diverse range of , including extruded aluminum and copper-based options.

- : This component directly cools the intended object or area, transferring the chill produced by the module to the desired location. Recent applications include temperature regulation for PC processors and scientific equipment.

- : Crucial for operation, the power supply delivers the necessary DC voltage to the temperature control module, enabling its cooling function.

- : This substance enhances thermal conductivity between the module and the heat sink or cold plate, optimizing heat transfer efficiency.

- : This framework monitors and adjusts the energy supplied to the thermal module, maintaining the intended temperature and ensuring peak performance.

Together, these elements enhance the efficiency and reliability of like the thermoelectric cooling system, making them suitable for various applications across different sectors. Gagner-Toomey Associates distinguishes itself as a leading provider of innovative cooling solutions, offering both custom and standard designs tailored to the needs of electronics and automotive applications. For instance, bulk energy conversion modules are projected to capture the largest share of the market due to their versatility and ease of integration into diverse systems.

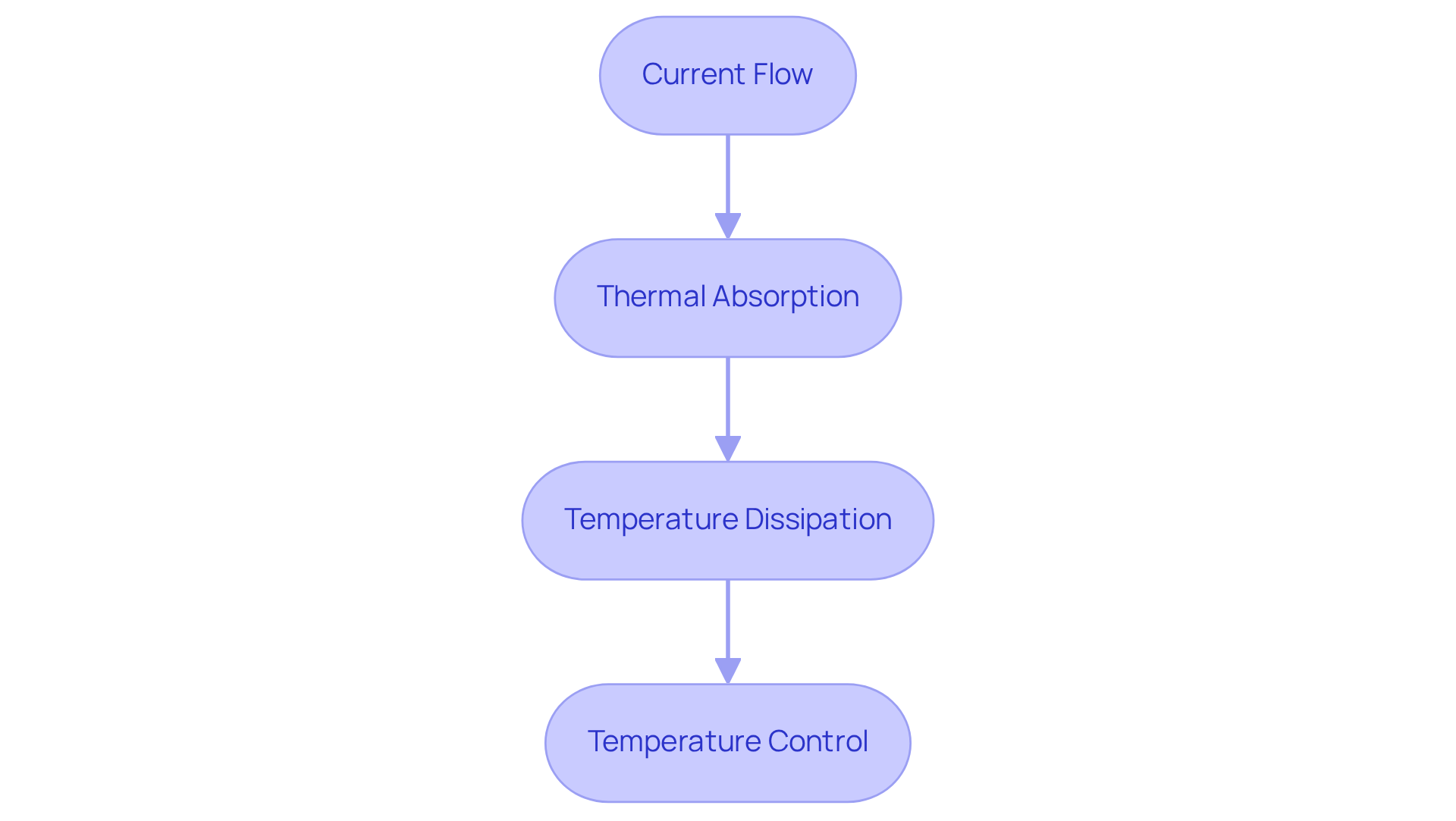

Explain the Operational Mechanics of Thermoelectric Coolers

The operational mechanics of a are fundamentally based on the , which elucidates how energy is absorbed or released when an electric current traverses two distinct types of semiconductor materials. This process can be understood through the following steps:

- Current Flow: Upon the application of DC power, electrons migrate from the n-type semiconductor to the p-type semiconductor. This movement of charge carriers instigates the .

