Overview

This article presents a comprehensive overview of seven essential micro fan blower models that are vital for electronics engineers. It underscores the critical role these devices play in effective heat management, showcasing their compact designs and advanced features that significantly enhance performance and reliability across various electronic applications.

Introduction

Innovative cooling solutions are increasingly vital for electronics engineers navigating the complexities of modern thermal management. As technology evolves rapidly, the demand for efficient micro fan blowers has surged, providing engineers with a powerful tool to combat overheating in compact electronic devices. However, with a plethora of models available, determining the most suitable micro fan blower for specific applications can be challenging. This article explores seven essential micro fan blower models, examining their unique features and benefits, while guiding engineers through the selection process to enhance performance and reliability in their designs.

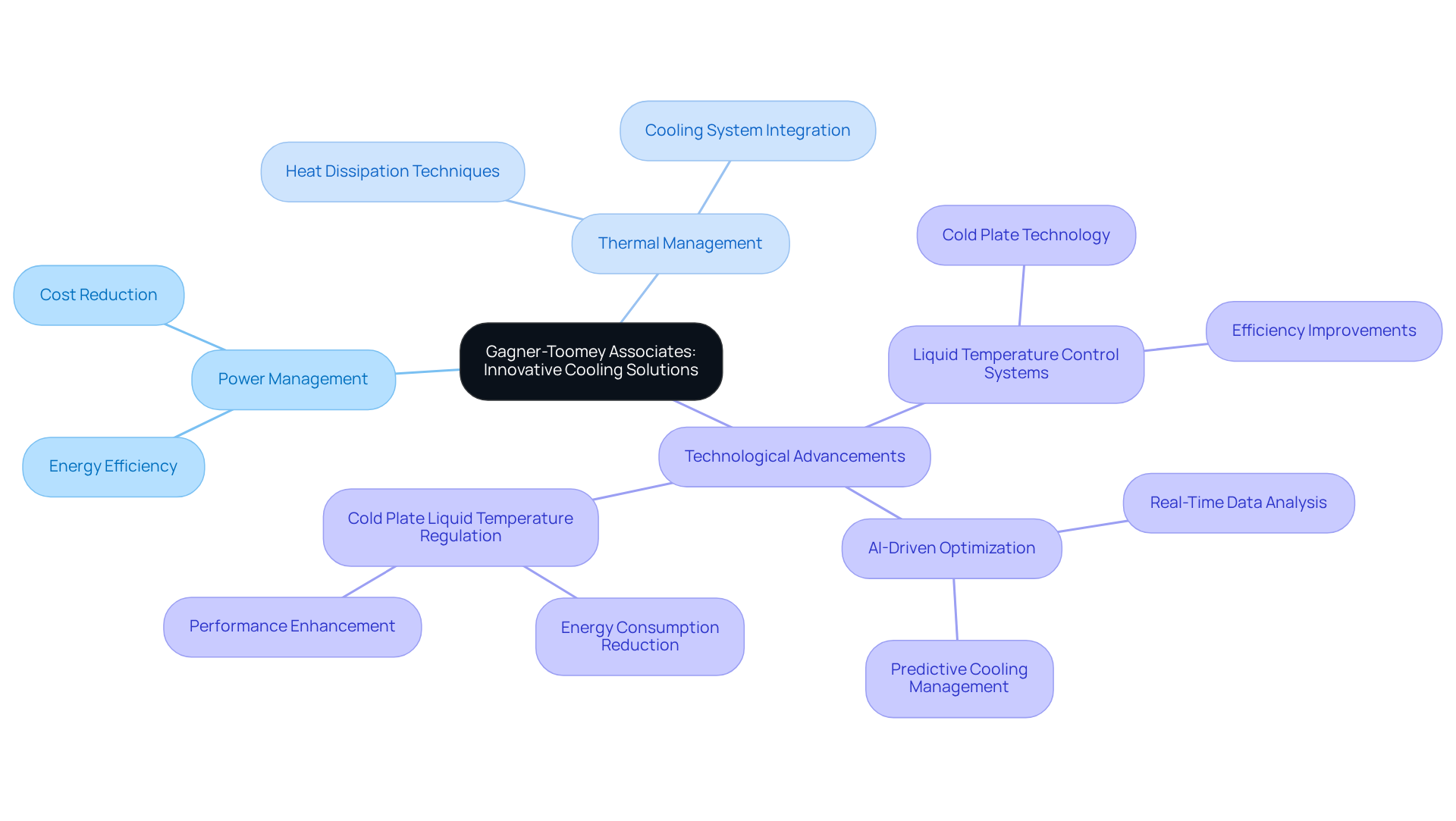

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineers

Gagner-Toomey Associates stands at the forefront of innovative specifically designed for electronics engineers. By concentrating on critical areas such as and , the company showcases a diverse portfolio of manufacturers that provide . Their unwavering commitment to excellence guarantees that engineers have access to the , empowering them to tackle effectively.

Recent advancements in , particularly and AI-driven optimization, are revolutionizing the thermal management landscape within electronics. For instance, cold plate liquid temperature regulation technology achieves an efficiency that surpasses conventional air-cooled systems by 80%, significantly reducing energy consumption.

As the demand for effective temperature regulation solutions escalates—especially with the increasing prevalence of —Gagner-Toomey remains steadfast in delivering the latest innovations to enhance performance and reliability in engineering designs. Industry leaders underscore the necessity of integrating to uphold optimal operating conditions, highlighting the essential role of effective thermal management in the electronics sector.

