Overview

The article examines the types, principles, and implementation of heat sink pipes, underscoring their vital role in managing thermal energy within electronic devices. It articulates that effective heat dissipation is crucial for averting component failure and optimizing performance. The discussion is bolstered by insights into material selection, design considerations, and the latest advancements in cooling technologies. Collectively, these elements underscore the escalating demand for efficient thermal management solutions in the electronics industry.

Introduction

Cooling is a critical aspect of modern electronics, where excessive heat can compromise performance and longevity. As devices become more powerful and compact, the role of heat sink pipes emerges as a vital solution for efficient thermal management. This article delves into the types, principles, and implementation techniques of heat sink pipes, exploring how they can enhance electronic performance and address the challenges posed by increasing thermal demands. Key factors engineers must consider to optimize heat dissipation and ensure reliability in their designs will be examined.

Define Heat Sinks and Their Importance in Electronics

Cooling devices, such as heat sink pipes, serve as vital passive thermal exchangers, effectively dispersing heat generated by electronic components into the surrounding environment. Their significance in the electronics sector is paramount; excessive heat can lead to increased failure rates, reduced performance, and a shortened lifespan of devices. Thus, efficient temperature management through the use of a heat sink pipe and other cooling components is essential for maintaining optimal operating conditions, ensuring reliable and effective device performance.

