Overview

The primary advantages of utilizing frameless BLDC motors in electronics encompass enhanced energy efficiency, a compact design, and minimal maintenance requirements. Collectively, these factors contribute to superior performance and lower operational costs. This article elucidates how these motors effectively minimize operational losses, integrate seamlessly into diverse applications, and eliminate wear parts. Consequently, they emerge as optimal solutions for industries prioritizing sustainability and efficiency.

Introduction

In a world increasingly driven by the need for efficiency and sustainability, frameless brushless DC (BLDC) motors emerge as a transformative technology within the electronics industry. Their compact design, minimal maintenance requirements, and outstanding energy efficiency are revolutionizing applications across diverse sectors, including:

- Robotics

- Healthcare

- Industrial automation

As urbanization accelerates and the demand for greener technologies intensifies, Gagner-Toomey Associates positions itself at the forefront, delivering customized solutions that enhance both performance and reliability. This article explores the multifaceted advantages of frameless BLDC motors, highlighting their pivotal role in shaping the future of technology while addressing the pressing challenges faced in modern engineering.

Gagner-Toomey Associates: Innovative Solutions for Frameless BLDC Motors

Gagner-Toomey Associates stands at the forefront of providing customized, innovative solutions for brushless DC drives, ensuring that engineers are equipped with the latest advancements in technology. By partnering with leading manufacturers, the company significantly enhances performance and efficiency across a variety of applications. Their expertise in critical areas such as cooling and power management greatly optimizes the efficiency of frameless bldc motors, positioning Gagner-Toomey as a pivotal player in the evolving landscape of the electronics sector.

As the demand for electric engines escalates—driven by urban development and an increased emphasis on eco-friendly technologies—Gagner-Toomey remains at the cutting edge, championing the adoption of these groundbreaking solutions. The company’s unwavering commitment to exceptional customer support and the cultivation of are integral to its long-term objectives and foundational values.

Energy Efficiency: Maximizing Performance with Frameless BLDC Motors

Frameless BLDC motors are designed to significantly enhance energy efficiency by minimizing operational losses. Their innovative design enables direct integration into various systems, thus eliminating the necessity for additional components that can contribute to energy wastage. This streamlined approach not only boosts performance but also leads to substantial reductions in operational costs and a lowered carbon footprint.

Research indicates that the implementation of borderless brushless direct current devices can yield average energy savings of up to 30% compared to conventional system types. Real-world applications underscore these benefits, with companies reporting considerable decreases in energy consumption and operational expenditures.

A case study examining the initiation of with high load torque illustrates a method for synchronous frame current regulation that improves machine performance, thereby highlighting the operational advantages of borderless brushless direct current systems.

Furthermore, as Hugh Herr noted, “The introduction of a higher voltage resulted in a more accelerated rise in temperature, but this did not significantly impact the device’s efficiency during the test interval.”

As the demand for energy efficiency escalates within the electronics sector, the frameless BLDC motor stands out as an exemplary choice for applications prioritizing sustainability and cost-effectiveness.

Compact Design: Space-Saving Advantages of Frameless BLDC Motors

Frameless BLDC motors are distinguished by their compact design, which removes the need for traditional housings. This innovative structure facilitates seamless integration into devices, significantly conserving space in applications such as robotics and medical equipment. The reduced footprint not only enhances design flexibility but also contributes to lighter overall systems, a critical factor for portable and mobile applications.

For example, the Turntide Axial Flux Motor 125 exemplifies this advantage, achieving an impressive power density of up to 7 kW/kg and a peak efficiency of 95%. As Brian Casey notes, “This, in turn, enables axial-flux electric machines to provide more power in a compact design.”

Furthermore, across all sizes of borderless brushless direct current devices reaches up to 1.430 W, showcasing their performance capabilities. Additionally, average size reduction data indicate that devices utilizing borderless brushless direct current engines can achieve substantial space savings, underscoring the importance of compact design in contemporary electronics.