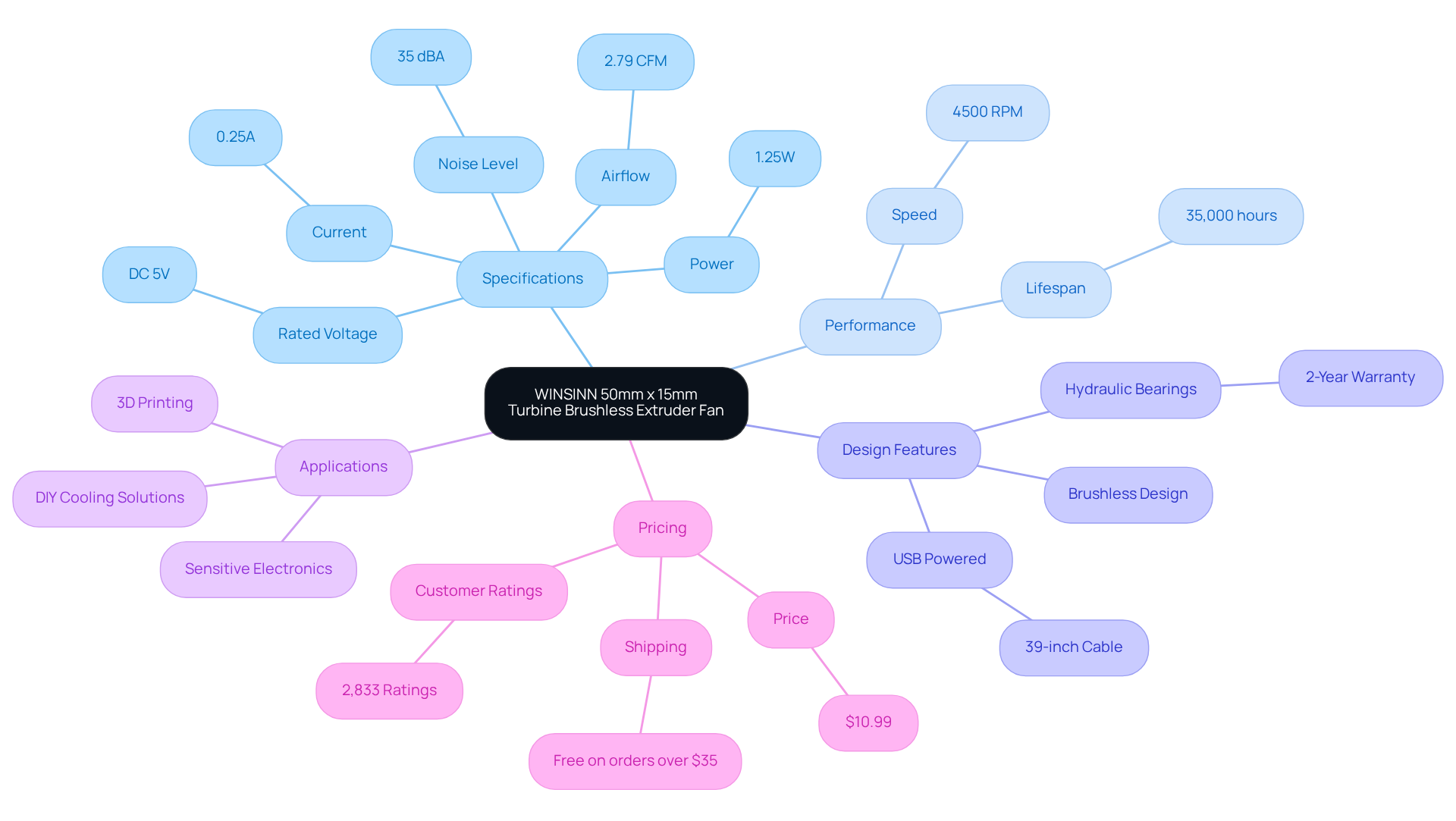

WINSINN 50mm x 15mm Turbine Brushless Extruder Fan: Compact and Efficient Cooling

The WINSINN 50mm x 15mm Turbine Brushless Extruder Fan serves as a compact and efficient , functioning as a specifically designed for tight spaces in electronic applications. The micro fan blower features a that not only extends its lifespan to an impressive 35,000 hours but also minimizes operational sound, making it an exceptional choice for environments such as 3D printing and other sensitive electronics.

With a of 2.79 CFM and a noise level of just 35 dBA, this micro fan blower effectively dissipates heat from critical components, ensuring . Furthermore, its robust construction and , supported by a 2-year warranty, enhance its durability.

The micro fan blower operates at a speed of 4500 RPM, generates an air pressure of 9.36 mmH₂O, and has a rated voltage of DC 5V, a current of 0.25A, and a power of 1.25W, making it a formidable option for compact refrigeration solutions in 2025. Its , featuring a convenient 39-inch cable, facilitates easy integration of the micro fan blower into various setups, whether at home, in the office, or during business trips.

Priced at $10.99, it also qualifies for free shipping on orders over $35, rendering it a practical choice for engineers seeking .

