Overview

A high pressure blower fan is a specialized centrifugal fan engineered to produce substantial air pressure while sustaining low airflow volumes. This design makes it particularly suitable for applications that demand focused airflow against resistance. The article underscores its pivotal features, including:

- Durability

- Energy efficiency

- Versatility in various applications such as cooling systems and dust collection

These attributes highlight its critical role across diverse industrial sectors, reinforcing the necessity for such technology in enhancing operational efficiency.

Introduction

High pressure blower fans play a pivotal role in various industrial settings, expertly engineered to deliver concentrated airflow while overcoming significant resistance. These specialized centrifugal fans not only enhance operational efficiency but also cater to a multitude of applications, including:

- Cooling electronic components

- Facilitating pneumatic conveying

As industries increasingly demand tailored solutions, the pressing question arises: how can businesses effectively leverage the unique features of high pressure blower fans to optimize their processes and meet evolving challenges?

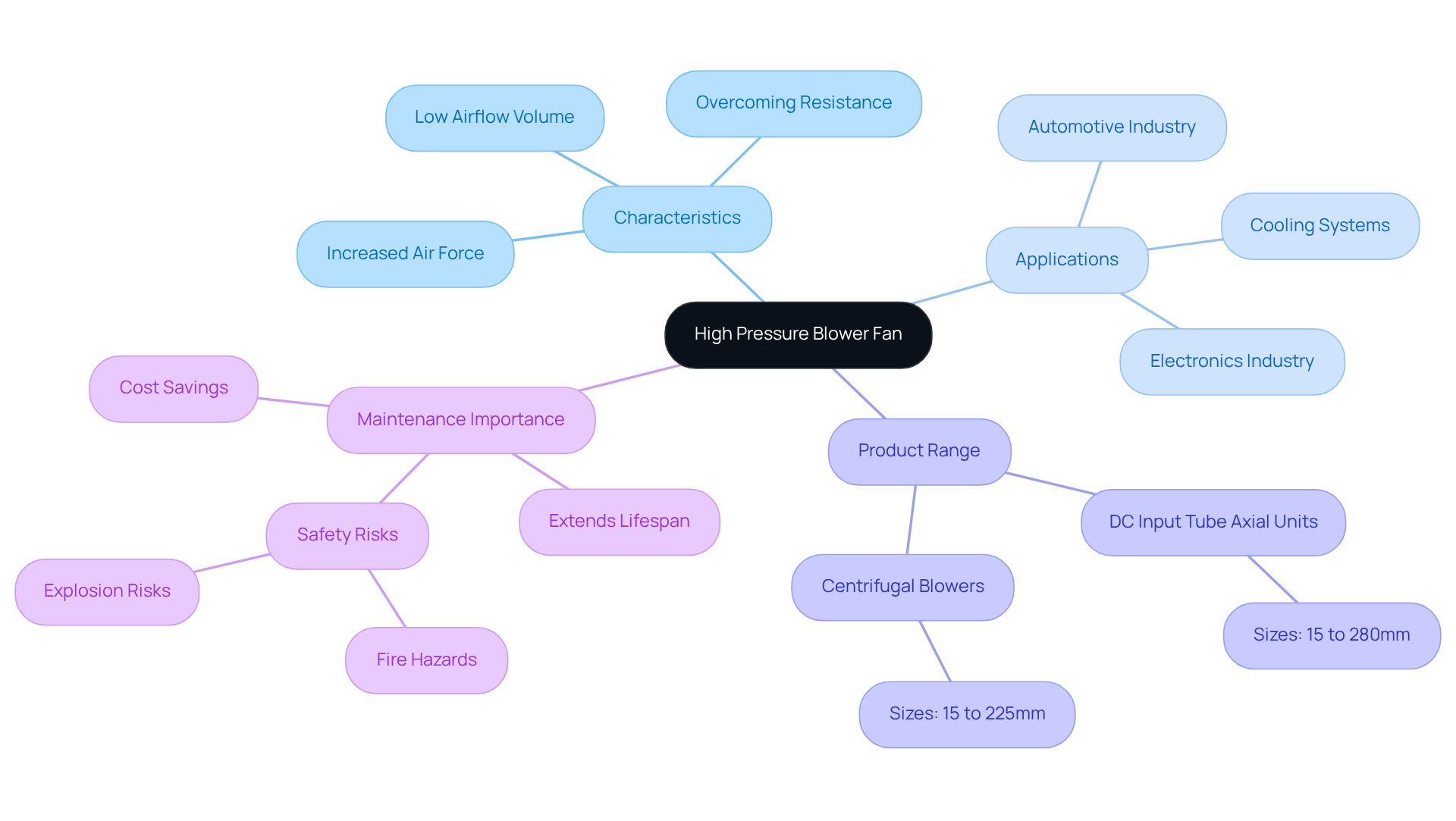

Define High Pressure Blower Fan

A high-force blower fan is a specialized centrifugal fan engineered to generate increased air force while managing a relatively low airflow volume. These devices function by drawing air through an inlet, directing it through a housing, and expelling it at a 90-degree angle. This innovative design enables them to overcome significant resistance across various applications, making them particularly effective for tasks that necessitate under elevated conditions. In contrast to conventional devices, which primarily aim to circulate substantial amounts of air at reduced pressures, high pressure blower fans are specifically tailored for scenarios where pressure is a critical factor.

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive selection of high pressure blower fans designed for diverse industrial applications, including the electronics and automotive sectors. Their product range encompasses:

- DC input Tube Axial units varying from 15 to 280mm

- Centrifugal Blowers from 15 to 225mm

