Overview

This article aims to provide a structured approach for selecting the right commercial blower fan, highlighting crucial specifications and assessment criteria. It delineates four essential steps:

- Understanding key specifications such as CFM and SP

- Assessing project requirements alongside environmental conditions

- Comparing performance metrics

- Implementing best practices for installation and maintenance

By following these steps, one can ensure that the selected fan effectively meets operational needs.

Introduction

Selecting the right commercial blower fan is crucial for optimizing the efficiency and effectiveness of ventilation systems across various applications. Understanding essential specifications such as CFM, static pressure, and air density empowers professionals to make informed decisions that align with their specific project requirements. Yet, with a multitude of options available, navigating the complexities of performance metrics, installation prerequisites, and maintenance protocols can be daunting. This guide offers a structured approach to selecting the ideal blower fan, addressing key considerations that can enhance performance and extend longevity.

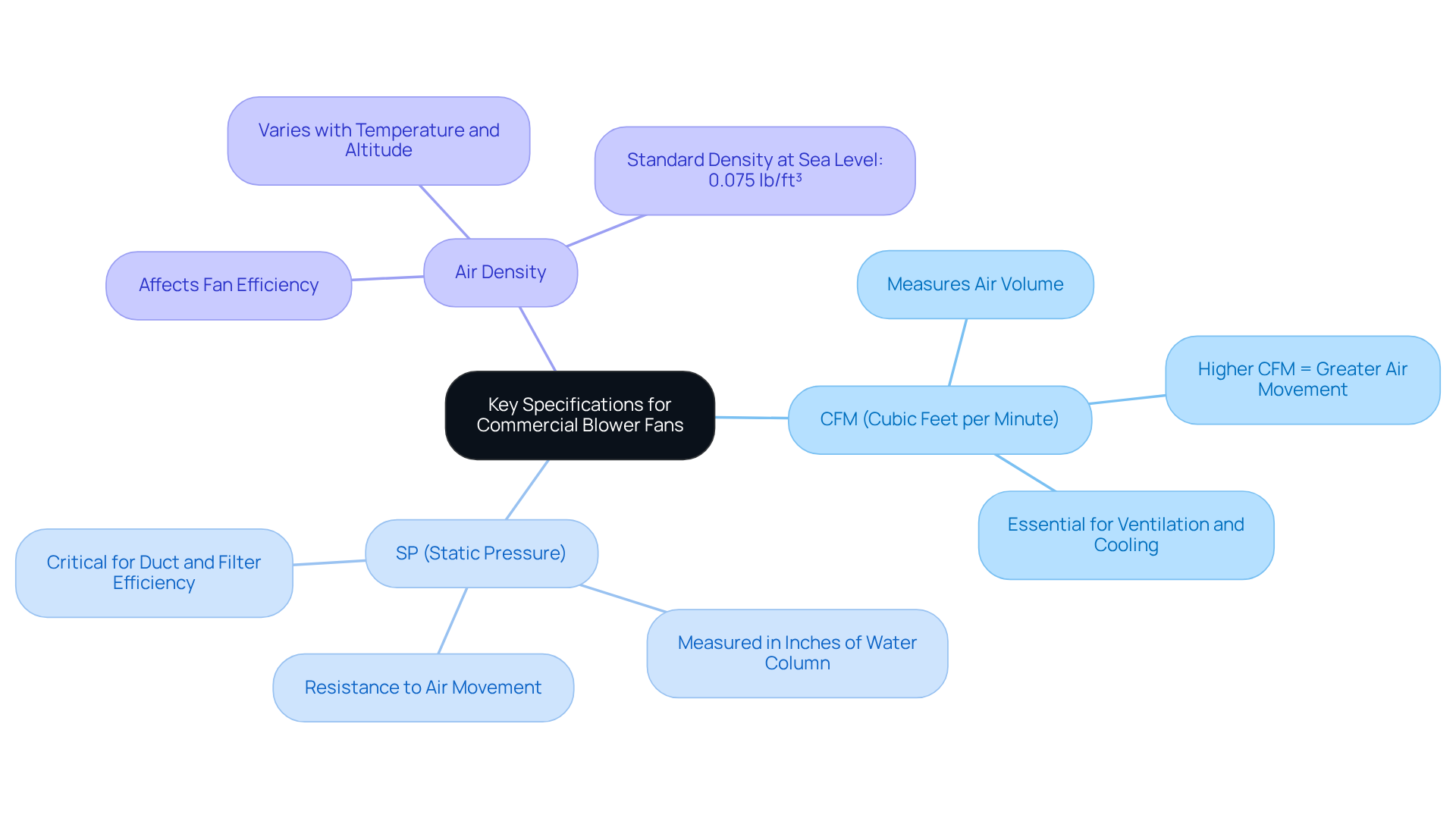

Understand Key Specifications: CFM, SP, and Air Density

Selecting the appropriate commercial blower fan necessitates a clear understanding of key specifications that influence performance:

