Overview

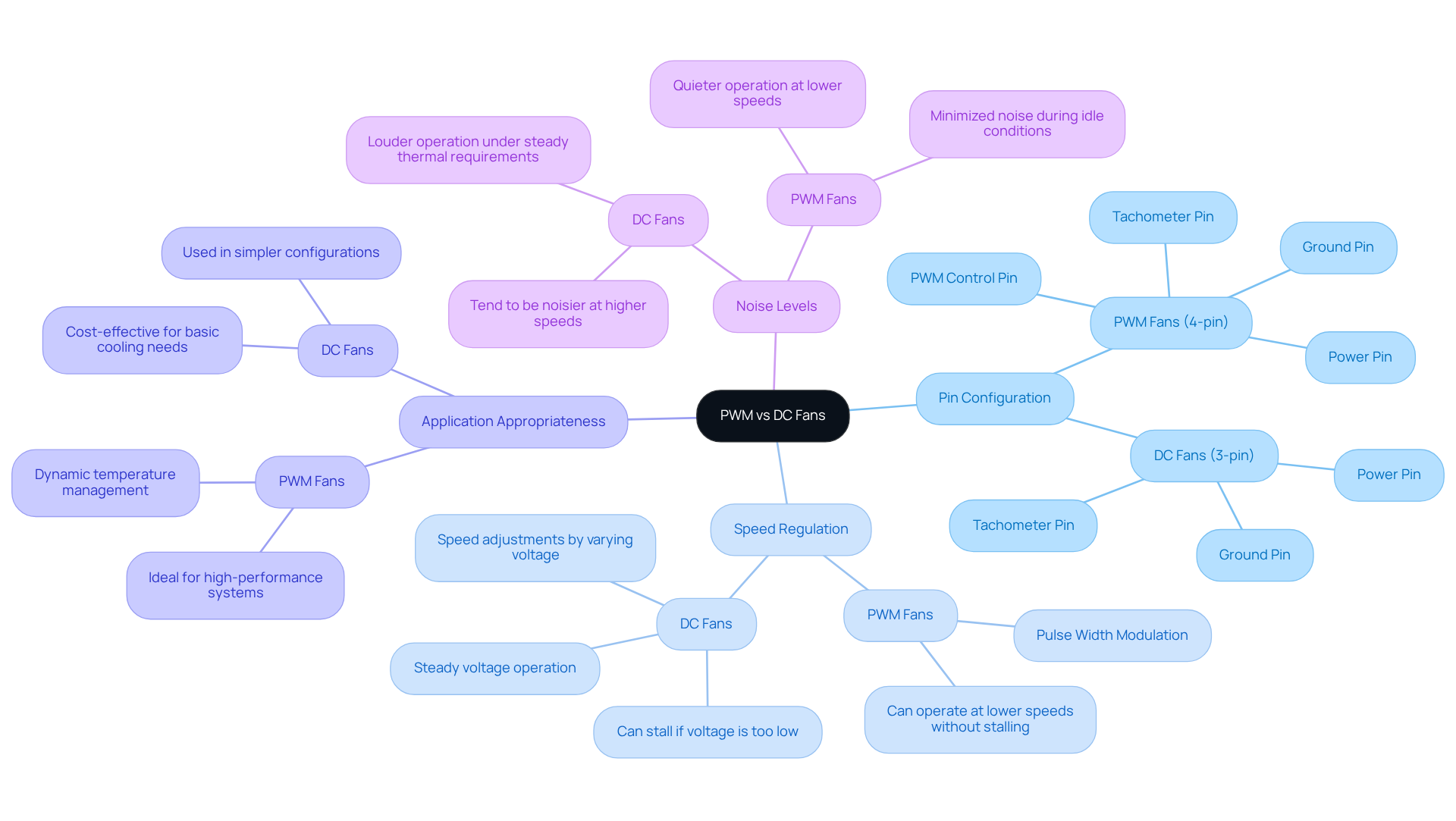

This article examines the critical factors involved in choosing between PWM (Pulse Width Modulation) and DC (Direct Current) fans. It emphasizes the distinctions in:

- Configuration

- Speed regulation

- Application suitability

- Noise levels

- Energy efficiency

By detailing how PWM fans provide superior energy savings, quieter operation, and an extended lifespan compared to their DC counterparts, it becomes evident that PWM fans are more appropriate for environments that demand precise temperature management and reduced noise levels. Understanding these differences is essential for making an informed decision that aligns with specific operational needs.