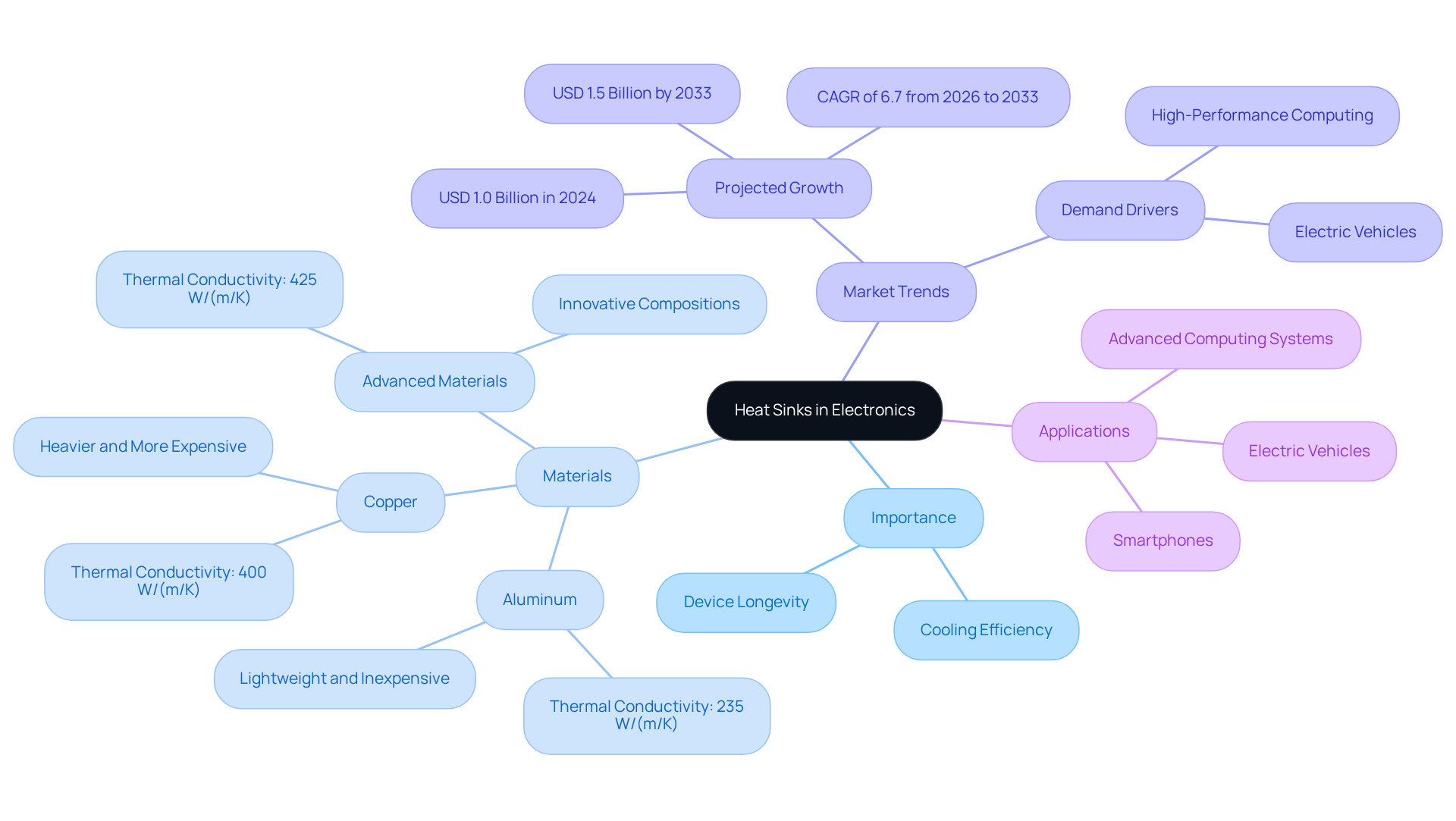

Gagner-Toomey Associates stands out as the world’s largest manufacturer of standard and custom air-movers for cooling, offering a comprehensive range of temperature management solutions, including extruded aluminum cooling components and copper-based cooling elements. Recent advancements in cooling component technology, such as the integration of AI for design optimization and the utilization of advanced materials, have significantly enhanced their efficiency. Notably, the market for cooling components is projected to grow from USD 1.0 billion in 2024 to USD 1.5 billion by 2033, underscoring the increasing demand for effective temperature management in high-performance electronics.

The design and material selection of the heat sink pipe are critical factors influencing its performance. Engineers must prioritize maximizing surface area and heat conductivity in order to improve heat dissipation through the heat sink pipe. Materials like aluminum and copper are commonly used due to their excellent thermal properties, with copper boasting a conductivity of approximately 400 W/(m/K). However, innovative materials developed by Gagner-Toomey Associates, featuring a thermal conductivity of 425 W/(m/K), present exciting alternatives, including the use of a heat sink pipe, that could further enhance performance. The choice of materials also affects cost and manufacturing efficiency.

The practical applications of thermal dissipators, such as heat sink pipes, are evident in various electronic devices, ranging from smartphones to advanced computing systems. For instance, active thermal dissipators, which utilize forced air from fans, are particularly effective in environments where heat generation is substantial. Conversely, passive thermal dissipators rely on natural convection, making them suitable for compact devices with limited space. Furthermore, the growing adoption of electric vehicles emphasizes the importance of cooling devices in addressing temperature challenges within this expanding industry.

Understanding the significance of is essential for engineers tasked with designing systems capable of withstanding thermal stresses. As the electronics industry continues to evolve, the role of the heat sink pipe in preventing component failure and ensuring device longevity remains critical. Moreover, automation in the production of thermal components at Gagner-Toomey Associates is enhancing manufacturing efficiency and cost-effectiveness, establishing it as a key trend to consider in design and production processes.