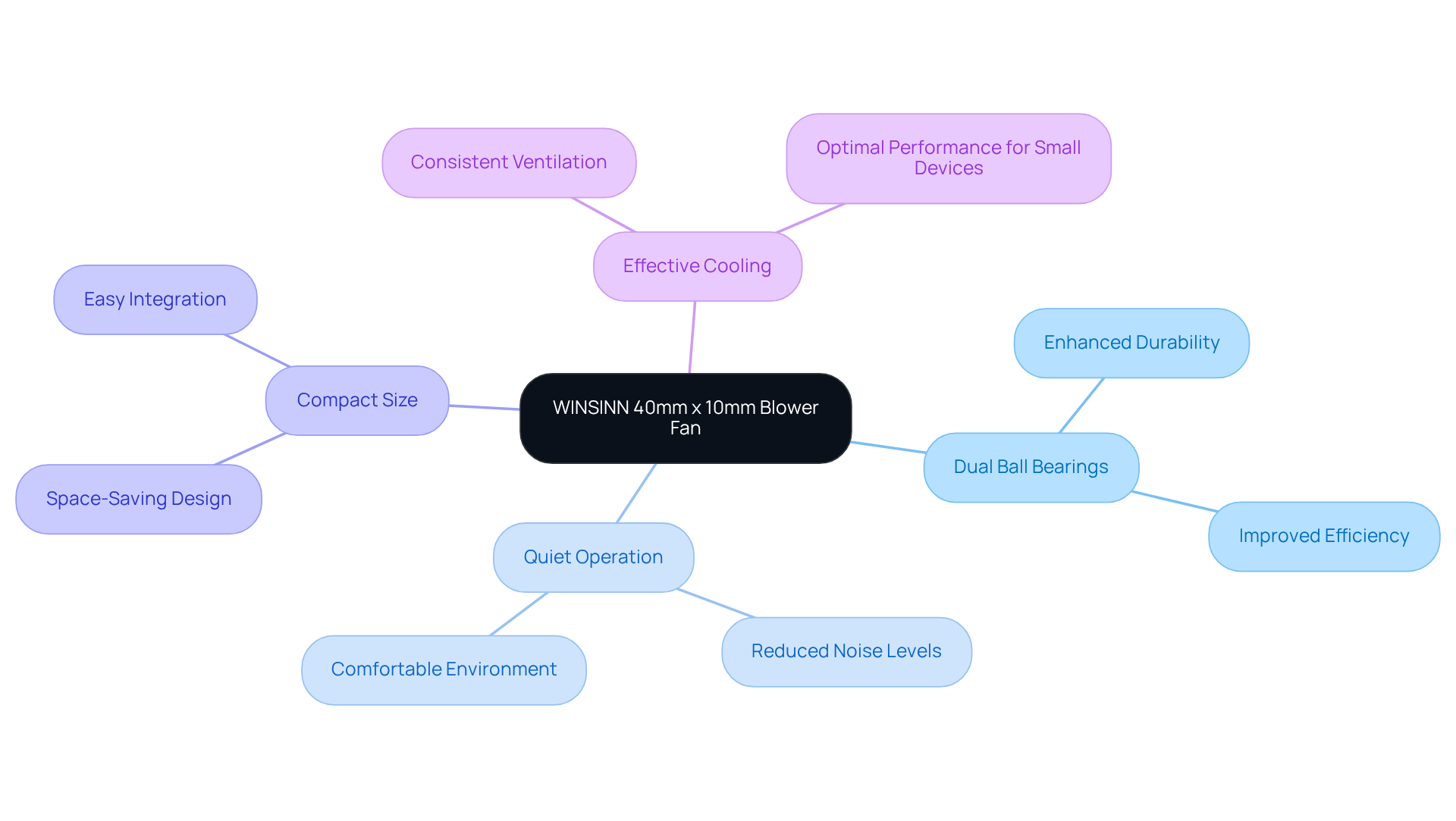

WINSINN 40mm x 10mm Blower Fan: Reliable Performance with Dual Ball Bearings

The WINSINN 40mm x 10mm Blower Fan stands out for its , engineered with dual ball bearings that significantly enhance durability and efficiency. This fan operates quietly while delivering , making it suitable for a variety of electronic applications, including small devices and enclosures. Its , coupled with , position it as a favored choice among . For those looking to , the WINSINN fan offers an exceptional blend of performance and reliability.

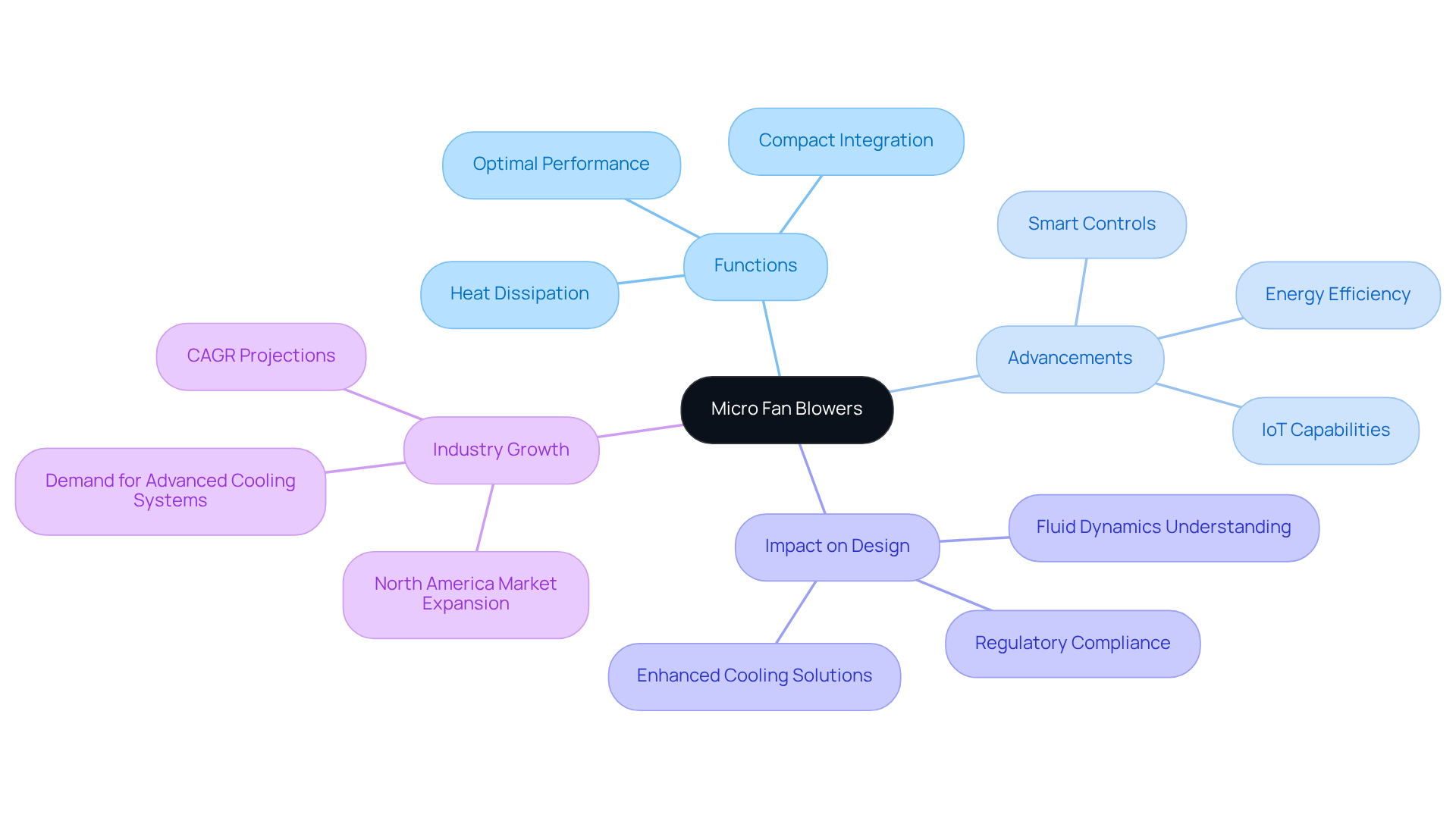

Micro Fan Blowers: Essential Tools for Heat Management in Electronics

in electronics relies on the use of . These compact devices, such as the micro fan blower, are engineered to facilitate air movement that dissipates heat from sensitive components, thereby preventing overheating and ensuring optimal performance. Their small size allows for seamless integration into tight spaces, making them , smartphones, and other compact electronic devices.