Introduction

Selecting the right fan technology is paramount, as it can significantly impact system performance, energy efficiency, and noise levels. With options such as Pulse Width Modulation (PWM) and Direct Current (DC) fans, understanding their distinct features becomes essential for optimizing cooling solutions. As users navigate the complexities of fan selection, a pressing question emerges: how do PWM and DC fans compare in terms of efficiency, noise, and application suitability? This article explores five key considerations that will empower readers to make informed decisions tailored to their specific cooling needs.

Differentiate Between PWM and DC Fans

- Identify the Pin Configuration: Devices that use PWM or DC for fan control, commonly referred to as 4-pin units due to their additional control pin, typically consist of four pins: power, ground, and two for PWM control. In contrast, DC units generally feature a three-pin configuration, which includes power, ground, and a tachometer pin for performance monitoring.

- Understand Speed Regulation Mechanisms: PWM devices utilize pulse width modulation to adjust their operational rate, enabling precise control in accordance with system demands. This capability allows them to operate effectively at reduced rates without the risk of stalling. Conversely, DC motors function at a steady voltage, with speed adjustments achieved by varying the supplied voltage, such as using pwm or dc for fan applications; however, this can lead to stalling if the voltage is decreased excessively. Furthermore, motors using PWM or DC for fan applications are known for their longevity compared to DC counterparts, enhancing their appeal for prolonged usage.

- Identify Application Appropriateness: PWM devices excel in environments where adjustable speed regulation is essential, such as high-performance computing systems that require dynamic temperature management in response to fluctuations. However, compatibility issues may arise, as not all cases or motherboards are equipped with sufficient 4-pin connectors for pwm or dc for fan cooling devices. On the other hand, PWM or DC for fan applications are frequently employed in simpler configurations where constant speeds suffice, making them a cost-effective solution for basic cooling needs.

- Assess Noise Levels: A significant advantage of PWM ventilators is their ability to operate quietly at lower speeds, which minimizes noise during idle conditions. Friedrich Stiemer noted that ‘PWM models are quieter than DC models,’ underscoring this benefit. In contrast, DC supporters often generate more noise as they tend to operate at higher speeds, particularly under steady thermal requirements. This disparity in can be critical for applications where sound levels are a significant concern.

