Overview

Static pressure is typically quantified in units such as Pascals (Pa) or inches of water column (in WC), both of which are essential for evaluating airflow within HVAC systems.

Accurate measurement of static pressure is not merely a technical detail; it is a critical factor for optimizing system performance and preventing operational issues. This measurement directly influences airflow rates and energy efficiency, underscoring the necessity of precision in these assessments.

To achieve optimal performance, professionals must prioritize accurate static pressure measurements, thereby enhancing the overall functionality of HVAC systems.

Introduction

Understanding static pressure is crucial for engineers engaged in HVAC systems, as it significantly influences airflow dynamics and the overall efficiency of these systems. By comprehending the units used to measure static pressure—such as Pascals or inches of water column—professionals can optimize performance and mitigate costly operational issues.

However, the challenge lies in the accurate assessment and management of static pressure levels; both excessive and insufficient resistance can result in energy inefficiency and undue strain on equipment.

How can engineers adeptly navigate these challenges to enhance HVAC performance and extend system longevity?

Define Static Pressure: Understanding the Basics

Static force is defined as the force exerted by a fluid at rest, measured perpendicular to the flow direction. In HVAC systems, understanding static force is crucial for comprehending how air moves through ducts and interacts with various components.

What is typically includes units such as Pascals (Pa) or inches of water column (in). In order to determine what is static pressure measured in, static force assessment requires a digital manometer and stationary force probes, which should be placed into pre-drilled openings at critical locations within the duct system. This measurement is essential for ensuring efficient and effective operation, as it directly impacts airflow rates and overall performance.

Elevated air resistance indicates excessive obstruction in the ductwork, which hinders proper air circulation, potentially stressing the heating and cooling apparatus and resulting in increased energy consumption. Conversely, low atmospheric force suggests inadequate resistance, leading to excessive fan operation and causing inconsistent heating or cooling.

Consistent observation of static force is vital for sustaining optimal heating and cooling performance, ensuring that equipment operates within appropriate parameters and enhancing comfort throughout the environment. By addressing static force challenges, engineers can prevent shortened operational lifespans and uneven temperature distribution across different areas.

