Overview

This article primarily emphasizes the critical role of high-temperature fans tailored for diverse electronics applications. It explores various manufacturers and their groundbreaking solutions, underscoring the significance of these fans in enhancing energy efficiency, ensuring safety, and optimizing operational performance across sectors such as:

- Metal processing

- Chemical manufacturing

- Food production

Introduction

High-temperature fans are increasingly vital in the electronics industry, driven by the surging demand for effective temperature regulation solutions. Projections indicate significant growth in the Electronics Thermal Management Solutions market, presenting engineers with a unique opportunity to explore innovative fan technologies that not only enhance performance but also improve energy efficiency. However, as applications grow more complex, a pressing challenge emerges: how can engineers ensure reliability and longevity in high-temperature environments while simultaneously meeting stringent operational demands?

Gagner-Toomey Associates: Leading Provider of High-Temperature Fan Solutions

Gagner-Toomey Associates stands out as a premier supplier of , focusing on innovative tailored for the electronics sector. The company is committed to excellence, representing a diverse portfolio of manufacturers renowned for their . Their expertise in temperature regulation, , and ensures that engineers have access to reliable and efficient solutions, including high temperature fans, for high-temperature applications.

The global is anticipated to expand from $6,416.7 million in 2024 to $11,653.3 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.9%. This growth underscores the increasing demand for . Industry leaders, including Delta Electronics, highlight the importance of energy-efficient temperature regulation technologies, which aligns with Gagner-Toomey’s dedication to in product representation.

Moreover, the successful implementation of cooling technologies, including high temperature fans, by Gagner-Toomey Associates illustrates their capability to address the challenges posed by elevated temperature environments.

AirPro Fan: High-Temperature Blower Fans for Extreme Conditions

AirPro presents a range of meticulously engineered to perform exceptionally in extreme conditions, capable of withstanding temperatures up to 1800°F. Constructed from robust materials and utilizing , these devices ensure . Their design is particularly tailored for demanding applications in metal processing and chemical manufacturing, where reliability is critical.

In practical scenarios, these high temperature fans have , significantly in environments characterized by high temperatures and corrosive substances. Manufacturers have noted that the in industrial blowers, designed for a service life exceeding 50,000 hours, enhances the operational stability of AirPro units.

As highlighted by Epcon Industrial Systems, “The success of the system is proof that this type of control configuration is indeed the for the aerospace industry.” This assertion reinforces AirPro products’ position as .

For engineers seeking , integrating AirPro ventilators into their processes can .

Smoki: Specialized High-Temperature Fans for Fume Extraction

Smoki specializes in specifically engineered for . These robust devices are meticulously designed to endure the extreme heat and corrosive properties of fumes generated in industrial operations. Featuring , including grades such as 1.4410 and 1.4622, these blowers exhibit yield strengths generally exceeding 550 MPa and 300 MPa, respectively, alongside elongation percentages of ≥ 20% and ≥ 22%. This engineering ensures the efficient removal of harmful fumes while upholding . The choice of stainless steel not only enhances durability but also provides essential resistance to wear, which is a critical factor for applications involving high temperature fans.

Successful applications of Smoki devices across various industrial settings have demonstrated their efficacy in fume extraction. Research indicates that specialized devices can achieve , significantly reducing airborne pollutants and enhancing air quality. Industry experts underscore the necessity of adhering to safety standards, asserting that are vital for regulatory compliance and the protection of worker health. As one expert aptly noted, “Without proper ventilation, welding fumes can turn your workshop into a toxic playground.”

Looking ahead to 2025, advancements in fume extraction fan technology continue to progress, with innovations focused on . The integration of smart monitoring systems facilitates real-time assessments of airflow and pressure, enabling predictive maintenance and mitigating the risk of equipment failure. This proactive strategy not only boosts operational performance but also extends the lifespan of the fans, rendering them a reliant on . Regular maintenance remains crucial to ensure optimal performance and safety in industrial environments, further highlighting the significance of these .

TCF: Industry-Leading Roof Exhausters for High-Temperature Environments

In high-temperature settings, like TCF roof exhausters play a vital role in ensuring and enhancing . These exhausters, known as , are meticulously engineered to effectively expel hot air from facilities such as and power generation stations.

By employing and resilient materials, TCF exhausters not only assure dependable performance but also significantly improve . The average temperature reduction achieved by TCF exhausters in manufacturing plants can reach up to 15°F, which leads to and productivity while minimizing energy costs.

