Overview

This article emphasizes four essential practices for the effective utilization of high-powered fans in electronics, underscoring their critical role in maintaining optimal temperatures and enhancing system reliability. It delineates best practices for the selection, installation, and maintenance of these fans, supported by data that illustrates how proper thermal management can significantly reduce component failure rates and improve overall performance in high-density electronic environments.

Introduction

In the realm of electronics design, the significance of high-powered fans is paramount. These essential components play a pivotal role in dissipating the excess heat generated by electronic devices, which is crucial for maintaining optimal performance and extending the lifespan of equipment. As the demand for high-density environments, such as data centers and gaming systems, increases, so too does the necessity for effective cooling solutions. Research indicates that inadequate cooling can drastically elevate failure rates of electronic components.

Therefore, understanding the intricacies of fan selection, installation, and maintenance becomes vital for engineers. This article explores:

- The importance of high-powered fans

- The criteria for selecting the right models

- Best practices for installation

- Strategies for long-term performance monitoring

All aimed at ensuring reliability and efficiency in modern electronic systems.

Understand the Importance of High-Powered Fans in Electronics Design

High powered fans play a pivotal role in electronics design, efficiently dissipating the excess heat generated by electronic components. Maintaining optimal operating temperatures is crucial, as it directly impacts both performance and longevity. In high-density environments, such as servers and gaming setups, significant heat production necessitates . Research indicates that inadequate temperature management can lead to a staggering 55% increase in electronic component failure rates, underscoring the importance of powerful ventilators in sustaining system reliability and efficiency.

Gagner-Toomey Associates is recognized as the world’s largest manufacturer of standard and custom air-movers, offering an extensive range of DC input tube axial devices from 15 to 280mm and centrifugal blowers from 15 to 225mm. These solutions are optimized for effectiveness, efficiency, and low noise, addressing the thermal requirements across various applications, including the electronics and automotive sectors.

For instance, Deaton Engineering’s collaboration with Dell and TyRex Group culminated in the creation of an automated testing device capable of assessing up to 450 ventilation units simultaneously. This innovation streamlined the testing process and ensured that only the most efficient devices were employed, thereby enhancing overall functionality. The outcome of this partnership was a solution that significantly improved the efficiency of evaluating cooling devices, highlighting the essential role of high powered fans in modern electronics design.

Incorporating high-powered fans enables engineers to:

- Significantly improve airflow

- Mitigate thermal hotspots

- Elevate the performance of electronic systems

As Mary Burke noted, “Finally, running the fan slower also improves its lifetime, increasing system reliability.” This insight emphasizes the technical advantages of high powered fans, particularly regarding the extension of electronic devices’ lifespan. By understanding and applying these principles, engineers can ensure optimal temperature control solutions that enhance the reliability and efficiency of their designs. Furthermore, Gagner-Toomey Associates offers a variety of , including extruded aluminum heatsinks, copper-based heat sinks, and integrated liquid cooling options, further supporting engineers in their temperature control endeavors.