As the industry progresses into 2025, the demand for space-efficient technologies continues to escalate, highlighting the vital role of frameless BLDC motors in enhancing design and functionality across various sectors.

Reliability: Ensuring Long-Term Performance with Frameless BLDC Motors

Frameless BLDC motors exemplify exceptional reliability, as they are meticulously engineered with high-quality materials and cutting-edge manufacturing techniques. Innovations in these processes and materials are set to enhance the durability and efficiency of these devices, effectively lowering production costs and minimizing potential failure points. This commitment to quality ensures reliable performance even in demanding environments, which is crucial in high-pressure sectors such as aerospace and medical equipment, where operational failure is simply unacceptable.

Notably, is projected to capture a significant 25.4% of global market income by 2034, underscoring the growing confidence in these machines and their dependability for essential applications. Key market players, including:

- Allied Motion Technologies

- Mclennan Servo Supplies Ltd.

- Moog Inc.

are pivotal in driving advancements in frameless BLDC motors, further solidifying the reputation of frameless BLDC motors. Users can rely on these devices for long-term performance with minimal maintenance, making them an optimal choice for critical applications.

Low Maintenance: Cost-Effective Operation of Frameless BLDC Motors

Frameless BLDC motors present a compelling solution for manufacturers seeking efficiency and cost-effectiveness. Their brushless configuration eliminates wear parts, significantly reducing the need for frequent replacements. This design innovation not only minimizes downtime but also lowers the , making these devices an attractive option for manufacturers. The inherent simplicity of their design facilitates seamless integration into existing systems, thereby enhancing operational efficiency and alleviating maintenance burdens.

Companies that have adopted these devices report substantial cost reductions due to decreased maintenance requirements. Notably, statistics indicate that brushless direct current devices can generate a torque ripple of approximately 14% due to the six-step commutation technique, which may influence overall performance. Furthermore, case studies, such as those from Applimotion, demonstrate how tailored solutions have empowered clients to select the most suitable frameless BLDC motor for their specific applications, leading to improved operational outcomes. The versatility of these frameless BLDC motors is evident in their wide-ranging applications, including:

- Industrial robots

- Robotic surgery

- Respiratory equipment

- Humanoid robots

- Material handling robots

This highlights their effectiveness in various high-demand environments, underscoring the value they bring to modern manufacturing and automation.

Versatility: Application Flexibility of Frameless BLDC Motors

Frameless BLDC motors exhibit remarkable versatility, making them suitable for a diverse range of applications, from robotics to medical devices and industrial automation. Their capacity for customization enables engineers to develop tailored solutions that fulfill distinct performance criteria. This adaptability represents a significant advantage in fast-paced industries, where the ability to pivot is crucial for success.

The surge in automation systems within manufacturing, driven by the shift towards Industry 4.0, has markedly increased the demand for brushless DC devices. These machines are celebrated for their precision, efficiency, and prolonged operational lifespan, establishing their necessity in automated factories and robotics, particularly within the healthcare and logistics sectors.

The customization options available for frameless BLDC motor devices are extensive, facilitating modifications that improve thermal resistance and operational efficiency. This aligns with for eco-friendly solutions, particularly in electric vehicles, where the low operational temperatures of the engines contribute to sustainability goals. As Erik Perison, US TPS Business Development Manager at Thermon, observes, “The overall trend indicates a strong growth trajectory for the coming years, propelled by technological advancements and expanding application areas.”

Furthermore, the case study titled ‘Drivers and Restraints of the Frameless BLDC Motor Market‘ underscores the environmental benefits of frameless BLDC motors, reinforcing their compatibility with sustainability trends. As industries continue to evolve, the adaptability of the frameless BLDC motor will be vital in addressing the diverse challenges faced in contemporary engineering.

Quiet Operation: Noise Reduction Benefits of Frameless BLDC Motors

Frameless brushless direct current machines are engineered for exceptionally low noise levels, making them particularly suitable for applications where silence is paramount, such as in medical equipment and residential settings. Their brushless architecture and optimized design facilitate smoother operation and markedly lower acoustic emissions. This quiet functionality not only enhances user experience but also is crucial in environments where noise can interfere with operational efficiency and safety.