Explore Types of Heat Sinks: Heat Pipes vs. Vapor Chambers

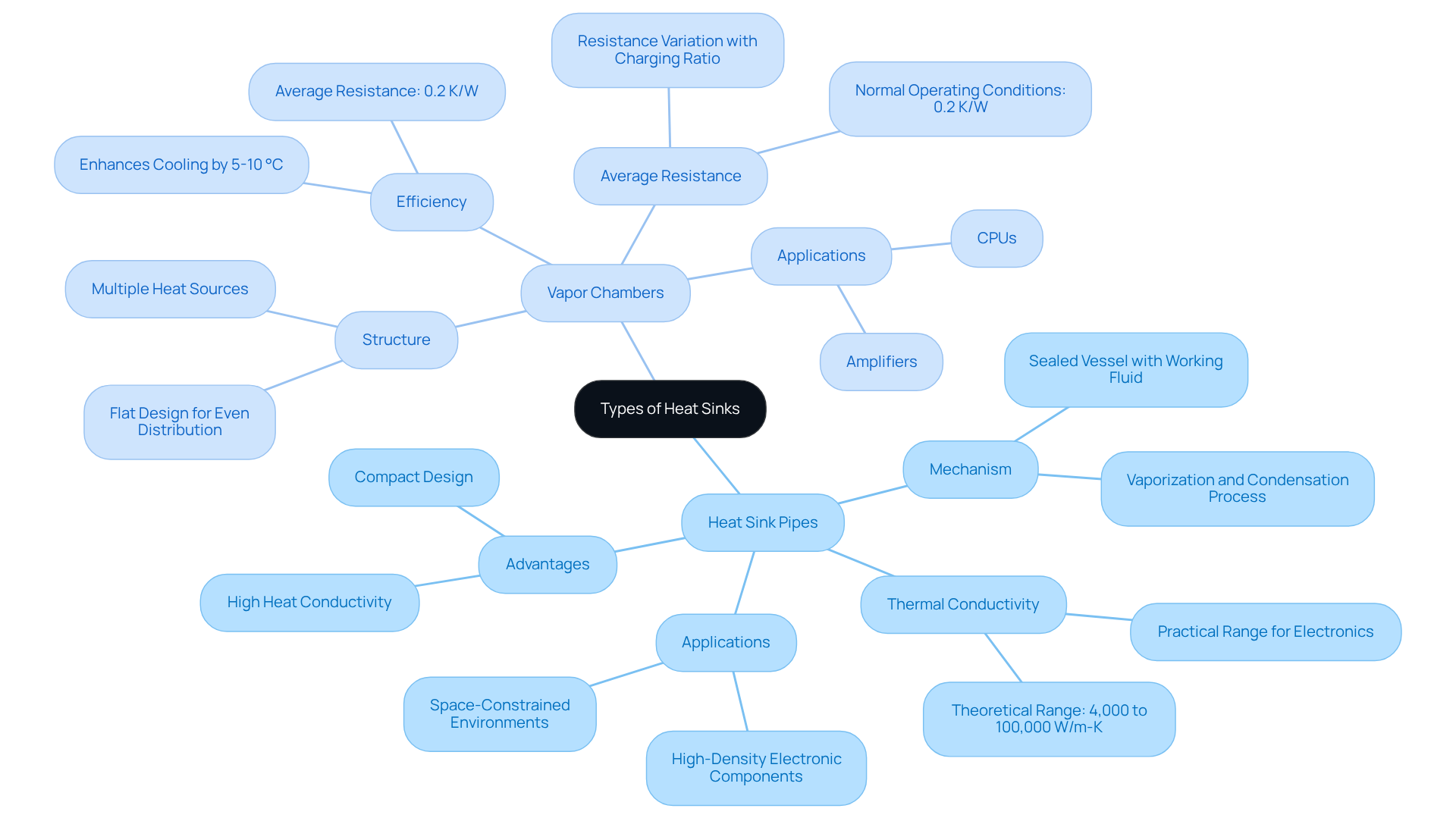

Cooling sinks are available in a variety of designs, with the heat sink pipe and vapor chambers emerging as two of the most efficient solutions for temperature regulation. Heat sink pipes operate through a sealed vessel filled with a working fluid that absorbs energy at one end, vaporizes, and subsequently condenses at the cooler end, facilitating effective thermal transfer. Their high heat conductivity theoretically ranges from 4,000 to 100,000 W/m-K; however, practical ranges for electronics typically fall lower. This characteristic renders the heat sink pipe ideal for applications where space is constrained and performance is paramount. For instance, a heat sink pipe can achieve thermal conductivities suitable for high-density electronic components.

