Overview

This article delineates the definition of small centrifugal blowers and investigates their diverse applications across various industries. It underscores their critical role in augmenting airflow efficiency within HVAC systems, cooling applications, dust collection, and beyond. Supported by data illustrating market growth, the article emphasizes the efficiency advantages these devices provide through their compact designs.

Introduction

Small centrifugal blowers serve a crucial function in contemporary industrial applications, expertly utilizing centrifugal force to move air and gases with remarkable precision. As the global fan market is projected to experience substantial growth, it becomes imperative to comprehend the definition, operational principles, and varied applications of these compact devices.

Nevertheless, as industries increasingly depend on these blowers for enhanced efficiency and performance, what challenges do they encounter in adapting to the shifting technological landscape and stringent environmental standards?

Define Small Centrifugal Blower

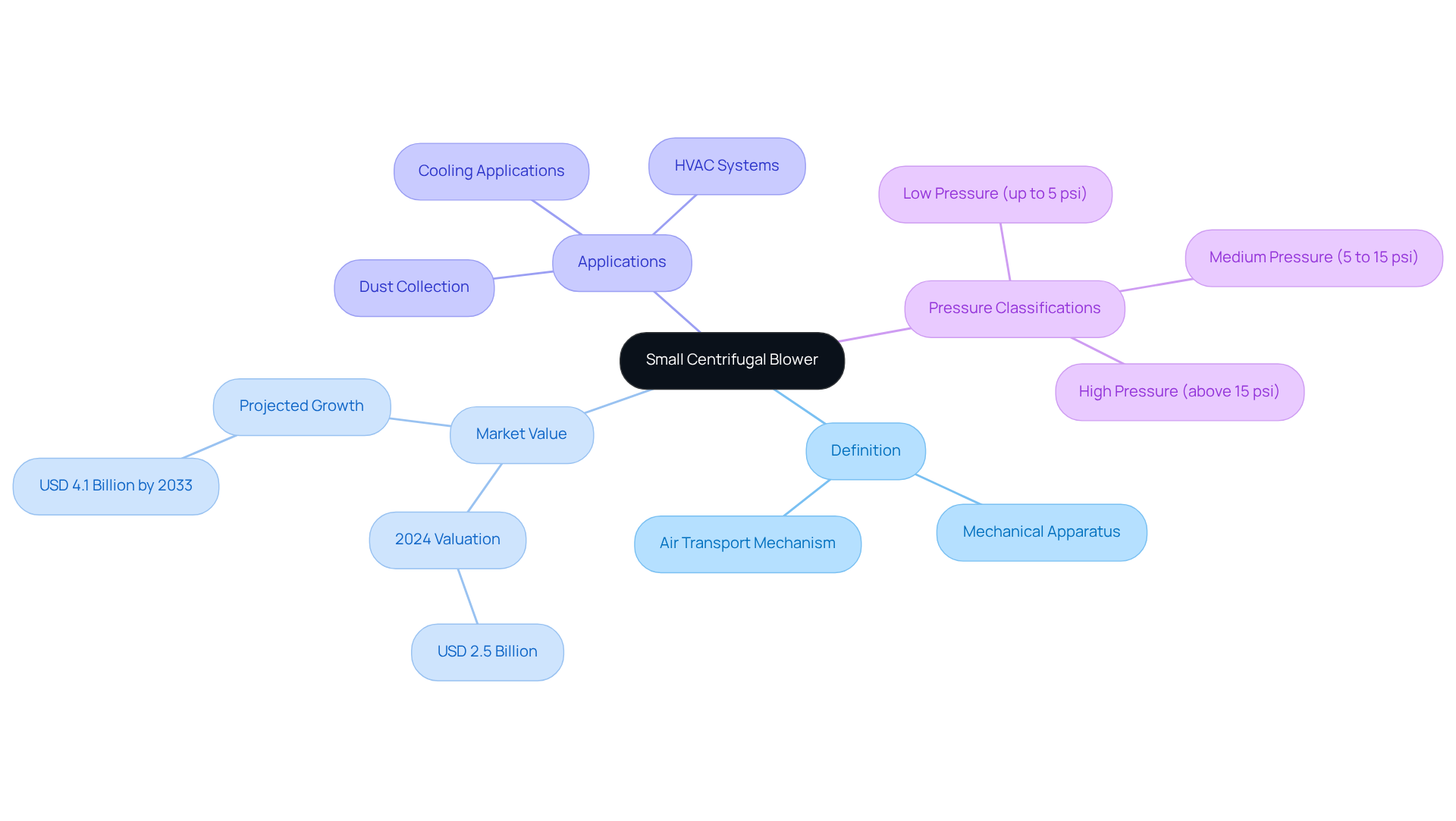

A compact rotary fan serves as a mechanical apparatus designed to transport air or gases by harnessing the force generated by a spinning impeller. In contrast to axial fans, which push air parallel to the axis of rotation, radial fans expel air at a right angle to the intake. This design allows for the creation of greater pressure and airflow, making them suitable for a variety of applications in industrial and commercial settings. Typically compact in size, the small centrifugal blower is engineered for efficiency and effectiveness in air movement, commonly utilized in HVAC systems, cooling applications, and dust collection systems.

The global fan market was valued at USD 2.5 billion in 2024 and is projected to grow to USD 4.1 billion by 2033, highlighting a significant demand for these devices across various industries. According to Grand View Research, the HVAC sector dominated the fan market, accounting for the largest revenue share of 25.4% in 2024. This underscores the critical role that small centrifugal blowers play in facilitating efficient air circulation and ventilation within HVAC systems.

Moreover, small rotary fans are categorized by pressure levels:

- low pressure (up to 5 psi)

- medium pressure (5 to 15 psi)

- high pressure (above 15 psi)

Understanding this classification is vital for recognizing their capabilities and applications in diverse environments, such as the , where they are essential for maintaining air circulation and adhering to FDA regulations for food processing equipment.

