Overview

This article provides an in-depth examination of the various types of centrifugal fans and their applications, serving as a comprehensive guide for engineers in selecting the most suitable fan for their specific requirements. It begins by addressing the critical factors that influence fan selection, including:

- Airflow requirements

- Static pressure

- Efficiency

- Noise levels

- Size

- Material compatibility

These elements are essential for optimizing performance and ensuring reliability across diverse environments. By understanding these key considerations, engineers can make informed decisions that enhance operational efficiency and effectiveness.

Introduction

Centrifugal fans are essential components across various industries, acting as the backbone for efficient air and gas movement by transforming rotational energy into kinetic energy. Engineers responsible for selecting the appropriate type of centrifugal fan encounter a vast array of options, each tailored for specific applications and environments.

With numerous classifications and performance criteria to evaluate, how can one guarantee the optimal choice for their project? This guide explores the complexities of centrifugal fan types, selection criteria, and vital maintenance strategies, empowering engineers with the insights needed to enhance system efficiency and reliability.

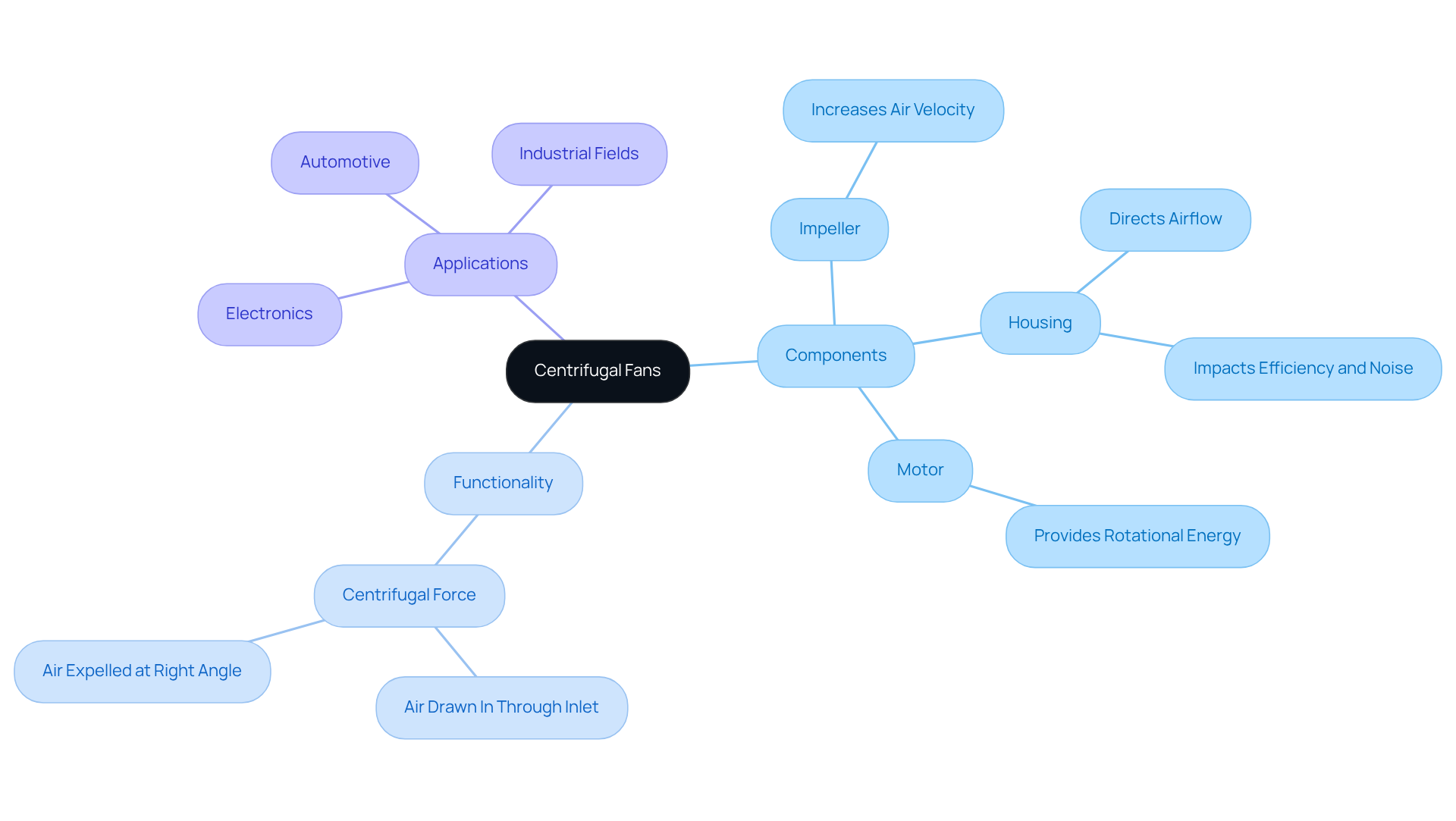

Understand Centrifugal Fans: Basics and Functionality

Centrifugal fan type blowers are mechanical devices designed to efficiently move air or gas by converting rotational energy into kinetic energy. Operating on the principle of centrifugal force, these centrifugal fan type blowers draw air into the fan through an inlet and expel it at a right angle through a discharge outlet. Understanding the fundamental components of the centrifugal fan type—such as the impeller, housing, and motor—is crucial for optimizing their performance. The impeller, typically a wheel with blades, plays a vital role in the operation of a centrifugal fan type by increasing the air’s velocity. Meanwhile, the housing of the centrifugal fan type directs airflow and has a significant impact on both the fan’s efficiency and noise levels.

Gagner-Toomey Associates offers an extensive selection of centrifugal fan type blowers and ventilators, which are meticulously enhanced for effectiveness and efficiency across various applications in electronics, automotive, and industrial fields. Their portfolio includes both standard and custom designs of centrifugal fan type, with dimensions ranging from 15mm to 225mm for blowers and 15mm to 280mm for other devices, ensuring that engineers can find the ideal solution for their cooling requirements.