Recent advancements in , including smart controls and IoT capabilities, have resulted in significant improvements in energy efficiency and noise reduction, further enhancing their suitability for modern applications. Research indicates that inadequate ventilation contributes to approximately 30% of overheating occurrences in electronic devices, underscoring the management.

Micro fan blowers can effectively mitigate overheating risks by achieving average temperature reductions of up to 30%. As the demand for escalates, understanding the role of fluid dynamics becomes essential for .

with various manufacturers to supply engineers with cutting-edge technologies that bolster . As North America is projected to experience the highest growth rate in the ventilation and exhaust industry, micro fan blowers will remain essential in the evolution of electronic systems.

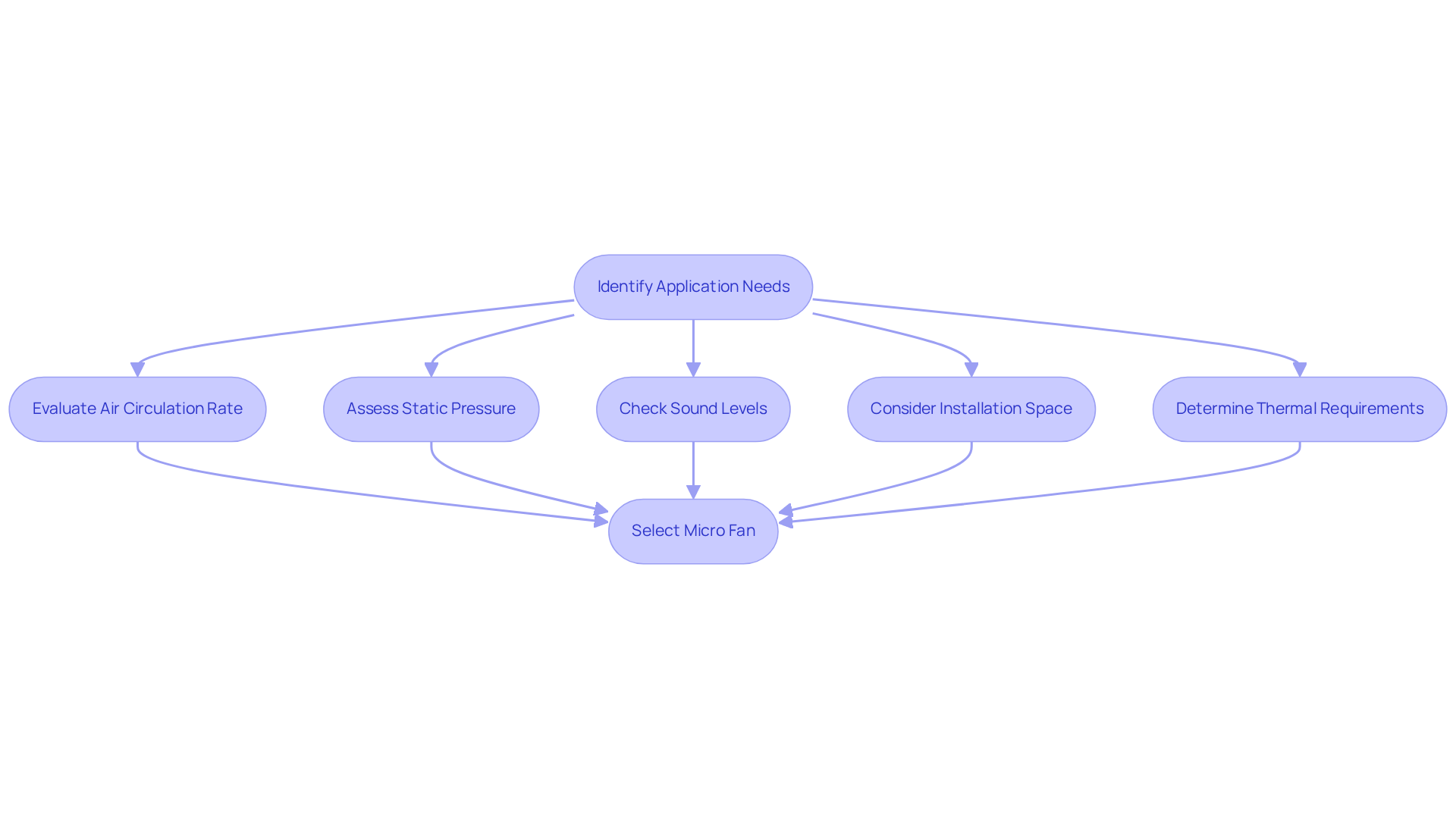

Choosing the Right Micro Fan Size and Specifications for Optimal Performance

Selecting a micro fan blower requires careful consideration of tailored to your specific application. The —such as , static pressure, and sound levels—must be thoroughly evaluated to ensure . Furthermore, the available and the of the components that need cooling. Choosing the right fan is not merely a preference; it can significantly and longevity of . Thus, making an in this regard is imperative.

