Overview

This article delves into the distinctions and interconnections between static pressure and CFM (Cubic Feet per Minute) within HVAC systems, underscoring their critical roles in system efficiency and indoor air quality. It articulates that static pressure serves as an indicator of airflow resistance, whereas CFM quantifies the volume of air flow. Furthermore, it emphasizes that achieving an optimal balance between these two metrics is vital for sustaining effective airflow, enhancing energy efficiency, and ensuring comfort in HVAC operations.

Introduction

Understanding the intricacies of HVAC systems is crucial, particularly when examining the critical relationship between static pressure and CFM (Cubic Feet per Minute).

- Static pressure measures airflow resistance within the system.

- CFM quantifies the volume of air circulating through it.

Mastering these concepts is essential for optimizing HVAC efficiency, enhancing indoor air quality, and ensuring comfort. However, the challenge lies in balancing these two factors:

- Excessive static pressure can stifle airflow, resulting in increased energy costs and discomfort.

HVAC professionals must navigate this delicate interplay to achieve peak performance.

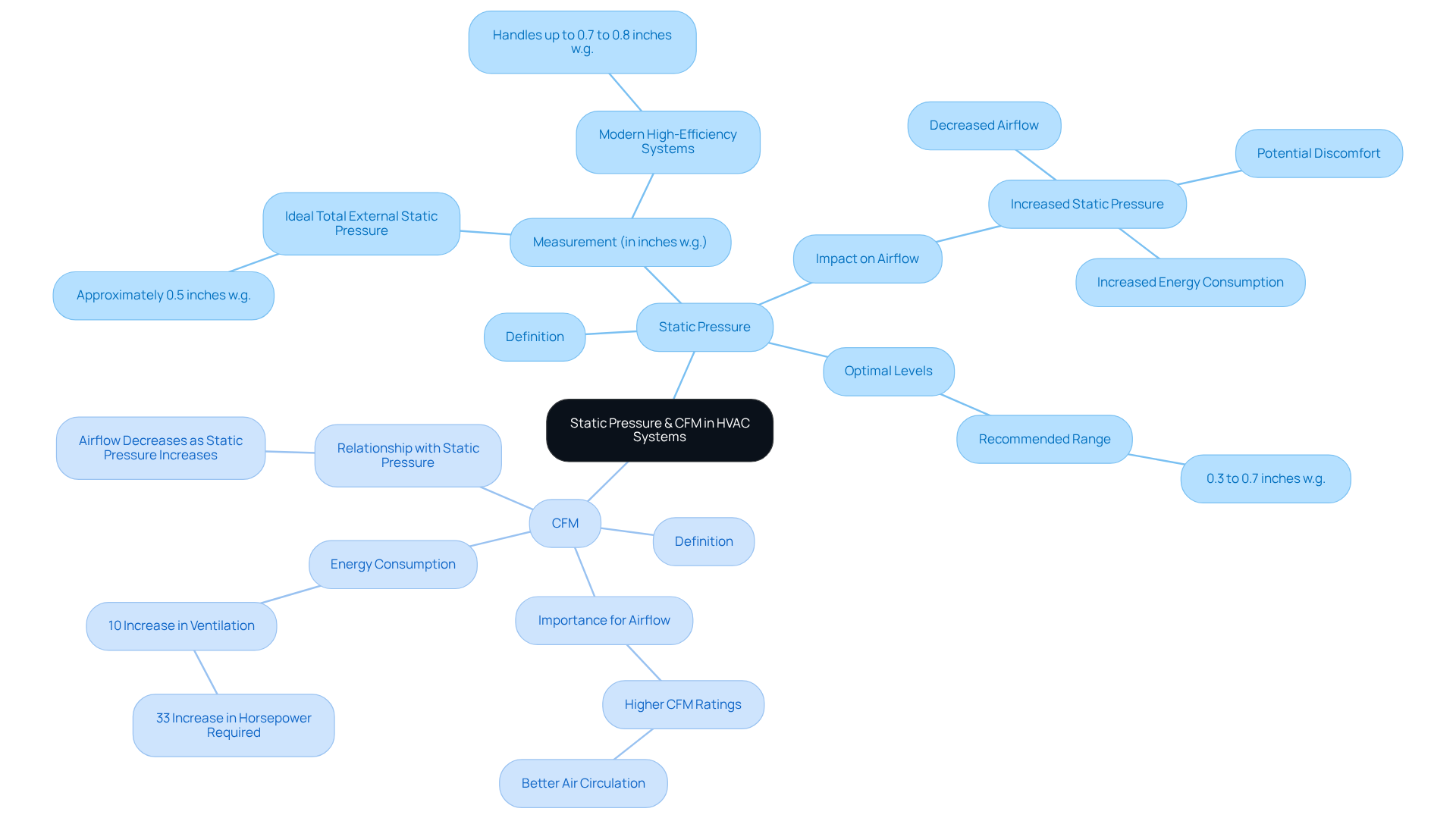

Define Static Pressure and CFM in HVAC Systems