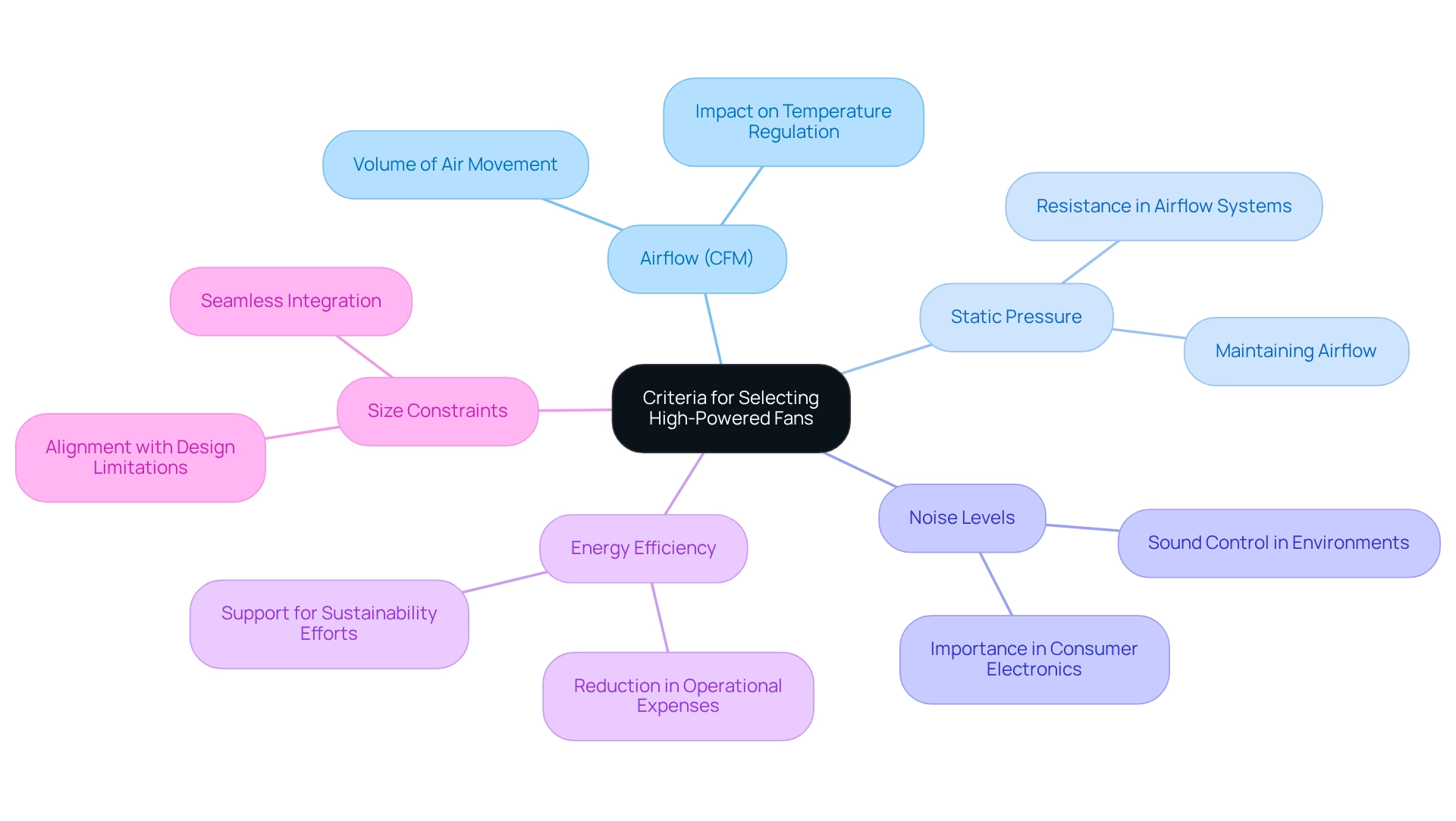

Establish Criteria for Selecting High-Powered Fans

Establish Criteria for Choosing High-Efficiency Blowers

Choosing high-efficiency blowers requires engineers to evaluate several critical standards to ensure optimal functionality and effectiveness. The key factors to consider include:

- Airflow (CFM): This parameter dictates the volume of air the fan can move, which directly impacts the effectiveness of temperature regulation.

- Static Pressure: This is particularly important in systems where airflow faces resistance, as it determines the fan’s ability to maintain airflow under such conditions.

- Noise Levels: This factor is critical in consumer electronics and environments where sound control is essential.

- Energy Efficiency: Since fans can account for a substantial portion of power consumption in electronic systems, selecting devices that enhance energy use not only lowers operational expenses but also supports sustainability efforts.

- Size Constraints: The physical dimensions of the unit must align with the design limitations of the application to ensure seamless integration.