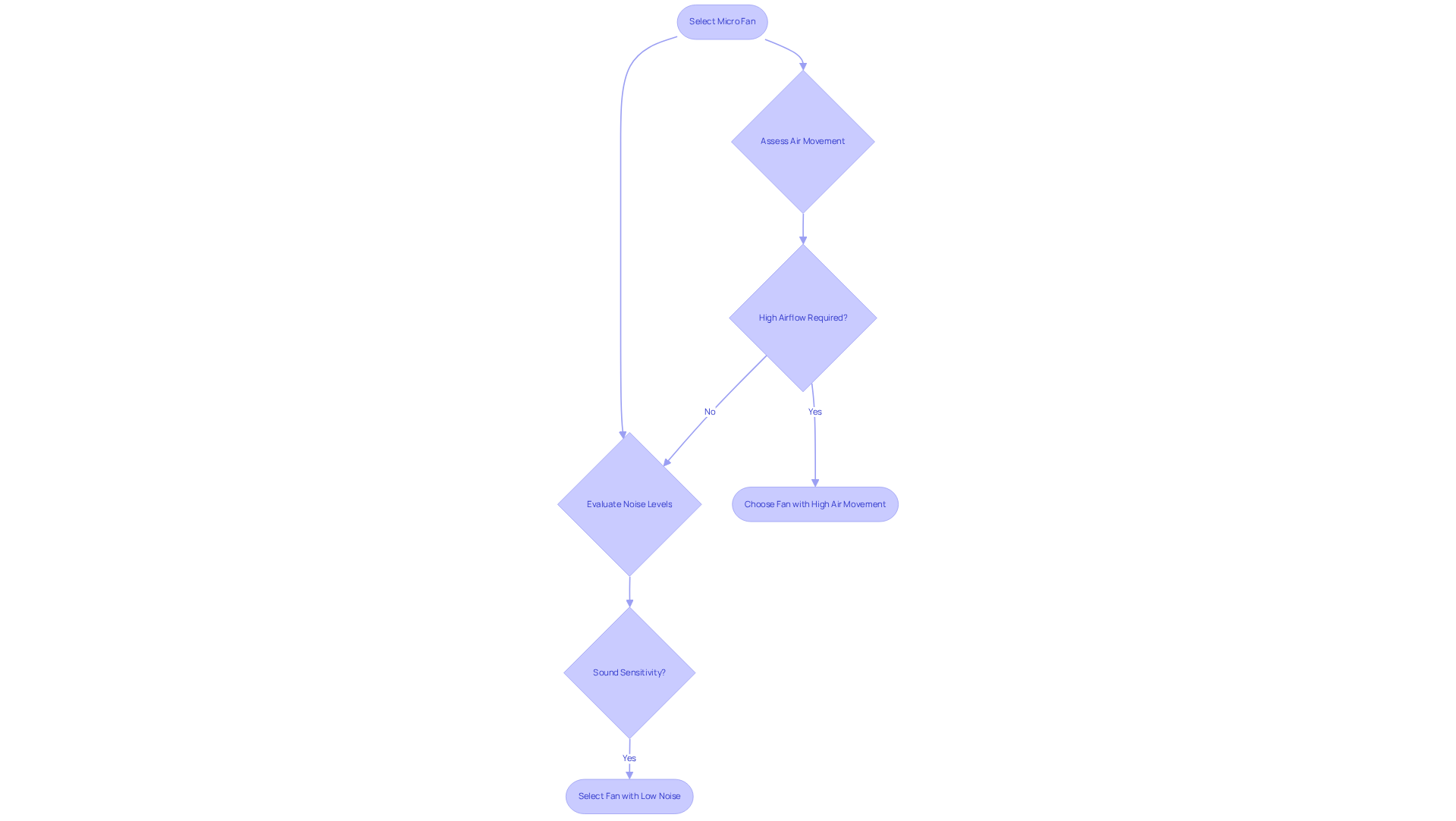

Airflow and Noise Levels: Key Considerations for Selecting Micro Fans

When selecting , engineers must carefully assess both and , especially with a . is essential for effective cooling, and a micro fan blower can provide this; however, it often leads to increased sound levels, which can be detrimental in sound-sensitive applications such as . For instance, sound levels of micro devices in these contexts typically range from 20 to 30 dBA, a critical factor for ensuring a positive . In medical environments, excessive noise can interfere with patient monitoring and comfort, which highlights the importance of selecting devices such as a micro fan blower that without compromising airflow.

Real-world examples underscore the importance of achieving this balance. In , the noise generated by cooling fans can distract medical personnel and hinder their concentration. Similarly, in consumer electronics like laptops and gaming consoles, the noise from the micro fan blower can diminish user satisfaction. Engineers can leverage (CFD) analysis, particularly through ANSYS Fluid Flow (Fluent) utilizing the K-épsilon turbulence model, to optimize fan designs, ensuring maximum air movement while keeping sound levels to a minimum.

To attain the desired performance, it is vital to scrutinize the specifications of the micro fan blower and perform testing in real-world scenarios. This approach not only aids in selecting the right fan model but also ensures that the final product meets the stringent sound requirements of sensitive applications. Balancing airflow and noise is not merely a technical hurdle; it is a fundamental aspect of delivering high-quality, reliable products that enhance the user experience.