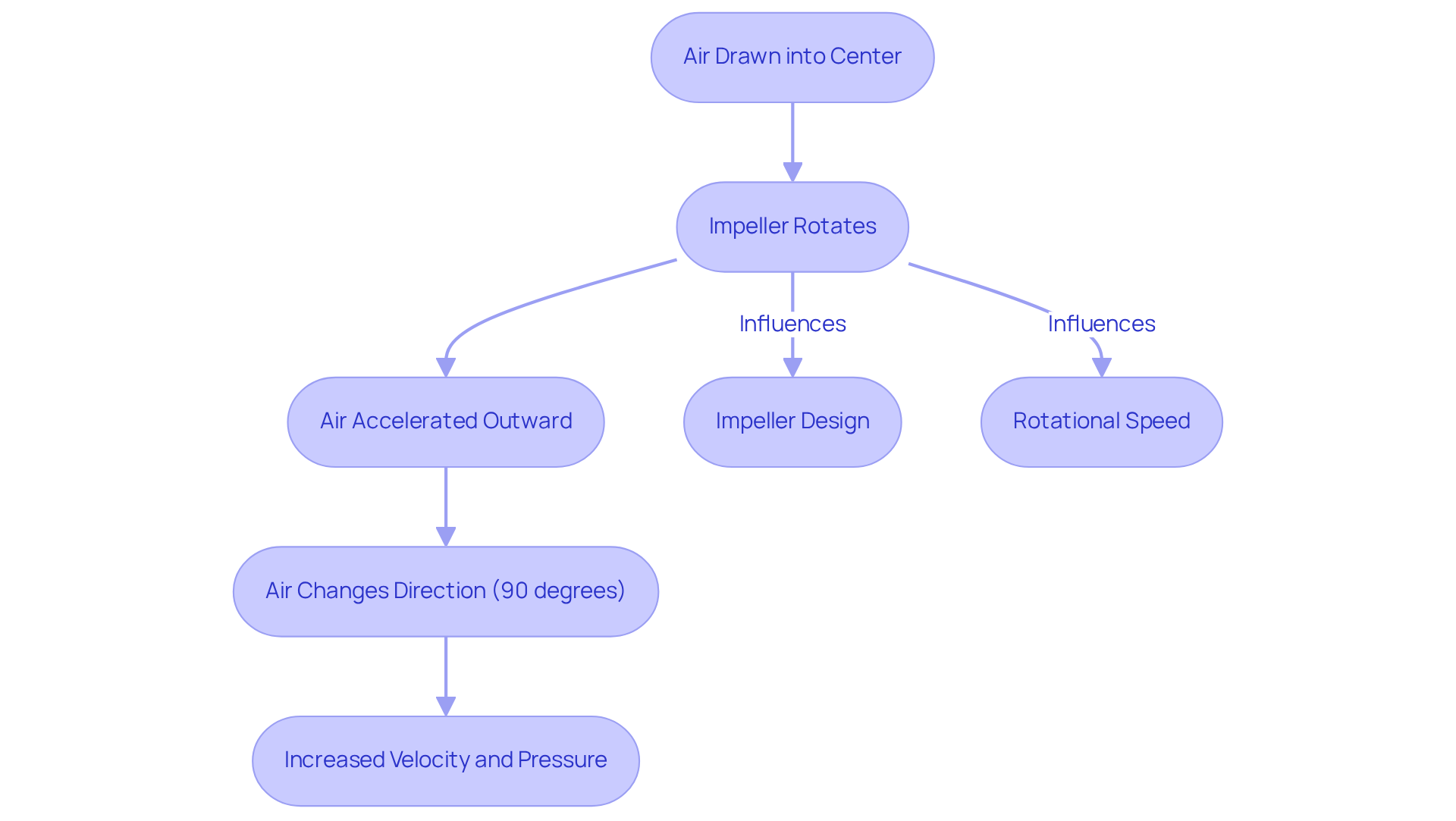

Explain Operational Principles

Small centrifugal blowers operate on the principle of centrifugal force. When the impeller rotates, it draws air into the center of the device and accelerates it outward through the . As the air flows through the device, it is compelled to change direction, typically at a 90-degree angle, which enhances both its velocity and pressure.

The design of the impeller and the housing is critical in determining the device’s efficiency and performance. Moreover, the rotational speed of the impeller in a small centrifugal blower, along with its blade design, directly influences the airflow rate and pressure produced by the device.

Explore Applications in Industry

Small centrifugal blowers are vital components across various industries, recognized for their ability to deliver high pressure and airflow within compact designs. Their applications encompass several critical areas:

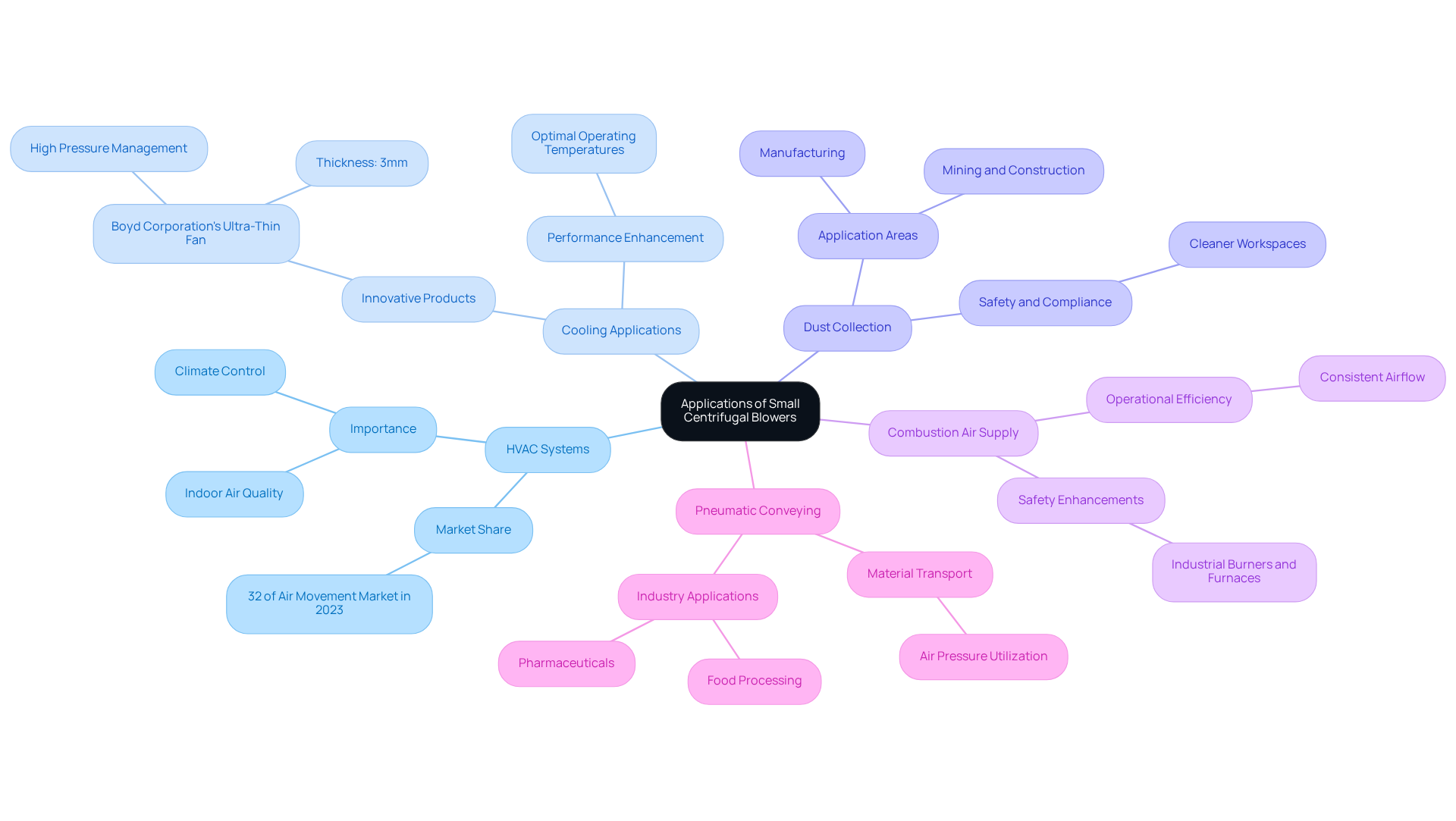

- HVAC Systems: These fans are essential in heating, ventilation, and air conditioning systems, ensuring adequate airflow for effective climate control. The HVAC sector alone accounted for over 32% of the air movement market in 2023, underscoring its importance in maintaining indoor air quality and comfort.

- Cooling Applications: In the realm of electronic equipment cooling, a small centrifugal blower is crucial for sustaining optimal operating temperatures, thereby enhancing performance and longevity. For instance, Boyd Corporation’s ultra-thin fan, developed in September 2021, exemplifies innovation in cooling technology, measuring as thin as 3mm while effectively managing high pressure. This advancement is significant as it enables more efficient cooling solutions in compact electronic devices.

- Dust Collection: Within manufacturing and processing environments, these devices are instrumental in dust collection systems, efficiently removing particulate matter from the air to ensure a cleaner workspace. This application is particularly vital in industries such as mining and construction, where dust control is essential for safety and compliance.

- Combustion Air Supply: Small centrifugal blowers provide critical air for combustion processes in industrial burners and furnaces, enhancing operational efficiency and safety. Their capacity to maintain consistent airflow is pivotal in optimizing combustion efficiency.

- Pneumatic Conveying: These devices are also employed in pneumatic conveying systems, which transport materials through pipelines using air pressure. This technology is prevalent in sectors like food processing and pharmaceuticals, where controlled airflow is necessary for effective material handling.

The rotating fan market is projected to expand significantly, with a compound annual growth rate (CAGR) of 4.54% from 2024 to 2032, driven by the increasing demand for across diverse applications. Industry leaders emphasize the reliability and energy-efficient characteristics of these devices, which are transforming air handling solutions in HVAC, manufacturing, and waste management sectors. As noted by industry specialists, the air-moving device market is expected to reach USD 4.01 billion by 2032, reflecting the growing importance of these systems in contemporary industrial applications.