Contextual Importance of Static Pressure in HVAC Systems

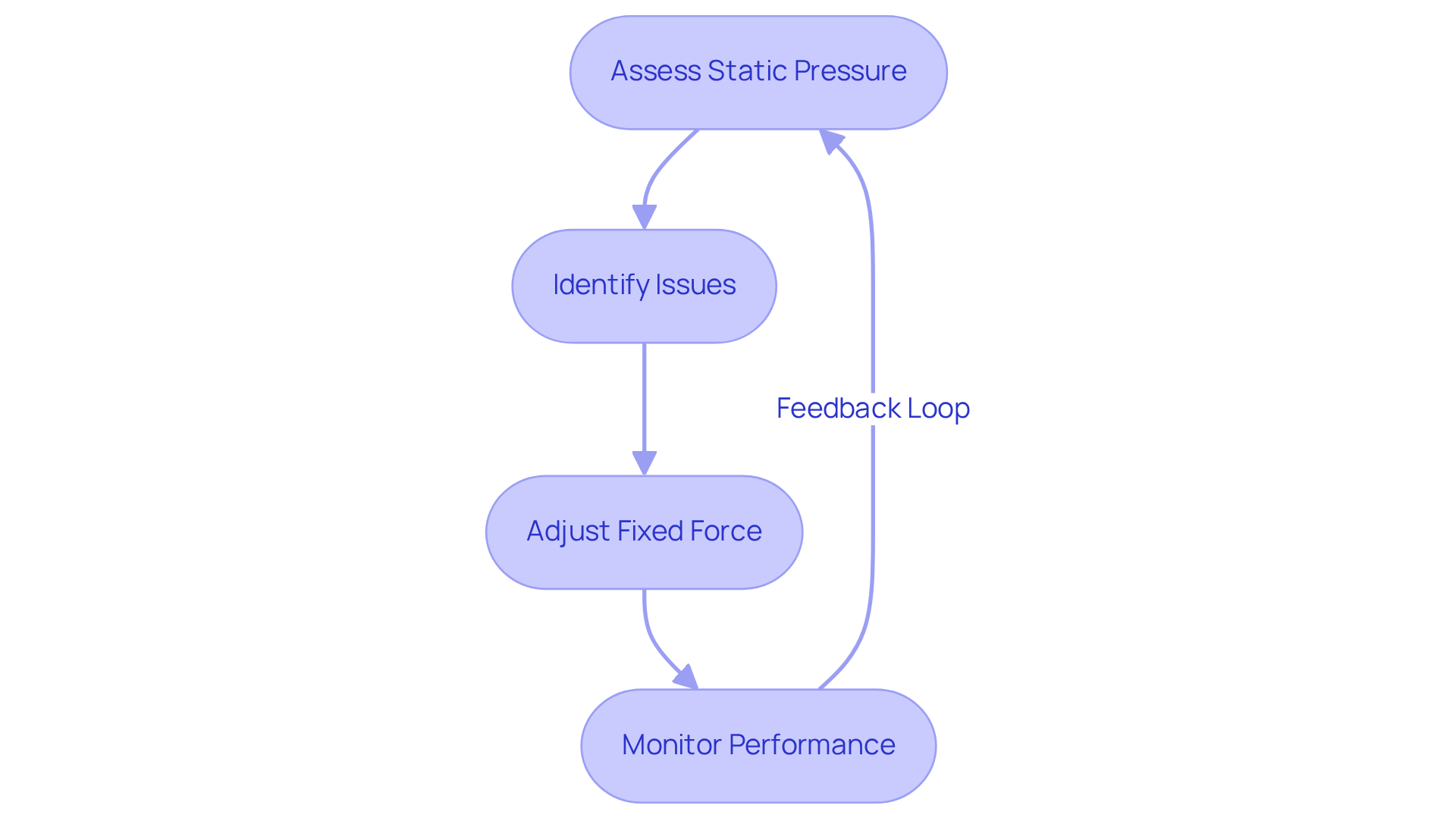

In HVAC setups, fixed force serves as a critical element that significantly influences airflow and operational efficiency. Ensuring appropriate fixed air levels is essential for uniformly distributing air across a building, thereby preventing the occurrence of hot or cold areas. Engineers must diligently assess fixed force at various locations within the system to identify potential issues, enhance overall efficiency, and ensure compliance with industry standards.

For instance, a low fixed force may indicate obstructions within the ducts or insufficient fan strength, leading to inadequate heating or cooling. Conversely, an excessively high fixed force can result in increased energy consumption and potential damage to system components. Therefore, regular assessment and adjustment of fixed force are vital for .