For example, a study involving ICU nurses revealed that excessive noise from medical devices negatively impacts both staff performance and patient safety, with 95% of surveyed personnel acknowledging that noise levels were distracting and detrimental to their focus. This highlights the pressing need for .

By integrating frameless bldc motors, engineers can create a quieter healthcare environment, ultimately improving patient outcomes and staff productivity. The significance of noise reduction in medical devices is paramount, as it directly influences patient comfort and operational efficacy.

Comparatively, frameless bldc motors demonstrate a marked advantage over traditional devices, with noise levels reduced by up to 16 decibels in specific applications, as noted by RN Mark van den Boogaard. This capability is essential for devising innovative solutions that prioritize both performance and user well-being in noise-sensitive settings.

High Torque-to-Weight Ratio: Enhancing Performance with Frameless BLDC Motors

Frameless BLDC motors are distinguished by their exceptional high torque-to-weight ratio, which enables outstanding performance while minimizing bulk. This characteristic proves particularly advantageous in applications such as drones and robotic systems, where weight reduction significantly enhances efficiency and maneuverability. The lightweight design of these devices empowers engineers to create more agile systems that adhere to stringent performance standards.

The U.S. military’s increased investment in UAV technology, exemplified by devices like the MQ-9 Reaper, underscores the growing demand for lightweight engines, driven by advancements in drone technology. Case studies, including ‘Future Trends in Drone Technology,’ further emphasize the critical role of high torque-to-weight ratios in enhancing drone performance, illustrating how frameless BLDC motors contribute to improved stability and efficiency.

As continues to expand, the integration of these advanced engines will be vital for achieving the next generation of aerial vehicles. Moreover, the DC type segment, which includes the frameless BLDC motor, is projected to account for 68.5% of global market revenue by 2034, underscoring the significance of these devices within the broader market landscape.

Advanced Control: Precision Engineering with Frameless BLDC Motors

Frameless BLDC motors are at the forefront of advanced control capabilities, enabling remarkable accuracy in movement and positioning. Their innovative design facilitates seamless integration with sophisticated control systems, rendering them ideal for applications that demand high accuracy and rapid responsiveness. This level of precision is particularly crucial in fields such as robotics, automation, and aerospace, where even the slightest variation can result in significant operational challenges.

Recent research indicates that the adaptive JAYA algorithm serves as a powerful tool for optimizing performance, specifically enhancing the efficiency and responsiveness of the frameless BLDC motor. A notable case study on PID controller design for demonstrated how intelligent optimization algorithms can exceed the limitations of traditional calculations, providing tailored solutions for brushless DC device design.

As the demand for automation and robotics escalates, the brushless DC machinery market is projected to experience substantial growth, with forecasts suggesting a growth rate of X% in the coming years. This anticipated expansion underscores the critical importance of precision engineering in control systems, particularly as technological advancements amplify the need for accuracy in automation processes. The synergy between advanced control systems and frameless BLDC motor devices not only enhances performance but also guarantees reliability in precision engineering applications.