In HVAC systems, understanding static pressure vs CFM is crucial as static pressure represents the resistance to airflow, measured in inches of water column (in WC). This measurement reveals the force exerted by air against duct walls and components when the air is stationary. Conversely, when discussing static pressure vs CFM, CFM, or Cubic Feet per Minute, quantifies the volume of air flowing through the system each minute. This metric, specifically static pressure vs CFM, is crucial for assessing HVAC efficiency, as it directly impacts indoor air quality and comfort levels.

For instance, modern high-efficiency systems can manage fixed forces up to 0.7 to 0.8 inches w.g. without notable performance loss. However, excessive fixed force may hinder air movement into specific rooms, leading to inconsistent temperatures and discomfort. In practical applications, maintaining an optimal fixed force is vital, as the balance of static pressure vs CFM is crucial; too much fixed force can lead to reduced air movement, increased energy consumption, and potential discomfort from uneven temperatures.

A 10% increase in ventilation correlates with a 33% increase in horsepower required, illustrating the relationship between air movement and energy usage. The ideal total external static pressure for many residential systems is approximately 0.5 inches w.g., striking a balance between effective airflow and quiet operation. It is essential to review the manufacturer’s fan performance data to ensure the fan is appropriately matched to the load, thereby enhancing efficiency. Understanding these principles is critical for aiming to improve performance and effectively address troubleshooting challenges.

