Overview

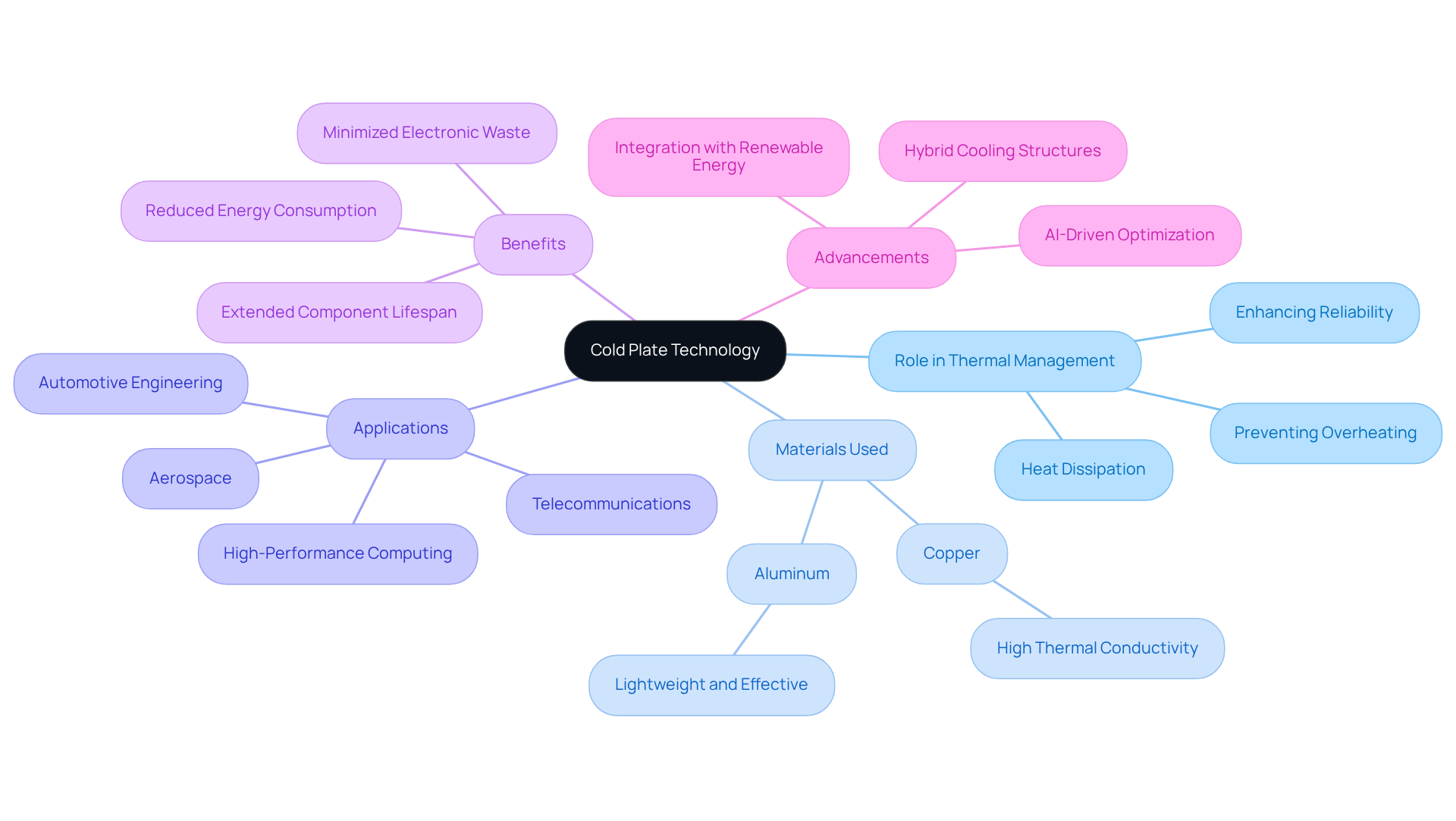

Cold plate cooling technology is crucial for effective thermal management in high-performance electronics. By utilizing thermally conductive surfaces, it dissipates heat and prevents overheating, addressing a significant challenge in the industry. This technology finds applications across various sectors, including telecommunications and aerospace, where the need for efficient thermal solutions is paramount. Notably, advancements such as liquid cooling solutions have emerged, enhancing efficiency, reducing energy consumption, and extending the lifespan of electronic components. These innovations not only improve performance but also contribute to sustainability efforts within the industry.

