Overview

The article addresses the critical challenge engineers face in selecting and optimizing axial fans for diverse applications. It underscores the necessity of understanding key parameters such as airflow rate, static pressure, and fan speed. Additionally, it highlights the importance of considering various types of fans and their specific applications. This comprehensive approach ultimately aids in enhancing performance and ensuring compliance within thermal management systems.

Introduction

Understanding the intricacies of axial fan systems is essential for engineers seeking to enhance efficiency and performance across various applications. These fans, engineered to move air along their axis through rotating blades, play a pivotal role in cooling and ventilation solutions in numerous industries. By mastering the selection and optimization of axial fans, engineers can unlock significant benefits, ranging from improved airflow to enhanced energy conservation. However, with a myriad of fan types and performance metrics to consider, navigating the complexities of axial fan selection to achieve optimal results presents a unique challenge.

Explore the Fundamentals of Axial Fan Systems

Axial blowers are specifically designed to move air along their axis, employing rotating blades to generate a pressure difference that facilitates airflow. The operation of these devices is fundamentally rooted in the principles of fluid dynamics, wherein the blades push air in a linear direction. Gagner-Toomey Associates, recognized as the largest manufacturer of standard and custom air-movers globally, offers an extensive range of [DC input fan axial products](https://gagner-toomey.com/10-benefits-of-compact-axial-fans-for-electronics-cooling), available in sizes ranging from 15 to 280mm, all optimized for functionality, efficiency, and low noise. Understanding key parameters is essential:

- Airflow Rate: This is measured in cubic feet per minute (CFM) and indicates the volume of air the fan can move.

- Static Pressure: This refers to the resistance the fan must overcome to move air through a system, typically measured in inches of water gauge (in. wg).

- Fan Speed: Usually expressed in revolutions per minute (RPM), this parameter affects both airflow and noise levels.

Grasping these fundamentals is crucial for optimizing fan axial performance across various applications, including cooling electronic components and enhancing ventilation systems. Gagner-Toomey’s innovative cooling solutions also encompass a comprehensive portfolio of DC input centrifugal blowers and miniature blower/fan solutions, ensuring that engineers have access to the appropriate tools for diverse thermal management requirements. For example, centrifugal blowers are particularly suited for applications necessitating greater static pressure, while small-scale ventilators excel in compact spaces within consumer electronics.

Identify Different Types of Axial Fans and Their Applications

Axial fans are categorized into several types, each tailored for specific applications, making it essential for engineers to grasp their characteristics and uses:

- Propeller Fans: Representing the most straightforward design, these fans excel in low-pressure, high-volume applications such as ventilation in expansive spaces. Their simplicity facilitates effective airflow management, rendering them a popular choice in large industrial settings. For instance, propeller blowers are frequently utilized in vast warehouses and manufacturing facilities, where their capacity to move significant amounts of air at low pressure is crucial. Market analysis reveals that propeller units command a substantial share in ventilation systems, primarily due to their cost-effectiveness and ease of installation.

- Tube Axial Blowers: Designed for higher pressure scenarios, tube axial blowers are commonly employed in HVAC systems and various industrial processes. Their design enables them to sustain air movement against elevated resistance, making them suitable for environments where air must be transported through ducts or other constricted routes. The Dayton Electric fan axial, for example, has a capacity of 239 CFM, exemplifying its effectiveness in such applications.

- Vane Axial Blowers: Equipped with guide vanes, these devices enhance performance and are ideal for applications necessitating precise air movement control. The inclusion of vanes allows for improved directionality and reduced turbulence, which is vital in contexts where airflow consistency is paramount. The enhancement of these units can yield significant advancements in metrics, such as increasing peak effectiveness from 69% to 72%.

When contrasting propeller fans with fan axial fans, it is imperative to recognize that while propeller fans are more suited for general ventilation, fan axial fans deliver superior performance in high-pressure environments. This distinction is critical for engineers tasked with selecting the appropriate fan type based on specific operational requirements.

Understanding these distinctions and applications empowers engineers to make informed decisions that in their designs. Moreover, the case study on “Axial Fan Optimization Using TCFD and CAESES” underscores the importance of improving efficiency and air movement capacity, presenting a practical example of how these principles can be applied in real-world situations.

