Overview

Centrifugal blowers function by transforming rotational kinetic energy into high-velocity airflow via an impeller, positioning them as crucial components in a multitude of applications, including HVAC systems, electronics cooling, and industrial processes. This article delineates their advantages:

- High efficiency

- Compact design

- Low noise levels

- Durability

These attributes collectively highlight the blowers’ importance in bolstering performance and energy efficiency across a variety of engineering sectors. Understanding these benefits not only underscores their operational value but also encourages consideration of their integration into existing systems.

Introduction

In the realm of engineering, centrifugal blowers emerge as indispensable tools, deftly combining efficiency and versatility across a myriad of applications. They play a critical role in maintaining optimal temperatures in electronic devices and ensuring proper ventilation in HVAC systems. By harnessing the power of rotational kinetic energy, these blowers generate high-velocity airflow that is essential for various industrial processes.

With technological advancements propelling their evolution, a comprehensive understanding of their principles and the advantages they offer is crucial for engineers and technicians alike. As industries increasingly prioritize energy efficiency and performance, the significance of centrifugal blowers continues to rise, paving the way for innovative solutions in manufacturing, automotive, and environmental control sectors.

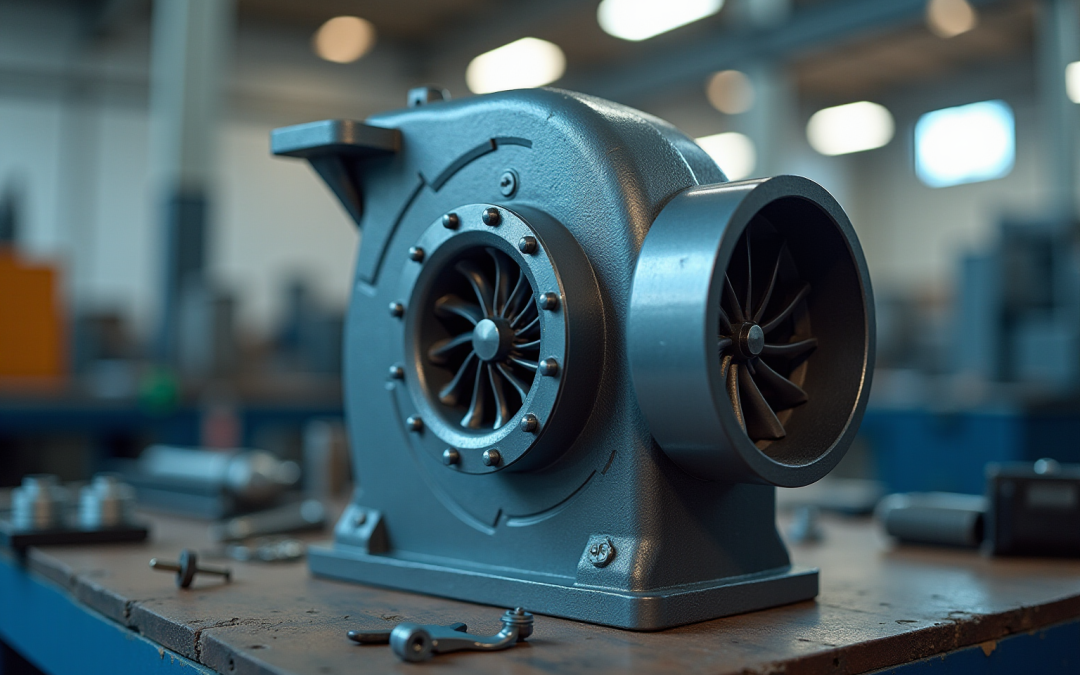

Understand Centrifugal Blowers: Principles and Functionality

Centrifugal blowers operate by converting rotational kinetic energy into airflow, a process fundamentally reliant on the design and operation of the impeller. The impeller, a vital component, consists of blades affixed to a central hub. As it rotates, the impeller draws air into its center and expels it outward at a right angle, thereby generating high-velocity airflow. This mechanism adheres to the principles of fluid dynamics, where the outward force produced by the rotating blades amplifies both air pressure and flow rate. Understanding these principles is essential for selecting the appropriate air mover for specific applications, as they significantly affect performance metrics such as airflow rate and pressure generation. Gagner-Toomey Associates distinguishes itself as the world’s largest manufacturer of both standard and custom centrifugal blowers, offering an extensive range of DC input centrifugal fans optimized for performance, efficiency, and low noise. Their products span sizes from 15 to 225mm, addressing diverse industrial applications, including the electronics and automotive sectors. Most models also provide IP protection upon request, ensuring reliability across various environments.

