Overview

A PWM fan speed controller represents a pivotal advancement in technology, enabling precise control of fan speeds through Pulse Width Modulation. This innovation significantly enhances cooling efficiency in electronic systems. For engineers, understanding its critical role is paramount, as it not only optimizes thermal management but also reduces energy consumption by up to 30% and minimizes noise. These advantages make PWM fan speed controllers indispensable for high-performance applications across both consumer electronics and industrial environments.

Introduction

The rapid evolution of electronic devices has rendered efficient cooling solutions more critical than ever. Enter the PWM fan speed controller—a transformative technology that employs Pulse Width Modulation to optimize fan performance while significantly reducing energy consumption and noise. As engineers work diligently to enhance the reliability and lifespan of sensitive components, a pivotal question emerges: how can a comprehensive understanding and implementation of PWM technology revolutionize cooling strategies in high-performance systems? Delving into this innovative approach not only unveils its technical advantages but also underscores its essential role in advancing the efficiency of modern electronics.

Define PWM Fan Speed Controller

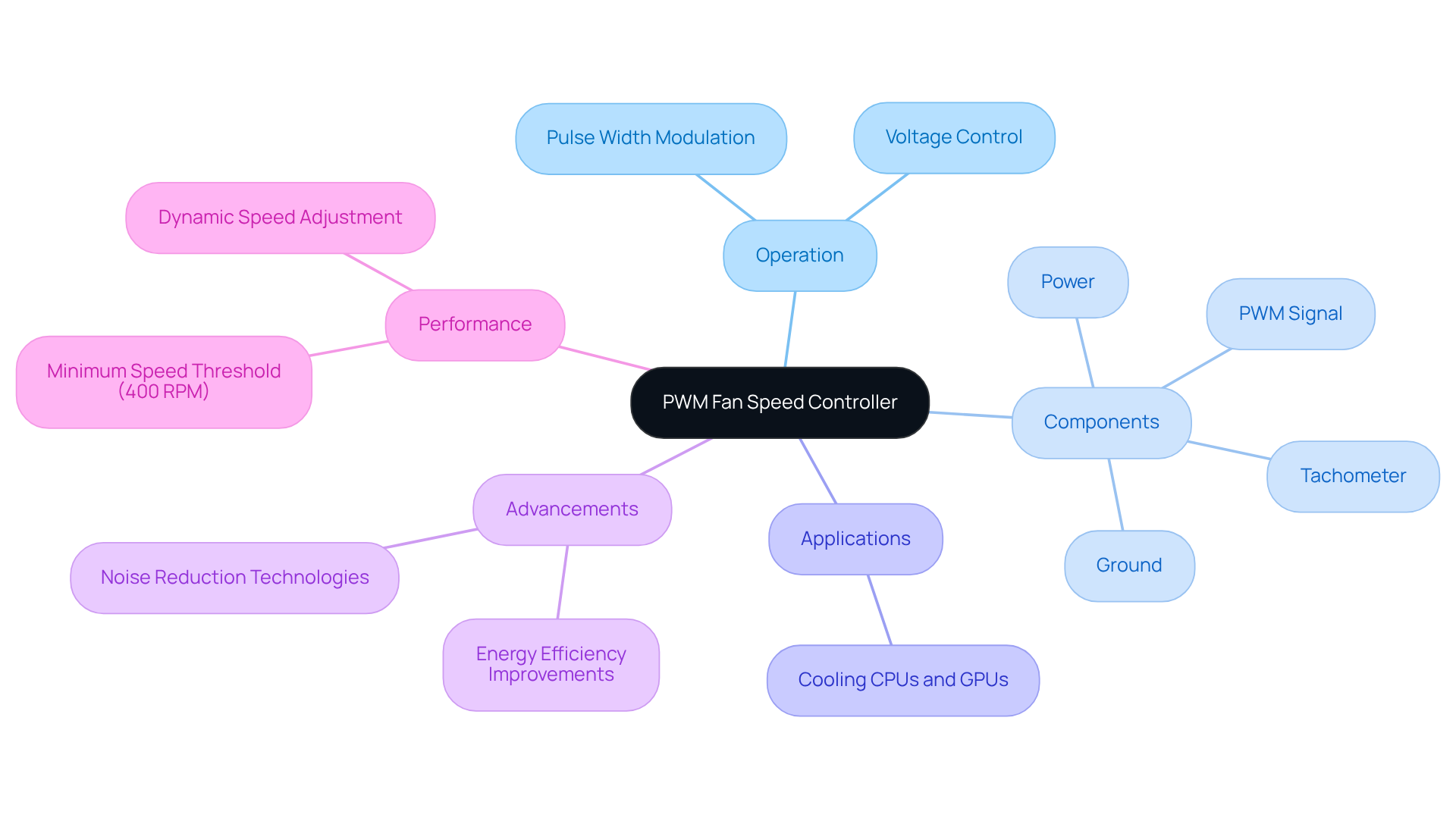