Optimize Axial Fan Selection for Performance and Compliance

To optimize axial fan selection, engineers must consider several key factors:

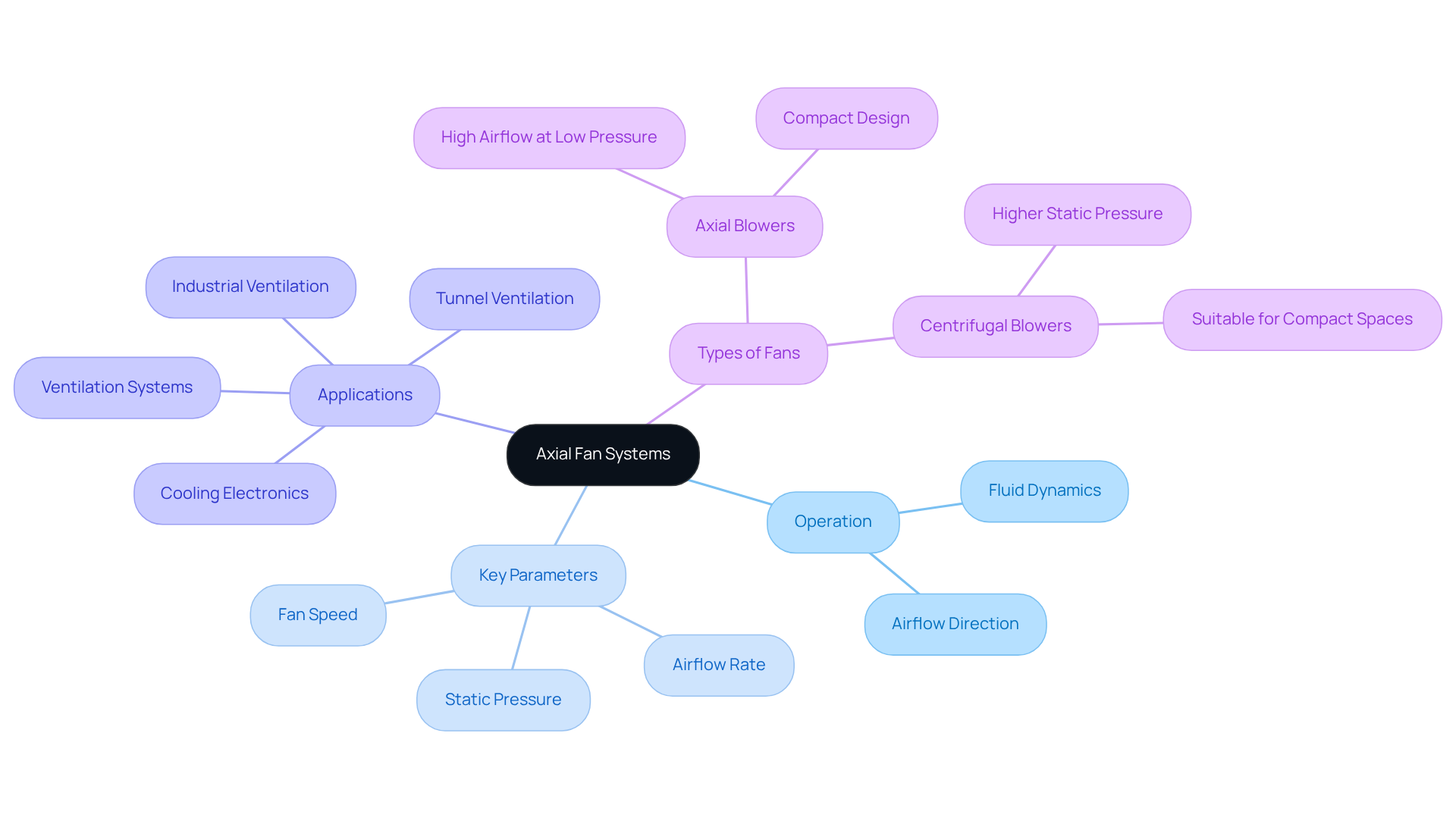

- Fan Curves: Analyzing the fan’s performance curves is essential, as they illustrate the relationship between airflow, static pressure, and fan speed. Comprehending these curves enables engineers to choose a fan that operates effectively within the necessary parameters, ensuring optimal performance across varying conditions. Fan performance curves typically display a bell shape, indicating that both air movement and static pressure must be balanced for effective cooling. Notably, at zero airflow, there is no airpower, and at maximum airflow, static pressure is zero, which is crucial for understanding fan performance dynamics.