Introduction

Cold plate cooling technology stands at the forefront of thermal management solutions, essential for ensuring the reliability and longevity of high-performance electronic systems. By utilizing thermally conductive materials to efficiently dissipate heat, cold plates play a critical role across various industries, including:

- Telecommunications

- Aerospace

- Electric vehicles

As electronic components become increasingly compact and powerful, the challenge of integrating these cooling systems effectively raises significant questions:

- How can engineers optimize design and functionality while overcoming space, weight, and cost constraints?

This article delves into the key concepts, applications, and design insights of cold plate cooling, offering a comprehensive exploration of its pivotal role in modern technology.

Define Cold Plate Technology and Its Role in Thermal Management

Cold plate cooling technology represents a critical thermal management solution, using a flat, thermally conductive surface to effectively dissipate heat from electronic components. Typically constructed from such as aluminum or copper, cold plate cooling components are engineered to transfer heat away from essential areas, ensuring devices operate within safe temperature limits. This technology is especially crucial in high-performance electronics, where cold plate cooling is necessary to prevent catastrophic failures due to overheating. By facilitating efficient heat transfer, cold plate cooling significantly enhances the reliability and lifespan of electronic systems.

For example, they find extensive application in telecommunications, aerospace, and automotive engineering, where cold plate cooling is essential for maintaining optimal operating temperatures. Data indicates that effective thermal management through chilled surfaces can reduce energy consumption and extend component lifespan; notably, Google’s DeepMind reportedly achieved a reduction in cooling power by over 30% through AI-driven optimization.

Moreover, advancements in cold plate cooling technology—such as integration with renewable energy systems and the development of hybrid cooling structures—are increasingly recognized by industry leaders for their role in bolstering efficiency and sustainability in modern electronic applications. Additionally, chilled surfaces contribute to minimizing electronic waste by preventing early component failure, thereby lessening environmental impact.