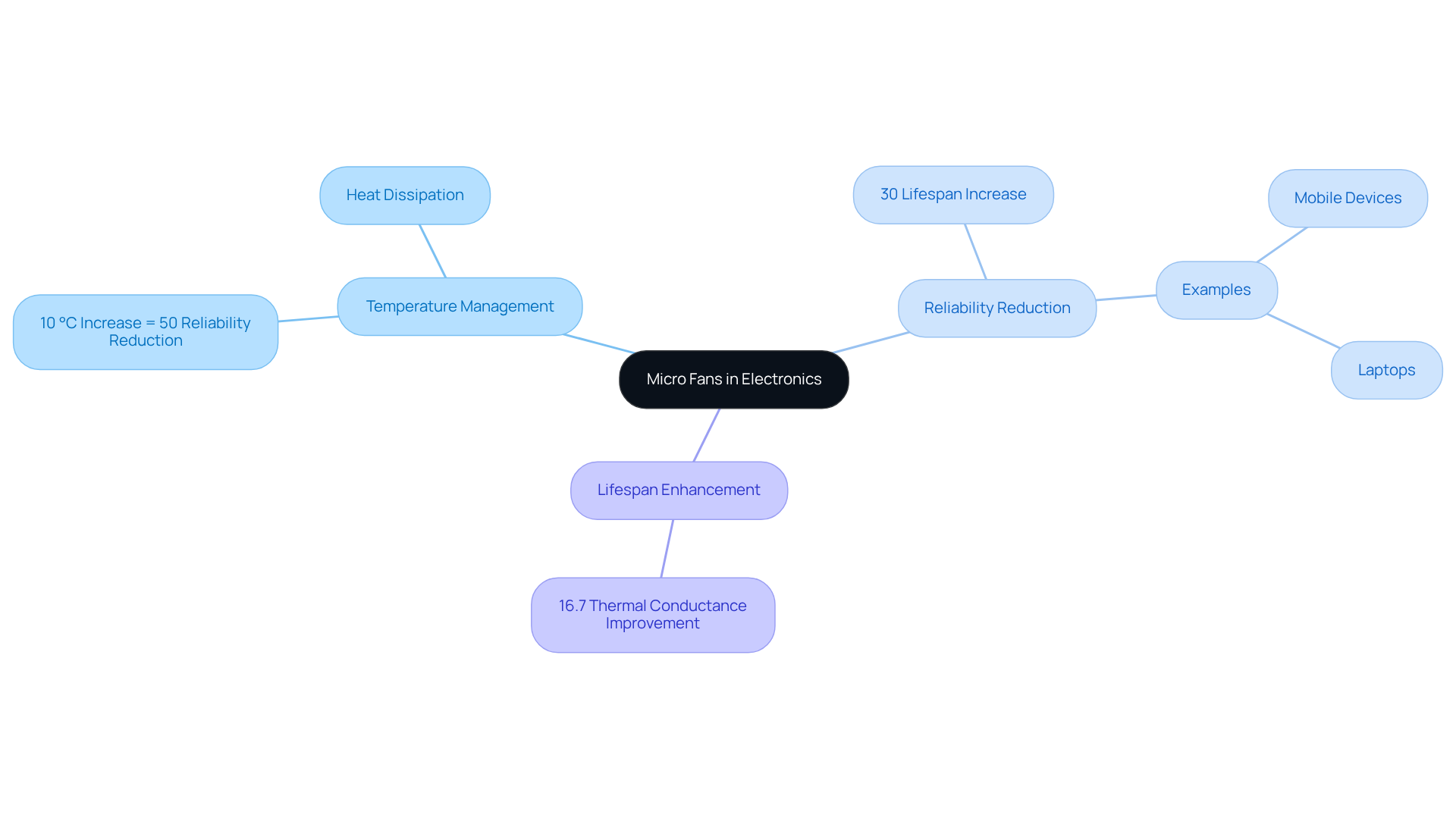

Enhancing Component Longevity: The Role of Micro Fans in Electronics

Micro devices play a pivotal role in by maintaining optimal operating temperatures. Overheating presents a ; a mere 10 °C increase in temperature can result in a staggering . By efficiently dissipating heat, the ensures that devices remain within safe temperature thresholds, thereby preventing premature failure of sensitive components and minimizing costly repairs and downtime.

For instance, the integration of has been shown to substantially prolong the typical lifespan of electronic components, with certain studies indicating enhancements of up to 30%. Notable applications include , where micro fan blowers have effectively mitigated overheating risks, ensuring consistent performance even under heavy workloads.

Furthermore, , such as the optimization of heat pipe geometry, have demonstrated a 16.7% improvement in thermal conductance, underscoring the critical role of micro devices in effective . As electronic devices continue to evolve, the necessity for becomes increasingly apparent, establishing them as an indispensable component of modern electronics.

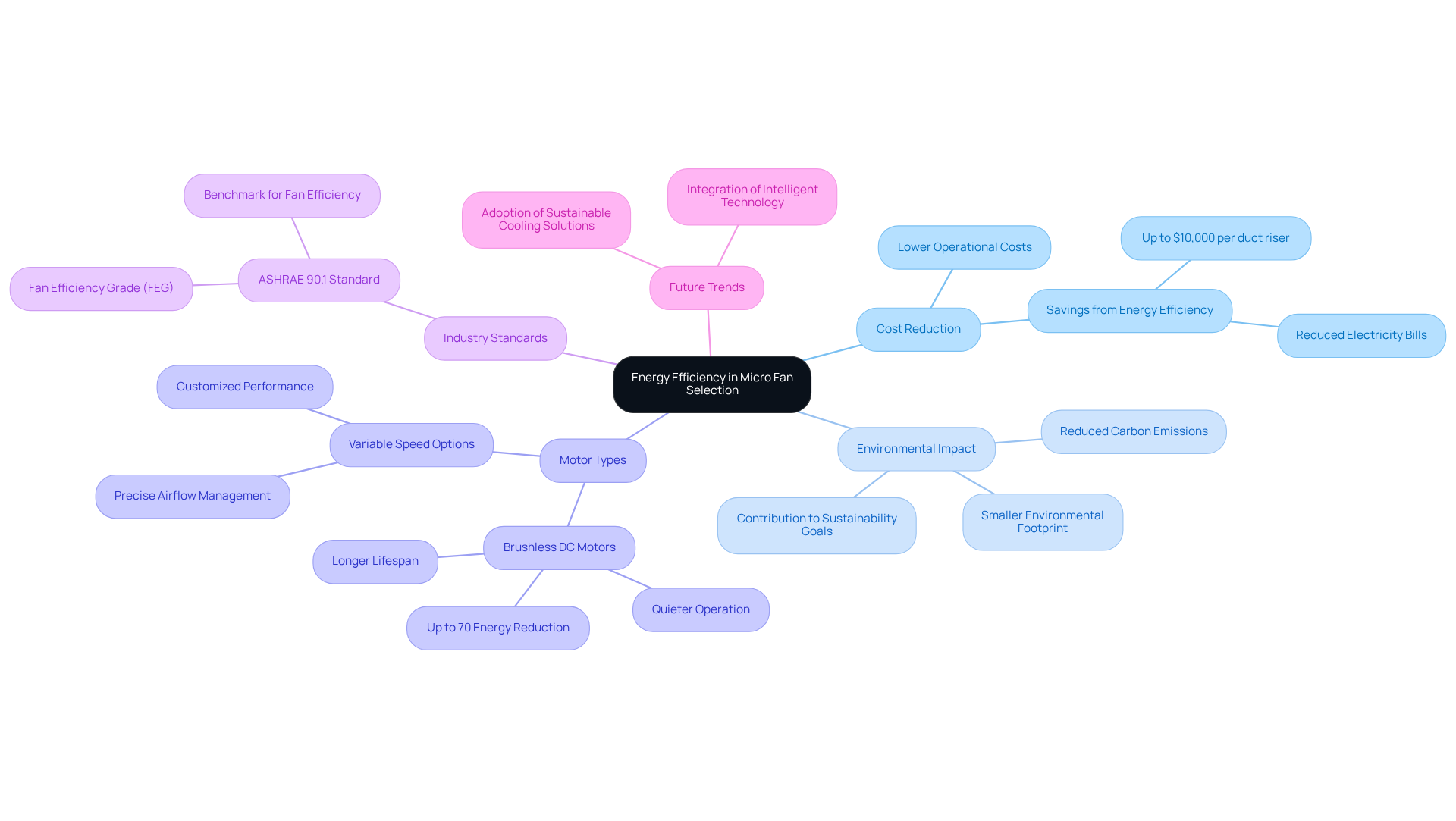

Energy Efficiency: A Crucial Factor in Micro Fan Selection

plays a pivotal role in the selection of devices like the , especially in the context of today’s environmentally conscious market. Micro fan blowers engineered for lower power consumption not only reduce operational costs but also bolster the sustainability of electronic devices. For instance, can cut energy usage by up to 70% compared to traditional AC motors, significantly impacting both utility expenses and environmental footprint.