Industry leaders underscore the importance of for sustainable operations, with one stating, ‘Effective exhaust systems are not just a luxury; they are a necessity for modern manufacturing.’

As we approach 2025, the demand for innovative roof exhausters is on the rise, reflecting the industry’s commitment to enhancing energy efficiency and operational performance in response to the urgent need for .

Bearing Protection: Essential for High-Temperature Fan Longevity

is essential for extending the lifespan of . Increased heat can lead to , which negatively impacts fan performance. To address this issue, engineers can implement several protective measures:

- Utilizing specialized lubricants designed for elevated temperature settings ensures that bearings operate smoothly, reducing friction and wear.

- Incorporating can effectively dissipate excess heat, thereby maintaining optimal operating conditions.

- Heat shields can also be employed to protect bearings from direct thermal exposure, further enhancing their durability.

Real-world applications underscore the effectiveness of these strategies. For instance, in a recent project involving elevated-temperature blowers in industrial settings, in bearing lifespan following the implementation of and . These measures not only extended the operational life of the units but also lowered maintenance costs, highlighting the importance of .

As we approach 2025, the focus on prolonging the durability of elevated-temperature ventilators continues to intensify. Engineers increasingly recognize that can yield substantial long-term benefits. Industry specialists emphasize this trend, stating, “Proper bearing upkeep is crucial in elevated temperature applications; it can signify the distinction between a fan that endures for years and one that breaks down early.” By prioritizing bearing protection, engineers can ensure the reliability and performance of fans operating in challenging conditions.

Insulation and Coating: Enhancing High-Temperature Fan Performance

Insulation and specialized coatings are essential for maximizing the efficiency of . The use of and protects high temperature fans and their components from extreme temperatures and corrosive environments. This protective layer not only extends the lifespan of the fans but also significantly boosts their performance, ensuring reliable airflow and consistent operation in demanding applications.

As Malcolm Forbes asserts, depend on people, product, and profit, underscoring the in enhancing . Moreover, Bill Gates emphasizes that based on operational effectiveness, which directly relates to the implementation of in fan technology.

Manufacturers acknowledge that improving fan performance through these innovations is vital for meeting the rigorous demands of the electronics industry. To further elevate fan performance, that offer superior thermal resistance and investigate insulation materials that minimize heat transfer, thereby optimizing overall system efficiency.

Design and Maintenance: Key Considerations for High-Temperature Blower Fans

Creating and maintaining requires careful consideration of several critical elements. that can withstand extreme temperatures, as can operate at levels exceeding 1,000°F (538°C), with temperatures inside the fan housing often surpassing this threshold.

Proper airflow design is essential to minimize resistance, which can significantly impact fan efficiency and longevity. , with data indicating that inadequate lubrication and are common issues in elevated temperature settings. Bearings, for example, frequently represent the first point of failure, particularly when subjected to temperatures above 600°F (316°C), and the operating temperature of roller bearings should never exceed 200°F.

Implementing strategies such as utilizing to dissipate heat from bearings—where a cooling wheel may be employed on the fan shaft to transfer heat away from the bearings—and incorporating temperature sensors can aid in early detection of potential problems, thus . Engineers stress the importance of these practices, citing H. Daniel Banyay’s assertion that ‘ is crucial in avoiding failure.’

By adhering to these maintenance best practices, including regular inspections and the use of , engineers can ensure the reliability and performance of high temperature fans in essential applications.