By establishing these criteria, engineers can confidently select units that meet efficacy requirements while advancing energy efficiency objectives. Gagner-Toomey Associates, the largest producer of standard and custom air-movers for temperature regulation globally, offers a comprehensive collection of DC input tube axial units and centrifugal blowers, designed for efficiency, effectiveness, and reduced noise. Their product range includes:

- DC Input Tube Axial Devices: Available in sizes ranging from 15mm to 280mm.

- Centrifugal Blowers: Offered in sizes from 15mm to 225mm.

- EC Devices and Blowers: Ranging in size from 120mm to 910mm.

- : Starting from 15x3mm, suitable for consumer applications and compact space ventilation.

Innovative designs, such as the DiaForce series, exemplify how advanced thermal solutions can enhance efficiency while minimizing noise, making them suitable for high-density applications in telecommunications and data centers.

It is also essential to be aware of common pitfalls in selecting high powered fan devices, such as overlooking the specific airflow requirements of the application or failing to consider the impact of noise levels on user experience. With over 170 experienced sales engineers across 56 offices in the U.S. and Canada, Gagner-Toomey Associates provides exceptional local support, ensuring that engineers have access to knowledgeable resources when making these critical selections.

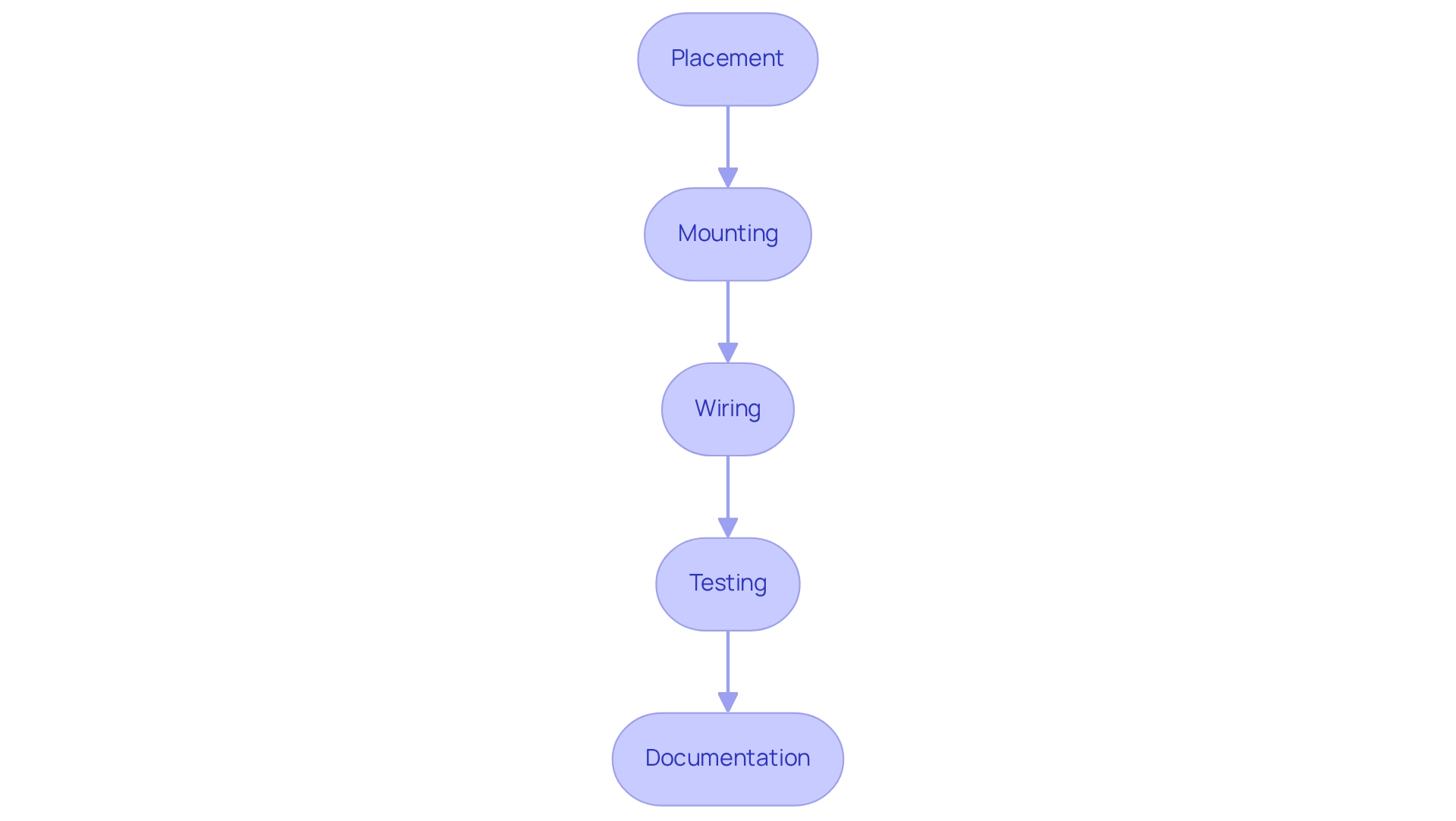

Implement Best Practices for Fan Installation and Integration

To achieve optimal performance from the high powered fan in electronics cooling systems, adhering to best practices during installation and integration is essential.

Placement:

- Strategically install devices to maximize airflow and minimize obstructions.

- For instance, intake vents should ideally be situated at the front or bottom of enclosures, while exhaust vents are best placed at the top or rear.

- This arrangement promotes efficient airflow and improves temperature regulation.