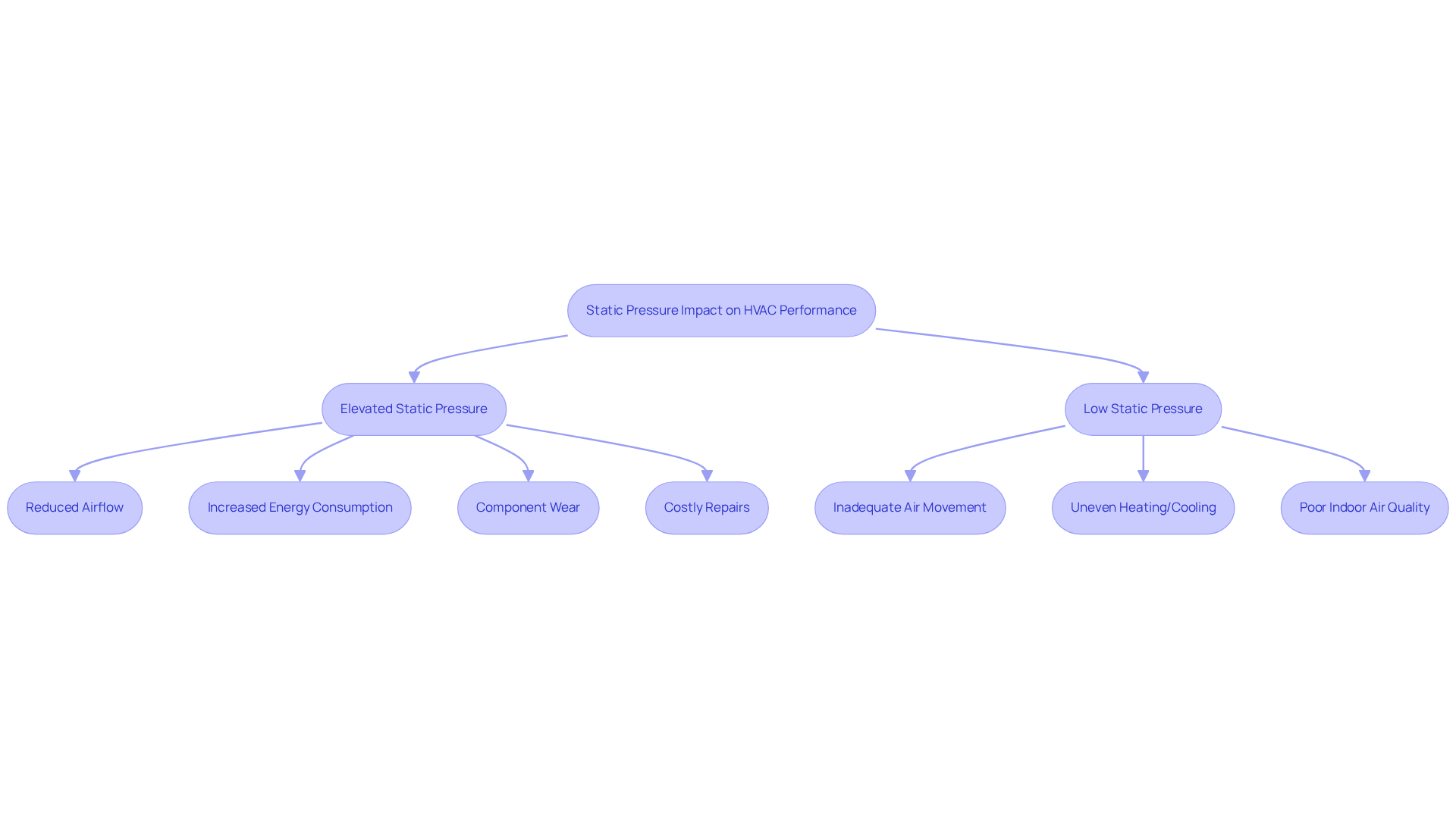

Analyze the Impact of Static Pressure on System Performance

Elevated atmospheric force significantly impacts HVAC performance, leading to reduced airflow, increased energy consumption, and potential system failures. As fixed resistance rises, the blower motor faces greater opposition, necessitating additional effort to push air through the ducts. This heightened workload accelerates wear on components, ultimately shortening the system’s lifespan. For instance, substantial increases in fixed force—from 50 to 350 Pa—can result in average energy cost hikes of approximately 9% with electronically commutated motors (ECM) and around 18% with permanent split capacitor (PSC) blowers. This underscores the critical need for effective management of fixed force.

Conversely, low ambient force presents its own set of challenges, such as inadequate air movement that can lead to uneven heating or cooling and compromised indoor air quality. Insufficient airflow may also elevate airborne pollutant levels, as reduced circulation through filters diminishes their ability to trap dust and allergens.

Consistent monitoring and adjustment of fixed force are vital for optimizing HVAC functionality. Keeping static pressure within the ideal range, specifically in the context of static pressure vs cfm, is generally around 0.5 in. For residential systems, the range of WC or lower, specifically between 0.25 – 0.3 in, is relevant when discussing static pressure vs cfm. The static pressure vs cfm for the supply ductwork is 0.2 – 0.25 in. WC for return ductwork—ensures , reduces energy usage, and enhances overall comfort, particularly when evaluating static pressure vs cfm.

Common causes of elevated air resistance include:

- Dirty or restrictive filters

- Inadequate ductwork

- Closed or obstructed vents

- Insufficient return air pathways

Ignoring fixed force issues can lead to costly repairs and increased operational expenses, making proactive management essential for any HVAC system.