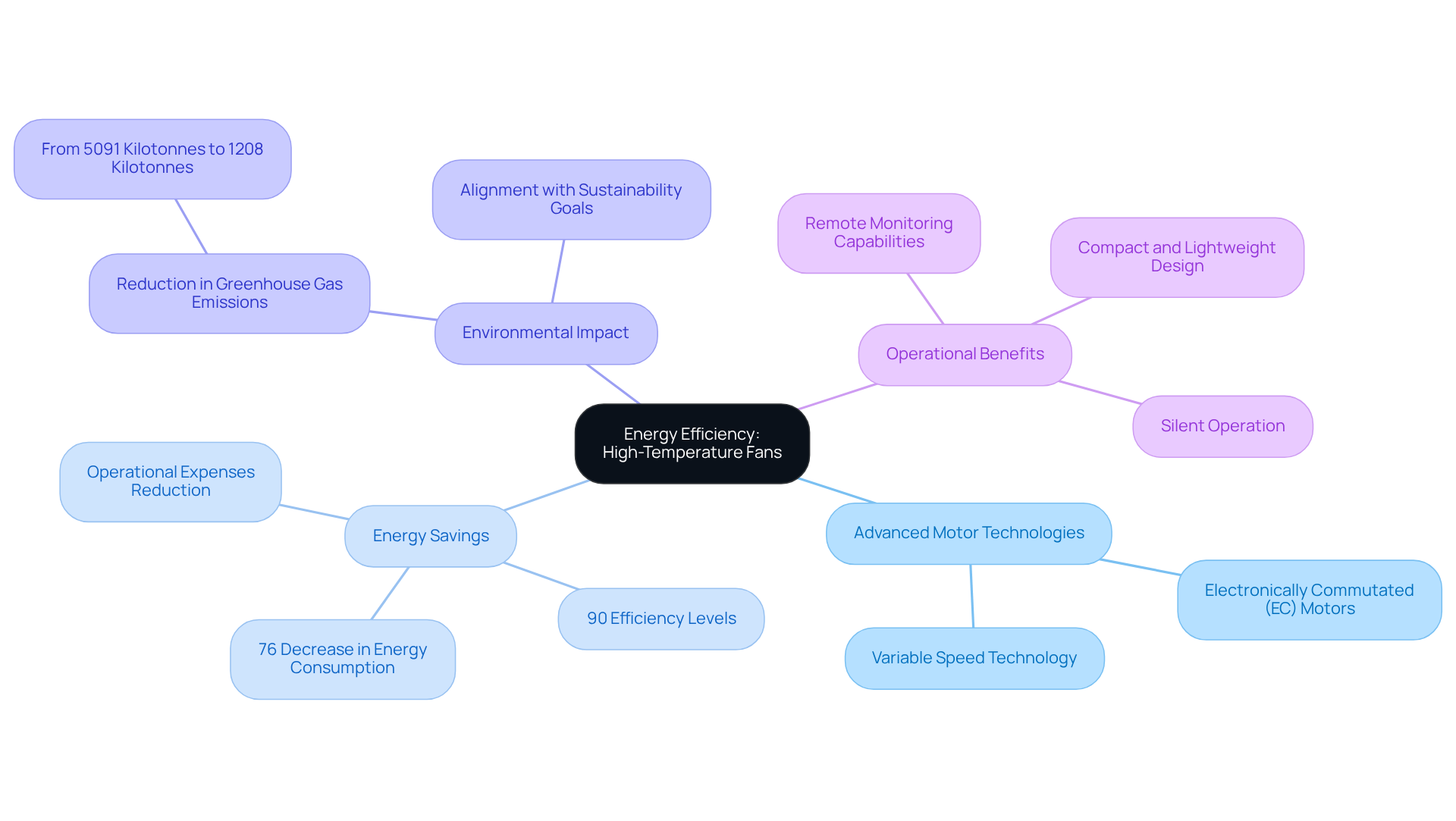

Energy Efficiency: The Role of High-Temperature Fans in Electronics

are crucial for enhancing . By utilizing , such as electronically commutated (EC) motors, these devices significantly improve airflow and reduce , achieving efficiency levels that exceed 90%. This enhancement not only optimizes but also leads to .

Research indicates that employing air circulators at velocities of 1.2 m/s can yield an impressive 76% decrease in energy consumption, correlating with a notable reduction in . This results in significant savings for large-scale operations, such as data centers, where .

Moreover, the integration of aligns with the industry’s increasing focus on minimizing carbon footprints. EC devices, recognized for their silent operation and compact design, are ideally suited for space-constrained environments, making them appropriate for modern electronic applications.

As Arunima Malik, a PhD expert, observes, “Moving air with electric devices could act as a sustainable substitute, decreasing air conditioner usage and related greenhouse gas emissions without compromising thermal comfort.” Industry leaders advocate for these technologies, underscoring their importance in promoting energy conservation and achieving sustainability goals.

Furthermore, the remote monitoring capabilities of EC units empower facility managers to optimize performance and reduce downtime. As the demand for continues to escalate, high temperature fans become essential components for engineers aiming to innovate and enhance the performance of electronic systems.

