Overview

The article defines Fan CFM (Cubic Feet per Minute) as a critical metric for measuring airflow, quantifying the volume of air a fan can move in one minute. This measurement is paramount in maintaining optimal operating temperatures in electronic devices. Proper airflow is essential for preventing overheating and ensuring the reliability of components. Consequently, engineers must understand CFM ratings when designing cooling systems, as this knowledge is vital for effective thermal management.

Introduction

Understanding airflow is crucial in a technology-driven world, where effective cooling can determine the difference between peak performance and catastrophic failure. Cubic Feet per Minute (CFM) serves as a vital metric in this context, quantifying the volume of air moved by fans and directly influencing the efficiency of cooling systems across various industries.

However, with the myriad of fan types and specifications available, engineers face the challenge of selecting the right fan to meet specific cooling needs. This article delves into the definition, importance, and key factors of fan CFM, revealing insights that can enhance thermal management strategies and optimize system performance.

Define Fan CFM: Understanding Cubic Feet per Minute

To understand , it is important to note that serves as a crucial metric for measuring airflow, quantifying the volume of air a fan can move within a minute. This measurement is , particularly in the electronics sector, where is vital for the longevity and reliability of components.

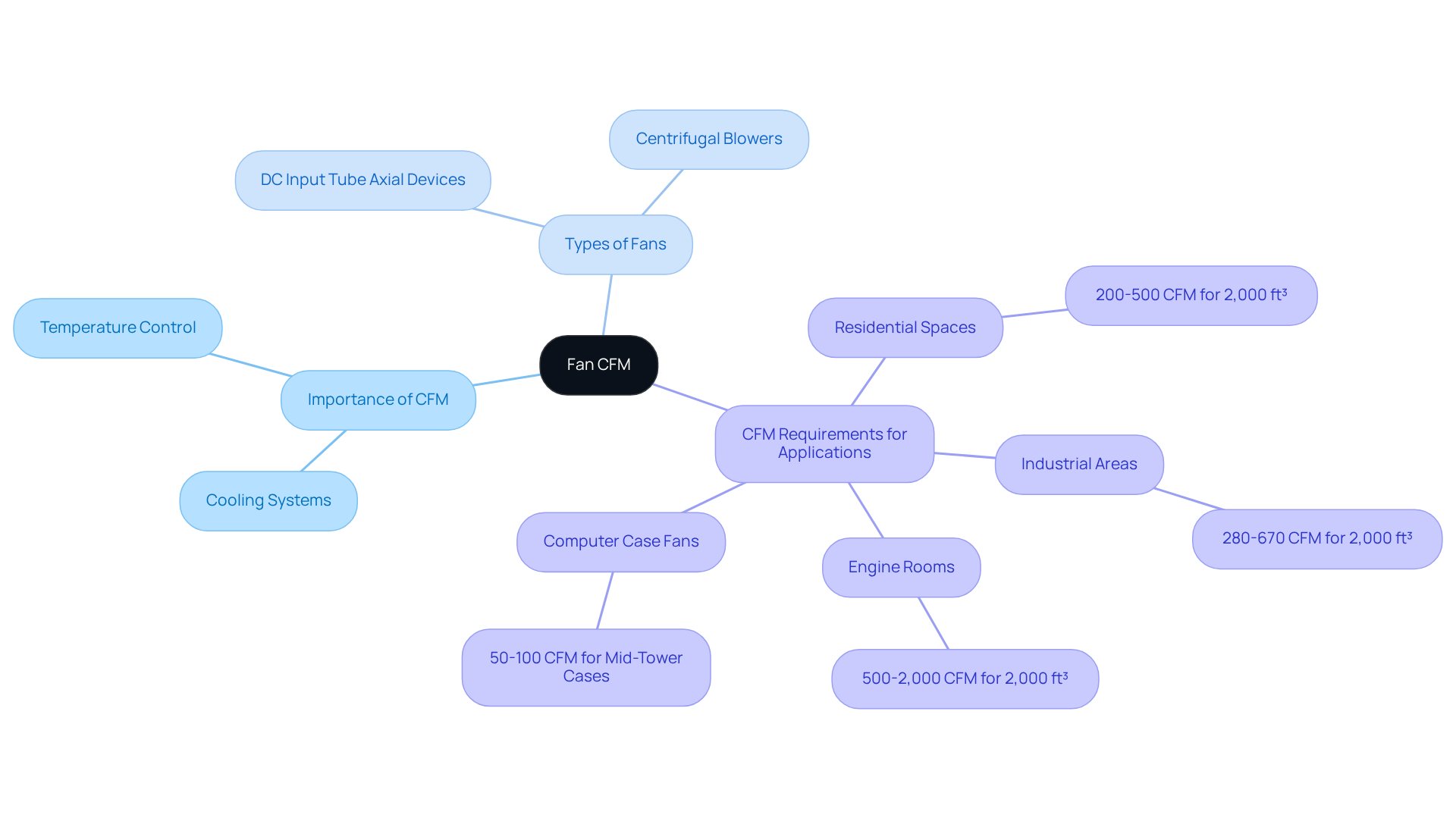

, recognized as the world’s largest producer of standard and custom air-movers, provides an extensive array of DC input tube axial devices and centrifugal blowers, meticulously refined for performance, efficiency, and low noise. These units range in size from 15 to 280mm for tube axial models and 15 to 225mm for centrifugal blowers, with IP protection available in most designs upon request.

A higher CFM indicates an increased , which is essential for maintaining in electronic devices. For instance, in a typical mid-tower enclosure, airflow devices with a CFM range of 50 to 100 are generally adequate, while larger setups, such as engine rooms, may require systems capable of moving 500 to 2,000 CFM to ensure proper air exchange every 1-4 minutes.

Understanding what is is imperative for engineers when selecting fans for specific applications, as this knowledge directly influences the effectiveness of across various industries, including automotive and telecommunications. By mastering ventilation metrics, professionals can significantly enhance system performance and mitigate common challenges associated with inadequate cooling. Notably, the ideal CFM for a computer case fan typically resides within the range of 50 to 100, underscoring the importance of careful selection based on distinct requirements.