Key Components:

- Impeller: The rotating element responsible for moving air.

- Housing: Directs airflow and encases the impeller.

- Motor: Powers the rotation of the impeller.

Operational Mechanics:

- Air Intake: Air is drawn in through the inlet located at the impeller’s center.

- Centrifugal Action: The rotation of the impeller forces air outward, increasing velocity.

- Air Discharge: Air escapes through the outlet, typically at a 90-degree angle to the intake direction.

This foundational knowledge is crucial for engineers and technicians aiming to enhance performance across various applications, from HVAC systems to industrial processes. Recent innovations in air-moving technology, particularly those from Gagner-Toomey Associates, highlight the significance of centrifugal blowers in impacting the future of steel production and underscore the importance of selecting the right type of fan to meet specific operational needs. Furthermore, improper wiring of can result in underperformance that is often more challenging to diagnose than that of an axial fan, highlighting the necessity for correct installation and configuration to achieve optimal results.

Evaluate Advantages of Centrifugal Blowers in Electronics

Centrifugal blowers offer a multitude of advantages in electronic applications, solidifying their status as a preferred choice for cooling and ventilation.

- High Efficiency: These fans deliver substantial airflow rates while consuming minimal energy, which is crucial for maintaining optimal temperatures in electronic devices. For example, backward curved wheels can generate significant air volumes at moderate pressures ranging from 5 to 20 inches of static pressure, enhancing their effectiveness across various settings. Case studies illustrate that air movers are not only effective but also long-lasting and adaptable, resulting in lower maintenance costs and improved performance in industrial applications.

- Compact Design: The compact nature of centrifugal fans facilitates installation in restricted areas, making them particularly suitable for modern electronic systems where space constraints are prevalent. This design flexibility allows engineers to integrate centrifugal blowers seamlessly into a variety of applications, as they are employed in diverse environments, including data centers, telecommunications equipment, and consumer electronics, ensuring efficient heat dissipation and optimal performance in critical operations.

- Low Noise Levels: Operating more quietly than other fan types, these devices are ideal for settings where noise reduction is paramount, such as offices and residential areas.

- Durability: Engineered to endure challenging environments, these devices offer reliability and durability in demanding electronic applications, thereby reducing maintenance costs and downtime.

- Emerging Technologies: Recent advancements in rotary fan designs are further enhancing efficiency and sustainability, rendering them increasingly suitable for contemporary electronic applications.

By acknowledging these advantages, engineers can make informed decisions when selecting cooling solutions for electronic systems, ultimately boosting both performance and durability. Gagner-Toomey Associates is dedicated to excellence in customer service and product representation, assisting engineers in identifying the best solutions for their specific needs. The ongoing evolution in underscores their significance in improving energy efficiency and sustainability in electronic applications.

Explore Applications of Centrifugal Blowers in Engineering

Centrifugal blowers are integral to a wide array of engineering applications, showcasing their versatility and effectiveness across various sectors.

- HVAC Systems: Centrifugal blowers are crucial for air circulation and ventilation, ensuring comfortable indoor environments. Their role in enhancing airflow is vital, particularly in light of the increasing demand for energy-efficient solutions.

- Industrial Processes: In manufacturing, rotary fans are indispensable for dust collection, material handling, and cooling equipment, thereby enhancing operational efficiency and safety.

- Electronics Cooling: They are essential for maintaining optimal temperatures for servers, computers, and other electronic devices, ensuring reliability and performance in high-demand environments.