Additionally, Gagner-Toomey provides cutting-edge thermal management solutions, featuring extruded aluminum heatsinks, copper-based heat sinks, and integrated cooling setups. These innovations further in cooling and power management applications, solidifying Gagner-Toomey’s position as a leader in the field.

Explore Different Types of Centrifugal Fans

Centrifugal fans can be categorized into several types based on their design and application, each serving distinct purposes in various environments:

- Forward Curved Fans: Featuring blades that curve in the direction of rotation, these fans deliver high airflow at low pressure. Commonly utilized in HVAC setups and light-duty applications, they may encounter challenges in high-pressure scenarios, leading to potential overloads if system resistance increases unexpectedly.

- Backward Curved Blowers: A specific centrifugal fan type, these have blades curving against the direction of rotation, excelling in high-pressure environments and making them ideal for industrial applications. Their efficiency ranges from 80-85%, with the capability to achieve static efficiency approaching 90%. Backward models are often 10%-20% more efficient than forward models under similar conditions, significantly exceeding forward models, which typically achieve 60-70% efficiency. This design reduces energy loss and enhances performance stability, especially in setups with greater resistance.

- Radial Blowers: A centrifugal fan type designed with blades extending directly from the hub, these are intended for high-pressure uses and are frequently employed in dust collection setups. Their robust construction and reliability are crucial for effectively handling contaminated air, rendering them suitable for harsh industrial environments.

- Mixed Flow Fans: These combine features of both axial and centrifugal fan types, offering a balance of high airflow and pressure capabilities. This versatility makes them appropriate for a broad spectrum of applications, from ventilation to air conditioning systems.

When selecting a fan, engineers must consider both the , alongside factors such as airflow requirements, pressure conditions, and available installation space to ensure optimal operation and efficiency.