- Thermal Absorption: At the junction where the n-type and p-type materials converge, energy is absorbed from the cold side, resulting in a .

- Temperature Dissipation: The warmth that has been absorbed is subsequently transferred to the hot side of the module, where it is released into the thermal sink. The efficiency of this process is contingent upon the and the design of the thermoelectric cooling system utilized.

- : By modulating the voltage supplied to the thermoelectric cooling system, users can precisely regulate the temperature of the cold side, facilitating effective across various applications.

Evaluate Advantages and Disadvantages of Thermoelectric Cooling

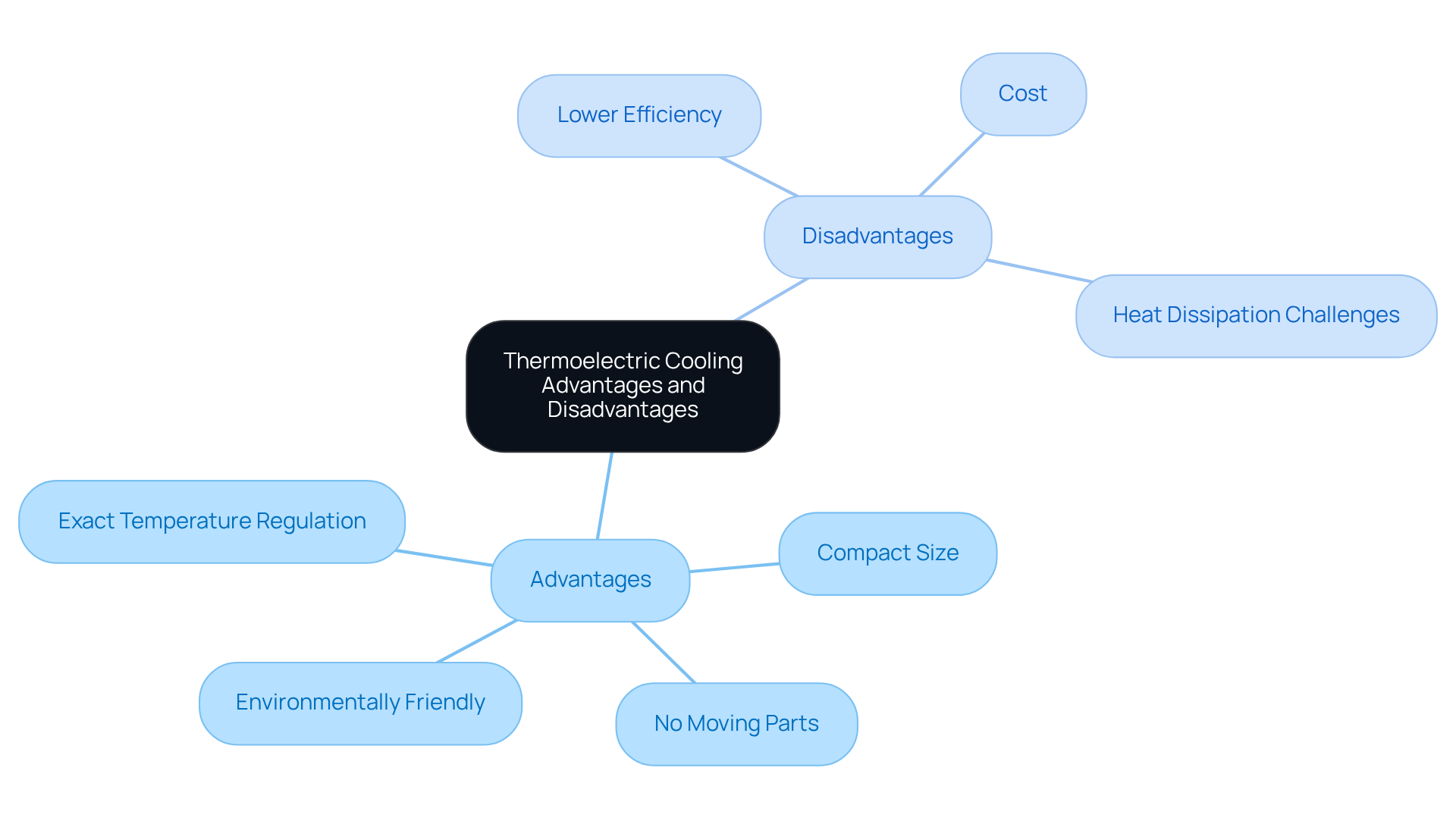

A distinctive combination of advantages and disadvantages is embodied in s, which engineers must carefully evaluate for their applications.