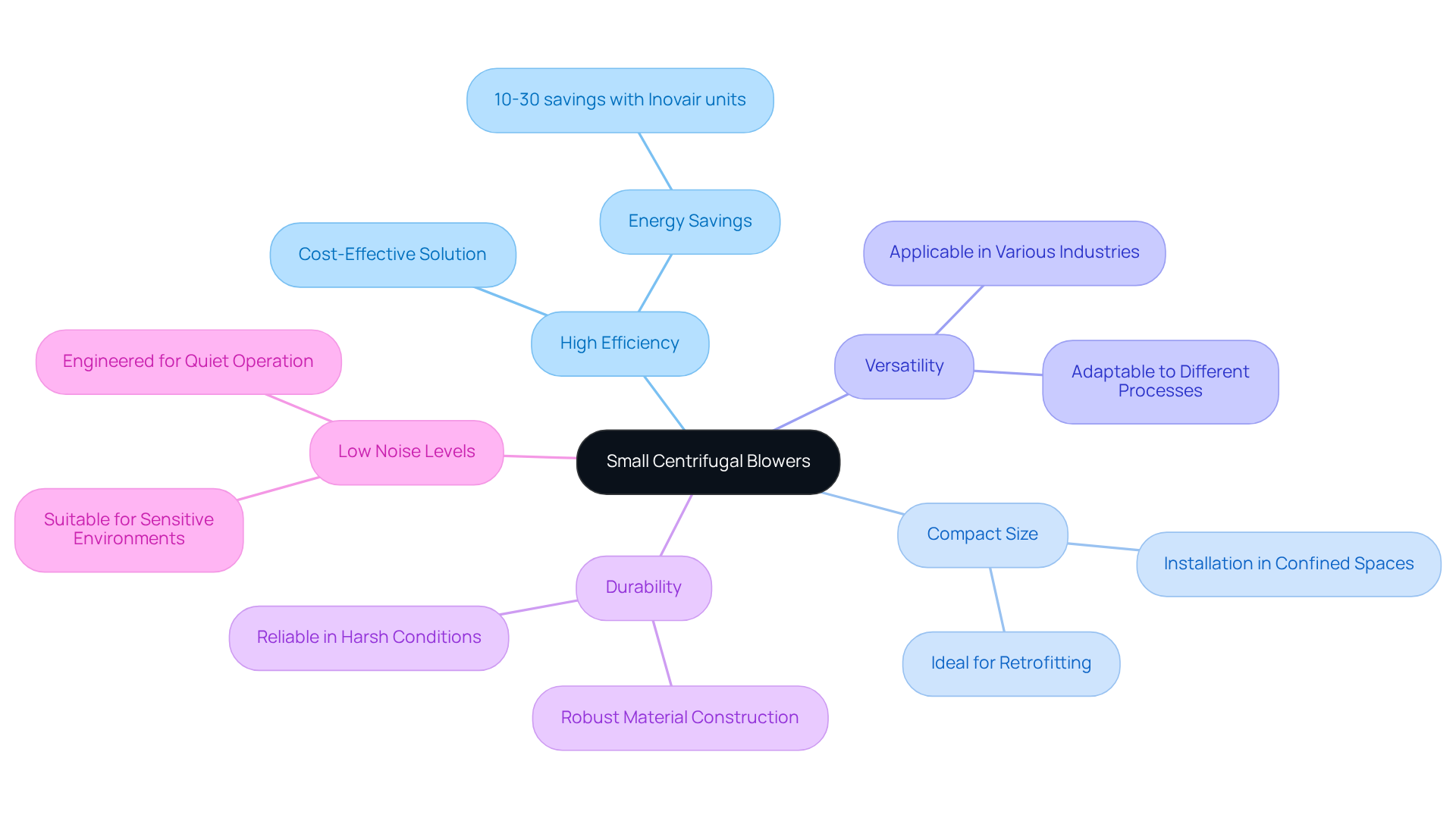

Identify Key Characteristics and Benefits

Small centrifugal blowers are characterized by several essential features that significantly enhance their effectiveness across various applications:

- High Efficiency: These devices are engineered to optimize airflow while minimizing energy consumption, presenting a cost-effective solution for air movement that can lead to substantial reductions in operational expenses. For instance, selecting Inovair units can yield energy savings ranging from 10% to 30%. The small centrifugal blower is essential for efficient airflow compared to Positive Displacement devices.