A pwm fan speed controller represents a sophisticated solution for adjusting fan rotation through Pulse Width Modulation (PWM) technology. PWM operates by rapidly switching the power supplied to the fan on and off at a specific frequency, thereby effectively controlling the average voltage and current received by the fan. This method allows for precise adjustments of velocity without the necessity for variable voltage, which makes the more efficient and effective than traditional fan velocity controllers. Typically, PWM units are equipped with four wires: power, ground, tachometer, and PWM signal, with the latter playing a crucial role in speed control.

PWM devices are particularly efficient for cooling CPUs and GPUs, which are critical components in high-performance computing systems and gaming PCs. Gagner-Toomey Associates, recognized as the world’s leading producer of standard and custom air-movers, offers an extensive selection of PWM units optimized for performance, efficiency, and low noise. The pwm fan speed controller is an essential element in modern electronic systems. Recent advancements in PWM fan regulation technology have focused on enhancing energy efficiency and minimizing noise levels, further underscoring the innovative cooling solutions provided by Gagner-Toomey Associates.

Moreover, PWM devices maintain a minimum rotation threshold of 400 RPM to prevent unacceptable noise levels, thus improving their performance in sensitive environments. This combination of features positions the PWM fan speed controller as an indispensable tool for achieving optimal cooling in advanced electronic applications.