Contextualize CFM: Importance in Electronics Engineering

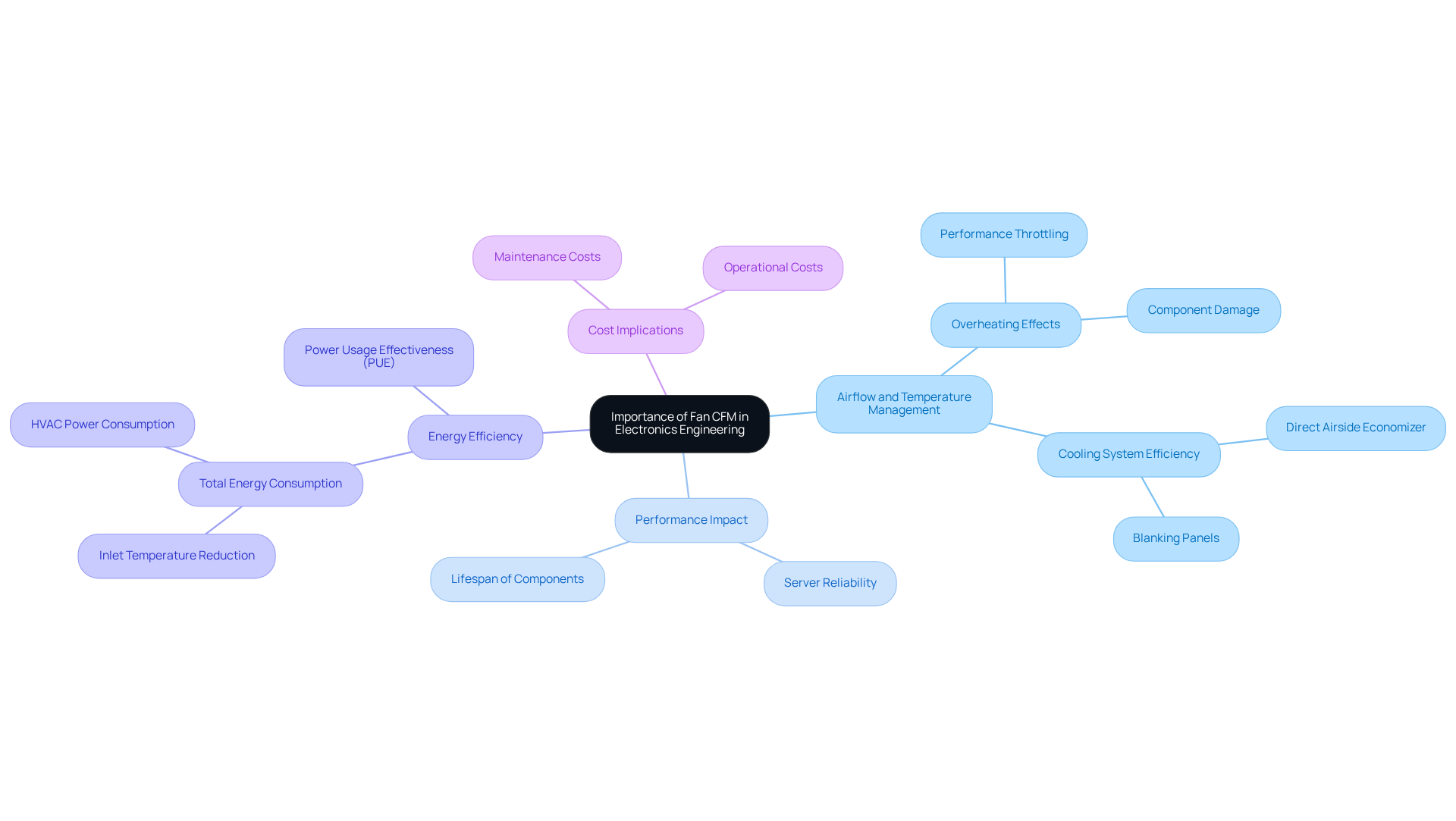

In electronics engineering, what is is of great significance when it comes to maintaining . Insufficient air circulation can lead to , resulting in decreased performance, shortened lifespan, or even catastrophic failure of electronic devices. , for instance, rely heavily on adequate airflow to dissipate heat generated by processors and other critical components.

Research indicates that from 27 °C to 18 °C can reduce total energy consumption by approximately 10%, underscoring the importance of . Furthermore, studies demonstrate that prolonged exposure to high inlet temperatures can cause servers to throttle performance or shut down entirely.

Expert opinions highlight that even minor overheating can lead to , ultimately driving up maintenance costs. Notably, air-conditioning systems account for over 30% of the energy consumed by the entire data center, emphasizing the critical need for effective .

Consequently, engineers must prioritize understanding what is fan cfm in their designs to ensure devices provide sufficient ventilation, thereby , reliability, and overall performance of electronic systems.