- CFM (Cubic Feet per Minute): This crucial metric measures the volume of air the fan can move. A higher CFM rating indicates a greater air movement capacity, essential for applications requiring substantial ventilation or cooling.

- SP (Static Pressure): This specification denotes the resistance the fan must overcome to effectively move air through the system, measured in inches of water column (in. w.c.). Understanding static pressure is vital for determining whether the fan can through ducts or filters.

- Air Density: The density of air plays a significant role in the fan’s operation. Standard air density is approximately 0.075 lb/ft³ at sea level and 70°F. Variations in temperature and altitude can alter air density, subsequently affecting the fan’s efficiency.

By thoroughly comprehending these specifications, you can more effectively assess the requirements of your specific application, ensuring that the fan you select will perform optimally under those conditions.

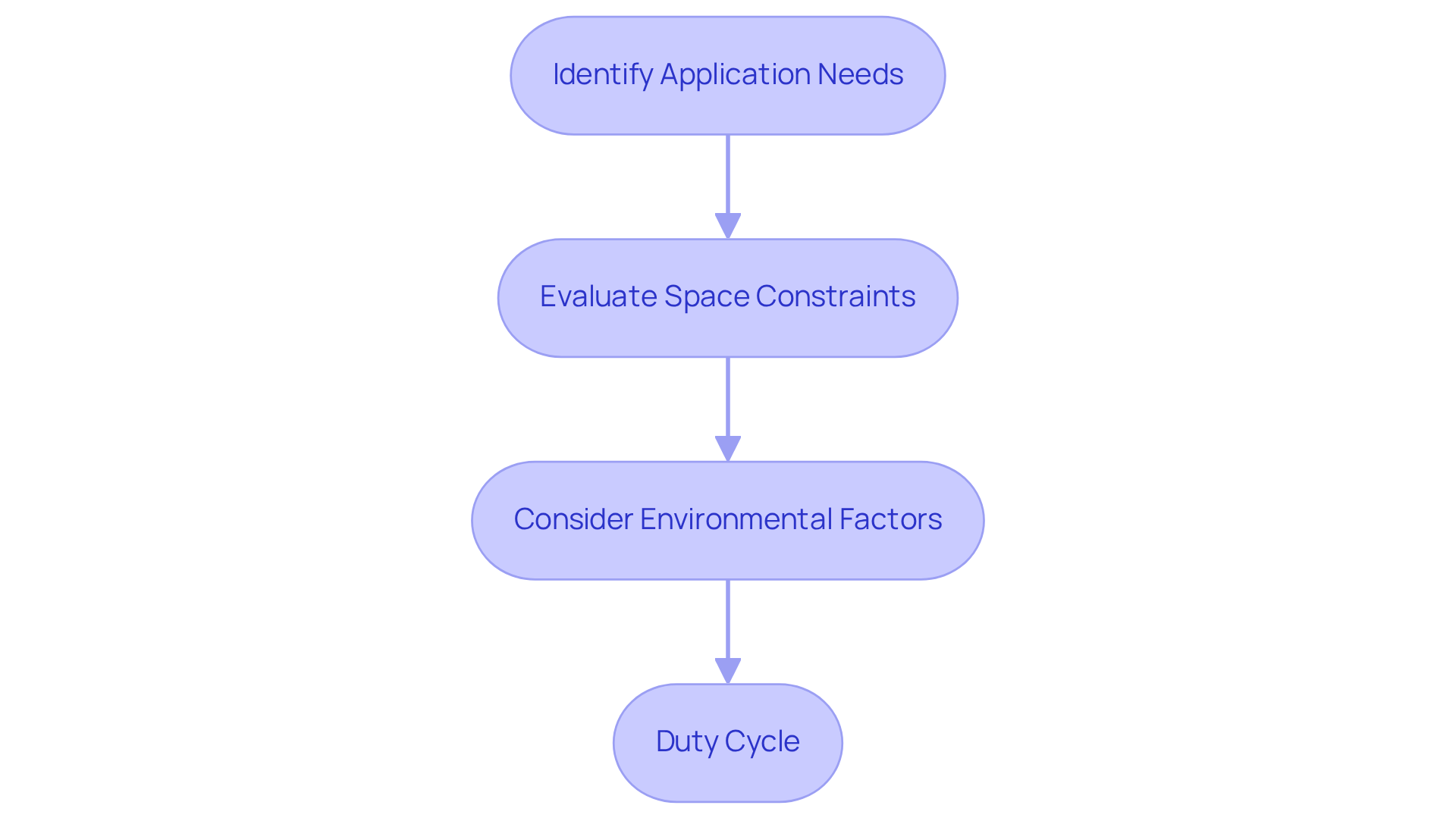

Assess Project Requirements and Environmental Conditions

Next, assess your project requirements and environmental conditions:

- Identify Application Needs: Determine the primary function of the blower fan. Is it for cooling, ventilation, or exhaust? Understanding the will guide your selection.

- Evaluate Space Constraints: Measure the available space for installation. Ensure that the fan’s dimensions fit within the designated area and that there is adequate clearance for airflow.

- Consider Environmental Factors: Analyze the operating environment, including temperature, humidity, and potential contaminants. For instance, high humidity may require a fan designed to resist corrosion, while extreme temperatures may necessitate specialized materials.

- Duty Cycle: Determine how often the fan will operate. Continuous operation may require a more robust fan design compared to intermittent use.

By thoroughly assessing these factors, you can narrow down your options and select a fan that is well-suited for your specific project.