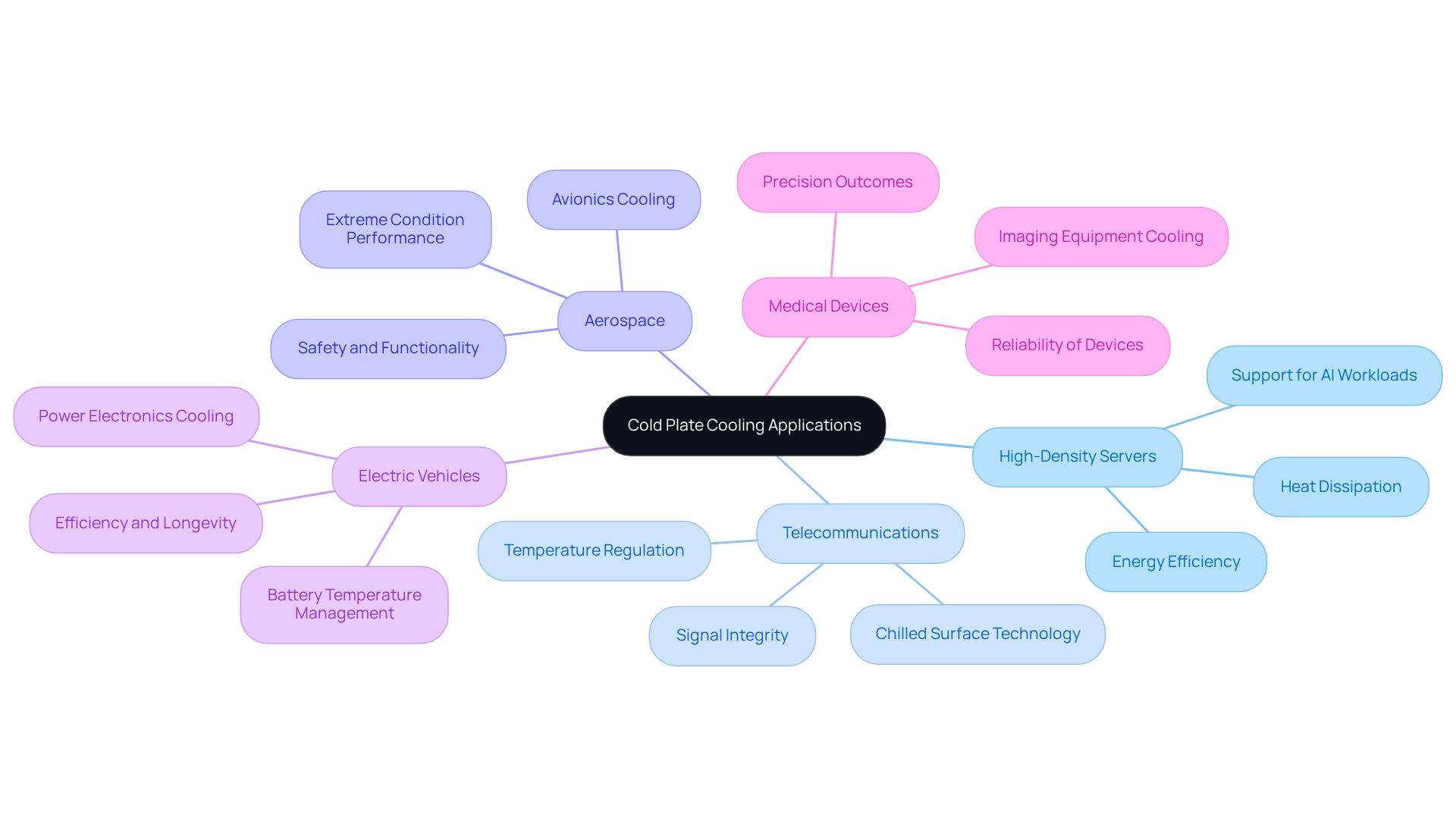

Explore Applications of Cold Plates in Electronics and Beyond

Cold plate cooling plays a crucial role across various applications, leveraging thermal management capabilities to enhance performance and reliability.

In high-density server environments, cold plate cooling is indispensable for dissipating heat generated by processors and other components, ensuring optimal performance and energy efficiency. The shift towards liquid cooling solutions is driven by the increasing deployment of high-performance computing and AI workloads, which produce significantly more heat than traditional IT equipment. Industry forecasts suggest that the data center liquid cooling market is projected to reach USD 36,589.23 million by 2034, reflecting the growing demand for efficient cooling solutions.

Telecommunications: Cold plate cooling is vital for regulating the temperature of essential communication equipment, preventing signal deterioration and ensuring dependable operation. As the telecommunications industry evolves with the increasing deployment of high-performance computing and AI workloads, the demand for efficient cooling solutions continues to rise. Recent case studies, such as the ‘Chilled Surface Liquid Cooling Technology in Data Centers,’ highlight successful applications of chilled surface technology in telecommunications infrastructure, demonstrating their efficiency in enhancing system reliability. Lucas Beran from Dell’Oro Group remarked, “There is a change unfolding…This has led to an upward revision of our liquid cooling forecast,” underscoring the anticipated growth in this sector.

Aerospace: In aircraft systems, cold plate cooling is essential for lowering the temperature of avionics and other electronic components, which is critical for safety and functionality in extreme conditions. The rigorous demands of aerospace applications necessitate advanced cooling technologies to ensure operational integrity.