Options for low noise and IP protection are available upon request. These advanced cooling solutions are indispensable for cooling systems, power management, and other critical processes, ensuring optimal performance and efficiency.

Explore Key Features of High Pressure Blower Fans

Several essential features distinguish high pressure blower fans, making them indispensable across various industrial applications.

- Centrifugal Design: These fans leverage centrifugal force to effectively increase air pressure, enabling them to propel air through restrictive environments, such as lengthy ducts and high-resistance filtration systems. This design proves particularly advantageous in scenarios requiring consistent airflow, even in the face of obstacles.

- High Static Pressure: With the capability to generate substantial static pressure, high-pressure fans excel in demanding environments, including dust collection and pneumatic conveying. Their unique impeller design allows them to surpass other fan types, making them ideal for addressing complex system requirements.

- Durability: Constructed from robust materials such as polypropylene, known for its lightweight and chemical-resistant properties, these devices are engineered to endure harsh operating conditions. This durability ensures both , even in corrosive or abrasive environments, as evidenced by case studies showcasing their performance in industrial settings.

- Versatile Applications: High pressure blower fans can be customized for a wide range of industrial uses, including cooling electronic components, exhaust systems, and material handling. Their adaptability renders them suitable for diverse sectors, from food processing to chemical manufacturing.

- Energy Efficiency: Contemporary high-pressure fan units are meticulously designed with energy efficiency in mind, optimizing energy consumption while upholding high performance. These devices deliver airflow at 1,800 to 20,000 RPM, which not only reduces operational expenses but also supports sustainability initiatives across various sectors.

Recent advancements in centrifugal fan design have further enhanced these features, resulting in improved performance and reliability. Expert opinions emphasize the importance of selecting the appropriate fan based on specific application requirements, considering factors such as airflow, specification details, and material design to achieve optimal outcomes.