Moreover, HVAC systems can account for over 50% of total energy consumption in multi-family buildings, underscoring the importance of energy-efficient units within broader energy usage frameworks. Engineers must prioritize micro fan blowers with , particularly those employing , which not only enhance performance but also reduce energy consumption. These motors facilitate precise airflow management and offer , enabling customized performance tailored to specific temperature requirements.

As we approach 2025, the adoption of in electronics becomes increasingly critical, with advancements in micro fan blower technology leading the charge. The integration of intelligent technology within these systems further amplifies their efficiency, rendering them essential in contemporary electronic applications.

Experts advocate for a shift towards , highlighting their performance and cost-effectiveness as vital components of sustainable development in the electronics sector. Additionally, the established by the ASHRAE 90.1 standard provides a benchmark for fan efficiency, guiding engineers in their decision-making process. Insights from industry leaders, such as ENERVEX’s perspectives on , vividly illustrate the practical benefits of embracing energy-efficient devices.

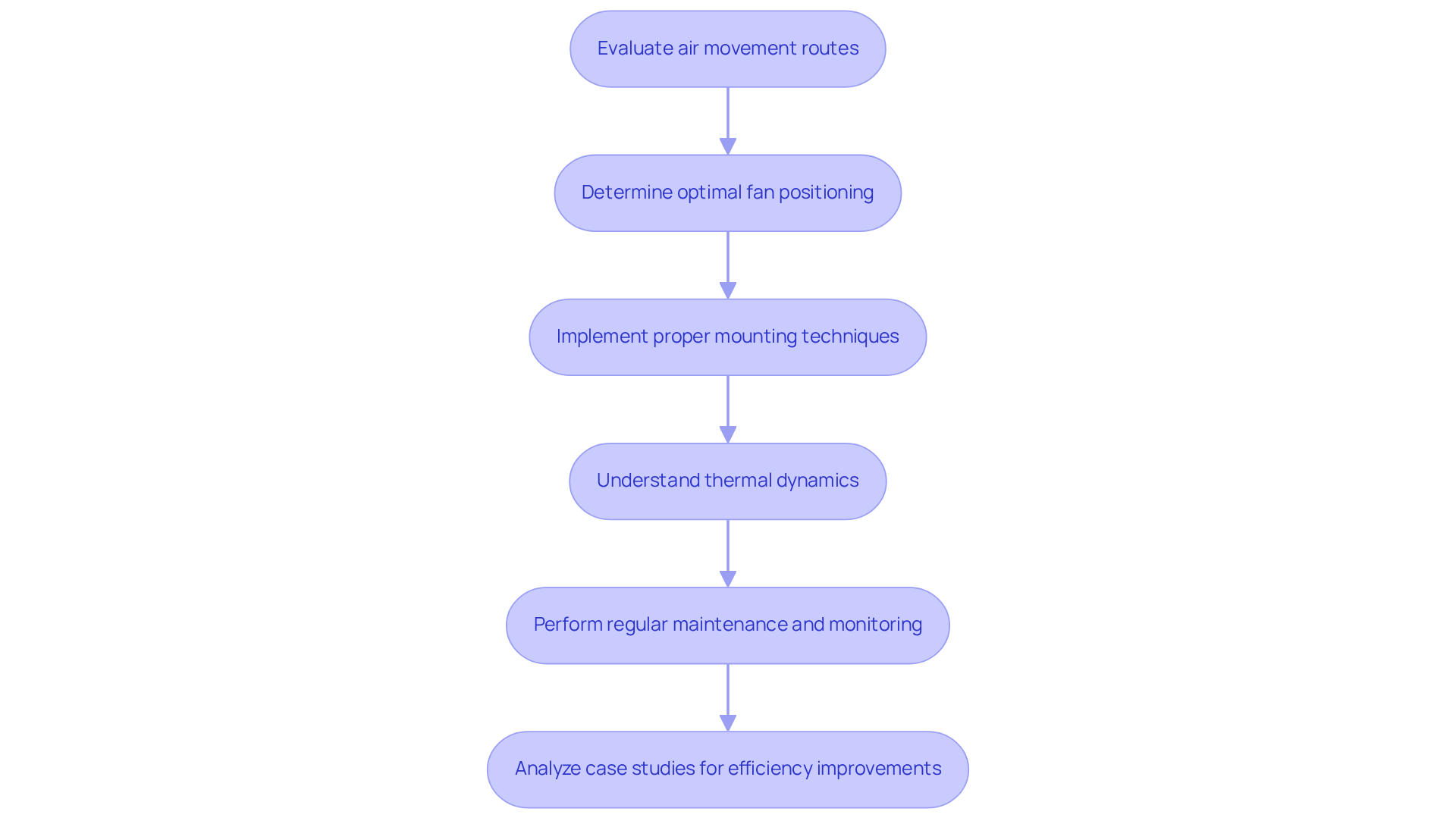

Integrating Micro Fans into Complex Electronic Systems: Best Practices

Integrating a into complex electronic systems presents a significant challenge that demands meticulous planning and execution. Engineers must begin by to identify the , ensuring that air can circulate freely without obstruction. Proper mounting techniques for a micro fan blower are not merely recommendations; they are essential, as they can dramatically .

Furthermore, a comprehensive understanding of the of the entire system—including the precise locations of heat sources and sinks—is critical for maximizing the performance of the micro fan blower. are indispensable for over time, as they facilitate the early identification of potential issues before they escalate.

Case studies have consistently demonstrated that the strategic use of a micro fan blower can yield , with some designs achieving optimized ventilation that reduces by over 10 degrees Celsius. By prioritizing these , engineers can significantly enhance the reliability and longevity of their electronic systems.