- Compact Size: The small centrifugal blower’s footprint allows for installation in confined spaces, making it particularly beneficial for applications where space is limited, such as retrofitting existing systems or operating within constrained industrial environments.

- Versatility: Small centrifugal blowers are —from HVAC systems to specialized industrial processes—demonstrating remarkable flexibility to meet diverse operational requirements.

- Durability: Constructed from robust materials, these devices are designed to endure harsh operating conditions, ensuring longevity and reliability even in challenging environments.

- Low Noise Levels: Many models are specifically engineered for quiet operation, making them ideal for settings where sound reduction is crucial, such as residential neighborhoods or sensitive industrial applications.

Real-world implementations of compact rotating fans in tight spaces have showcased their effectiveness. For example, Inovair’s high-efficiency solutions in wastewater treatment have resulted in significant operational cost savings, underscoring the practical advantages of these designs. Engineers have observed that these innovations not only enhance operational efficiency but also facilitate improved workflow in constrained environments. The combination of these characteristics positions small centrifugal blowers as essential assets in a variety of industrial and commercial applications.

Conclusion

Small centrifugal blowers are integral components in various industrial applications, recognized for their capacity to efficiently transport air and gases through a compact design. Their unique operational principles, characterized by centrifugal force and impeller mechanics, enable them to generate high pressure and airflow, making them indispensable across sectors ranging from HVAC systems to dust collection and pneumatic conveying.

Key insights reveal significant growth in the small centrifugal blower market, driven by an increasing demand for energy-efficient solutions. Their classification by pressure levels—low, medium, and high—underscores their versatility in addressing diverse operational needs. The benefits of these devices, including high efficiency, compact size, and durability, position them as reliable choices for enhancing productivity and maintaining safety standards in various environments.

The importance of small centrifugal blowers extends beyond mere functionality; they are pivotal in driving innovation across industries. As the market evolves, embracing energy-efficient technologies will be crucial for organizations aiming to optimize their operations. Investing in small centrifugal blowers not only supports operational excellence but also contributes to sustainability efforts, establishing them as vital assets in modern industrial applications.

Frequently Asked Questions

What is a small centrifugal blower?

A small centrifugal blower is a compact rotary fan designed to transport air or gases by utilizing the force generated by a spinning impeller. Unlike axial fans, which push air parallel to the rotation axis, centrifugal blowers expel air at a right angle, allowing for greater pressure and airflow.

What are the applications of small centrifugal blowers?

Small centrifugal blowers are commonly used in HVAC systems, cooling applications, and dust collection systems due to their efficiency and effectiveness in air movement.

What is the market value of the global fan market?

The global fan market was valued at USD 2.5 billion in 2024 and is projected to grow to USD 4.1 billion by 2033, indicating a significant demand for these devices across various industries.

Which sector dominates the fan market?

The HVAC sector dominates the fan market, accounting for the largest revenue share of 25.4% in 2024, highlighting the importance of small centrifugal blowers in efficient air circulation and ventilation.

How are small centrifugal blowers categorized by pressure levels?

Small centrifugal blowers are categorized into three pressure levels: low pressure (up to 5 psi), medium pressure (5 to 15 psi), and high pressure (above 15 psi). This classification is important for understanding their capabilities and applications.

Why are small centrifugal blowers important in the dairy industry?

In the dairy industry, small centrifugal blowers are essential for maintaining air circulation and ensuring compliance with FDA regulations for food processing equipment.