Overview

The article delineates four critical steps for selecting the appropriate centrifugal fan suppliers. These steps encompass:

- Understanding the various types of centrifugal fans

- Identifying essential selection criteria

- Researching and comparing potential suppliers

- Engaging with them effectively

Each step underscores the necessity of evaluating product quality, supplier reputation, and technical support. This thorough evaluation empowers buyers to make informed decisions that align with their specific needs and project objectives.

Introduction

Selecting the right centrifugal fan supplier is crucial, as it can significantly impact the efficiency and effectiveness of applications ranging from HVAC systems to industrial ventilation. With the increasing demand for energy-efficient solutions, it is essential to understand the nuances of centrifugal fans, including their types and operational characteristics. However, navigating the vast array of suppliers and evaluating them based on quality, support, and performance presents a considerable challenge. Engineers must consider key factors to ensure they partner with the most suitable suppliers tailored to their specific needs.

Understand the Basics of Centrifugal Fans

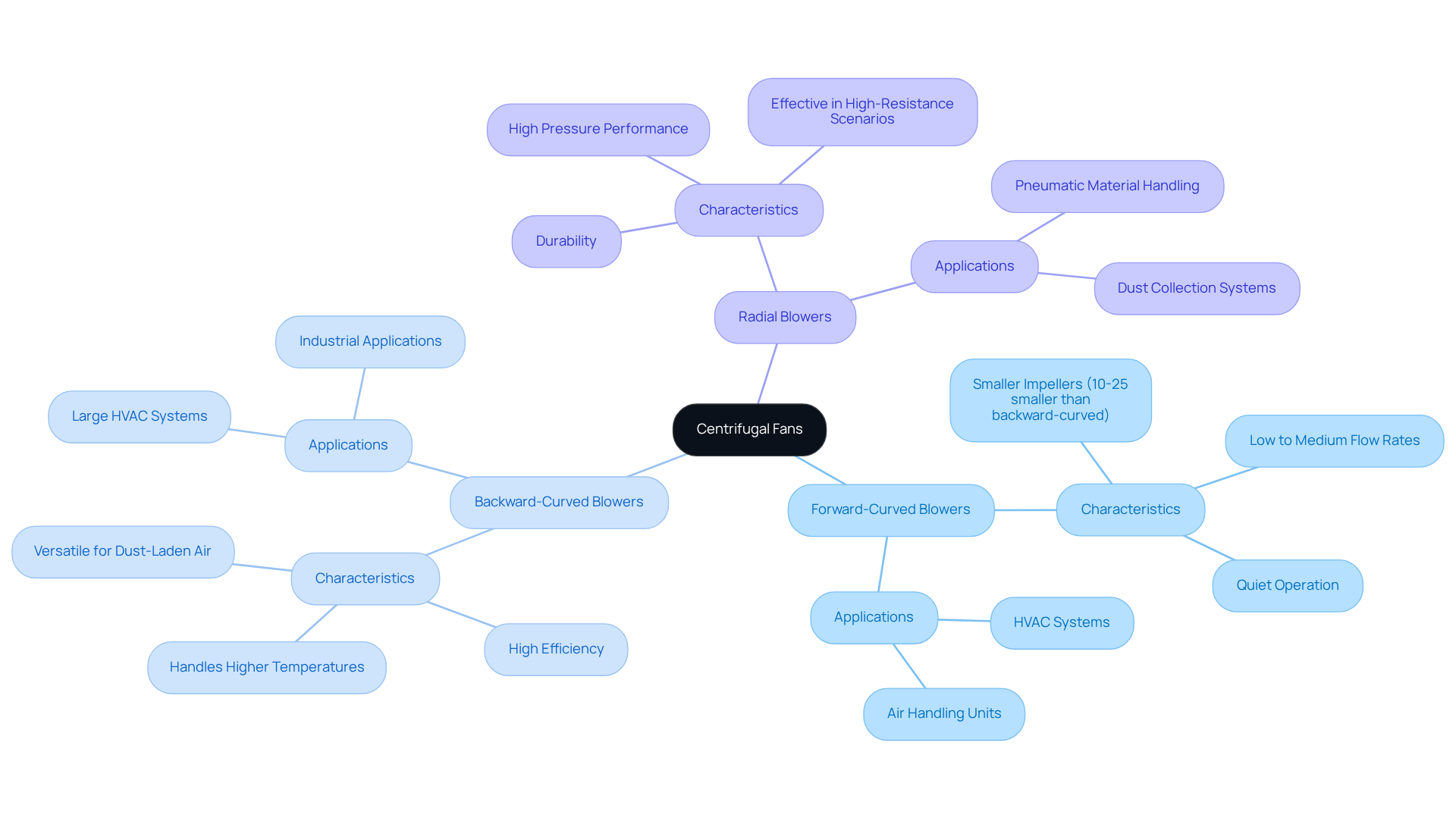

Centrifugal blowers are mechanical devices that efficiently move air or gases by converting rotational energy into kinetic energy. They function by drawing air into the fan through an inlet and expelling it at a right angle through an outlet. Understanding the various types of centrifugal fans—forward-curved, backward-curved, and radial—is crucial for selecting the appropriate model for specific applications such as ventilation, cooling, or exhaust systems.

- Forward-Curved Blowers: These devices feature impellers that are typically 10 to 25% smaller than their backward-curved counterparts for similar applications. They excel at low to medium flow rates and operate quietly, making them ideal for HVAC systems where noise reduction is a priority.

- Backward-Curved Blowers: Engineered for high efficiency and static pressure, backward-curved blowers are well-suited for larger HVAC systems and industrial applications. They can manage higher temperatures and dust-laden air, rendering them versatile across various environments.

- : Known for their durability, radial blade blowers perform effectively in high-resistance scenarios, such as pneumatic material handling and dust collection systems. They produce significant pressure and are frequently utilized in industrial settings.

In 2025, the market share for rotational blowers is projected to reflect a growing demand for energy-efficient solutions, particularly in sectors focused on sustainability. Practical applications include the integration of backward-curved fans in commercial HVAC systems, which enhance energy efficiency and reduce operational costs. By familiarizing yourself with these fan types and their respective applications, you can more effectively identify the right radial fan for your needs and the centrifugal fan suppliers that specialize in these technologies.