Examine CFM Ratings: Key Factors and Specifications

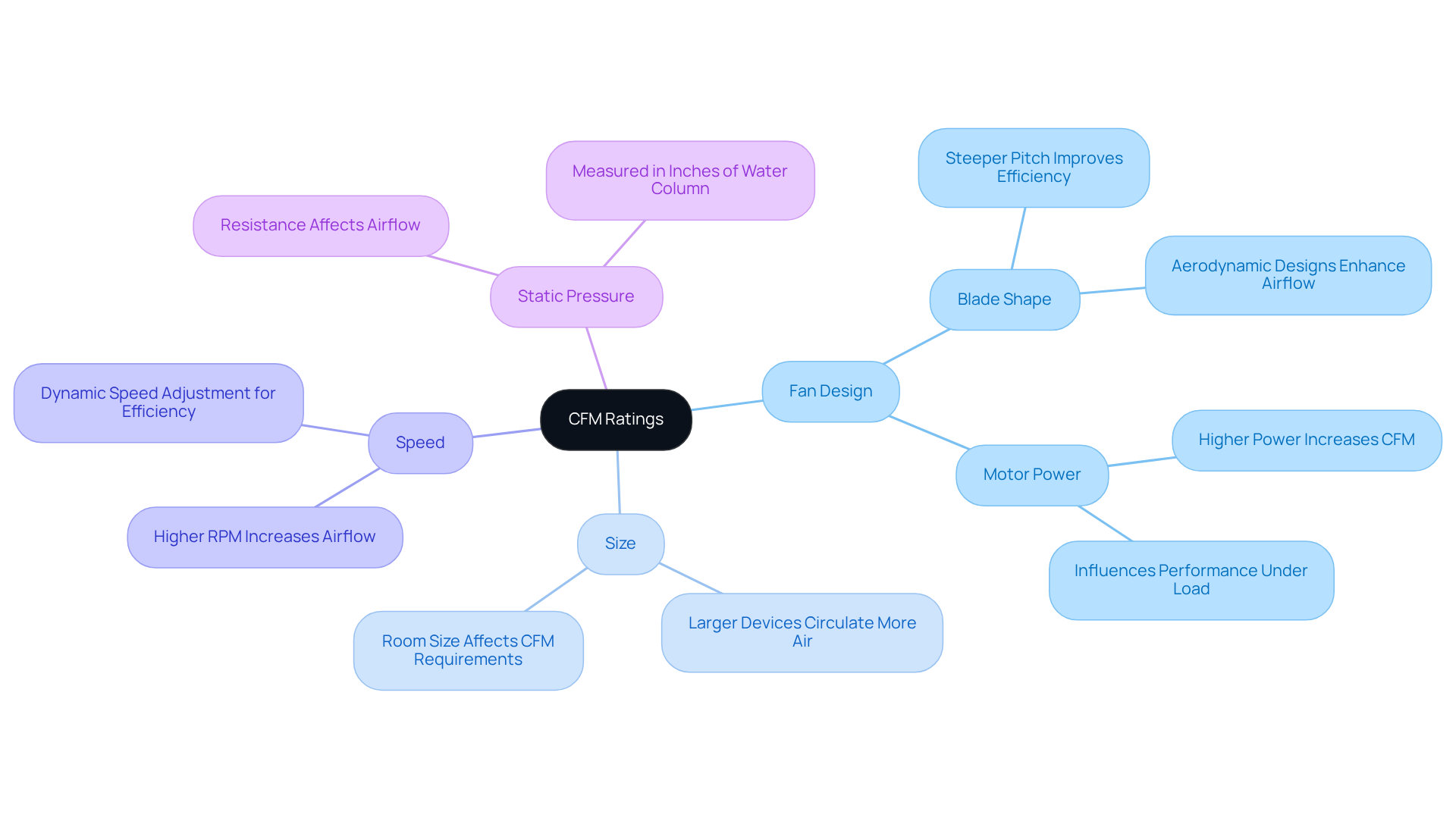

To understand , one must consider that are influenced by several key factors, including , size, speed, and blade shape. Larger devices generally circulate more air than their smaller counterparts, while . Moreover, the design of the fan blades—encompassing their angle and curvature—plays a crucial role in the efficiency of .

For instance, blades with a steeper pitch are capable of displacing more air, thereby improving movement efficiency. , which indicates the resistance to airflow within a system; are better equipped to sustain airflow in restrictive conditions.

To ensure an accurate performance evaluation, it is essential to understand what is fan cfm and compare CFM ratings under identical static pressure conditions. In commercial environments, blowers often necessitate CFM ratings exceeding 10,000 to guarantee adequate ventilation, leading to inquiries about what is fan cfm, whereas industrial units may require ratings surpassing 20,000 for expansive spaces.