- Automotive Uses: Centrifugal blowers are utilized in vehicle HVAC setups and engine cooling, improving performance and efficiency while complying with stringent environmental regulations.

- Environmental Control: These fans play a significant role in air pollution management frameworks, effectively controlling emissions and enhancing air quality in industrial settings.

Case Studies:

- Data Centers: In cooling mechanisms, these fans are vital for preventing server overheating, thus ensuring uninterrupted operations and data integrity.

- Manufacturing Plants: They are employed in dust collection frameworks, which are essential for maintaining a clean and safe working environment, particularly in industries with high particulate matter.

The U.S. fan market is currently witnessing a compound annual growth rate (CAGR) of 4.78%, reflecting the growing reliance on these systems across various applications. This growth is notably driven by the emphasis on automation and industrial process optimization in North America, as highlighted by SNS Insider. Furthermore, the Latin America centrifugal fan market is projected to expand at a CAGR of 4.9%, bolstered by industrial growth, infrastructure development, and urbanization. Understanding these applications equips engineers and designers with the knowledge necessary to select for their specific needs, ultimately optimizing performance and efficiency.

Conclusion

Centrifugal blowers play a crucial role in engineering, demonstrating their efficiency and versatility across a wide array of applications. By converting rotational kinetic energy into high-velocity airflow, these blowers operate through a meticulously designed mechanism that includes the impeller, housing, and motor. A comprehensive understanding of these operational principles is vital for engineers aiming to select the appropriate blower tailored to specific requirements, thereby ensuring optimal performance in applications that span HVAC systems to industrial processes.

The benefits of centrifugal blowers, particularly within electronic applications, further highlight their importance. Their exceptional efficiency, compact design, and low noise levels render them ideal for contemporary electronic systems, while their robust construction guarantees long-term reliability. As technological advancements perpetually enhance their performance, these blowers emerge as indispensable components in sustaining optimal operating conditions across various sectors, including automotive and environmental control.

The increasing dependence on centrifugal blowers is reflected in the burgeoning market, propelled by the rising demand for energy efficiency and performance optimization. By acknowledging the extensive benefits and applications of centrifugal blowers, engineers and technicians can make informed decisions that not only enhance operational efficiency but also contribute to sustainable practices within their fields. Embracing the potential of centrifugal blowers is imperative for fostering innovation and elevating performance across industries.

Frequently Asked Questions

How do centrifugal blowers operate?

Centrifugal blowers operate by converting rotational kinetic energy into airflow through the design and operation of the impeller, which draws air into its center and expels it outward at a right angle, generating high-velocity airflow.

What is the role of the impeller in a centrifugal blower?

The impeller is a vital component that consists of blades affixed to a central hub. It is responsible for moving air by rotating and creating an outward force that amplifies both air pressure and flow rate.

What are the key components of a centrifugal blower?

The key components include the impeller (responsible for moving air), the housing (which directs airflow and encases the impeller), and the motor (which powers the rotation of the impeller).

What are the main operational mechanics of a centrifugal blower?

The main operational mechanics include: 1. Air Intake: Air is drawn in through the inlet at the impeller’s center. 2. Centrifugal Action: The rotation of the impeller forces air outward, increasing its velocity. 3. Air Discharge: Air escapes through the outlet, typically at a 90-degree angle to the intake direction.

Why is understanding centrifugal blowers important for engineers and technicians?

Understanding centrifugal blowers is crucial for engineers and technicians as it helps them enhance performance across various applications, including HVAC systems and industrial processes.

What distinguishes Gagner-Toomey Associates in the centrifugal blower market?

Gagner-Toomey Associates is the world’s largest manufacturer of both standard and custom centrifugal blowers, offering a wide range of DC input centrifugal fans optimized for performance, efficiency, and low noise, with sizes ranging from 15 to 225mm.

What industrial applications do centrifugal blowers serve?

Centrifugal blowers serve diverse industrial applications, including the electronics and automotive sectors.

What should be considered regarding the installation of centrifugal fans?

Proper wiring and installation are essential for achieving optimal performance, as improper wiring can lead to underperformance that is often more challenging to diagnose than issues with axial fans.