- Considering the specific layout of electronic components can further optimize fan positioning strategies.

Mounting:

- Utilize vibration-dampening mounts to mitigate noise and prevent mechanical wear.

- This not only extends the lifespan of the devices but also helps create a quieter operating environment.

Wiring:

- Ensure that wiring is organized and does not obstruct airflow.

- Neat wiring assists in preserving optimal airflow routes, which is essential for efficient temperature regulation.

Testing:

- Conduct airflow tests post-installation to confirm that the fans are functioning as intended.

- This step is crucial for detecting any possible problems early and ensuring that the refrigeration apparatus functions effectively.

- Collaboration among industry professionals can lead to innovative solutions in testing methodologies, as highlighted in the case study “Significance of Events in .”

Documentation:

- Keep comprehensive records of fan specifications and installation procedures for future reference.

- This practice aids in troubleshooting and facilitates maintenance, ensuring long-term reliability.

Considering the EUR 220 million funding acquired by the Program for Energy Efficiency in Buildings (PEEB) in 2022, it is evident that energy efficiency is a vital component of refrigeration solutions.

By applying these best practices, engineers can significantly improve the reliability and efficiency of cooling solutions in electronic applications by utilizing a high powered fan.

Industry events, such as Electronics Cooling’s Spring gathering, highlight the critical role of temperature regulation devices and foster collaboration among professionals, further emphasizing the importance of effective fan installation strategies.

As Mike Humann noted, “If the losses are not accounted for, the fan will have to run at a speed higher than the one specified during fan selection,” underscoring the importance of careful planning in fan installation.