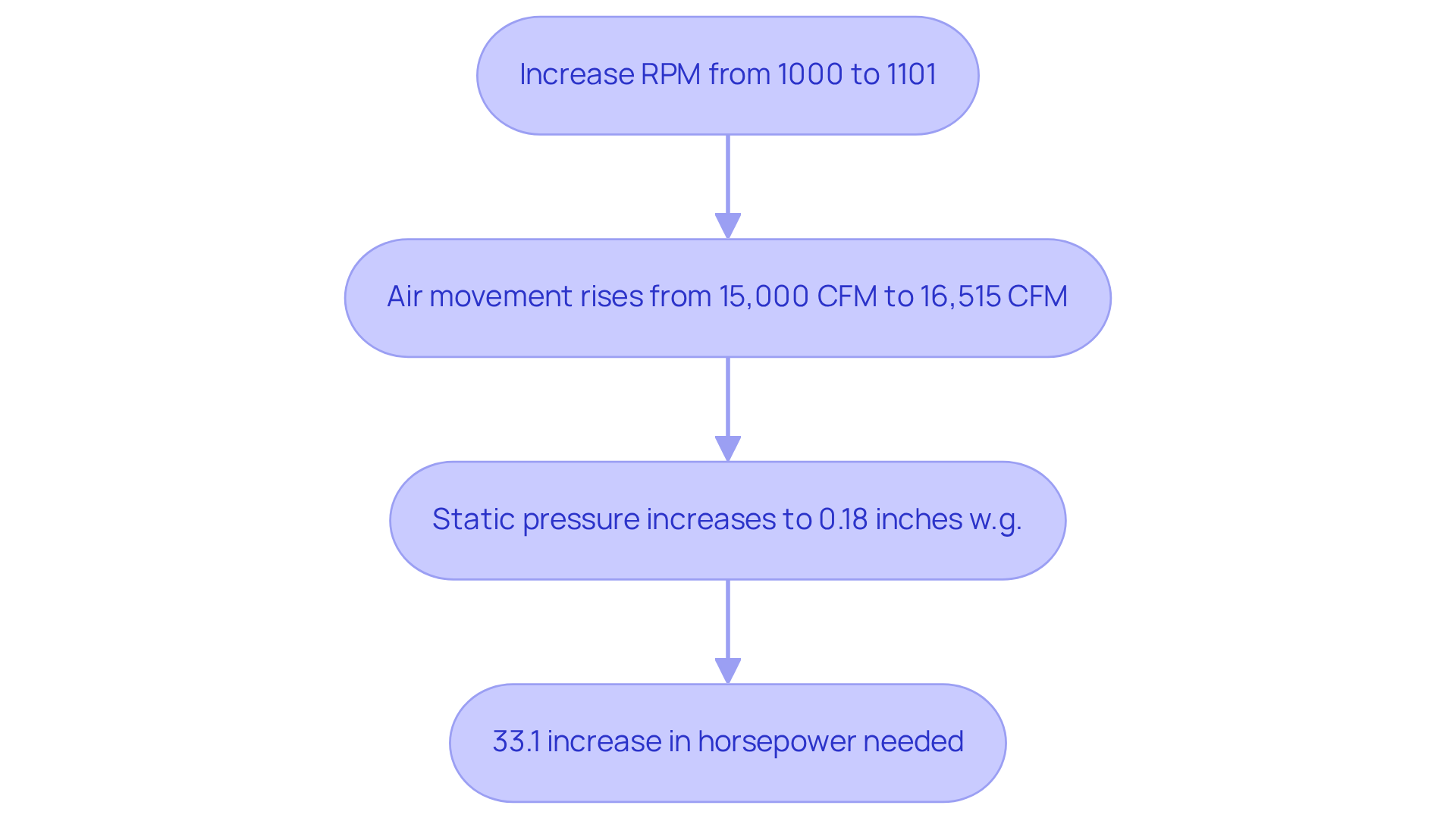

Examine the Relationship Between CFM and Static Pressure

The relationship of static pressure vs CFM shows that air movement rate (CFM) and ambient force are fundamentally inversely proportional; as CFM increases, ambient force generally declines, and vice versa. This dynamic is regulated by the three fundamental fan laws, which elucidate how changes in air movement influence force within the framework.

For instance, Fan Law 1 asserts that a 10% rise in propeller speed leads to a 10% rise in flow, while Fan Law 2 suggests that stationary force varies with the square of the flow change. Therefore, if a setup is designed to operate at a certain CFM, any rise in resistance can result in a decrease in effective air movement, potentially leading to inefficiencies.

In practical scenarios, such as a customer seeking to enhance the movement of air from their belt drive exhaust fans, applying these fan laws reveals that:

- Increasing the RPM from 1000 to 1101 could elevate air movement from 15,000 CFM to 16,515 CFM.

- This adjustment also raises static pressure to 0.18 inches w.g.

- Notably, this adjustment necessitates a 33.1% increase in horsepower, underscoring the energy implications of such changes.