Contextualize the Role in Electronics Cooling

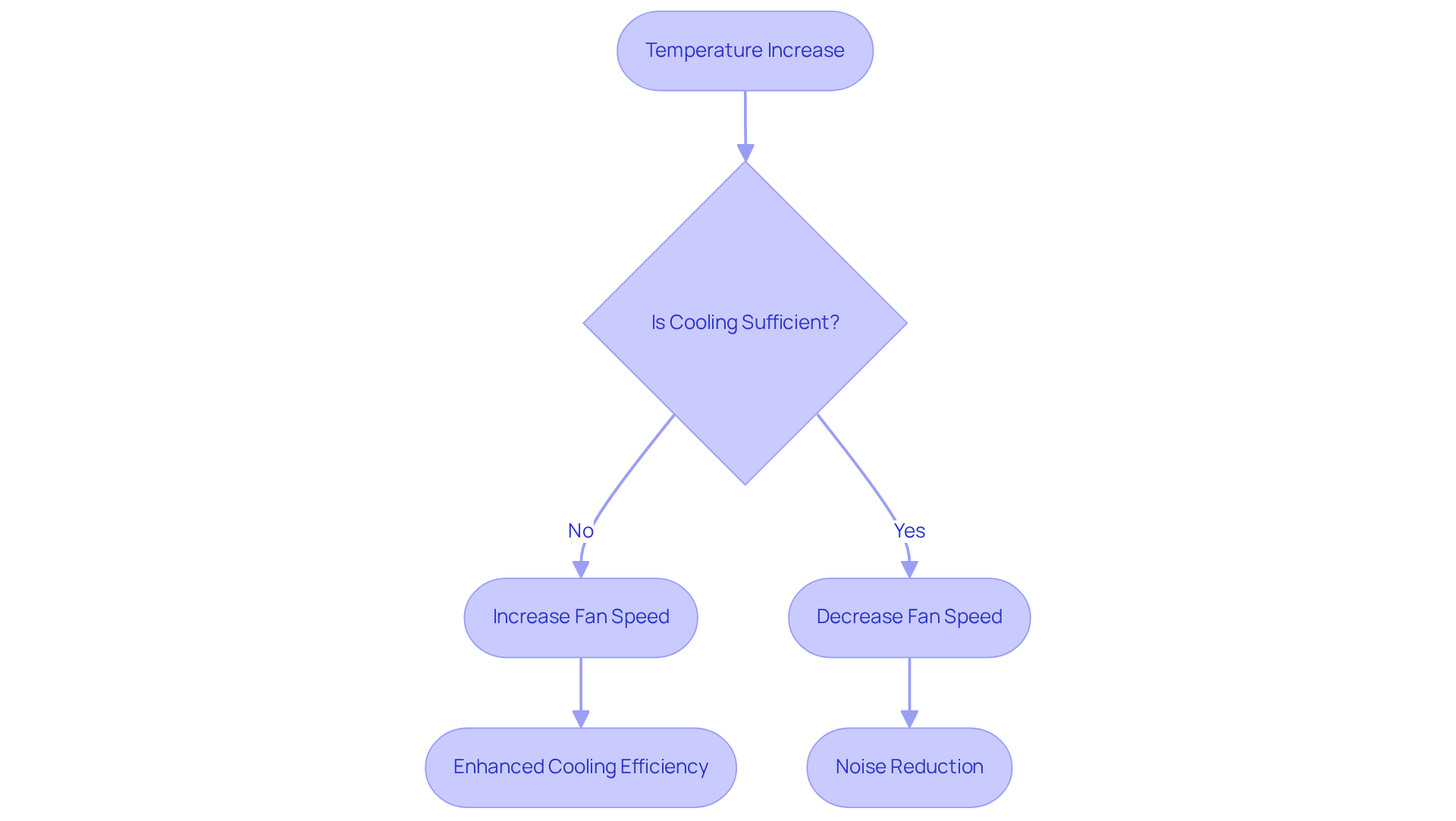

In the electronics industry, effective cooling is paramount for ensuring the longevity and reliability of components. The is crucial in this regard, enabling dynamic adjustments of fan speeds in response to real-time thermal conditions. In high-performance computing systems, where heat generation is significant, the PWM fan speed controller facilitates an increase in fan speed as temperatures rise and a decrease when cooling is sufficient. This functionality not only enhances cooling efficiency but also reduces noise levels, thereby creating a more comfortable user experience.

By optimizing airflow, a PWM fan speed controller substantially mitigates the risk of overheating, which is responsible for 55% of all electronics failures, thus averting system failures or diminished performance. For example, data centers utilizing a PWM fan speed controller have reported energy consumption reductions of approximately 20%, underscoring the effectiveness of these controllers in enhancing overall system performance.

Furthermore, the versatility of PWM units ensures quiet operation under low-load conditions while ramping up performance during periods of high demand, thus maintaining optimal thermal regulation and extending the lifespan of critical components.