Conversely, vapor chambers feature a flat structure that promotes even warmth distribution across a larger surface area. This quality is particularly advantageous in high-power applications, where rapid and uniform is critical. Recent studies indicate that vapor chambers can enhance cooling component efficiency by 5-10 °C, significantly improving temperature control in devices such as CPUs and amplifiers. The average resistance of vapor chambers generally hovers around 0.2 K/W under normal operating conditions, ensuring effective energy dissipation and reinforcing their reliability.

Engineers must consider these distinctions when selecting thermal dissipators for their projects. As Dean McClements, a B.Eng Honors graduate in Mechanical Engineering, emphasizes, “By recognizing the temperature needs, designers can choose a cooling component that upholds safe operating temperatures and enhances optimal performance of the parts.” This insight underscores the importance of understanding the specific thermal management requirements of each application to make informed decisions regarding cooling technology.

Understand the Principles of Heat Transfer in Heat Sinks

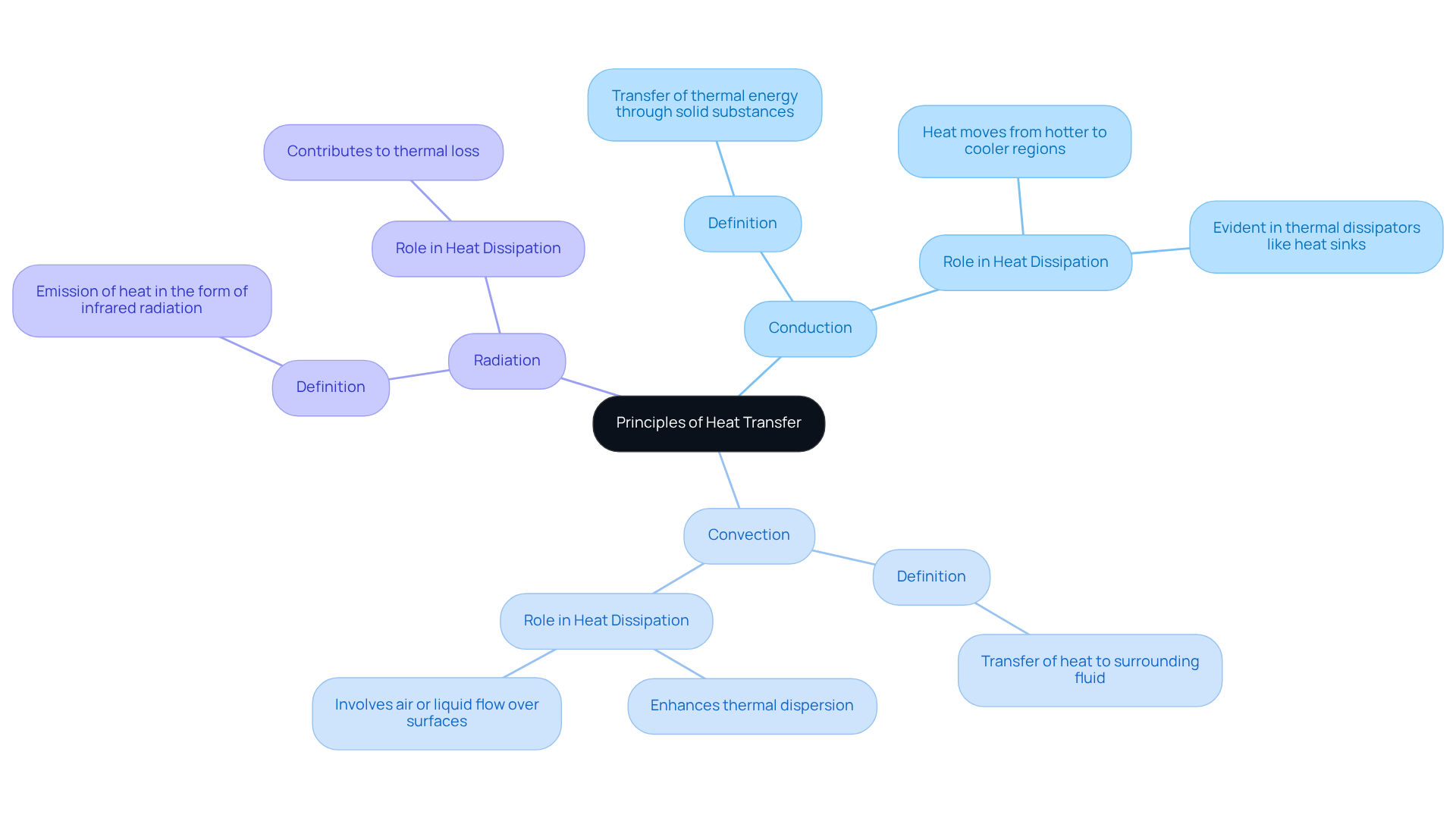

Thermal transfer in cooling devices occurs primarily through three methods: conduction, convection, and radiation.

- Conduction refers to the transfer of thermal energy through solid substances, where heat moves from the hotter to the cooler regions of the material. In thermal dissipators, this process is evident as heat from the electronic component is conducted through the heat sink pipe used in the thermal management material.

- Convection involves the transfer of heat to the surrounding fluid, typically air, as it flows over the thermal dissipation surface, thereby enhancing thermal dispersion.

- Finally, radiation is the emission of heat in the form of infrared radiation, which also contributes to thermal loss.

Understanding these principles empowers engineers to design thermal dissipators that , ensuring effective thermal control.