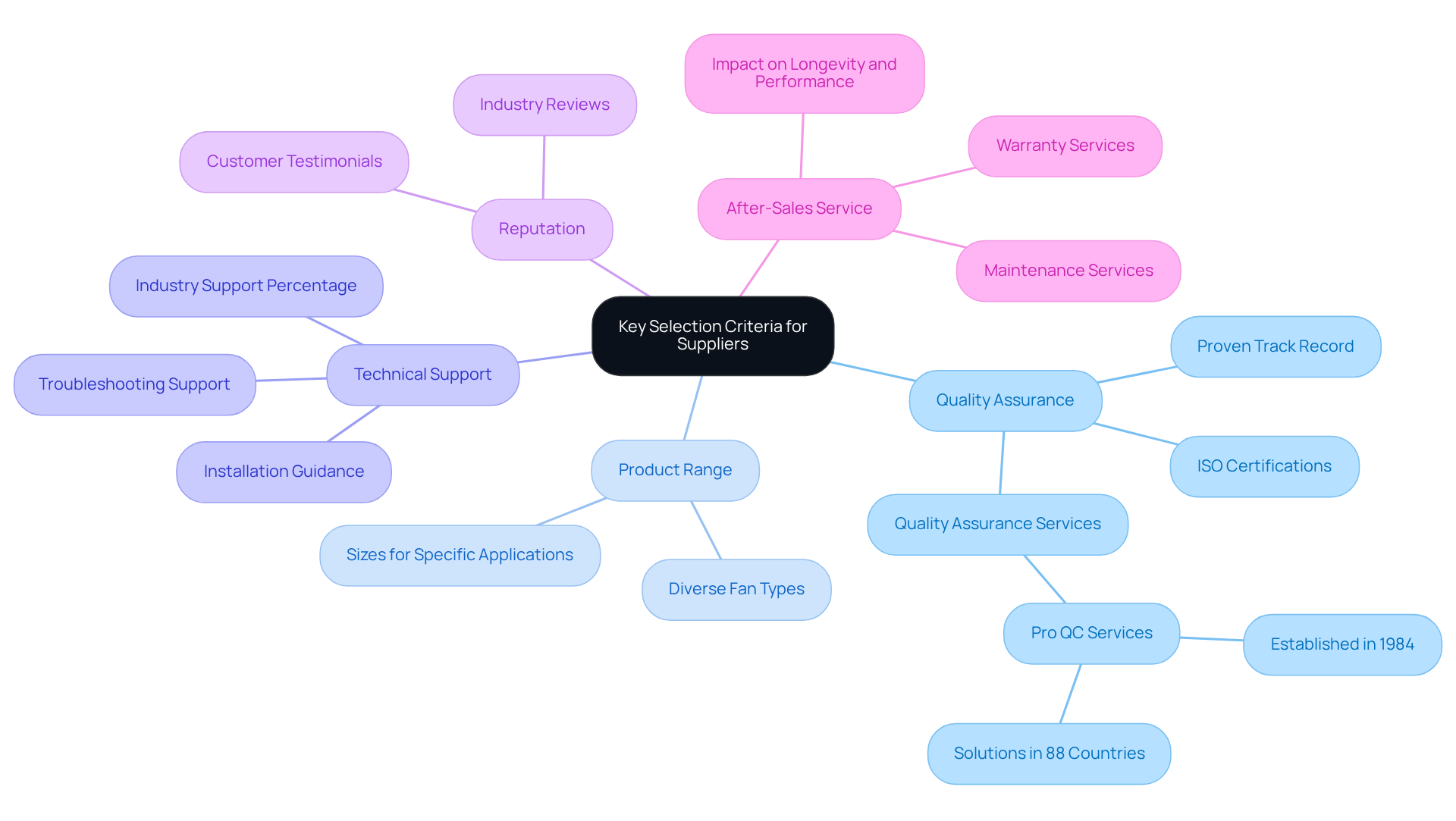

Identify Key Selection Criteria for Suppliers

When selecting centrifugal fan suppliers, it is crucial to consider the following key criteria:

- Quality Assurance: Prioritize vendors with ISO certifications and a proven track record of high-quality products. Additionally, consider those that offer quality assurance services, such as Pro QC, which has been delivering these services since 1984.

- Product Range: Ensure the provider offers a diverse array of fan types and sizes tailored to your specific application needs.

- Technical Support: Assess the level of technical assistance available, including installation guidance and troubleshooting support. Notably, a significant percentage of centrifugal fan suppliers in the industry offer such technical support, which is essential for maximizing efficiency.

- Reputation: Investigate the vendor’s reputation within the industry through reviews and testimonials. This can yield valuable insights into their commitment to quality and customer satisfaction.

- After-Sales Service: Evaluate the warranty and maintenance services provided, as these factors can greatly affect the longevity and performance of the fans. Understanding this in the context of enhances your comprehension of the vendor’s overall reliability.

For further assistance, you can reach out to suppliers using the following contact numbers:

- North America: +1 206 397 1145

- United Kingdom: +44 330 094 5589

- Mexico: +52 55 9990 7885

- Australia: +61 2 8252 7691

By focusing on these criteria, you can ensure that you partner with suppliers who not only fulfill your technical needs but also contribute to the overall success of your projects.