Electric Vehicles: Cold plate cooling plays a pivotal role in managing the heat of batteries and power electronics, significantly improving the efficiency and longevity of electric vehicles. As the automotive sector transitions towards electrification, the role of cooling components in temperature regulation becomes increasingly vital.

Medical Devices: In medical imaging and diagnostic equipment, cold plate cooling is crucial for sustaining the functionality of delicate electronic components, ensuring precise outcomes. The reliability of these devices is paramount, making efficient temperature control essential.

Looking ahead to 2025, the telecommunications industry is expected to see a rise in the utilization of chilled components, driven by the demand for effective cooling solutions in increasingly complex systems. This trend underscores the importance of in supporting the growth of telecommunications infrastructure.

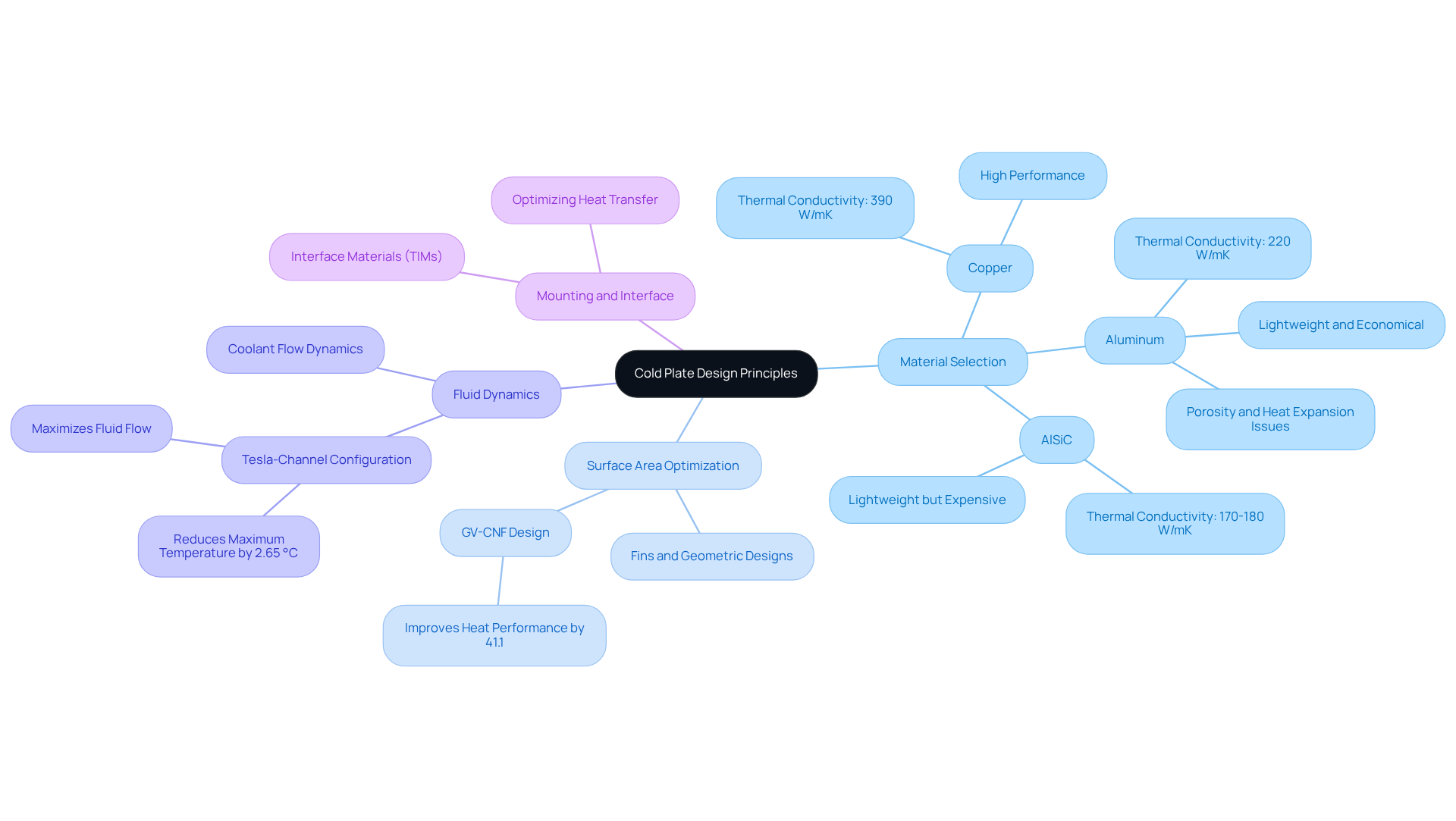

Understand Design Principles and Operational Mechanics of Cold Plates

Designing an effective cold plate necessitates a thorough understanding of several fundamental principles:

- Material Selection: The choice of materials is pivotal, as it directly influences thermal conductivity and weight. Copper stands out for its exceptional heat performance, with a conductivity of 390 W/mK. In contrast, aluminum, offering a conductivity of 220 W/mK, serves as a lighter and more economical alternative. However, the porosity and heat expansion issues associated with aluminum can pose challenges in specific applications. As Paul Hoffman articulates, “Simply put, you cannot get a higher conductivity material than copper without resorting to very expensive materials such as silver or diamond.”