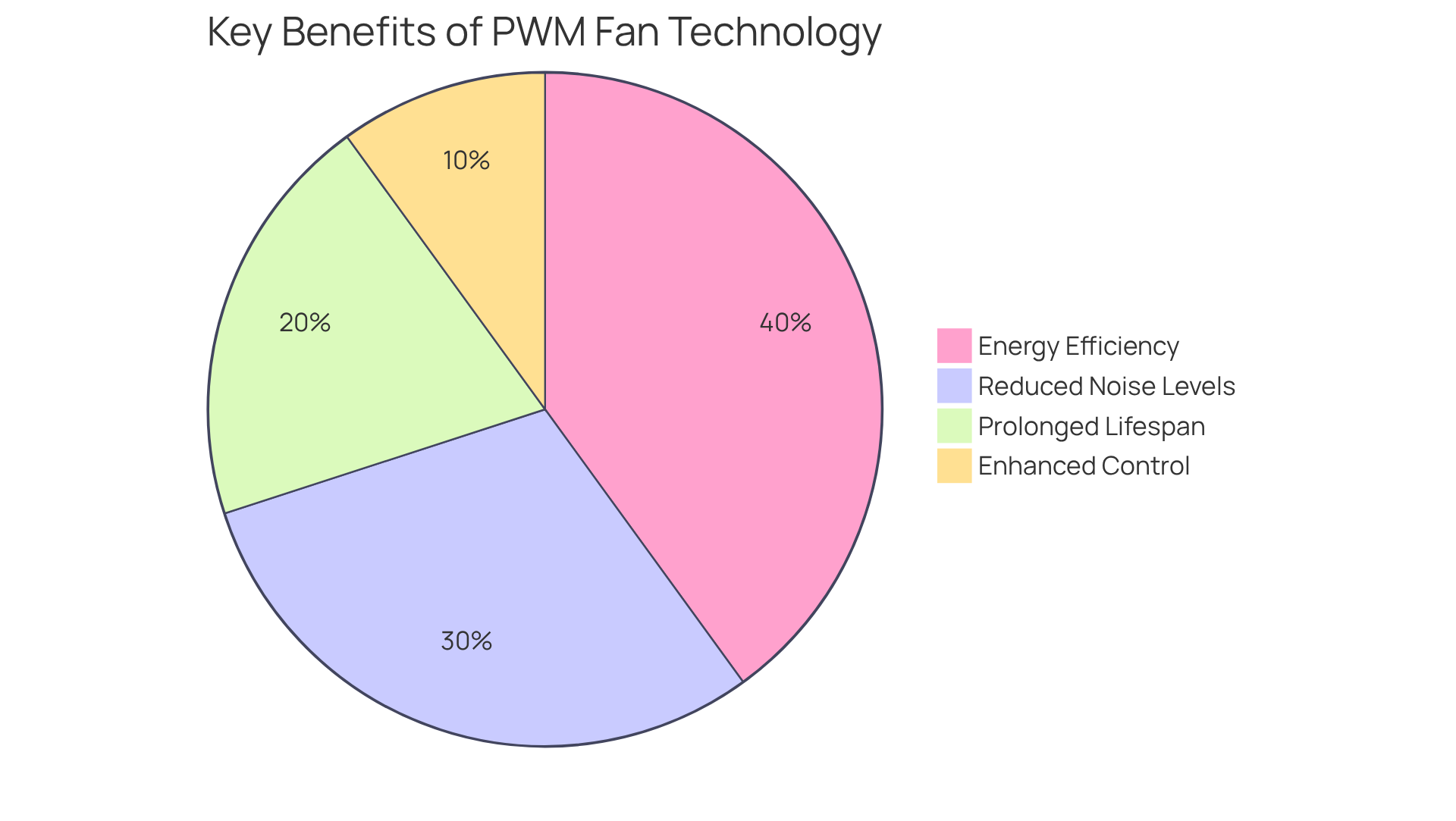

Evaluate the Benefits of PWM Fan Technology

- Energy Efficiency: PWM units significantly reduce energy consumption by dynamically adjusting their operational rates to align with current thermal requirements. This capability can lead to when compared to conventional DC devices that operate at a fixed rate and demand more power, highlighting the advantages of using PWM or DC for fan applications based on temperature needs. Notably, PWM devices can function at rates as low as 10% of their maximum performance, further enhancing their efficiency.

- Reduced Noise Levels: Operating at lower rates during periods of minimal thermal demand allows fans using PWM or DC for fan technology to produce markedly less noise than their DC counterparts. This characteristic is particularly advantageous in environments where noise levels are critical, such as data centers and quiet office spaces. Cooling devices that use PWM or DC for fan operations adjust based on system temperature, thereby increasing their versatility in noise-sensitive settings.

- Prolonged Lifespan: The ability of PWM devices to run at reduced rates not only optimizes temperature regulation but also diminishes mechanical strain, potentially extending their operational lifespan. In fact, PWM fan controllers can enhance the longevity of electronic components by as much as 50%, which is essential for maintaining the reliability of electronic systems, particularly in high-density applications.

- Enhanced Control: PWM technology offers precise control over fan speeds, enabling customized cooling solutions that adapt to varying thermal loads. Most modern motherboards are equipped to support PWM devices, allowing for the creation of custom curves that optimize performance while minimizing noise. This adaptability enhances overall system performance and thermal management, ensuring optimal operating conditions for sensitive electronic equipment.