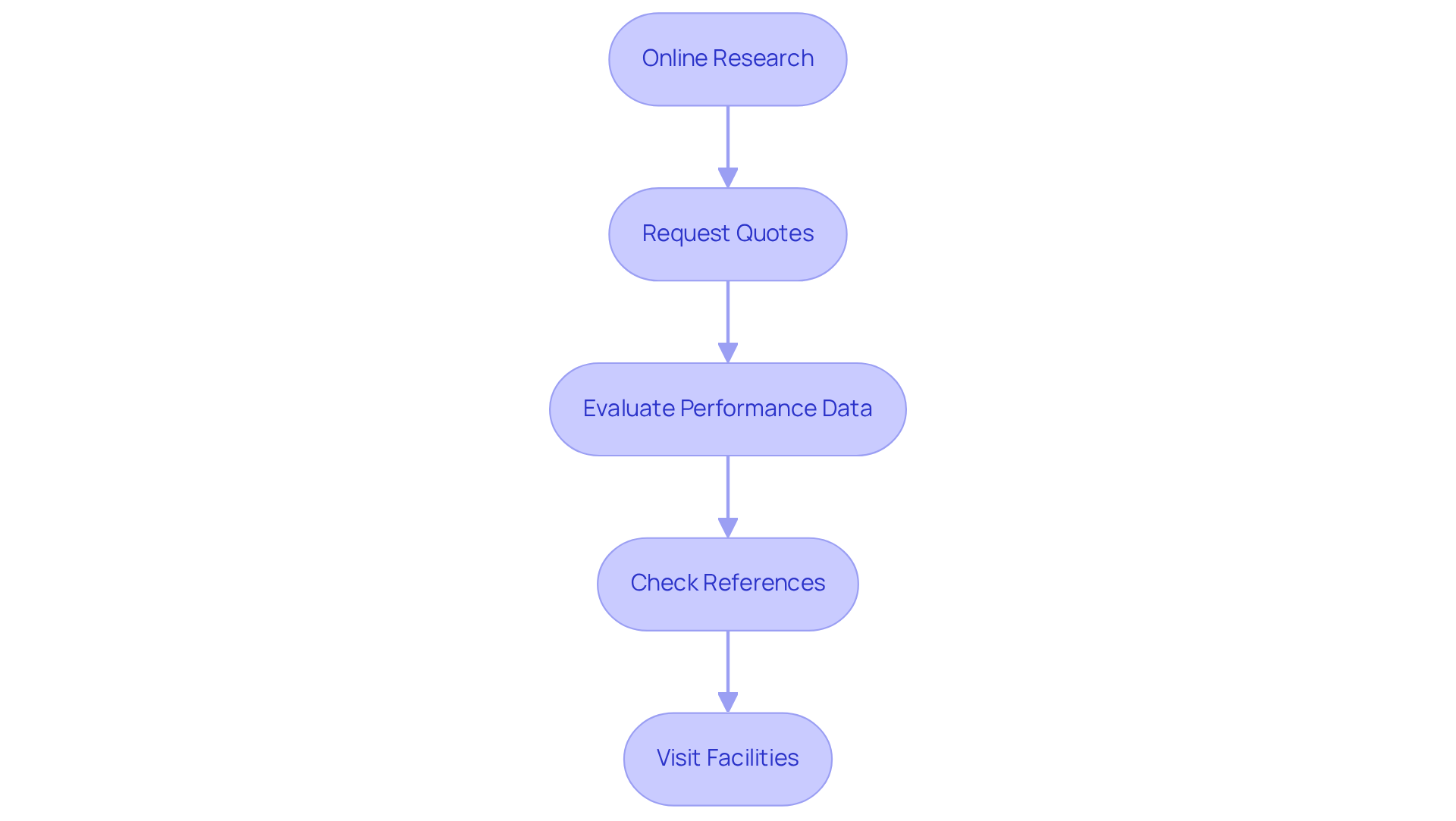

Research and Compare Potential Suppliers

To effectively research and compare potential centrifugal fan suppliers, particularly those like Gagner-Toomey Associates, it is essential to follow these steps:

- Online Research: Begin by utilizing industry-specific websites, forums, and directories to compile a comprehensive list of potential vendors. This initial step is crucial for identifying reputable companies in the electronics sector, particularly those renowned for their advanced cooling solutions.

- Request Quotes: Engage with multiple suppliers, including Gagner-Toomey Associates, to obtain quotes and detailed product specifications. This practice will provide a clearer understanding of pricing structures and available options, including average lead times for delivery.

- Evaluate Performance Data: Analyze the performance data of the devices offered, concentrating on key metrics such as airflow rates (measured in CFM), efficiency ratings, and noise levels. Understanding these parameters is vital, as rotary blowers are essential to numerous applications, including HVAC systems and industrial ventilation. Notably, backward inclined fans consume less power compared to forward curved fans, which can significantly impact operational costs. Gagner-Toomey Associates offers a broad product line of centrifugal blowers optimized for performance and efficiency, including options with low noise levels and IP protection features, positioning them as a strong contender in this sector.