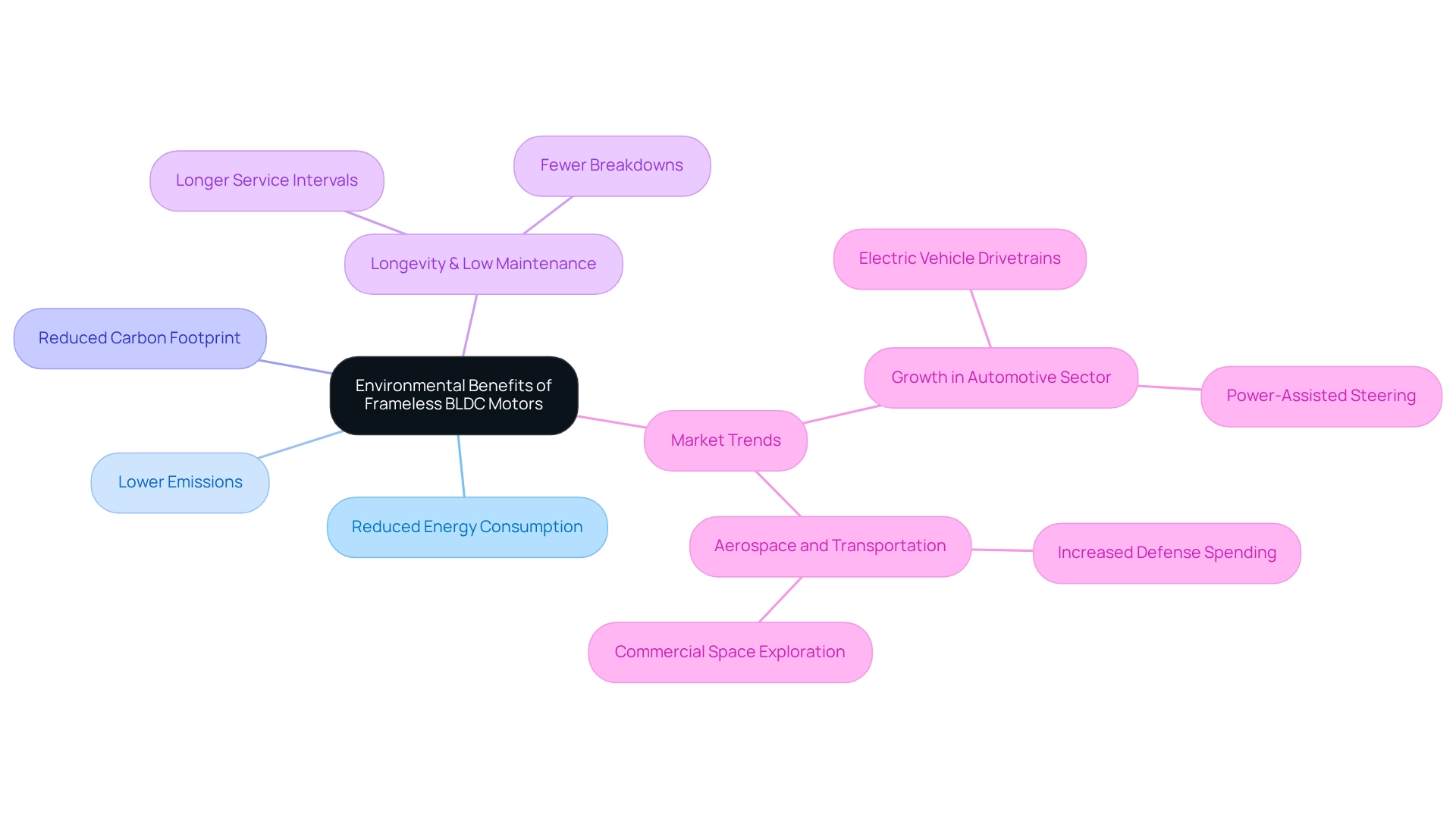

Environmental Benefits: Sustainable Solutions with Frameless BLDC Motors

The frameless BLDC motor is pivotal in promoting environmental sustainability, significantly reducing energy consumption and minimizing waste. Their innovative design incorporating a frameless bldc motor not only results in lower emissions but also contributes to a reduced carbon footprint, making them a compelling choice for organizations dedicated to green initiatives. Additionally, the longevity and low maintenance requirements of devices like the frameless bldc motor further amplify their ecological advantages, as they decrease the frequency of replacements and the associated waste.

The brushless DC machinery market is currently experiencing growth, driven by the escalating demand for energy-efficient technologies across various sectors. Notably, vehicles represent the primary end-use category for brushless direct current motors, with these technologies being integrated into applications such as electric vehicle drivetrains and power-assisted steering. This transition is particularly pronounced in the , where BLDC drives are supplanting traditional components, propelled by increased defense spending and commercial space exploration.