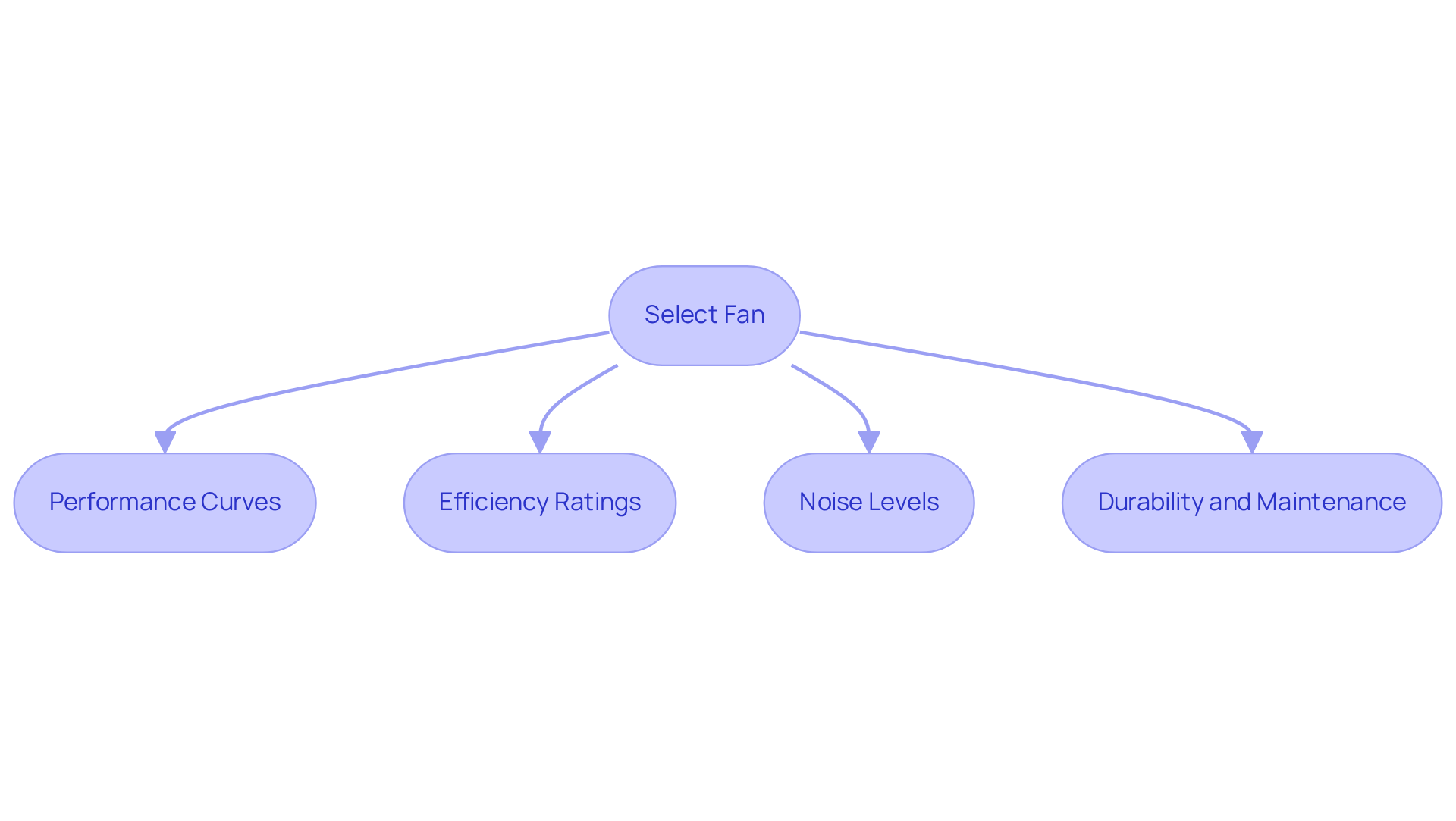

Compare Performance Metrics and Efficiency Ratings

Once you have a shortlist of potential fans, it is essential to compare their performance metrics and efficiency ratings to ensure optimal selection.

- Performance Curves: Begin by reviewing the fan’s performance curves, which illustrate the relationship between CFM, SP, and RPM. This data is crucial for understanding how the fan will perform under various operating conditions, allowing for informed decision-making.

- Efficiency Ratings: Next, seek out fans with high efficiency ratings, such as the Fan Efficiency Grade (FEG). A higher efficiency rating indicates reduced energy consumption for the same air movement, leading to significant cost savings over time.

- Noise Levels: Additionally, consider the noise generated by the fan during operation. In applications where noise sensitivity is a concern, selecting a quieter fan becomes imperative to maintain a conducive environment.

- Durability and Maintenance: Finally, evaluate the materials used in the fan’s construction and any maintenance requirements. While a durable fan may entail a higher upfront cost, it can through decreased maintenance and replacement needs.

By systematically comparing these metrics, you can select a fan that not only meets your ventilation and pressure requirements but also operates efficiently and quietly.