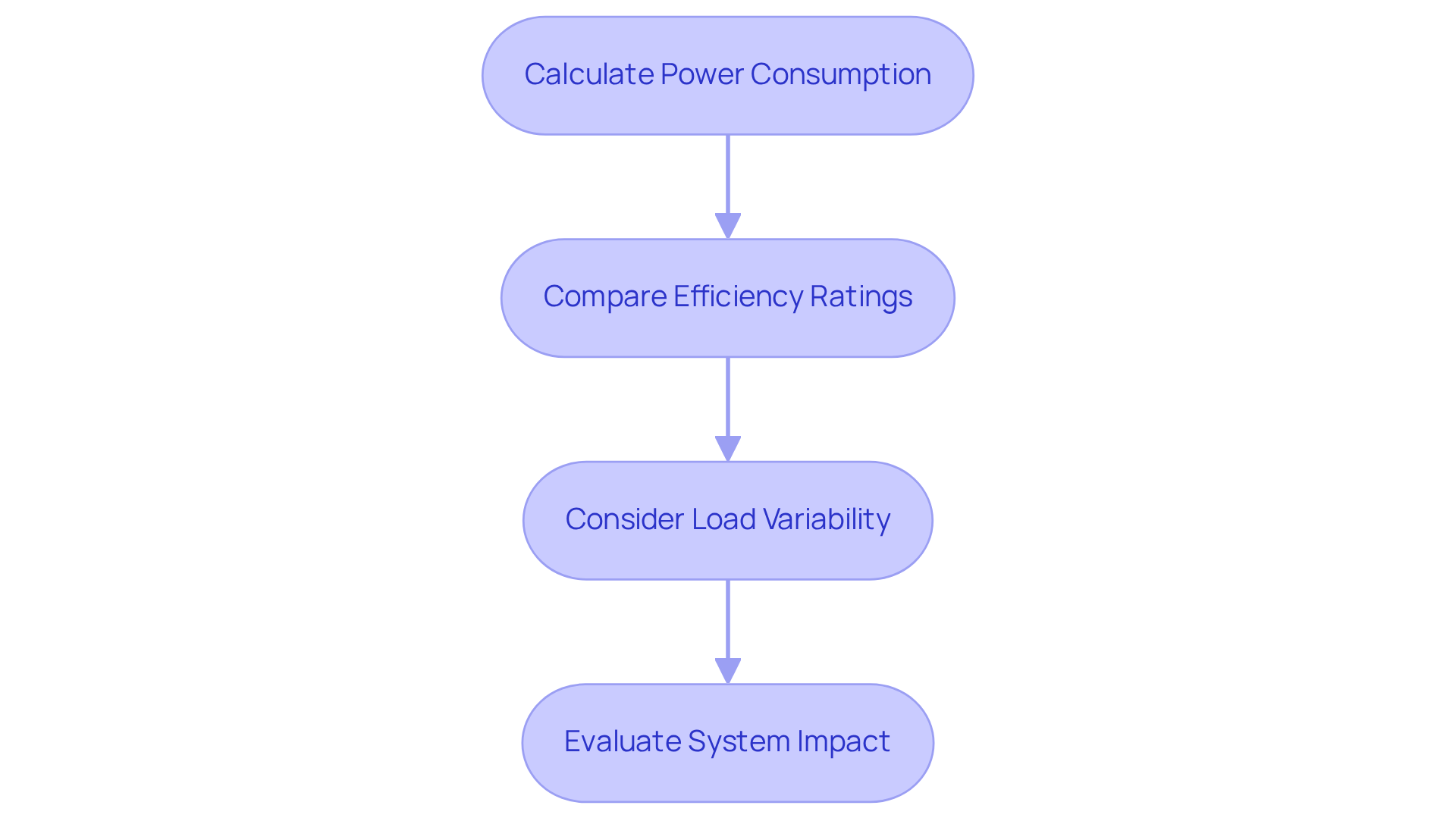

Assess Energy Efficiency and Consumption

- Calculate Power Consumption: To accurately assess the energy costs associated with pwm or dc for fan units, it is essential to first determine the wattage of each type. For PWM devices operating at a constant voltage of 12 volts, power usage is calculated based on their duty cycle. For example, a fan running at a 50% duty cycle consumes approximately half of its maximum wattage. Estimating annual energy costs requires multiplying the wattage by the number of hours the fan operates annually, providing a clear picture of potential expenses.