Select and Implement Heat Sinks: Key Considerations for Engineers

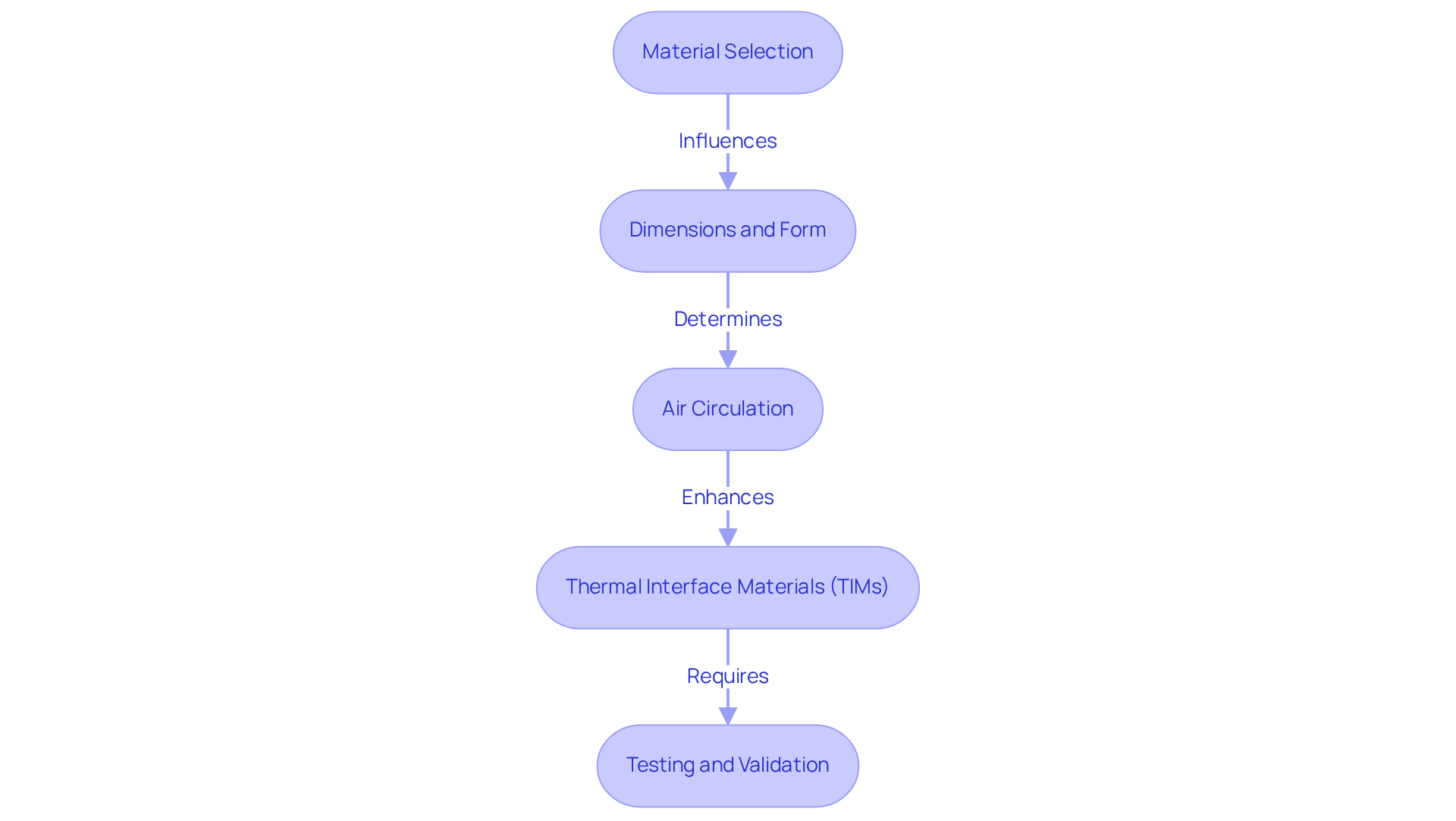

When selecting and implementing heat sinks, engineers must consider several key factors:

- Common choices include aluminum and copper. While copper boasts a conductivity of approximately 400 W/(m/K), making it superior for heat transfer, it does come at a higher cost and weight compared to aluminum, which has a conductivity of around 235 W/(m/K). The emergence of groundbreaking substances such as CarbAl, with a conductivity of 425 W/(m/K), presents an encouraging option that merges lightweight characteristics with excellent heat performance. Additionally, natural graphite composite materials possess a conductivity of 370 W/(m/K), offering further selection opportunities. Gagner-Toomey Associates provides a variety of copper-based and fully copper thermal solutions, ensuring engineers have access to high-performance materials for their temperature management requirements.

- Dimensions and Form: The thermal component must fit within the design limitations of the electronic device while providing sufficient surface area for thermal dispersion. Usual dimensions vary, but designs frequently incorporate elements such as fins or pins to optimize surface area within a compact volume, thereby enhancing transfer efficiency. It is also crucial to note that increasing the surface area may necessitate a taller cooling component, potentially influencing enclosure fit. Gagner-Toomey Associates offers both standard and custom designs, enabling engineers to select thermal management components that fulfill specific size and shape specifications.

- Air circulation: Ensuring proper airflow around the thermal component is vital for effective cooling. Engineers should consider the orientation of the device and any fans or vents that may assist in airflow. Active cooling solutions, which utilize powered fans, can significantly enhance thermal transfer rates compared to passive designs that rely solely on natural convection. Gagner-Toomey Associates focuses on a wide range of DC input tube axial fans and centrifugal blowers, optimized for performance and low noise, which can improve airflow around thermal dissipators.

- Thermal Interface Materials (TIMs): The application of TIMs between the cooling element and the component can greatly . These substances fill air gaps and improve the contact for temperature exchange, ensuring effective transfer from the component to the sink. It is essential to minimize the thickness of the TIM to enhance thermal transfer efficiency.

- Testing and Validation: Following implementation, temperature performance should be assessed under various operating conditions to ensure reliability. This involves operating the system at peak capacity and monitoring temperatures to confirm that the cooling component effectively manages thermal dissipation. For instance, for a 1A current draw, a necessary resistance of 33.4 ˚C/W is required, while for a 2A current draw, it is 10.9 ˚C/W.