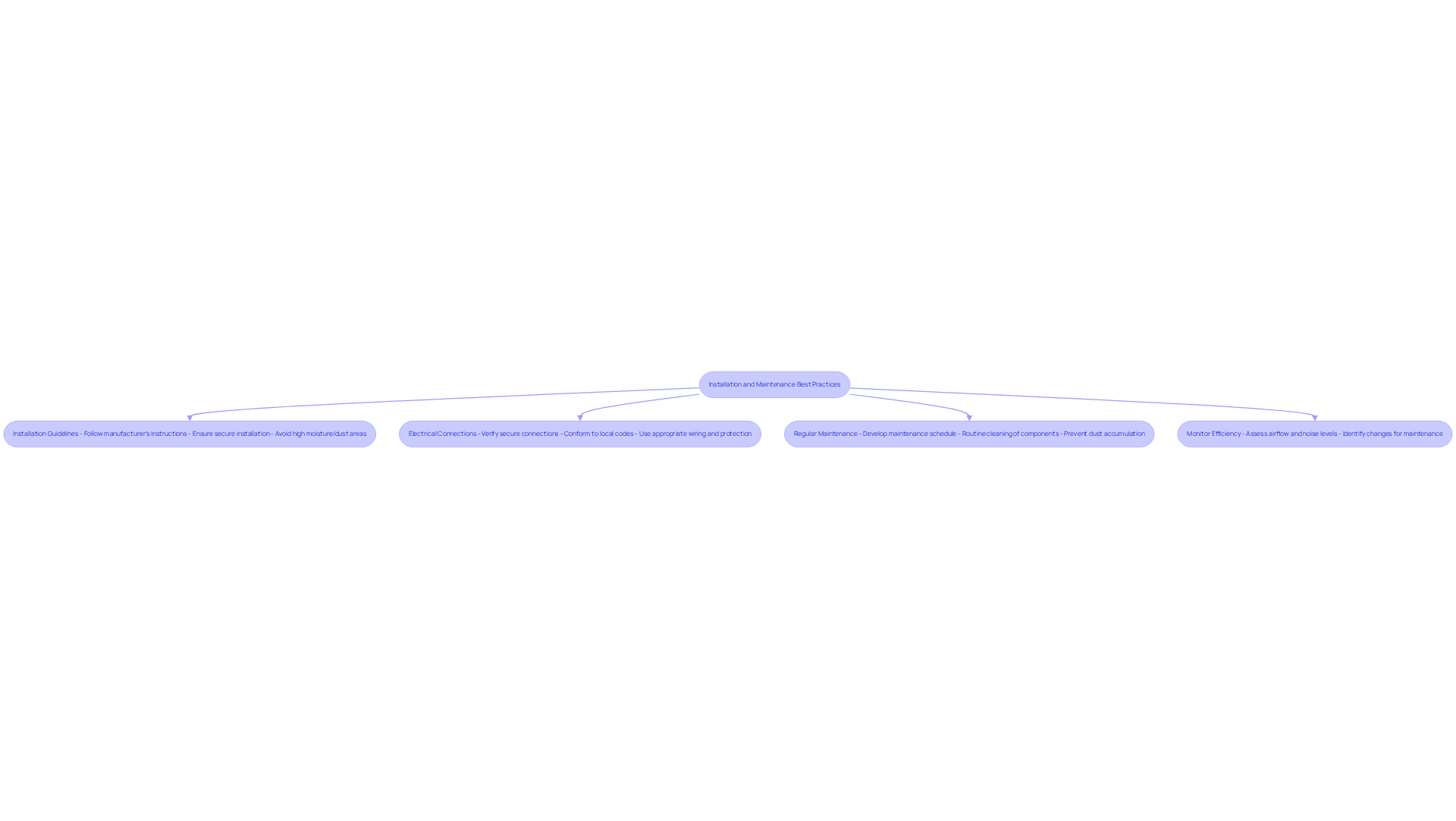

Implement Installation and Maintenance Best Practices

To maximize the performance and lifespan of your commercial blower fan, it is essential to implement installation and maintenance best practices:

- Installation Guidelines: Adhere strictly to the manufacturer’s installation instructions. Ensure that the fan is installed securely and that there is ample space for proper circulation. It is crucial to avoid positioning the fan in areas with high moisture or dust unless it is specifically designed for such environments.

- Electrical Connections: Verify that all electrical connections are secure and conform to local codes. Utilize appropriate wiring and to prevent electrical failures.

- Regular Maintenance: Develop a comprehensive maintenance schedule that includes routine cleaning of the fan and its components. Accumulated dust and debris can significantly impair functionality and efficiency.

- Monitor Efficiency: Consistently assess the fan’s efficiency metrics, including airflow and noise levels. Notable changes in these metrics may signal a need for maintenance or adjustments.

By following these best practices, you ensure that your project’s requirements are effectively met by your commercial blower fan.

Conclusion

Selecting the appropriate commercial blower fan is essential for ensuring optimal performance in various ventilation applications. Understanding critical specifications such as CFM, static pressure, and air density empowers professionals to make informed choices tailored to their specific needs. This guide serves as a valuable resource for navigating the complexities of blower fan selection, installation, and maintenance.