- Compare Efficiency Ratings: When selecting ventilators, it is imperative to prioritize those with , particularly those featuring a low Energy Index (FEI). PWM units typically demonstrate superior efficiency, often achieving energy savings of up to 30% compared to conventional units that use PWM or DC for fan operation. This efficiency is particularly crucial in applications requiring prolonged operation, such as data centers, where effective temperature management can result in significant cost reductions.

- Consider Load Variability: A notable advantage of PWM devices is their ability to dynamically adjust velocity according to thermal requirements. This adaptability facilitates substantial energy savings, as PWM units can operate at reduced speeds during periods of lower load, in contrast to DC models, which maintain a constant rate regardless of system needs. This capability not only conserves energy but also minimizes wear on fan motors, thereby extending their lifespan.

- Evaluate System Impact: The choice between using PWM or DC for fan units can profoundly affect the overall energy consumption of a system. PWM blowers enhance temperature management and contribute to increased stability and longevity of electronic devices. Moreover, when integrated into systems alongside other components such as power supplies, the cumulative impact of selecting energy-efficient units can lead to a significant reduction in total power consumption, further optimizing operational expenses.

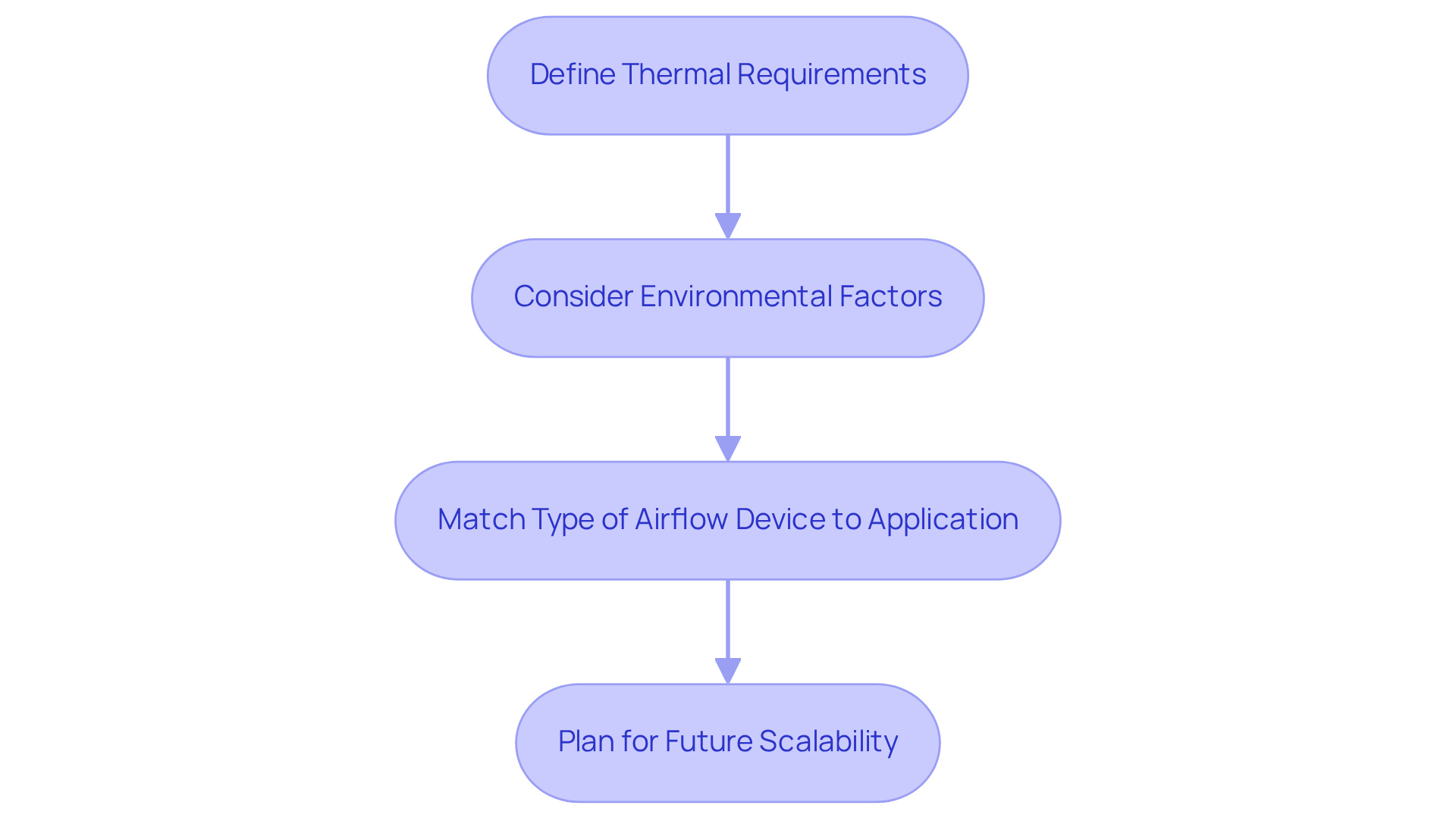

Identify Your Cooling Requirements and Applications

- Define Thermal Requirements: Begin by evaluating the thermal load of the system to ascertain the necessary airflow (CFM) essential for efficient temperature regulation. This foundational step ensures that the aligns with operational demands.

- Consider Environmental Factors: Next, assess the operating environment—such as temperature and humidity—that may significantly influence fan performance. Recognizing these variables is crucial for optimizing system efficiency.

- Match Type of Airflow Device to Application: It is imperative to determine whether units that utilize pwm or dc for fan are more suitable for specific applications, including high-performance computing or general electronics heat dissipation. This decision can impact overall system effectiveness.

- Plan for Future Scalability: Finally, anticipate potential future cooling needs by selecting fans that can accommodate increased demands without necessitating a complete system overhaul. This foresight is vital for long-term operational success.

Conclusion