In contrast, residential blowers typically demand approximately 2,000 CFM, illustrating what is fan cfm, for effective cooling in living rooms. Furthermore, it is imperative for engineers to recognize that elevated CFM ratings can result in increased noise levels, a critical trade-off when selecting fans.

By focusing on these specifications and understanding the impact of environmental barriers on effective CFM, engineers can make informed decisions that and enhance system performance.

Explore Fan Types: Variations and Their CFM Outputs

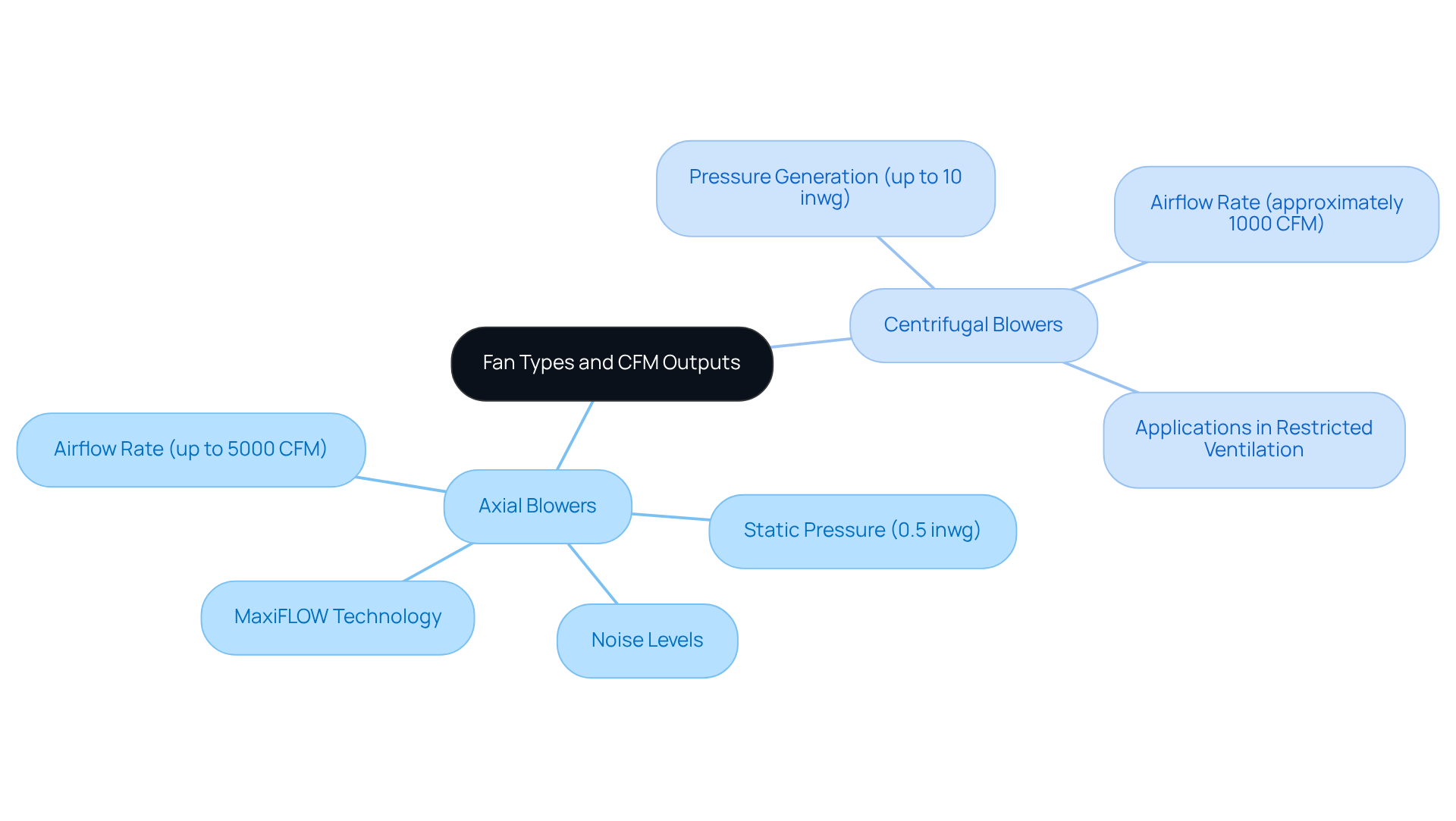

In the realm of electronics , various fan types highlight in terms of their distinct outputs and applications. Axial blowers are favored for their ability to deliver —reaching up to 5,000 CFM with a static pressure of 0.5 inwg—while maintaining lower noise levels, rendering them ideal for general tasks. The incorporation of MaxiFLOW technology further enhances their performance in temperature regulation and operational efficiency.

Conversely, in high static pressure environments, generating pressures up to 10 inches of water gauge (inwg) while sustaining approximately 1,000 CFM. This capability makes them particularly effective in enclosures or setups with restricted ventilation, where precise temperature control is paramount. Additionally, specialized blower devices are employed in applications that require .

It is imperative for thermal management early in the design phase, as this significantly impacts the efficiency of the temperature regulation strategies implemented. Moreover, both fan types can generate (EMI), a critical factor for engineers engaged in sensitive applications. Understanding what is fan CFM and the variances in performance, alongside the of axial and centrifugal devices, is vital for engineers aiming to deploy the most tailored to their specific needs.

As Ryan Smoot, a Technical Support Engineer, aptly states, ‘When it comes to dealing with excess heat in a system, fans are a go-to thermal management solution for removing unwanted heat and providing cooler air across critical components.

Conclusion

Understanding fan CFM is essential for optimizing airflow and ensuring effective cooling across various applications. This metric, which represents the volume of air a fan can move per minute, is crucial for maintaining safe operating temperatures in electronic devices and enhancing overall system performance. By grasping the significance of CFM, engineers can make informed decisions that directly impact the reliability and longevity of their systems.

The article highlights several key arguments, including:

- The importance of selecting the right fan based on CFM ratings

- The influence of fan design and specifications on airflow efficiency

- The critical role of adequate ventilation in preventing overheating

Different fan types, such as axial and centrifugal blowers, cater to specific cooling needs, demonstrating that understanding CFM is not merely a technical detail but a vital aspect of thermal management strategies.

Ultimately, the insights shared underline the profound impact that proper airflow management has on performance, energy consumption, and maintenance costs in electronic systems. Professionals in the field are encouraged to prioritize CFM considerations in their designs, as doing so will lead to more effective cooling solutions and enhanced operational efficiency. Embracing this knowledge can transform how engineers approach thermal management, ensuring that they meet the demands of modern technology with confidence and precision.

Frequently Asked Questions

What does CFM stand for and why is it important?

CFM stands for Cubic Feet per Minute, which is a crucial metric for measuring airflow. It quantifies the volume of air a fan can move within a minute and is essential for evaluating the performance of cooling systems, especially in the electronics sector.

How does CFM impact the performance of cooling systems?

A higher CFM indicates increased airflow capacity, which is vital for maintaining optimal operating temperatures in electronic devices. This helps in effective heat dissipation, ensuring the longevity and reliability of components.

What is the typical CFM range for different setups?

In a typical mid-tower enclosure, airflow devices with a CFM range of 50 to 100 are generally adequate. However, larger setups, like engine rooms, may require systems capable of moving 500 to 2,000 CFM to ensure proper air exchange every 1-4 minutes.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers. They provide a wide range of DC input tube axial devices and centrifugal blowers, designed for performance, efficiency, and low noise, with sizes ranging from 15 to 280mm for tube axial models and 15 to 225mm for centrifugal blowers.

What is the ideal CFM for a computer case fan?

The ideal CFM for a computer case fan typically resides within the range of 50 to 100, highlighting the importance of careful selection based on specific requirements.

Why is it important for engineers to understand fan CFM?

Understanding fan CFM is imperative for engineers when selecting fans for specific applications, as it directly influences the effectiveness of temperature control solutions across various industries, including automotive and telecommunications.