- Surface Area Optimization: Enhancing the surface area of the cooling component is vital for improving heat dissipation. This can be achieved through the integration of fins or innovative geometric designs, such as the gradually varied circular notched fins (GV-CNF) design, which has been shown to enhance heat performance by 41.1% compared to conventional structures.

- Fluid Dynamics: A comprehensive understanding of coolant flow dynamics is critical for liquid-cooled systems. Optimal channel design, exemplified by the Tesla-channel configuration, maximizes fluid flow and boosts heat transfer efficiency while minimizing pressure drops. Research indicates that increasing coolant flow rates significantly enhances convective heat transfer, which is essential for maintaining optimal battery temperatures. Notably, the Tesla-channel design reduces maximum temperature by 2.65 ℃ compared to direct channels, underscoring its effectiveness.

- Mounting and Interface: The interface between the heat exchanger and the electronic component must be meticulously optimized to maximize heat transfer. Utilizing interface materials (TIMs) effectively fills gaps and , ensuring efficient thermal transfer from the component to the chill surface.

Testing and validation are crucial, as rigorous testing is imperative to validate the heat management capabilities of the cold plate cooling design under real-world conditions. This process guarantees reliability and effectiveness, particularly in high-load scenarios typical in electric vehicle applications, where maintaining temperatures below 40 °C is crucial to prevent deterioration. Research emphasizes that effective battery thermal management systems are essential for ensuring the safety and functionality of lithium-ion batteries under high-power operating conditions.

By adhering to these principles, engineers can develop cooling surfaces that not only meet performance standards but also elevate the overall efficiency and safety of electronic systems.