Selecting the right fan technology is crucial for optimizing both performance and efficiency across various applications. The choice between PWM and DC fans hinges on a thorough understanding of their distinct characteristics, including pin configuration, speed regulation mechanisms, and suitability for specific environments. Recognizing these differences empowers users to make informed decisions that align with their cooling requirements and operational goals.

Key considerations highlighted in this article underscore the advantages of PWM technology, such as energy efficiency, reduced noise levels, and enhanced control over fan speeds. PWM fans not only adapt to thermal demands but also offer significant longevity, establishing them as an ideal choice for high-performance systems. In contrast, while DC fans may suffice for simpler applications, their fixed-speed operation can lead to inefficiencies and increased noise.

Ultimately, the decision between PWM and DC fans should be guided by a comprehensive assessment of thermal requirements, environmental factors, and future scalability. By prioritizing energy-efficient solutions, users can enhance system performance while contributing to long-term operational savings. Embracing the benefits of PWM technology paves the way for a more sustainable and effective cooling strategy, ensuring that systems operate optimally in any setting.

Frequently Asked Questions

What is the pin configuration difference between PWM and DC fans?

PWM fans typically have a 4-pin configuration consisting of power, ground, and two pins for PWM control. In contrast, DC fans usually have a 3-pin configuration, which includes power, ground, and a tachometer pin for performance monitoring.

How do PWM and DC fans regulate speed?

PWM fans use pulse width modulation to adjust their operational rate, allowing precise control and effective operation at reduced speeds without stalling. DC fans, on the other hand, regulate speed by varying the supplied voltage, which can lead to stalling if the voltage is decreased too much.

In what applications are PWM fans most appropriate?

PWM fans excel in environments requiring adjustable speed regulation, such as high-performance computing systems that need dynamic temperature management. However, compatibility issues may arise since not all cases or motherboards have sufficient 4-pin connectors for PWM fans.

What are the advantages of PWM fans regarding noise levels?

PWM fans can operate quietly at lower speeds, minimizing noise during idle conditions. This makes them quieter than DC fans, which often generate more noise as they operate at higher speeds, especially under steady thermal requirements.

Why might someone choose a DC fan over a PWM fan?

DC fans may be chosen for simpler configurations where constant speeds are sufficient, making them a cost-effective solution for basic cooling needs.