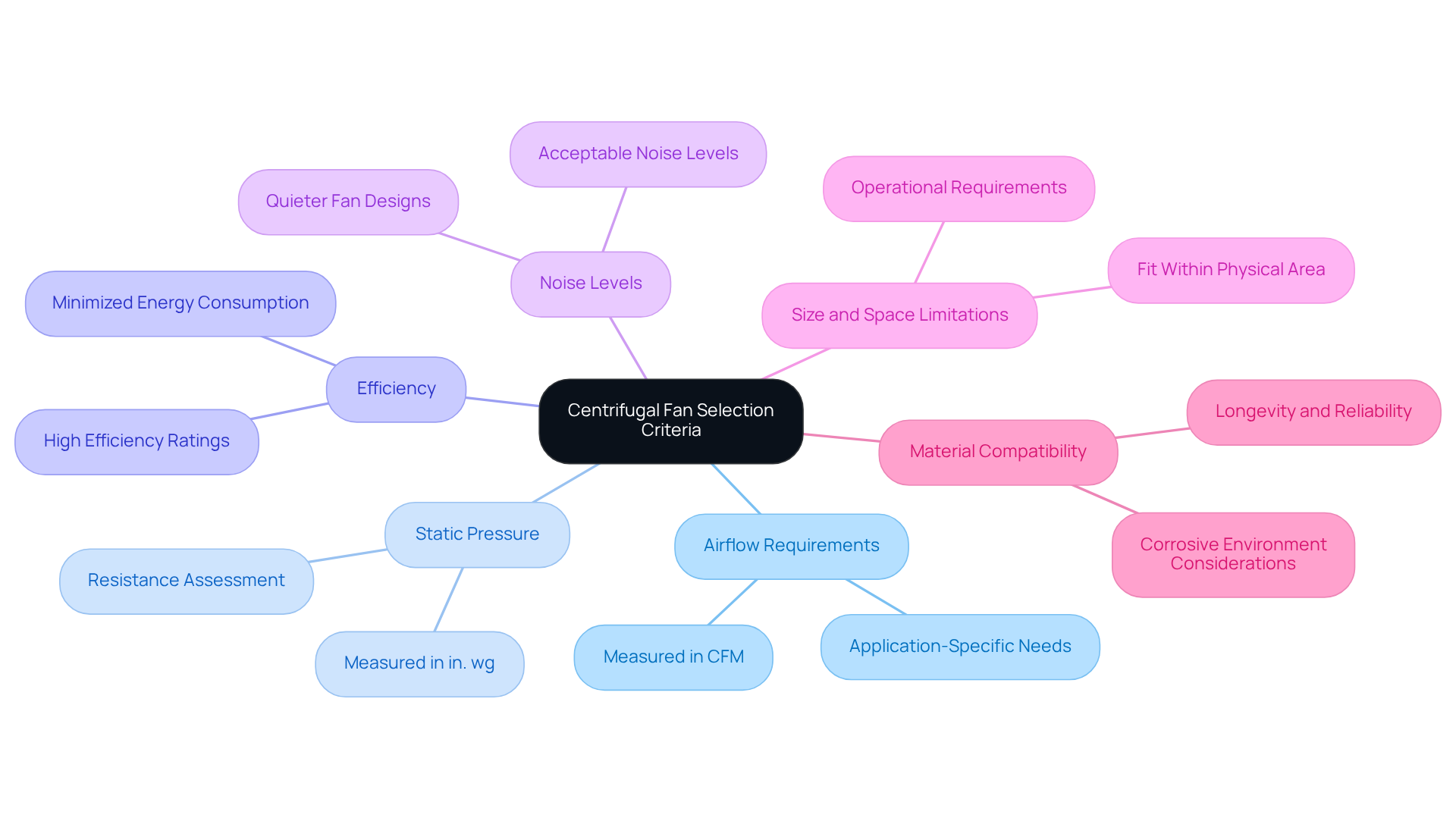

Evaluate Selection Criteria for Your Project

When selecting a for your project, it is essential to consider several key criteria that will directly impact your system’s performance and efficiency.

- Airflow Requirements: Begin by determining the volume of air necessary for your application, measured in cubic feet per minute (CFM). This foundational step ensures that the fan can adequately meet your needs.

- Static Pressure: Next, assess the resistance the fan will encounter in the system, as this significantly affects its performance. Static pressure is typically measured in inches of water gauge (in. wg).