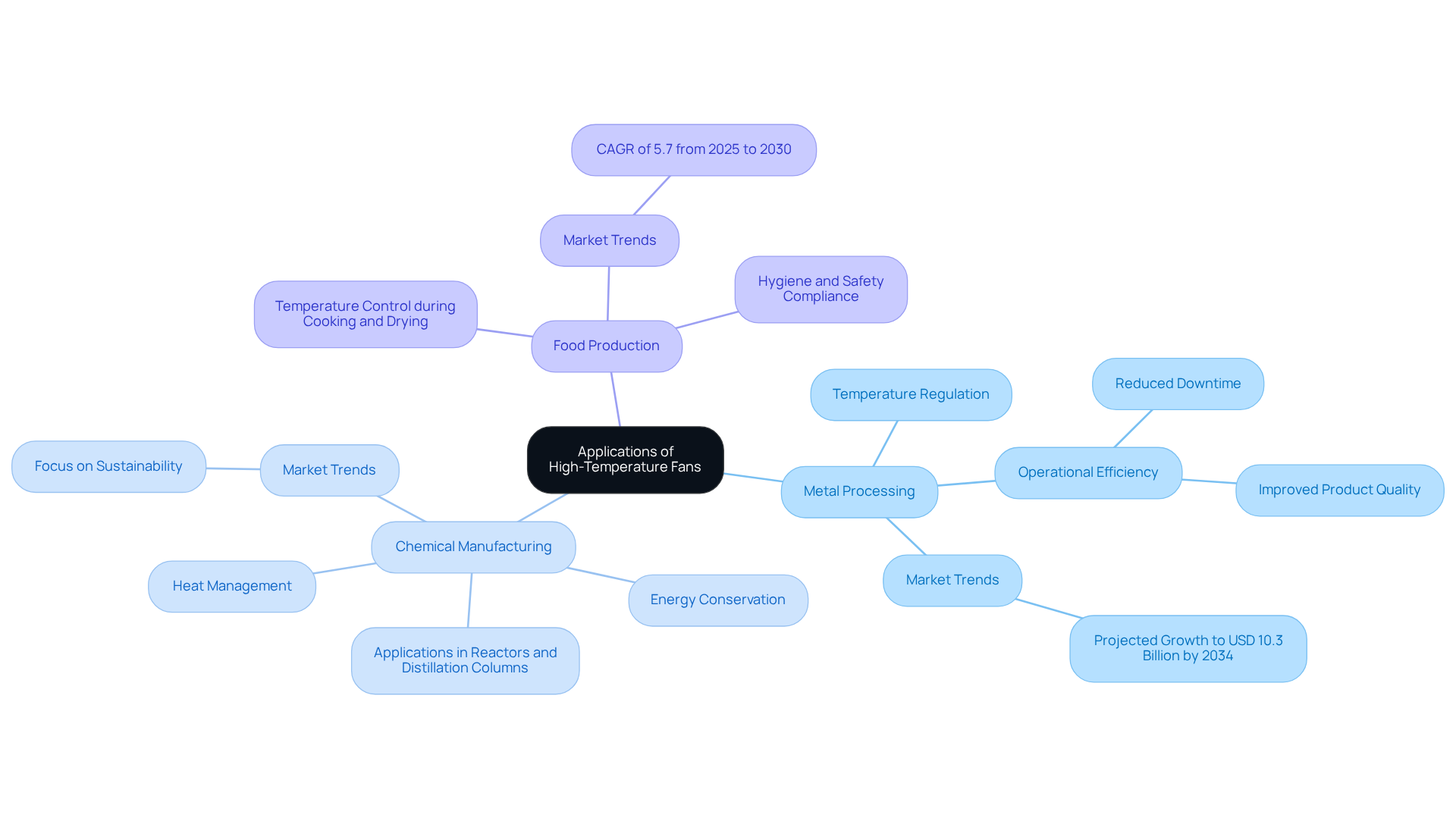

Applications of High-Temperature Fans Across Industries

are essential in various industries, such as metal processing, chemical manufacturing, and food production. In metal processing, these devices are vital for regulating temperatures in furnaces, which helps prevent overheating and ensures safe operations. Industry specialists emphasize that are essential for preserving the integrity of metal components during production. , for instance, can significantly enhance operational efficiency by reducing downtime and improving product quality. Market projections indicate that the industrial ventilation segment is expected to experience substantial growth, reaching USD 10.3 billion by 2034, underscoring the increasing demand for in this sector.