Understanding the is crucial for HVAC experts when designing ductwork and selecting appropriate fan setups, as it directly impacts efficiency and performance. As Tim De Stasio, an HVAC and building performance consultant, emphasizes, ‘Ultimately, a service technician should be able to understand the 3 Fan Laws to be more accurate when making airflow adjustments.’

Furthermore, elevated air resistance may indicate oversized or leaking ducts, which can undermine performance and lead to increased energy expenses.

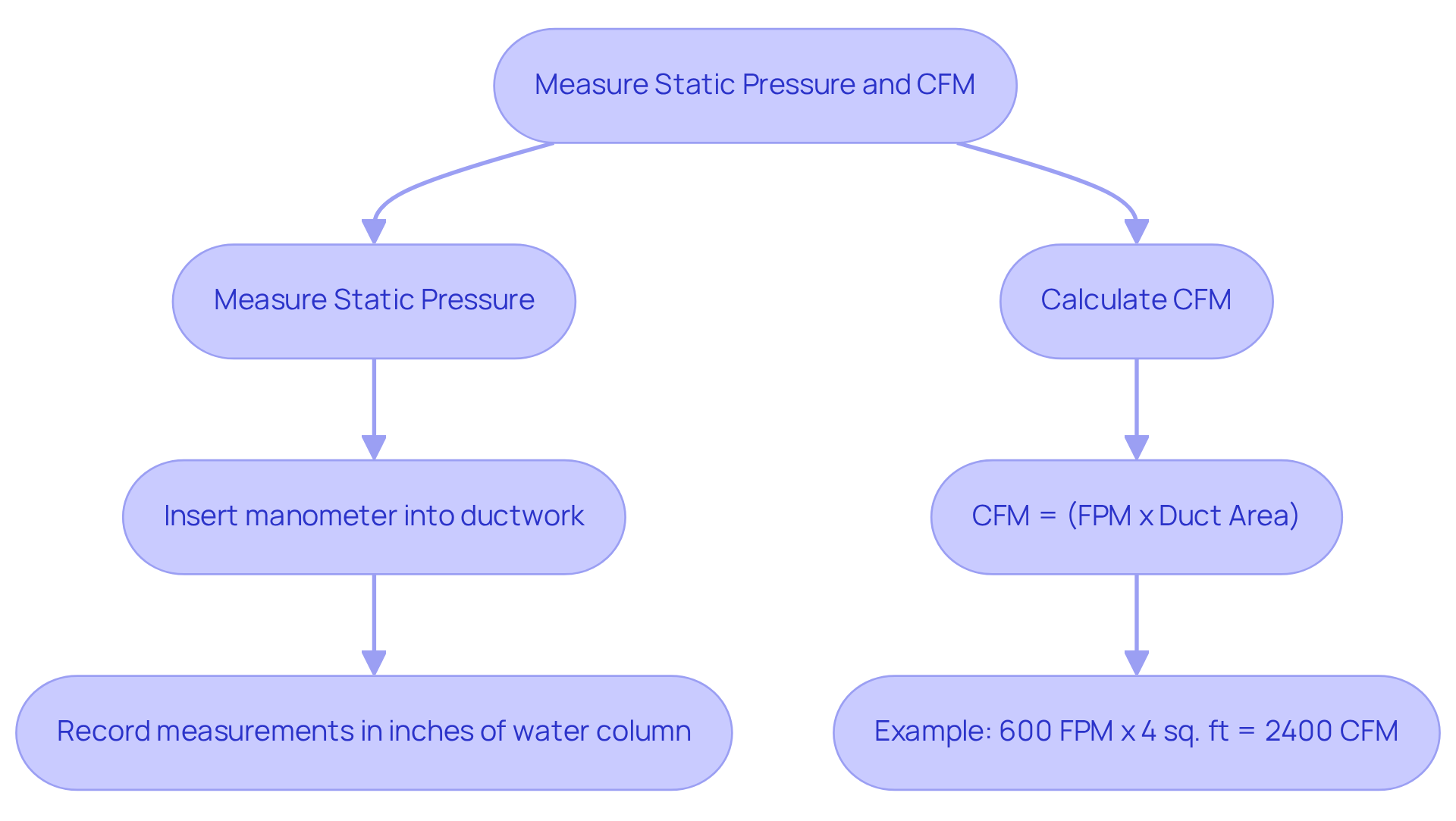

Measure and Calculate Static Pressure and CFM

To effectively gauge in HVAC systems, utilize a manometer by inserting the pressure tip into the ductwork at critical locations, such as before and after filters. Record the measurements in inches of water column to assess performance accurately.