Explore Technical Characteristics and Advantages

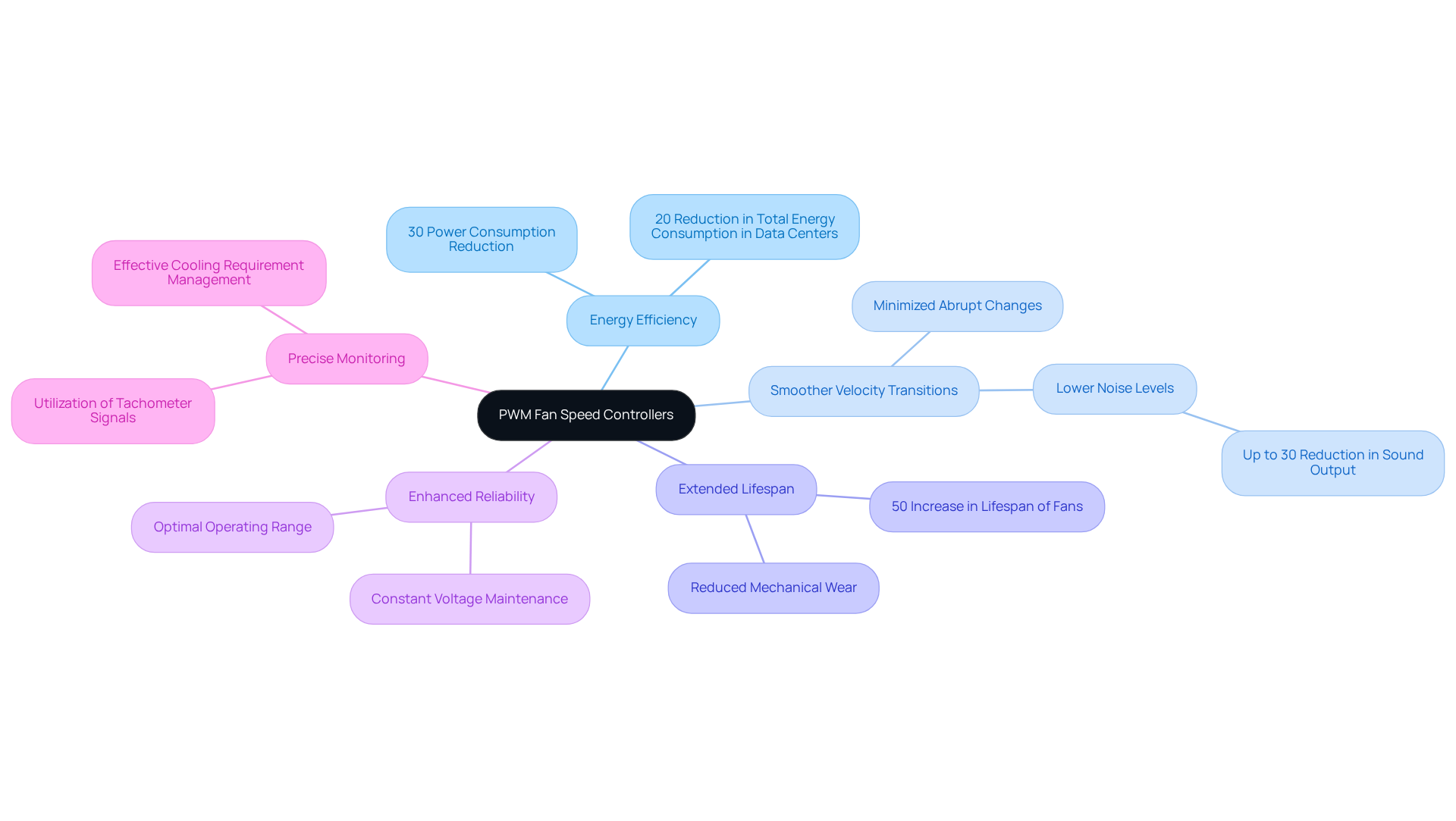

PWM fan speed controllers offer significant technical advantages over conventional DC fan controllers, particularly in terms of energy efficiency. Operating at reduced rates without compromising performance, a PWM fan speed controller allows PWM fans to lower power consumption by up to 30%, positioning them as an exceptional choice for energy-efficient designs. This technology facilitates smoother velocity transitions, thereby minimizing abrupt changes that can lead to noise and mechanical wear; as a result, the lifespan of the fan can be . By employing a PWM fan speed controller to maintain a constant voltage while varying the duty cycle of the PWM signal, these fans operate within their optimal range, significantly enhancing overall reliability. Additionally, the PWM fan speed controller utilizes tachometer signals for precise monitoring of fan performance, ensuring that cooling requirements are met effectively. Real-world implementations in data centers have illustrated that the adoption of PWM technology can achieve a 20% reduction in total energy consumption, underscoring its effectiveness in optimizing thermal management solutions.

Examine Variations and Applications

PWM fan speed controllers play an essential role across a variety of applications, ranging from personal computers to industrial equipment. In consumer electronics, PWM fan speed controllers play a critical role in cooling systems for CPUs and GPUs, where precise temperature management is vital for optimal performance. The integration of a PWM fan speed controller in these systems facilitates dynamic adjustments that enhance cooling efficiency while minimizing noise, making them particularly suited for noise-sensitive environments. Notably, the PWM fan speed controller enables PWM fans to operate at reduced rates during low-load situations, resulting in quieter operation and less wear compared to fans with fixed rates.