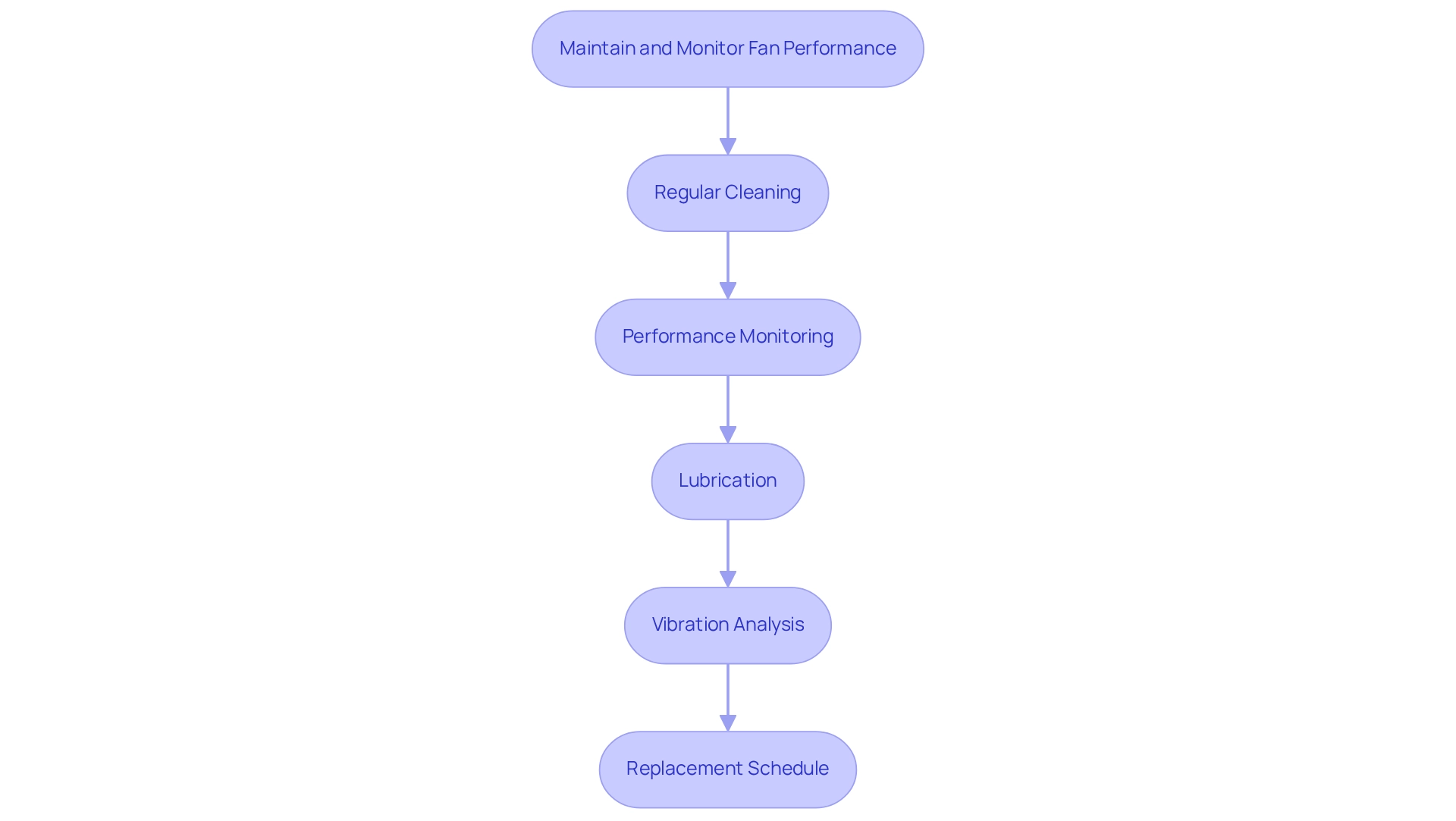

Maintain and Monitor Fan Performance for Long-Term Reliability

To ensure optimal performance and longevity of high-powered fans in electronic systems, implement the following strategies:

- Regular Cleaning: The accumulation of dust and debris on fan blades and housing can significantly hinder efficiency. Establish a regular cleaning timetable to maintain optimal airflow and prevent a decline in functionality.

- Performance Monitoring: Employ sensors to continuously track fan speed, airflow, and temperature. This real-time data is crucial for the early detection of performance issues, allowing for timely interventions. Notably, over 4,000 companies rely on asset operations management, underscoring the importance of these practices in the industry.