For calculating Cubic Feet per Minute (CFM), apply the formula:

- CFM = (FPM x Duct Area),

where FPM represents the flow speed in feet per minute, and Duct Area is the cross-sectional area of the duct in square feet.

For instance, an airspeed of 600 feet per minute combined with a duct area of 4 square feet results in 2,400 CFM. This calculation is essential, as it directly impacts the effectiveness of heating, cooling, and ventilation systems. Precise measurements are critical for identifying airflow issues and ensuring HVAC units function within their designed specifications.

Industry experts emphasize that accurate CFM calculations significantly enhance efficiency and indoor air quality. Rob, co-founder of the National Comfort Institute, asserts, “The performance of an HVAC unit can be effectively measured and diagnosed under live operating conditions in the field.”

Recommended practices include consistently monitoring fixed force and static pressure vs CFM to identify potential issues early, thereby ensuring optimal performance and energy savings. Regular maintenance, such as cleaning or replacing filters, optimizes airflow and enhances ventilation, which is vital for maintaining system efficiency.

Furthermore, low static pressure can result in air leaks that allow contaminants like dust and pet dander to infiltrate indoor air, adversely affecting air quality.

Conclusion

Understanding the relationship between static pressure and CFM in HVAC systems is crucial for optimizing performance and ensuring comfort in indoor environments. Static pressure acts as a vital indicator of airflow resistance, whereas CFM quantifies the volume of air flowing through the system. A balanced approach to managing these two factors can significantly enhance HVAC efficiency, leading to improved air quality and energy savings.

Key insights include:

- The impact of static pressure on airflow and energy consumption

- The necessity of regular monitoring and maintenance

- The inverse relationship between static pressure and CFM

Elevated static pressure can obstruct airflow, resulting in discomfort and increased operational costs, while low static pressure may compromise air quality and system performance. Grasping these dynamics empowers HVAC professionals to make informed decisions regarding system design and maintenance, ensuring optimal functionality.

In conclusion, recognizing the significance of static pressure and CFM is essential for all stakeholders in HVAC systems. By prioritizing the management of these parameters, one can enhance energy efficiency, improve indoor air quality, and extend the lifespan of HVAC equipment. Whether through regular maintenance or informed design choices, taking proactive steps in understanding and measuring static pressure and CFM will lead to a more comfortable and efficient living or working environment.

Frequently Asked Questions

What is static pressure in HVAC systems?

Static pressure in HVAC systems represents the resistance to airflow and is measured in inches of water column (in WC). It indicates the force exerted by air against duct walls and components when the air is stationary.

What does CFM stand for, and what does it measure?

CFM stands for Cubic Feet per Minute and measures the volume of air flowing through the HVAC system each minute.

Why is the relationship between static pressure and CFM important?

The relationship between static pressure and CFM is crucial for assessing HVAC efficiency, as it directly impacts indoor air quality and comfort levels.

What is the acceptable range of fixed forces for modern high-efficiency HVAC systems?

Modern high-efficiency HVAC systems can manage fixed forces up to 0.7 to 0.8 inches w.g. without significant performance loss.

What problems can excessive fixed force cause in an HVAC system?

Excessive fixed force can hinder air movement into specific rooms, leading to inconsistent temperatures and discomfort.

How does increased ventilation affect energy consumption in HVAC systems?

A 10% increase in ventilation correlates with a 33% increase in horsepower required, highlighting the relationship between air movement and energy usage.

What is the ideal total external static pressure for many residential HVAC systems?

The ideal total external static pressure for many residential systems is approximately 0.5 inches w.g., balancing effective airflow and quiet operation.

Why is it important to review the manufacturer’s fan performance data?

Reviewing the manufacturer’s fan performance data ensures that the fan is appropriately matched to the load, thereby enhancing efficiency in the HVAC system.

Who should understand these principles of static pressure and CFM?

Understanding these principles is critical for HVAC professionals aiming to improve system performance and effectively address troubleshooting challenges.