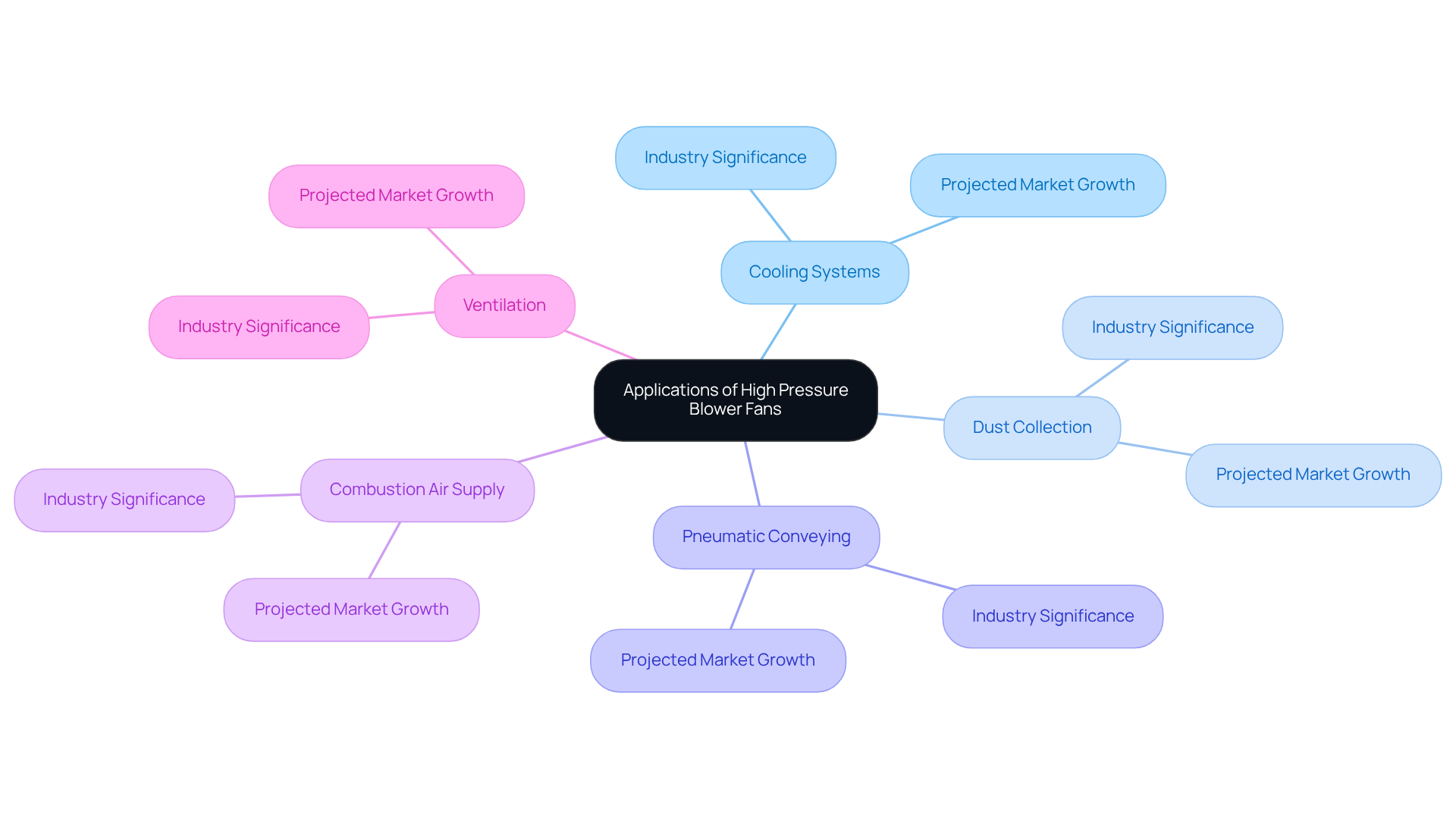

Examine Applications of High Pressure Blower Fans

High capacity ventilation devices are indispensable across various sectors, recognized for their ability to generate substantial force and effectively regulate airflow. Their applications encompass:

- Cooling Systems: Within the electronics industry, high pressure blower fans are critical for dissipating heat from components, thereby ensuring optimal performance and averting overheating. As data centers continue to expand, the demand for efficient cooling solutions is expected to surge significantly, with the commercial sector emerging as the largest end-user of these systems. Each data center facility typically requires approximately 200,000 square feet and 25 MW of power, underscoring the extensive cooling needs within the industry.

- Dust Collection: These devices are vital in dust collection systems, working to uphold air quality in manufacturing environments by effectively eliminating particulate matter. This application holds particular significance in industries where is crucial, such as pharmaceuticals and food processing. The escalating pollutant levels resulting from industrialization further highlight the necessity of these systems.

- Pneumatic Conveying: High force fans facilitate the transport of bulk materials through pipelines, making them essential in sectors like food processing and pharmaceuticals. Their efficiency in material transport contributes to streamlined operations and minimized downtime.