Historical Development of Static Pressure Measurements

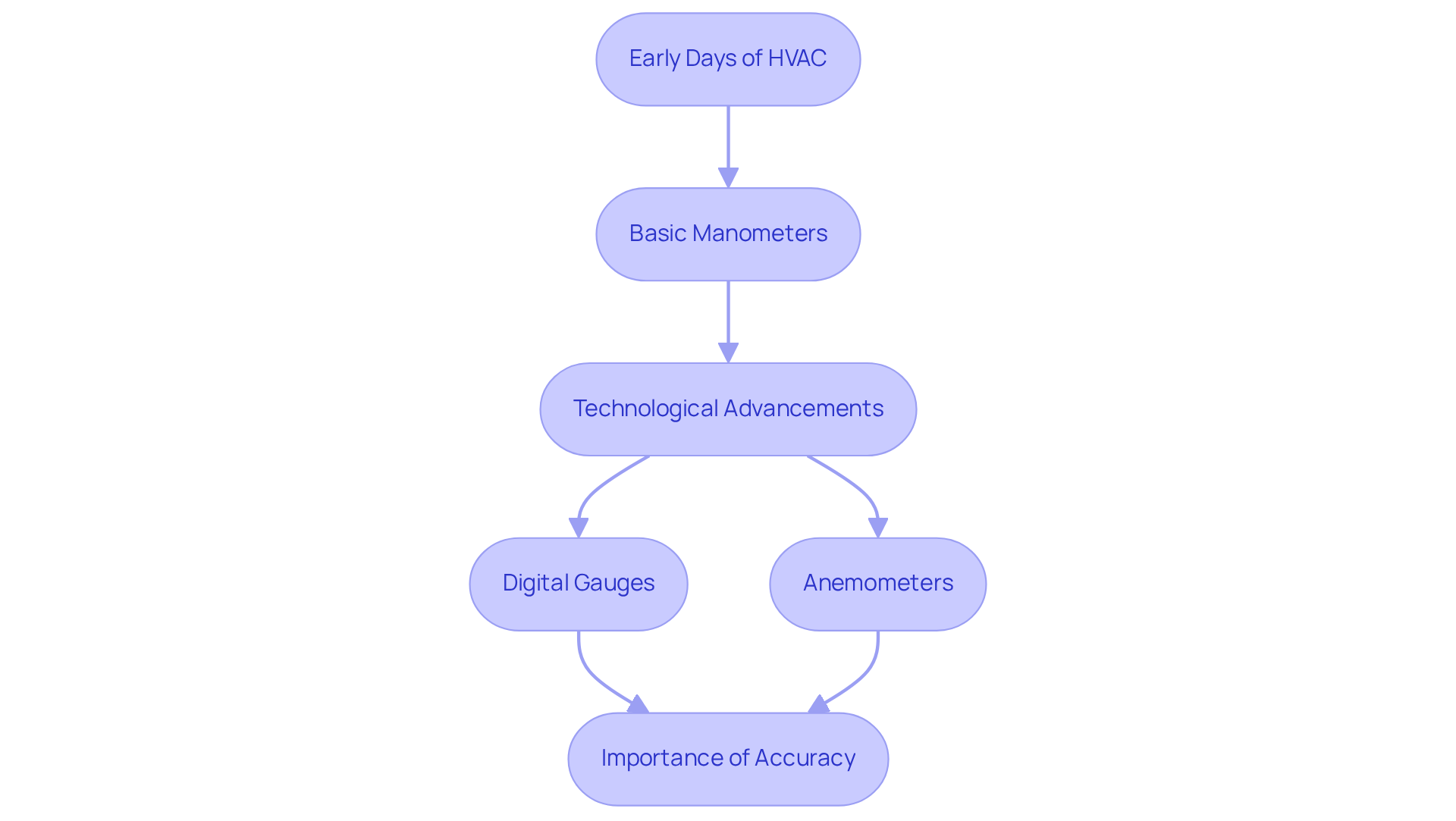

The assessment of static force has significantly evolved since the early days of HVAC and fluid dynamics. Initially, basic manometers were employed to measure force differentials; however, technological advancements have led to the development of sophisticated devices such as digital gauges and anemometers. These innovations have improved both precision and ease of use, empowering engineers to make more informed decisions regarding design and troubleshooting. Understanding the of fixed measurements is crucial for engineers, as it underscores the importance of accuracy in contemporary applications.