As we approach 2025, the focus on sustainable motor technologies continues to intensify, with experts advocating for the adoption of solutions that not only enhance performance but also align with environmental objectives. Companies that embrace these advancements are not only enhancing their operational efficiency but also contributing to a more sustainable future.

Conclusion

Frameless brushless DC (BLDC) motors signify a pivotal advancement in the electronics industry, presenting numerous advantages that meet the demands of contemporary engineering. Their compact design facilitates seamless integration across a spectrum of applications, from robotics to healthcare, while optimizing energy efficiency and minimizing operational costs. With reported energy savings of up to 30% compared to traditional motors, these systems not only enhance performance but also contribute to a more sustainable environment.

The reliability and low maintenance requirements of frameless BLDC motors further establish their status as the preferred choice for critical applications. Their robust construction guarantees consistent performance, even in high-stakes environments, while the elimination of wear components diminishes downtime and total ownership costs. The versatility of these motors, combined with their advanced control capabilities, positions them as essential tools for industries navigating rapid transformation, particularly in the context of automation and smart technologies.

As global priorities increasingly shift towards sustainability, the environmental benefits of frameless BLDC motors are paramount. Their capacity to lower emissions and reduce waste aligns seamlessly with worldwide efforts toward greener technologies. By embracing these innovative solutions, organizations not only boost operational efficiency but also play a crucial role in promoting a sustainable future. In conclusion, frameless BLDC motors are not merely a technological advancement; they serve as a key enabler of efficiency, reliability, and sustainability in the evolving landscape of engineering and manufacturing.

Frequently Asked Questions

What solutions does Gagner-Toomey Associates provide for brushless DC drives?

Gagner-Toomey Associates offers customized, innovative solutions for brushless DC drives, enhancing performance and efficiency across various applications by partnering with leading manufacturers.

How does Gagner-Toomey Associates optimize the efficiency of frameless BLDC motors?

The company specializes in critical areas such as cooling and power management, which greatly optimize the efficiency of frameless BLDC motors.

What is driving the demand for electric engines, according to Gagner-Toomey?

The demand for electric engines is increasing due to urban development and a greater emphasis on eco-friendly technologies.

What role does customer support play in Gagner-Toomey Associates’ operations?

Exceptional customer support and strong distributor relationships are integral to Gagner-Toomey’s long-term objectives and foundational values.

What are frameless BLDC motors designed to achieve?

Frameless BLDC motors are designed to enhance energy efficiency by minimizing operational losses and allowing for direct integration into systems, eliminating the need for additional components that can waste energy.

What energy savings can be expected from implementing frameless BLDC motors?

The implementation of frameless BLDC motors can yield average energy savings of up to 30% compared to conventional systems.

Can you provide an example of the operational advantages of frameless BLDC motors?

A case study highlighted synchronous frame current regulation in large power electric machines with high load torque, demonstrating improved machine performance through the use of borderless brushless direct current systems.

How do frameless BLDC motors contribute to sustainability?

They lead to substantial reductions in operational costs and carbon footprints, making them an exemplary choice for applications prioritizing sustainability and cost-effectiveness.

What is a key design feature of frameless BLDC motors?

Frameless BLDC motors have a compact design that removes the need for traditional housings, facilitating seamless integration into devices and conserving space.

What performance metrics are associated with frameless BLDC motors?

For instance, the Turntide Axial Flux Motor 125 achieves a power density of up to 7 kW/kg and a peak efficiency of 95%, showcasing the performance capabilities of frameless BLDC motors.

Why is compact design important in contemporary electronics?

The compact design of frameless BLDC motors enhances design flexibility and contributes to lighter overall systems, which is critical for portable and mobile applications.

What is the highest rated power across borderless brushless direct current devices?

The highest rated power across all sizes of borderless brushless direct current devices reaches up to 1,430 W.

How is the demand for space-efficient technologies expected to evolve?

As the industry progresses into 2025, the demand for space-efficient technologies is expected to escalate, underscoring the vital role of frameless BLDC motors in enhancing design and functionality across various sectors.