- Combustion Air Supply: They deliver the necessary airflow for combustion processes in boilers and furnaces, thereby enhancing both efficiency and safety. This application is especially critical in industries reliant on thermal processes.

- Ventilation: High force exhaust devices are utilized in ventilation systems to ensure adequate air circulation in enclosed spaces, such as tunnels and mines. Their capacity to maintain air quality in these environments is crucial for worker safety and operational efficiency.

The high capacity fan market is projected to grow at a CAGR of 4.5% from 2025 to 2030, driven by increasing industrialization and the demand for effective air movement solutions. In 2025, the requirement for high pressure blower fans in cooling systems is anticipated to rise, reflecting the ongoing expansion of data centers and commercial structures. As industries continue to prioritize air quality and operational efficiency, high-capacity fan systems will remain a fundamental component across diverse applications. Nonetheless, challenges such as high initial costs and stringent regulations on industrial emissions may influence market dynamics.

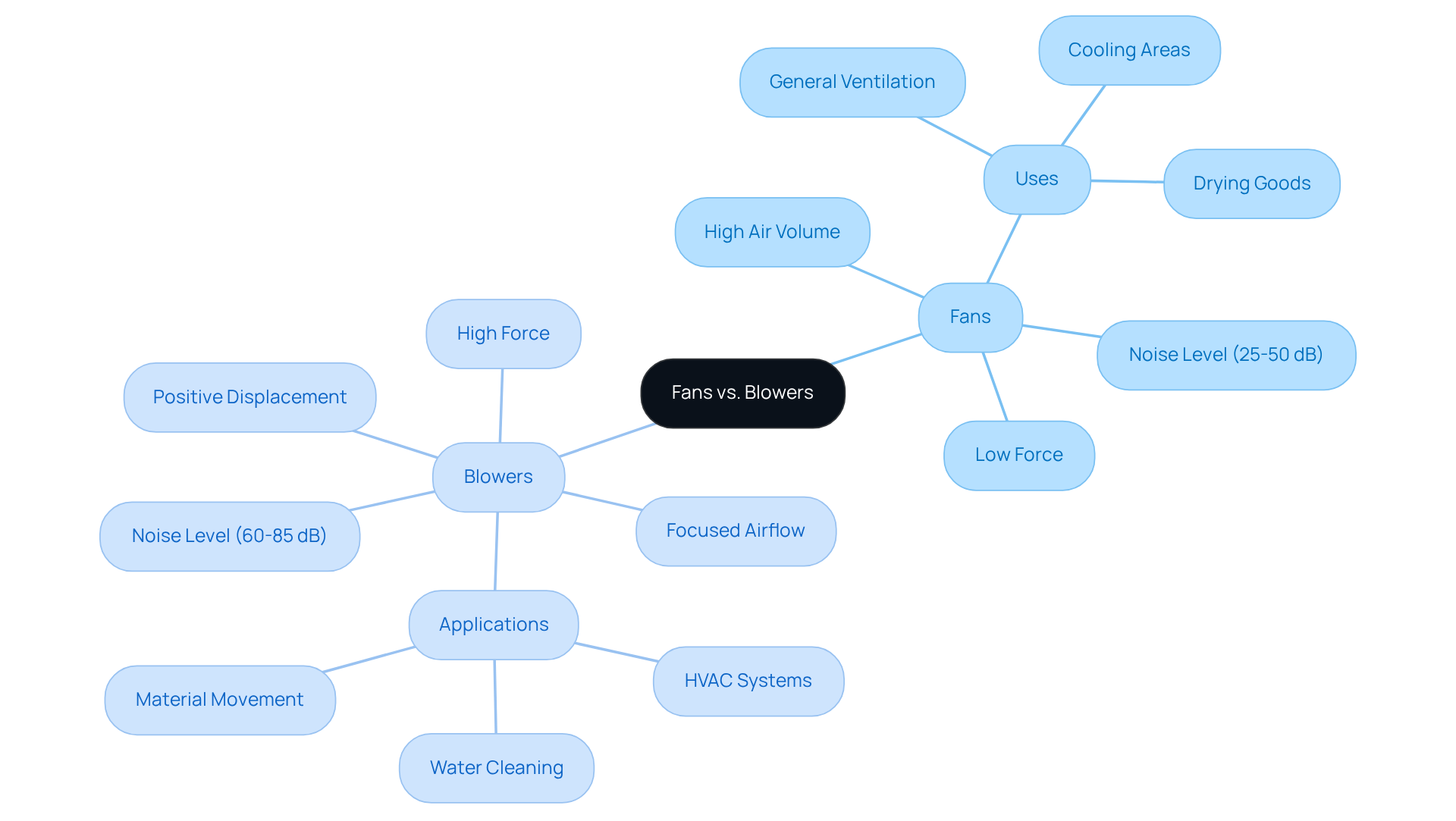

Understanding the Differences Between Fans and Blowers

Fans and blowers, such as the high pressure blower fan, fulfill distinct roles in air movement, operating on unique principles tailored to specific applications.

- Fans are engineered to move substantial volumes of air at low force, making them ideal for general ventilation tasks. Typically, they achieve compression ratios up to 1.11, enabling effective air circulation in environments such as residences and workplaces.

- Conversely, a high pressure blower fan operates within a ratio range of 1.11 to 1.2 and is designed to generate significantly greater forces. This capability renders high pressure blower fans particularly effective in applications that require focused airflow and the ability to overcome considerable resistance, such as in HVAC systems and industrial processes.

- For instance, positive displacement blowers maintain a consistent flow rate irrespective of discharge pressure, making them suitable for tasks like material movement and water cleaning.

Understanding these is vital for selecting the appropriate equipment to meet specific industrial needs, thereby ensuring optimal performance and energy efficiency.

As Gagner Toomey emphasizes, recognizing the distinctions between air movers and ventilators is essential for electronics engineers managing the complexities of airflow in various applications. Furthermore, it is noteworthy that fans operate at noise levels ranging from 25 to 50 dB, while blowers produce noise levels between 60 and 85 dB, further distinguishing their operational characteristics.

Conclusion