Key Characteristics and Influencing Factors of Static Pressure

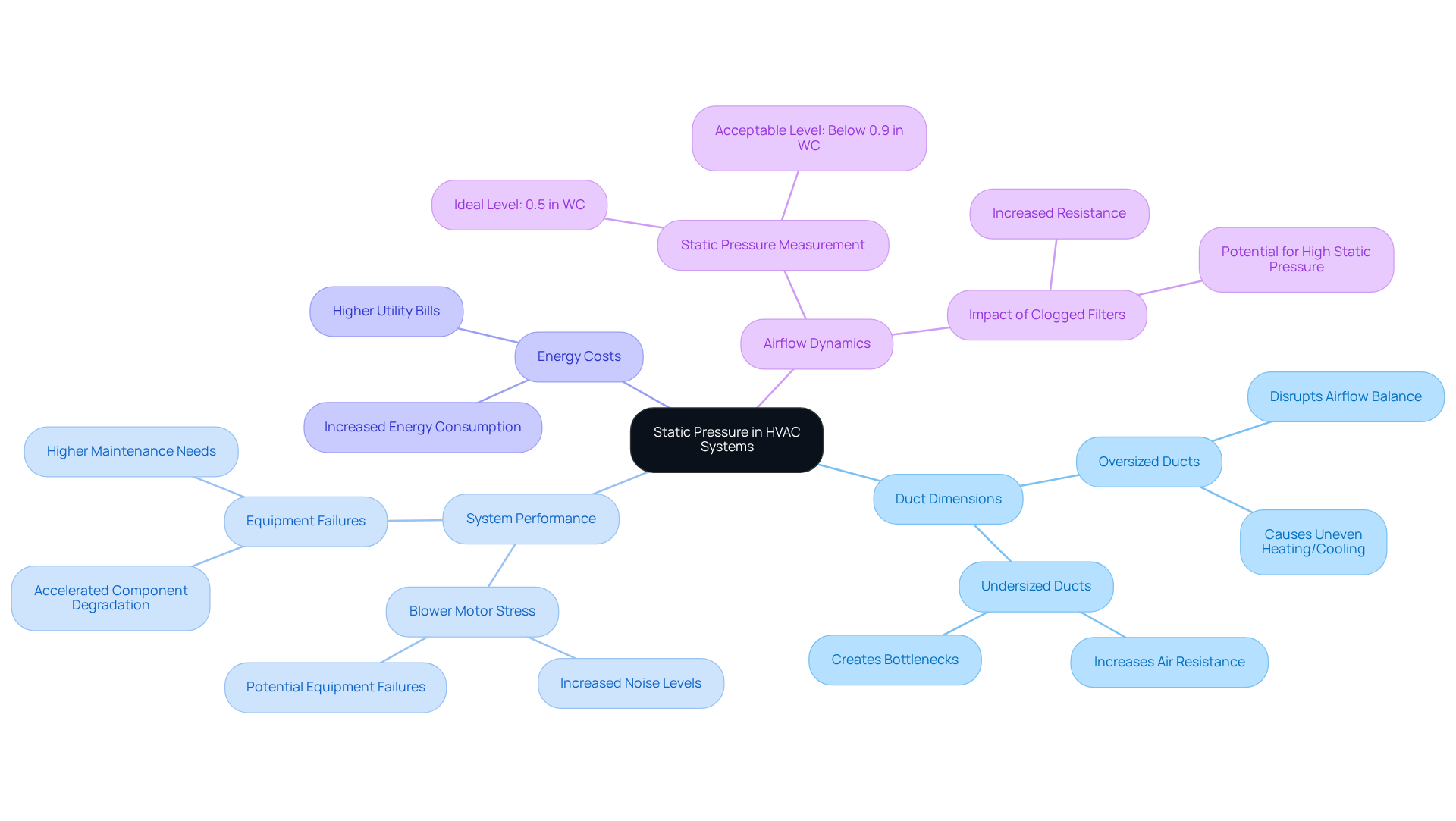

Static force in HVAC configurations significantly influences system performance, particularly through duct dimensions and form. A reduction in duct width can lead to increased resistance to airflow, stressing the system and escalating energy costs. For instance, undersized ducts often create bottlenecks, compelling the blower motor to work harder, resulting in noisier operation and potential equipment failures. Elevated air resistance indicates excessive obstruction within the ductwork, further straining the heating and cooling system while increasing energy consumption. Conversely, oversized ducts can disrupt airflow balance, causing uneven heating or cooling throughout a space.

The , which includes the strategic positioning of fans and the arrangement of ducts, is vital for maintaining optimal air levels. Engineers must meticulously evaluate these components to enhance performance and energy efficiency. Regular monitoring of what static pressure is measured in is essential; maintaining levels close to 0.5 inches of water column (in WC) is ideal, with values below 0.9 in WC still considered acceptable to prevent excessive wear on components and ensure reliable operation. Incorrect static force can place undue stress on your climate control unit, accelerating component degradation. Real-world examples illustrate that addressing duct design issues can yield substantial improvements in airflow dynamics, ultimately boosting comfort and reducing operational costs. By prioritizing effective duct design and maintenance, engineers can alleviate static pressure challenges and prolong the lifespan of HVAC systems.

Conclusion

Understanding static pressure is paramount for engineers engaged with HVAC systems, as it directly affects airflow and overall system performance. The importance of static pressure measurement transcends mere numerical values; it encompasses the efficiency and comfort of the environments these systems serve. By mastering the fundamentals of static force, professionals can ensure consistent and effective air distribution, ultimately leading to enhanced operational efficiency.

This article elucidates key insights into static pressure, including:

- Its definition

- Measurement techniques

- The critical role it plays within HVAC systems

It underscores the necessity of maintaining appropriate static pressure levels to avert energy inefficiency and undue strain on equipment. The historical evolution of measurement tools—from basic manometers to sophisticated digital gauges—demonstrates the ongoing advancements in accuracy and reliability, which are essential for contemporary engineering practices.

In light of these insights, engineers are urged to prioritize the regular monitoring and assessment of static pressure within HVAC systems. By doing so, they can identify potential issues early, optimize system performance, and contribute to energy conservation efforts. Understanding and addressing static pressure not only extends the lifespan of HVAC components but also ensures a comfortable and efficient environment for occupants.

Frequently Asked Questions

What is static pressure in the context of HVAC systems?

Static pressure is the force exerted by a fluid at rest, measured perpendicular to the flow direction. It is crucial for understanding how air moves through ducts and interacts with various components in HVAC systems.

What units are used to measure static pressure?

Static pressure is typically measured in units such as Pascals (Pa) or inches of water column (in).

How is static pressure measured?

To measure static pressure, a digital manometer and stationary force probes are used. These probes should be placed into pre-drilled openings at critical locations within the duct system.

Why is measuring static pressure important?

Measuring static pressure is essential for ensuring efficient and effective operation of HVAC systems, as it directly impacts airflow rates and overall performance.

What does elevated air resistance indicate in a duct system?

Elevated air resistance indicates excessive obstruction in the ductwork, which hinders proper air circulation and can stress the heating and cooling apparatus, resulting in increased energy consumption.

What does low atmospheric force suggest in terms of duct performance?

Low atmospheric force suggests inadequate resistance, leading to excessive fan operation and causing inconsistent heating or cooling.

Why is consistent observation of static pressure vital?

Consistent observation of static pressure is vital for maintaining optimal heating and cooling performance, ensuring that equipment operates within appropriate parameters, and enhancing comfort throughout the environment.

How can addressing static pressure challenges benefit HVAC systems?

Addressing static pressure challenges can prevent shortened operational lifespans of equipment and ensure even temperature distribution across different areas.