- Performance Ratings: Selecting fans with high performance ratings is vital for minimizing energy usage and operational costs. According to AMCA Standard 205, a maximum deviation of 15 percentage points below the fan’s total peak performance is acceptable when choosing an efficient fan. Furthermore, the Fan Energy Index (FEI) is a significant metric; values exceeding 1 indicate increased efficiency, supporting sustainability objectives and enhancing the overall functionality of electronic systems.

- Noise Levels: The acoustic performance of the fan is another critical consideration, particularly in applications where noise reduction is paramount. Fans designed for low noise operation can significantly improve user comfort, making them suitable for environments sensitive to sound. Understanding the of heat dissipation devices is essential for selecting the appropriate unit for your application.

By thoroughly evaluating these factors, engineers can ensure that their selection of fan axial aligns with operational objectives and regulatory standards, ultimately resulting in more reliable and effective cooling solutions.

Implement Best Practices for Installation and Maintenance of Axial Fans

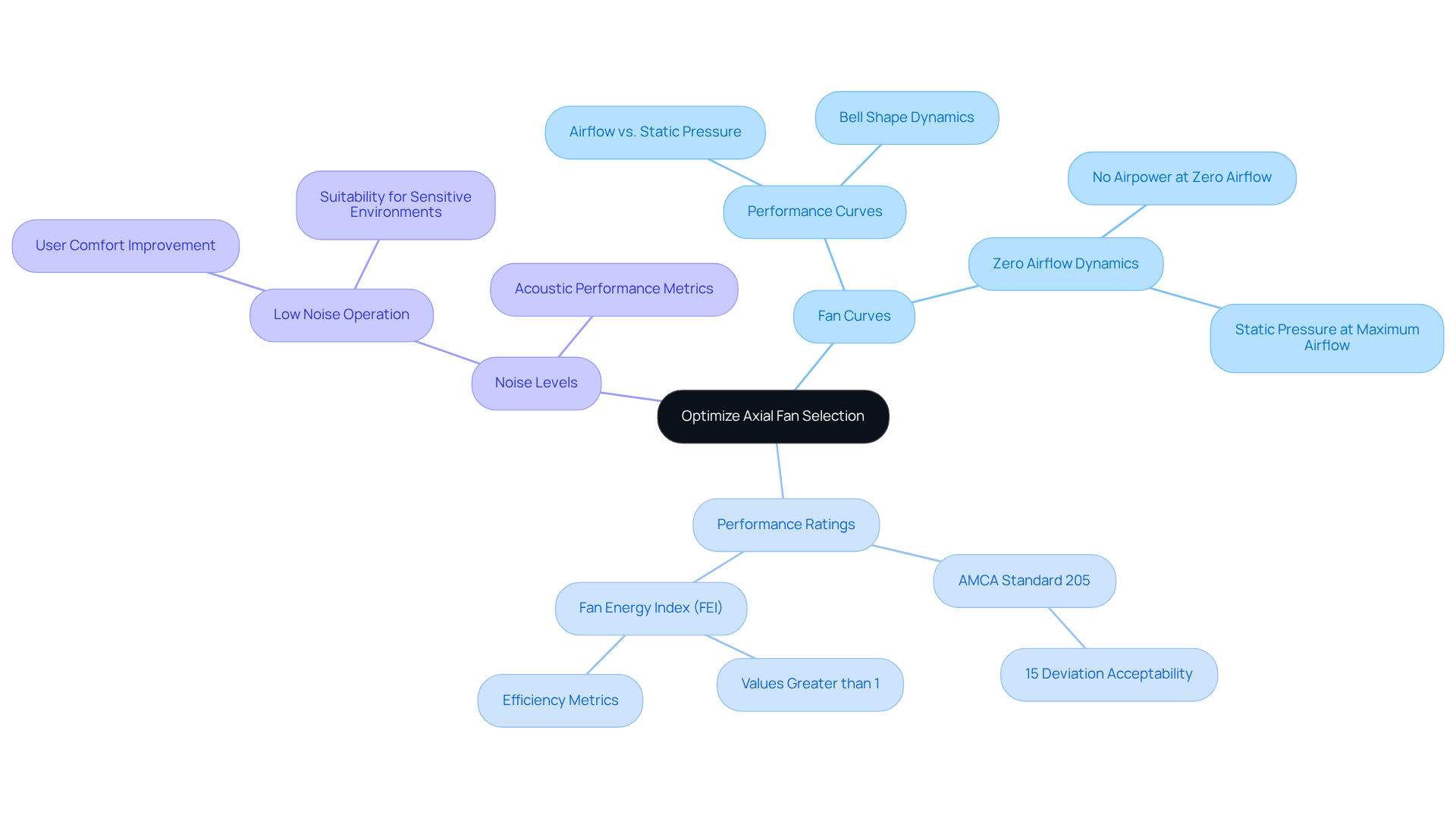

To ensure optimal performance and longevity of axial fans, it is crucial to adhere to the following best practices:

- Installation: Position the fan in a location that allows for unobstructed airflow. Correct alignment and stable mounting are essential to reduce vibration and noise, which can significantly influence overall performance.

- Regular Maintenance: Implement a routine inspection schedule to assess wear and tear, clean fan blades, and lubricate moving parts as needed. Regular maintenance not only sustains efficiency but also prevents unexpected failures that can disrupt operations. For instance, in industrial environments, blowers should be maintained every 6 to 12 months, including inspections of bearings and motor conditions. It is important to note that axial fans have a lifespan potential of 5-10 years, and the recommended cleaning frequency varies: weekly for heavy industrial use, monthly for moderate use, and quarterly for light usage.

- Monitoring Performance: Employ sensors to track airflow, temperature, and noise levels. This data can help identify potential issues early, allowing for proactive maintenance. Regular monitoring can lead to significant cost savings by addressing minor problems before they escalate into major repairs. Environmental factors such as corrosive air, dust, and high humidity can shorten fan life, making it essential to monitor these conditions as well.

By following these best practices, engineers can greatly enhance the reliability and efficiency of fan axial systems in their applications, ensuring they operate smoothly and effectively over time.

Conclusion

Mastering the selection and optimization of axial fans is paramount for engineers striving to elevate system performance and efficiency. Understanding the fundamental principles of axial fan systems enables engineers to make informed decisions that cater to specific operational needs. Navigating the complexities of airflow rates, static pressure, and fan speed is essential for ensuring the right fan is chosen for each unique application.