- Efficiency: It is crucial to look for fans with high efficiency ratings. This choice minimizes energy consumption and reduces operational costs, making it a wise investment.

- Noise Levels: Evaluate the acceptable noise levels for your application. Some fan designs are inherently quieter than others, which can be a deciding factor in environments where noise control is paramount.

- Size and Space Limitations: Ensure that the fan fits within the physical area available while still meeting all operational requirements. This consideration prevents potential installation challenges.

- Material Compatibility: Finally, consider the materials used in the fan’s construction, especially if it will be exposed to corrosive environments. Selecting the right materials is vital for longevity and reliability.

By thoroughly assessing these criteria, engineers can confidently choose a centrifugal fan type that not only satisfies their project’s specific requirements but also enhances overall system efficiency.

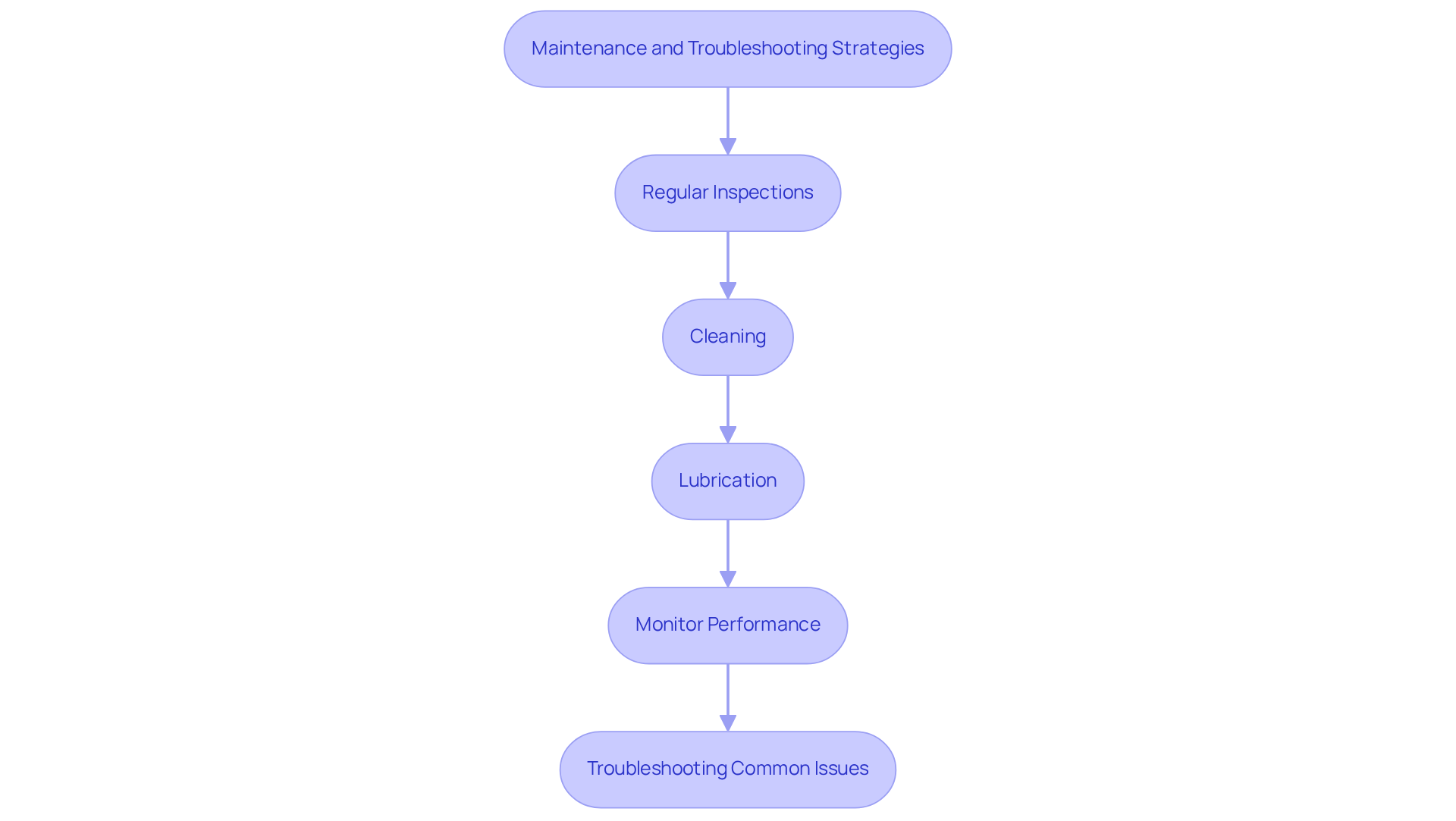

Implement Maintenance and Troubleshooting Strategies

To ensure optimal performance and longevity of the centrifugal fan type, it is essential to implement .

- Regular Inspections: Schedule routine inspections to identify any signs of wear, damage, or misalignment. Be vigilant for unusual noises or vibrations, as these may indicate underlying issues.

- Cleaning: Keep the fan and surrounding areas clean to prevent dust and debris accumulation, which can obstruct functionality. Employ appropriate cleaning methods tailored to the fan’s material and design.

- Lubrication: Ensure proper lubrication of bearings and moving parts according to the manufacturer’s specifications. This practice minimizes friction and wear, contributing to the fan’s longevity.

- Monitor Performance: Utilize performance metrics, such as airflow and pressure readings, to detect any deviations from expected performance. Such deviations may signal a need for maintenance.

- Troubleshooting Common Issues: Familiarize yourself with common problems, including reduced airflow or increased noise, and their potential causes. For instance, a decrease in airflow may stem from a clogged filter or ductwork.

By adhering to these strategies, engineers can effectively maintain the efficiency and reliability of the centrifugal fan type, ensuring they continue to perform optimally in their applications.

Conclusion

Centrifugal fans are indispensable mechanical devices that transform rotational energy into kinetic energy, effectively transporting air or gas across a multitude of applications. A thorough understanding of their functionality and the various types available empowers engineers to choose the most appropriate fan for their specific requirements, thereby ensuring optimal performance in diverse environments.