In industrial settings, the PWM fan speed controller is integral to ventilation systems, ensuring effective air quality management and temperature regulation. Their capacity to adapt to varying thermal demands makes the PWM fan speed controller indispensable for . Real-world applications include large-scale manufacturing facilities, where they optimize airflow and reduce energy consumption. Research indicates that a 25% decrease in fan speed, achieved through a PWM fan speed controller, can yield a 60% reduction in power consumption, underscoring the energy efficiency advantages of PWM technology.

Furthermore, the automotive sector is increasingly leveraging the PWM fan speed controller technology to manage cabin temperatures and engine cooling systems. This trend reflects a broader growth in the adoption of PWM fan speed controllers across industrial applications, driven by the demand for energy-efficient solutions that prioritize noise reduction. As industry experts note, the PWM fan speed controller makes PWM fans the more advanced type that is efficient as well, reinforcing their versatility as a preferred choice in scenarios where effective cooling and operational efficiency are paramount.

Conclusion

The significance of PWM fan speed controllers in modern electronics is paramount. These devices leverage Pulse Width Modulation to provide precise control over fan speeds, thereby enhancing efficiency and performance across a multitude of applications. By dynamically adjusting fan speeds in response to varying thermal conditions, PWM controllers not only optimize cooling but also contribute to energy savings and noise reduction. This makes them an indispensable component in high-performance computing systems, industrial equipment, and beyond.

Key insights throughout this discussion reveal that PWM fan speed controllers surpass traditional fan controllers in several crucial aspects:

- Improving energy efficiency

- Extending fan lifespan

- Ensuring reliable cooling

Their capability to respond to real-time temperature fluctuations effectively mitigates the risks of overheating—a critical concern since overheating is responsible for a substantial percentage of electronic failures. Real-world examples illustrate significant energy savings, showcasing reductions in power consumption and noise levels, which underscore the advantages of adopting this innovative technology.

In summary, the integration of PWM fan speed controllers embodies a forward-thinking strategy for thermal management in electronics. As industries increasingly emphasize energy efficiency and operational effectiveness, the adoption of PWM technology is poised for continued growth. Engineers and designers are urged to regard PWM fan speed controllers as essential instruments for achieving optimal performance in their systems, ultimately leading to enhanced reliability and user satisfaction.

Frequently Asked Questions

What is a PWM fan speed controller?

A PWM fan speed controller is a device that adjusts fan rotation using Pulse Width Modulation (PWM) technology, which rapidly switches the power supplied to the fan on and off to control the average voltage and current, allowing for precise speed adjustments.

How does PWM technology work in fan speed control?

PWM technology works by switching the power to the fan on and off at a specific frequency, enabling control over the average voltage and current received by the fan without needing variable voltage, making it more efficient than traditional controllers.

What are the typical components of a PWM fan speed controller?

A typical PWM fan speed controller has four wires: power, ground, tachometer, and PWM signal, with the PWM signal being crucial for speed control.

What applications are PWM fan speed controllers commonly used for?

PWM fan speed controllers are commonly used for cooling CPUs and GPUs in high-performance computing systems and gaming PCs.

Who is a leading manufacturer of PWM fan speed controllers?

Gagner-Toomey Associates is recognized as the world’s leading producer of standard and custom air-movers, offering a wide selection of PWM units optimized for performance, efficiency, and low noise.

What advancements have been made in PWM fan regulation technology?

Recent advancements in PWM fan regulation technology have focused on enhancing energy efficiency and minimizing noise levels.

What is the minimum rotation threshold for PWM devices and why is it important?

PWM devices maintain a minimum rotation threshold of 400 RPM to prevent unacceptable noise levels, which improves their performance in sensitive environments.

Why is the PWM fan speed controller considered essential in modern electronic systems?

The PWM fan speed controller is considered essential due to its ability to provide optimal cooling in advanced electronic applications while maintaining efficiency and low noise.