Advantages:

- : Thermoelectric coolers (TECs) are significantly than conventional units, making them particularly well-suited for applications with limited space.

- No Moving Parts: The absence of moving components results in lower maintenance requirements and enhances reliability over time, which is critical for long-term operations.

- : The thermoelectric cooling system (TECs) operates without harmful refrigerants, establishing it as a more sustainable cooling solution in an era increasingly focused on environmental impact.

- : The thermoelectric cooling system excels at achieving precise temperature adjustments, which is particularly beneficial in sensitive applications such as medical devices and electronics. For example, Bhargav Sai’s research indicates that the cooler temperature of the setup can reach approximately 15°C for a 10L flow rate over 60 minutes, illustrating their practical application.

Disadvantages:

- Lower Efficiency: A primary challenge is the generally (COP) of cooling devices compared to traditional methods. The practical COP can vary significantly, with certain setups achieving a maximum of only 0.71. Notably, the average COP value of the air-to-water mode is about 30-50% higher than that of the air-to-air mode, providing a clearer context for efficiency comparisons.

- Cost: The can be substantial, often exceeding that of traditional systems. It is crucial to recognize that the thermoelectric cooling system typically incurs than conventional heating and cooling solutions, which can be a significant barrier to adoption, especially for high-performance applications.

- : In larger applications, effectively dissipating heat can present a challenge, necessitating careful design considerations to ensure optimal performance. Insights from industry studies underscore the need for thoughtful engineering to address these challenges effectively.

Industry leaders have noted that while these energy conversion devices hold promise, their higher costs and efficiency challenges relative to conventional systems warrant careful consideration. For instance, the was valued at $569 million in 2020 and is projected to reach $1.32 billion by 2030, reflecting a growing interest despite these challenges. As the market evolves, addressing these disadvantages will be essential to unlocking the full potential of the thermoelectric cooling system technologies.

Conclusion

Thermoelectric cooling systems represent a groundbreaking approach to temperature management, leveraging the Peltier effect to facilitate efficient heat transfer without traditional refrigerants or moving parts. This innovative technology not only enhances temperature control precision but also aligns with sustainable practices, establishing itself as a compelling alternative across automotive, medical, and electronic sectors.

Key components include:

- Thermoelectric module

- Heat sink

- Cold plate

- Power supply

These components work in unison to create effective cooling solutions. The operational mechanics hinge on the movement of electrons between different semiconductor materials, enabling precise temperature regulation. Despite their advantages—such as compact size, low maintenance, and environmentally friendly operation—thermoelectric cooling systems encounter challenges related to efficiency and cost.

As the demand for sustainable and efficient cooling solutions escalates, embracing the potential of thermoelectric technology becomes increasingly vital. Continued innovation in materials and design can address current limitations, paving the way for broader adoption and enhanced performance across diverse applications. Engaging with this technology not only promises improved cooling solutions but also contributes to a more sustainable future.

Frequently Asked Questions

What is thermoelectric cooling?

Thermoelectric cooling is a solid-state technology that uses the Peltier effect to transfer temperature within modules, allowing for precise temperature management without moving components or refrigerants.

How does the Peltier effect work in thermoelectric cooling?

The Peltier effect operates when direct current (DC) is applied, causing electrons to move through semiconductor material. This movement absorbs heat on the cold side (freezer side) and dissipates it on the hot side.

What factors influence the efficiency of thermoelectric refrigeration?

The efficiency of thermoelectric refrigeration is influenced by material quality, the configuration of the thermal-electric unit, and specific operating conditions.

What advancements are expected to improve thermoelectric cooling efficiency?

Recent studies suggest that advancements in materials science, particularly the development of thin film cooling devices, are expected to significantly enhance the efficiency of thermoelectric cooling.

In which sectors are thermoelectric cooling systems commonly used?

Thermoelectric cooling systems are commonly used in various sectors, including automotive, aerospace, telecommunications, and medical fields.

What are some practical applications of thermoelectric coolers (TECs)?

TECs are used for temperature regulation in electronic components, medical devices, and food storage solutions, highlighting their versatility and effectiveness.

Why is ongoing innovation important in thermoelectric cooling technologies?

Ongoing innovation in temperature-responsive materials is crucial for enhancing performance and expanding application ranges, thereby reinforcing the relevance of the Peltier effect in modern refrigeration technologies.