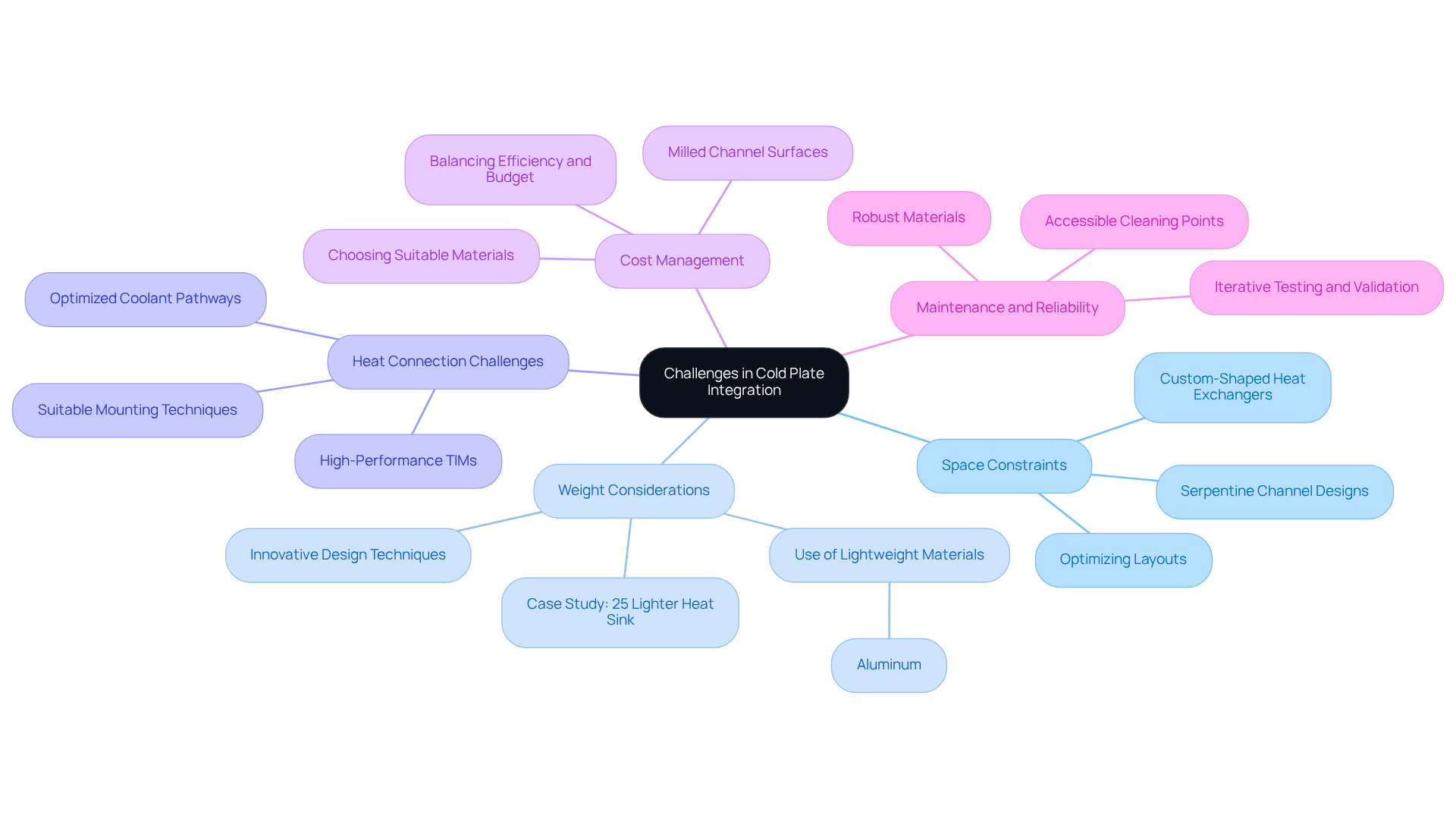

Identify Challenges and Solutions in Cold Plate Integration

Integrating cold plates into electronic systems presents several challenges, particularly in the areas of space and weight management:

- Space Constraints: In compact designs, finding adequate space for cold plates can be challenging. Solutions involve optimizing layouts and utilizing custom-shaped heat exchangers designed to fit the available space. Engineers frequently investigate different channel designs, such as serpentine arrangements, to optimize coolant distribution while reducing the size of the heat exchanger.

- Weight Considerations: The mass of chilled surfaces considerably influences overall design, particularly in mobile applications. Utilizing like aluminum and innovative design techniques can mitigate this issue. A case study involving a collaboration between Puntozero and Dynamis PRC resulted in a liquid-cooled heat sink that was 25% lighter than conventional systems, demonstrating the effectiveness of integrating flow guides that increased the heat transfer surface area by 300%. This design was particularly significant in the context of the Formula SAE Electric competition, where weight reduction is crucial for performance.