- Lubrication: Adhere to manufacturer guidelines for lubricating fan bearings. Proper lubrication minimizes friction and wear, contributing to smoother operation and an extended fan life.

- Vibration Analysis: Regularly monitor for unusual vibrations, which may signal underlying mechanical problems. Early detection of these issues can prevent more severe damage and costly repairs.

- Replacement Schedule: Develop a replacement schedule based on the expected lifespan of the fans, considering the specific operating conditions they face. This proactive approach helps avoid unexpected failures.

Additionally, case studies, such as ‘Importance of Routine Maintenance for High Powered Fans,’ highlight how regular maintenance of high powered fans can significantly enhance operational efficiency and workplace safety, particularly in industrial settings like New York.

By implementing these maintenance and monitoring strategies, engineers can significantly enhance the reliability of fan systems, ultimately reducing downtime and improving operational efficiency. Routine upkeep not only guarantees peak operation but also fosters a safer and more efficient work environment. Furthermore, workshop repairs offered by FBG Servicing, which encompass and testing for optimal functionality, demonstrate the practical application of these maintenance strategies. As emphasized by ebm-papst, the development of diagnostic tools that determine the individual service life of fans based on ambient and operating conditions is a testament to the innovative solutions available for monitoring fan performance.

Conclusion

High-powered fans are indispensable in the realm of electronics design, playing a crucial role in heat dissipation and ensuring the reliable operation of electronic systems. Selecting the right fans based on key criteria—such as airflow, static pressure, noise levels, energy efficiency, and size constraints—is paramount. By adhering to these guidelines, engineers can make informed choices that not only enhance cooling effectiveness but also contribute to the longevity of their designs.

Moreover, proper installation practices—including strategic positioning, vibration-dampening mounts, and organized wiring—are essential for maximizing fan performance. Regular testing and thorough documentation ensure that systems operate efficiently and reliably over time. The emphasis on maintenance and performance monitoring, through strategies like routine cleaning, lubrication, and vibration analysis, underscores the necessity of proactive measures to prevent failures and extend the life of cooling systems.

In conclusion, as electronic devices continue to evolve and the demand for effective cooling solutions grows, understanding the intricacies of fan selection, installation, and maintenance becomes increasingly critical. By prioritizing these aspects, engineers can not only improve system reliability but also drive efficiency, ultimately leading to enhanced performance in high-density environments such as data centers and gaming systems. Embracing these best practices is essential for safeguarding the integrity and longevity of modern electronic systems.

Frequently Asked Questions

What role do high-powered fans play in electronics design?

High-powered fans are essential for efficiently dissipating excess heat generated by electronic components, maintaining optimal operating temperatures crucial for performance and longevity.

Why is temperature management important in electronic systems?

Inadequate temperature management can lead to a significant increase in electronic component failure rates, with research indicating up to a 55% increase, highlighting the need for effective temperature control solutions.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest manufacturer of standard and custom air-movers, providing a wide range of DC input tube axial devices and centrifugal blowers optimized for effectiveness, efficiency, and low noise.

What specific applications do Gagner-Toomey’s products address?

Their products address thermal requirements across various applications, including the electronics and automotive sectors.

Can you give an example of a collaboration that improved ventilation testing?

Deaton Engineering collaborated with Dell and TyRex Group to create an automated testing device that can assess up to 450 ventilation units simultaneously, streamlining the testing process and ensuring the use of the most efficient devices.

What benefits do engineers gain from incorporating high-powered fans?

Engineers can significantly improve airflow, mitigate thermal hotspots, and elevate the performance of electronic systems by incorporating high-powered fans.

How do high-powered fans affect the lifespan of electronic devices?

Running the fan at slower speeds can improve its lifetime, thereby increasing system reliability and extending the lifespan of electronic devices.

What other thermal management solutions does Gagner-Toomey Associates provide?

They offer a variety of thermal management solutions, including extruded aluminum heatsinks, copper-based heat sinks, and integrated liquid cooling options.