By addressing these considerations, engineers can effectively integrate heat sink pipes into their designs, optimizing temperature control and enhancing overall system performance. Gagner-Toomey Associates stands out as a leading provider of innovative cooling solutions, offering a comprehensive portfolio of thermal management products, including vapor chambers, cold plates, and integrated cooling solutions tailored for electronics and beyond.

Conclusion

The role of heat sink pipes in electronics is paramount, as they are essential for maintaining optimal operating temperatures and ensuring the longevity of devices. By effectively dissipating heat generated by electronic components, these cooling devices prevent performance degradation and component failure, establishing themselves as a critical element in the design of modern electronic systems.

Key insights have emerged regarding the various types of heat sinks, including heat sink pipes and vapor chambers, each offering unique advantages tailored to different applications. The principles of heat transfer—conduction, convection, and radiation—are foundational concepts that engineers must grasp to optimize thermal management solutions. Moreover, practical considerations such as material selection, design dimensions, airflow, and thermal interface materials are crucial factors influencing the effectiveness of heat sink implementation.

In response to the increasing demand for efficient cooling solutions in high-performance electronics, it is imperative for engineers to remain informed about the latest advancements in heat sink technology. By leveraging knowledge of heat sink types, design principles, and implementation techniques, engineers can significantly enhance device performance and reliability. As the electronics industry continues to evolve, prioritizing effective thermal management through innovative cooling solutions will be vital for achieving optimal functionality and extending the lifespan of electronic devices.

Frequently Asked Questions

What are heat sinks and why are they important in electronics?

Heat sinks are passive thermal exchangers that disperse heat generated by electronic components into the surrounding environment. They are crucial in electronics because excessive heat can lead to increased failure rates, reduced performance, and a shortened lifespan of devices. Efficient temperature management through heat sinks is essential for maintaining optimal operating conditions.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest manufacturer of standard and custom air-movers for cooling. They provide a comprehensive range of temperature management solutions, including extruded aluminum cooling components and copper-based cooling elements.

What advancements have been made in cooling component technology?

Recent advancements include the integration of AI for design optimization and the use of advanced materials, which have significantly enhanced the efficiency of cooling components.

What is the projected market growth for cooling components?

The market for cooling components is projected to grow from USD 1.0 billion in 2024 to USD 1.5 billion by 2033, indicating an increasing demand for effective temperature management in high-performance electronics.

What factors influence the performance of heat sink pipes?

The design and material selection of heat sink pipes are critical factors that influence their performance. Engineers must focus on maximizing surface area and heat conductivity to improve heat dissipation.

What materials are commonly used for heat sinks?

Aluminum and copper are commonly used for heat sinks due to their excellent thermal properties, with copper having a conductivity of approximately 400 W/(m/K). Innovative materials developed by Gagner-Toomey Associates have a thermal conductivity of 425 W/(m/K), offering exciting alternatives.

What are the practical applications of heat sink pipes?

Heat sink pipes are used in various electronic devices, from smartphones to advanced computing systems. Active thermal dissipators, which use forced air from fans, are effective in high-heat environments, while passive thermal dissipators rely on natural convection and are suitable for compact devices.

How does the growing adoption of electric vehicles relate to cooling devices?

The growing adoption of electric vehicles highlights the importance of cooling devices in managing temperature challenges within this expanding industry.

Why is understanding heat sink pipes important for engineers?

Understanding heat sink pipes is essential for engineers to design systems capable of withstanding thermal stresses, preventing component failure, and ensuring device longevity as the electronics industry evolves.

What trend is emerging in the manufacturing of thermal components?

Automation in the production of thermal components is enhancing manufacturing efficiency and cost-effectiveness, establishing it as a key trend in design and production processes at Gagner-Toomey Associates.