- Heat Connection Challenges: Ensuring effective heat contact between the frigid surface and components is critical. High-performance heat transfer interface materials (TIMs) and suitable mounting techniques are essential to tackle this challenge, ensuring optimal heat exchange and system reliability. The efficiency of liquid cooling systems is greatly affected by the arrangement and size of internal coolant pathways, emphasizing the significance of design factors in attaining effective heat management.

- Cost Management: High-performance refrigeration units can be expensive. Balancing efficiency with budget constraints is essential, which can be accomplished by choosing suitable materials and designs that fulfill thermal requirements without excessive expenditure. Milled channel surfaces used in cold plate cooling are frequently preferred for their moderate performance and cost-effectiveness, offering a practical solution for budget-conscious projects.

- Maintenance and Reliability: Cold surfaces must be designed for easy upkeep and long-term dependability. Features such as accessible cleaning points and robust materials enhance durability, ensuring that the cooling systems remain effective over time. Engineers highlight the significance of iterative testing and validation in real-world scenarios to verify the durability of heat management solutions, especially in challenging applications.

By addressing these challenges with innovative solutions, engineers can effectively integrate cold plate cooling into electronic systems, ensuring optimal thermal management and system performance.

Conclusion

Cold plate cooling technology stands as a pivotal solution for effectively managing heat in high-performance electronic systems. By employing a flat, thermally conductive surface, cold plates excel at dissipating heat, thereby ensuring that devices operate within safe temperature ranges. This technology is vital across diverse industries, including telecommunications, aerospace, and automotive, where proficient thermal management directly influences performance, reliability, and sustainability.

The article thoroughly explores the various applications of cold plates, emphasizing their critical role in high-density server environments, electric vehicles, and medical devices. Fundamental design principles, such as material selection, surface area optimization, and fluid dynamics, are paramount for the development of efficient cold plate systems. Furthermore, the challenges associated with integrating cold plates—such as space limitations and weight considerations—are addressed through innovative solutions that guarantee optimal thermal management.

As industries evolve and the demand for more efficient cooling solutions intensifies, the importance of cold plate technology becomes increasingly apparent. Embracing advancements in this domain will not only elevate the performance and longevity of electronic systems but also foster sustainability by minimizing electronic waste. Stakeholders across various sectors are urged to explore the potential of cold plate cooling technology and invest in its development, thereby ensuring a more reliable and efficient future for electronic applications.

Frequently Asked Questions

What is cold plate technology?

Cold plate technology is a thermal management solution that uses a flat, thermally conductive surface to dissipate heat from electronic components.

What materials are commonly used in cold plate construction?

Cold plates are typically constructed from high-conductivity materials such as aluminum or copper.

Why is cold plate cooling important for electronic devices?

Cold plate cooling is crucial for preventing catastrophic failures due to overheating in high-performance electronics, ensuring devices operate within safe temperature limits.

In which industries is cold plate cooling widely used?

Cold plate cooling is extensively applied in telecommunications, aerospace, and automotive engineering.

How does effective thermal management impact energy consumption and component lifespan?

Effective thermal management through chilled surfaces can reduce energy consumption and extend the lifespan of electronic components.

Can you provide an example of a company that has benefited from cold plate technology?

Google’s DeepMind achieved a reduction in cooling power by over 30% through AI-driven optimization, showcasing the benefits of effective thermal management.

What advancements are being made in cold plate cooling technology?

Advancements include integration with renewable energy systems and the development of hybrid cooling structures, which enhance efficiency and sustainability in electronic applications.

How does cold plate technology contribute to environmental sustainability?

Cold plate technology helps minimize electronic waste by preventing early component failure, thereby reducing the environmental impact.