In this tutorial, various types of axial fans have been examined, each highlighting its specific applications and operational characteristics. From propeller fans, which excel in low-pressure environments, to tube axial blowers, designed for higher resistance scenarios, recognizing these distinctions empowers engineers to select the most effective solutions. Furthermore, the significance of considering fan curves, performance ratings, and noise levels as critical factors in optimizing axial fan performance and compliance with regulatory standards has been emphasized.

Ultimately, the insights shared in this article underscore the importance of diligent selection, installation, and maintenance practices. By adhering to best practices, engineers can enhance the reliability and efficiency of axial fans while contributing to energy conservation and sustainability goals. As the demand for effective thermal management solutions continues to rise, embracing these principles will be vital for achieving optimal outcomes in various engineering applications.

Frequently Asked Questions

What are axial blowers and how do they operate?

Axial blowers are devices designed to move air along their axis using rotating blades to create a pressure difference that facilitates airflow. They operate based on fluid dynamics principles, pushing air in a linear direction.

What is the significance of airflow rate in axial fans?

The airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air that the fan can move, which is crucial for determining the fan’s effectiveness in various applications.

How is static pressure defined in the context of axial fans?

Static pressure refers to the resistance that the fan must overcome to move air through a system, typically measured in inches of water gauge (in. wg).

What does fan speed indicate and how is it measured?

Fan speed is usually expressed in revolutions per minute (RPM) and affects both the airflow and noise levels produced by the fan.

Why is it important to understand the fundamentals of axial fan performance?

Understanding these fundamentals is essential for optimizing axial fan performance across various applications, such as cooling electronic components and enhancing ventilation systems.

What types of products does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a wide range of DC input fan axial products, available in sizes from 15 to 280mm, as well as DC input centrifugal blowers and miniature blower/fan solutions.

When are centrifugal blowers preferred over axial fans?

Centrifugal blowers are particularly suited for applications that require greater static pressure, while axial fans are more effective for applications that require high airflow at lower pressures.

What applications can benefit from small-scale ventilators?

Small-scale ventilators are ideal for compact spaces within consumer electronics, providing effective airflow in limited areas.