High pressure blower fans are essential components in a wide range of industrial applications, engineered to provide focused airflow under conditions of elevated pressure. In contrast to standard fans that circulate large volumes of air at low pressure, these specialized devices excel in overcoming substantial resistance, rendering them indispensable for tasks that demand precise air movement and operational efficiency.

This article has highlighted key features of high pressure blower fans, such as their:

- Centrifugal design

- High static pressure capabilities

- Durability

- Versatility across various applications

- Energy efficiency

These attributes not only enhance performance but also ensure reliability in demanding environments, including cooling systems, dust collection, pneumatic conveying, and ventilation. Furthermore, the discussion has emphasized the critical distinctions between fans and blowers, which are vital for selecting the appropriate equipment for specific industrial requirements.

As industries increasingly prioritize air quality and operational efficiency, the significance of high pressure blower fans will continue to escalate. Their applications in sectors such as electronics, pharmaceuticals, and food processing underscore the persistent demand for effective air movement solutions. By acknowledging the importance of these devices, stakeholders are empowered to make informed decisions that enhance productivity and sustainability in their operations.

Frequently Asked Questions

What is a high pressure blower fan?

A high pressure blower fan is a specialized centrifugal fan designed to generate increased air force while managing a relatively low airflow volume. It draws air through an inlet, directs it through a housing, and expels it at a 90-degree angle, making it effective for tasks that require focused airflow under elevated pressure conditions.

How does a high pressure blower fan differ from conventional fans?

Unlike conventional fans that aim to circulate large amounts of air at lower pressures, high pressure blower fans are specifically engineered for applications where pressure is a critical factor, allowing them to overcome significant resistance.

Who manufactures high pressure blower fans?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, offering a wide selection of high pressure blower fans designed for various industrial applications.

What types of high pressure blower fans are available?

The available types include DC input Tube Axial units ranging from 15 to 280mm and Centrifugal Blowers from 15 to 225mm.

Are there any special features available for high pressure blower fans?

Yes, options for low noise and IP protection are available upon request.

What are the applications of high pressure blower fans?

High pressure blower fans are essential for cooling systems, power management, and other critical processes across diverse industrial sectors, including electronics and automotive industries.