In chemical production, elevated-temperature blowers manage the heat generated during various reactions, ensuring that processes remain within safe temperature limits. This capability is particularly crucial as the industry increasingly focuses on . Practical applications include the use of elevated-temperature blowers in reactors and distillation columns, where precise temperature regulation is critical for . Case studies reveal that these devices are essential for , thereby enhancing overall process efficiency.

The versatility of high temperature fans extends to food production as well, where they are essential for maintaining optimal temperatures during cooking and drying processes. The food and beverage sector is projected to grow at a CAGR of 5.7% from 2025 to 2030, reflecting the rising need for . As industries evolve, the demand for advanced cooling solutions is anticipated to increase, with significant advancements in cooling technologies expected in the metal processing sector by 2025. Overall, elevated-temperature blowers are crucial for ensuring effectiveness and safety in these demanding environments.

Recent Advancements in High-Temperature Fan Technology

Recent advancements in technology have catalyzed the emergence of smart devices integrated with , facilitating . These innovations allow for precise modifications in response to operational circumstances, thereby significantly and effectiveness.

Furthermore, have led to the creation of more , which not only prolong the lifespan of these fans but also bolster their reliability in demanding environments. Consequently, these advancements are essential for in high temperature fans, rendering them indispensable in contemporary industrial processes.

The integration of IoT capabilities into fan technology is poised to redefine standards in monitoring and maintenance, paving the way for smarter, more responsive .

Conclusion

High temperature fans are essential for ensuring optimal performance and safety across diverse industrial applications, particularly within the electronics sector. With the increasing demand for effective temperature regulation solutions, these fans are pivotal in enhancing energy efficiency and operational reliability. Innovations and advancements in high temperature fan technology not only bolster durability but also resonate with the industry’s commitment to sustainability and energy conservation.

In this discussion, several key players, including Gagner-Toomey Associates, AirPro, Smoki, and TCF, have been recognized for their significant contributions to high temperature fan solutions. Each brand provides specialized products tailored for extreme conditions, fume extraction, and effective ventilation, underscoring the necessity of customized solutions to address specific industry requirements. The focus on bearing protection, insulation, and advanced materials further emphasizes the importance of investing in dependable fan technology to guarantee longevity and performance.

As industries continue to evolve and the demand for high temperature fans escalates, it is crucial for engineers and manufacturers to prioritize the integration of these advanced cooling solutions. By embracing innovative technologies and adhering to rigorous standards, the potential for enhanced efficiency and minimized environmental impact becomes attainable. Adopting these advancements not only improves operational effectiveness but also positions industries to adeptly confront future challenges.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is a leading provider of high-temperature fan solutions, specializing in innovative temperature regulation technologies tailored for the electronics sector.

What is the projected growth of the Electronics Thermal Management Solutions market?

The global Electronics Thermal Management Solutions market is expected to grow from $6,416.7 million in 2024 to $11,653.3 million by 2031, with a compound annual growth rate (CAGR) of 8.9%.

What types of products does Gagner-Toomey Associates represent?

Gagner-Toomey Associates represents a diverse portfolio of manufacturers known for their cutting-edge products in temperature regulation, power management, and interconnect technologies.

What are the capabilities of AirPro fans?

AirPro fans are high-temperature blower fans designed to perform in extreme conditions, capable of withstanding temperatures up to 1800°F, making them suitable for demanding applications in metal processing and chemical manufacturing.

How do AirPro fans ensure durability and reliability?

AirPro fans are constructed from robust materials and utilize advanced airflow technology, with high-quality bearings designed for a service life exceeding 50,000 hours, enhancing their operational stability.

What is the focus of Smoki fans?

Smoki specializes in high-temperature fans designed specifically for fume extraction applications, ensuring efficient removal of harmful fumes in industrial operations.

What materials are used in Smoki fan construction?

Smoki fans are made from stainless steel grades such as 1.4410 and 1.4622, which provide high yield strengths and resistance to wear, crucial for high-temperature applications.

What is the extraction effectiveness of Smoki devices?

Smoki devices can achieve extraction effectiveness exceeding 90%, significantly reducing airborne pollutants and enhancing air quality in industrial settings.

What advancements are expected in fume extraction fan technology by 2025?

Advancements are focused on enhancing performance and energy efficiency, including the integration of smart monitoring systems for real-time assessments of airflow and pressure, enabling predictive maintenance.

Why is regular maintenance important for high-temperature fans?

Regular maintenance is crucial to ensure optimal performance and safety in industrial environments, helping to extend the lifespan of the fans and mitigate the risk of equipment failure.