The importance of comprehending project requirements and environmental factors cannot be overstated. By comparing performance metrics and adhering to best practices for installation and maintenance, each step—from assessing application needs to evaluating efficiency ratings—contributes to the selection of a fan that meets operational demands while operating efficiently and quietly. By meticulously considering these elements, the right blower fan can significantly enhance overall system effectiveness.

Investing time in the selection process and following maintenance guidelines yields substantial long-term benefits. Ensuring that the chosen fan performs optimally will not only improve ventilation and air quality but also lead to cost savings and increased durability. Embrace these insights to make a confident decision that supports your project’s success and sustainability.

Frequently Asked Questions

What does CFM stand for and why is it important?

CFM stands for Cubic Feet per Minute, and it measures the volume of air a fan can move. A higher CFM rating indicates greater air movement capacity, which is essential for applications that require substantial ventilation or cooling.

What is static pressure (SP) in the context of blower fans?

Static Pressure (SP) denotes the resistance the fan must overcome to effectively move air through the system, measured in inches of water column (in. w.c.). Understanding SP is crucial for determining if the fan can adequately push air through ducts or filters.

How does air density affect the operation of a blower fan?

Air density significantly impacts a fan’s operation. Standard air density is approximately 0.075 lb/ft³ at sea level and 70°F. Variations in temperature and altitude can alter air density, which in turn affects the fan’s efficiency.

Why is it important to understand these specifications when selecting a blower fan?

A thorough understanding of CFM, SP, and air density allows you to effectively assess the requirements of your specific application, ensuring that the fan you select will perform optimally under those conditions.