This guide has examined the fundamental characteristics of several centrifugal fan types, including:

- Forward curved fans

- Backward curved blowers

- Radial blowers

- Mixed flow fans

Each type fulfills unique roles, ranging from delivering high airflow in HVAC systems to catering to high-pressure demands in industrial contexts. Moreover, essential selection criteria such as airflow requirements, efficiency, noise levels, and material compatibility have been emphasized to aid engineers in making informed choices.

The importance of selecting the correct centrifugal fan cannot be overstated. By taking into account the discussed factors and implementing effective maintenance strategies, engineers can significantly enhance system efficiency and reliability. Acquiring this knowledge equips professionals with the necessary tools to optimize cooling solutions and effectively tackle the challenges presented by modern applications across various industries.

Frequently Asked Questions

What is a centrifugal fan type blower?

A centrifugal fan type blower is a mechanical device designed to efficiently move air or gas by converting rotational energy into kinetic energy, operating on the principle of centrifugal force.

How does a centrifugal fan work?

A centrifugal fan works by drawing air into the fan through an inlet and expelling it at a right angle through a discharge outlet, utilizing the rotational motion of its impeller.

What are the key components of a centrifugal fan?

The key components of a centrifugal fan include the impeller, housing, and motor. The impeller increases the air’s velocity, while the housing directs airflow and affects the fan’s efficiency and noise levels.

What types of applications are centrifugal fans used in?

Centrifugal fans are used in various applications across electronics, automotive, and industrial fields, providing effective airflow and cooling solutions.

What range of sizes do centrifugal fans come in?

Gagner-Toomey offers centrifugal fans in standard and custom designs, with dimensions ranging from 15mm to 225mm for blowers and 15mm to 280mm for other devices.

What additional solutions does Gagner-Toomey provide for thermal management?

Gagner-Toomey provides advanced thermal management solutions, including extruded aluminum heatsinks, copper-based heat sinks, and integrated cooling setups, which enhance the performance of centrifugal fans in cooling and power management applications.