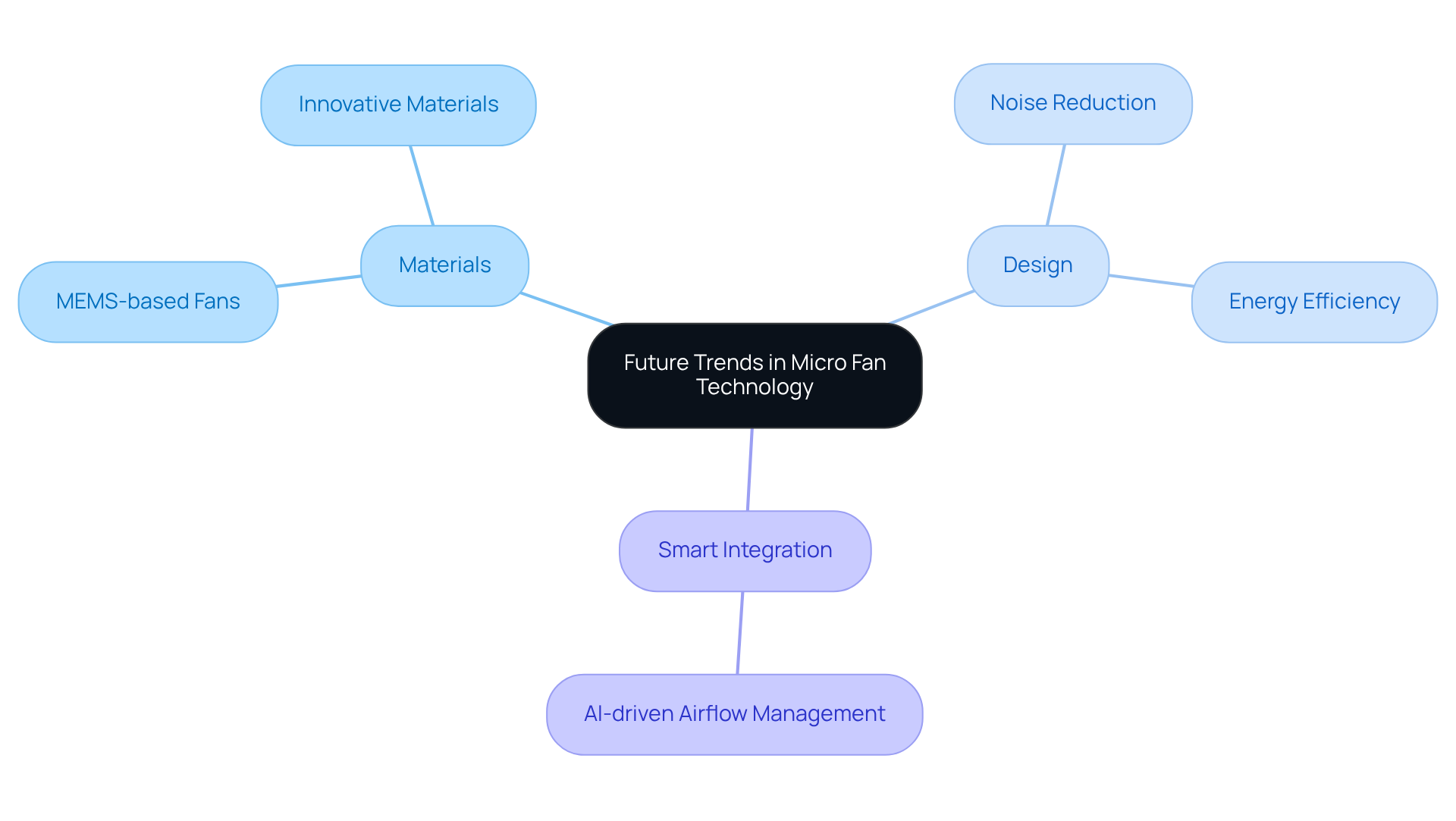

Future Trends in Micro Fan Technology: What Electronics Engineers Should Know

Future trends in are poised for significant advancements in materials, design, and integration with smart systems. Innovations such as and micro fan blowers, along with , promise to revolutionize . about these developments, as leveraging new technologies can enhance performance, reduce noise, and improve in their designs.

Conclusion

The landscape of electronics engineering is increasingly shaped by the pivotal role of micro fan blowers in thermal management. These compact devices not only facilitate efficient heat dissipation but also enhance the longevity and reliability of electronic components. As engineers seek to optimize their designs, understanding the various models and technologies available, such as those offered by Gagner-Toomey Associates and WINSINN, becomes essential.

Key insights highlighted throughout the article include:

- The significance of selecting the right micro fan blower based on specifications like airflow, noise levels, and energy efficiency.

- The advancements in micro fan technology, including smart controls and innovative materials, underscore their importance in modern applications.

- Best practices for integrating these fans into complex systems were discussed, emphasizing the need for careful planning and execution.

As the demand for innovative cooling solutions continues to rise, engineers are encouraged to stay informed about emerging technologies and trends within the micro fan industry. By prioritizing effective thermal management and energy efficiency, they can not only enhance the performance of their electronic systems but also contribute to sustainable practices in the field. Embracing these advancements will be crucial for engineers striving to meet the challenges of tomorrow’s electronic landscape.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for its innovative temperature control solutions specifically designed for electronics engineers, focusing on power management and thermal management.

What recent advancements are influencing thermal management in electronics?

Recent advancements include liquid temperature control systems and AI-driven optimization, which are significantly improving the thermal management landscape within electronics.

How efficient are cold plate liquid temperature regulation technologies compared to conventional air-cooled systems?

Cold plate liquid temperature regulation technology achieves an efficiency that surpasses conventional air-cooled systems by 80%, leading to significant reductions in energy consumption.

Why is effective temperature regulation increasingly important in electronics?

The demand for effective temperature regulation solutions is rising due to the increasing prevalence of high-performance servers, which require optimal operating conditions to enhance performance and reliability.

What is the WINSINN 50mm x 15mm Turbine Brushless Extruder Fan designed for?

The WINSINN 50mm x 15mm Turbine Brushless Extruder Fan is designed as a compact and efficient cooling solution for tight spaces in electronic applications, such as 3D printing.

What are the key features of the WINSINN 50mm x 15mm Turbine Brushless Extruder Fan?

Key features include a lifespan of 35,000 hours, maximum airflow of 2.79 CFM, noise level of 35 dBA, 4500 RPM speed, and a USB-powered design with a 39-inch cable.

What is the price of the WINSINN 50mm x 15mm Turbine Brushless Extruder Fan?

The fan is priced at $10.99 and qualifies for free shipping on orders over $35.

What makes the WINSINN 40mm x 10mm Blower Fan notable?

The WINSINN 40mm x 10mm Blower Fan is notable for its reliable performance, dual ball bearings for enhanced durability, and quiet operation, making it suitable for various electronic applications.

What applications is the WINSINN 40mm x 10mm Blower Fan suitable for?

This blower fan is suitable for small devices and enclosures, providing effective cooling capabilities in compact dimensions.