- Check References: Request references from previous clients to assess the vendor’s reliability and service quality. Insights from other engineers can provide valuable perspectives on the vendor’s performance and customer support, particularly for well-established manufacturers such as Gagner-Toomey Associates.

- Visit Facilities: If feasible, visit the vendors’ locations to evaluate their and quality assurance practices. This practical approach can reveal the provider’s commitment to product quality and innovation. Additionally, consider the materials used for fan blades; for example, steel is often favored for industrial applications due to its durability.

By adhering to these steps, engineers can make informed decisions when selecting centrifugal fan suppliers, ensuring they choose partners that align with their specific performance and reliability requirements.

Engage with Suppliers for Clarification and Support

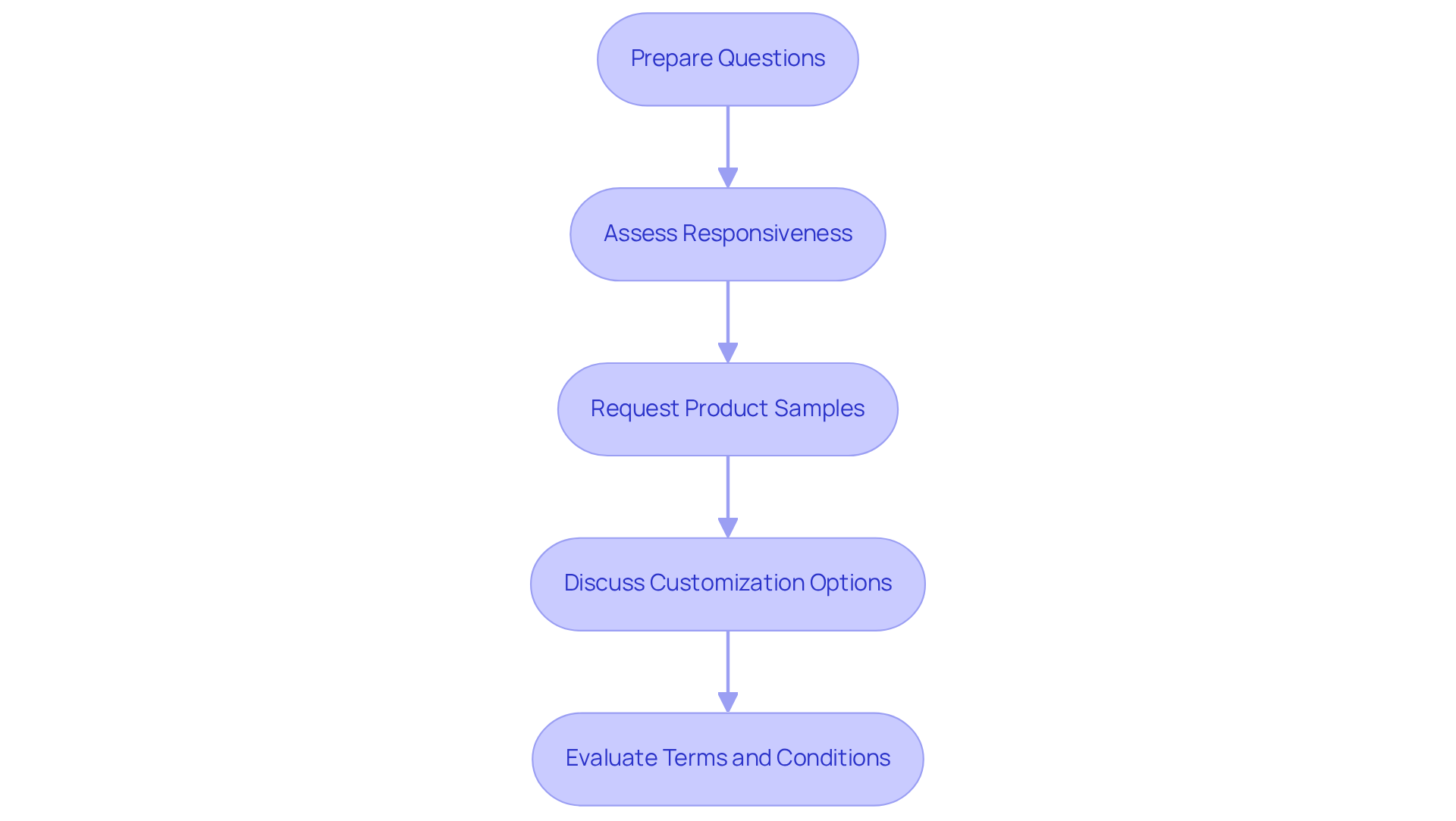

Once you have narrowed down your list of potential vendors, effective engagement becomes essential for clarifying any questions or concerns. To enhance your communication, consider the following strategies:

- Prepare Questions: Compile a comprehensive list of inquiries concerning product specifications, lead times, and support services prior to contacting vendors.

- Assess Responsiveness: Monitor the speed and thoroughness of providers’ responses to your inquiries; prompt and detailed replies often indicate a strong commitment to customer service.

- Request Product Samples: Whenever feasible, ask for samples of the fans to evaluate their firsthand, as this can significantly influence your purchasing decision.

- Discuss Customization Options: Inquire about available customization choices, as many providers now offer tailored solutions that can enhance efficiency and meet specific application requirements. For instance, a leading centrifugal fan supplier highlights flexible customization options, enabling clients to adapt fan specifications to their unique needs.

- Evaluate Terms and Conditions: Carefully scrutinize the terms of sale, including payment options, delivery timelines, and return policies, ensuring they align with your operational requirements.

Engaging suppliers effectively not only clarifies your needs but also fosters a collaborative relationship that can lead to successful project outcomes.

Conclusion

Choosing the right centrifugal fan suppliers is a pivotal decision that can profoundly influence the efficiency and success of your projects. Understanding the various types of centrifugal fans and their specific applications enables informed choices that align with operational needs. This article underscores the necessity of evaluating suppliers based on:

- Quality assurance

- Product range

- Technical support

- Reputation

- After-sales service

Ensuring that all essential criteria are met for optimal performance.

The key arguments presented highlight the importance of conducting thorough research and comparison when selecting suppliers. Engaging with potential vendors through effective communication, assessing their responsiveness, and exploring customization options are critical steps that can lead to fruitful partnerships. Furthermore, obtaining performance data and checking references solidifies the decision-making process, allowing engineers to choose suppliers that not only satisfy their technical requirements but also enhance overall project outcomes.

Ultimately, selecting the right centrifugal fan suppliers transcends a mere transactional process; it involves nurturing relationships that contribute to long-term success. By prioritizing quality, support, and a comprehensive understanding of product specifications, one can adeptly navigate the complexities of supplier selection. Embracing these best practices will elevate operational efficiency and position projects for sustainable success in an increasingly competitive market.

Frequently Asked Questions

What are centrifugal fans and how do they work?

Centrifugal fans are mechanical devices that move air or gases by converting rotational energy into kinetic energy. They draw air into the fan through an inlet and expel it at a right angle through an outlet.

What are the main types of centrifugal fans?

The main types of centrifugal fans are forward-curved blowers, backward-curved blowers, and radial blowers.

What are the characteristics of forward-curved blowers?

Forward-curved blowers have impellers that are typically 10 to 25% smaller than those of backward-curved blowers for similar applications. They excel at low to medium flow rates and operate quietly, making them ideal for HVAC systems where noise reduction is important.

What are backward-curved blowers used for?

Backward-curved blowers are designed for high efficiency and static pressure, making them suitable for larger HVAC systems and industrial applications. They can handle higher temperatures and dust-laden air, providing versatility across various environments.

What is unique about radial blowers?

Radial blowers are known for their durability and effectiveness in high-resistance scenarios, such as pneumatic material handling and dust collection systems. They produce significant pressure and are commonly used in industrial settings.

What is the projected market trend for centrifugal fans by 2025?

By 2025, the market share for rotational blowers is expected to reflect a growing demand for energy-efficient solutions, particularly in sectors focused on sustainability.

How can understanding different fan types help in selecting the right one?

Familiarizing yourself with the types of centrifugal fans and their applications allows you to more effectively identify the right radial fan for your needs and find suppliers that specialize in these technologies.