Overview

Centrifugal blower impeller selection is critical for project success, demanding meticulous attention to:

- Airflow requirements

- Static pressure

- Efficiency

- Noise levels

- Material durability

Understanding the characteristics of various impeller types, including backward-curved and forward-curved blades, is essential. By evaluating specific project needs, professionals can make informed decisions that significantly enhance performance and reliability across diverse applications.

Introduction

Understanding the intricacies of centrifugal blower impellers is essential for achieving optimal air movement across various applications. Different designs present distinct advantages—such as energy efficiency, noise reduction, and pressure handling—that can significantly influence system performance. The challenge, however, lies in navigating the multitude of options and criteria to identify the ideal match for specific project requirements. Therefore, it is imperative to prioritize factors that ensure both efficiency and reliability in centrifugal blower systems.

Understand Centrifugal Blower Impellers

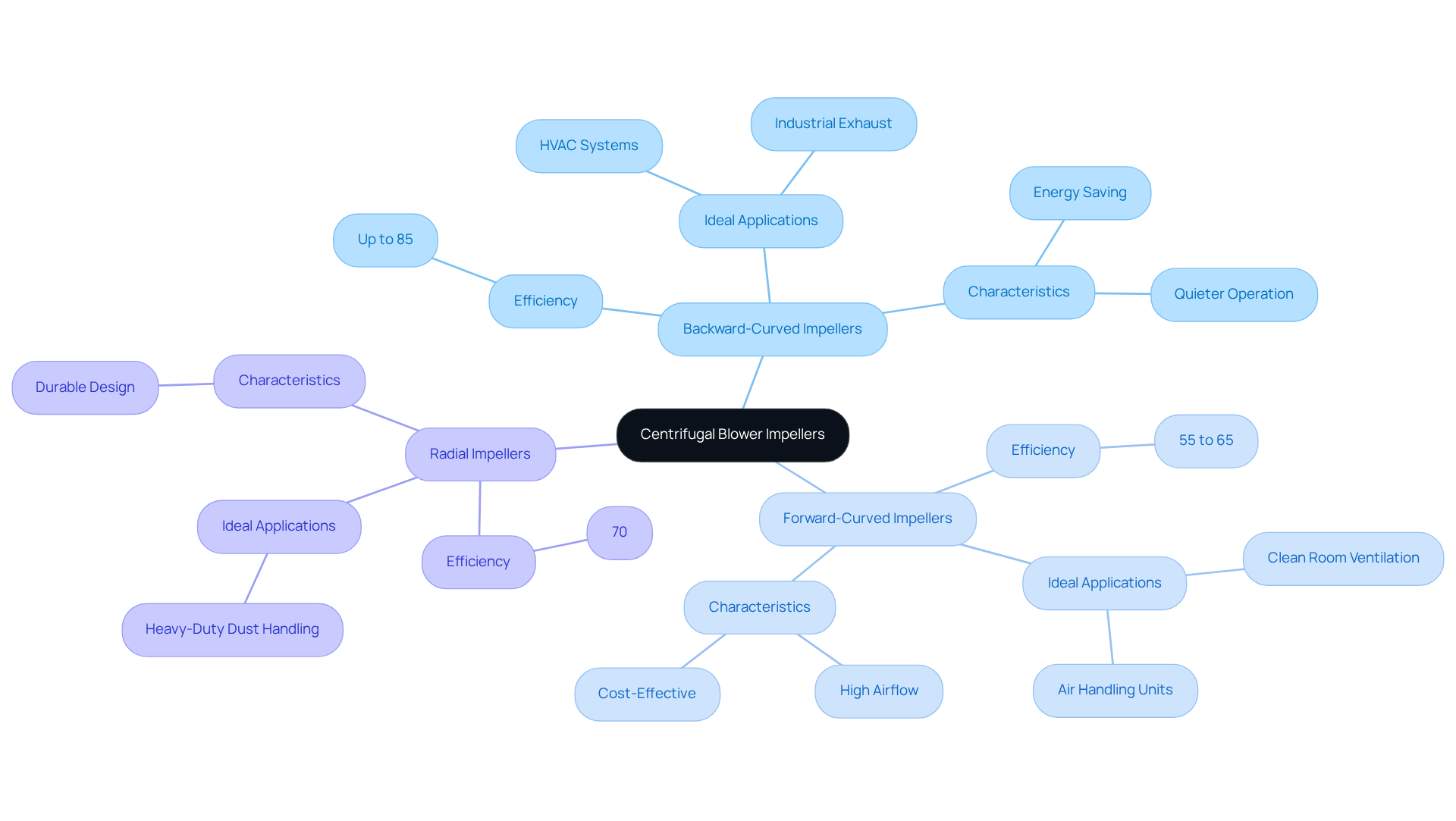

Centrifugal blower impellers are critical components that transform rotational energy into kinetic energy, effectively propelling air through the system. These rotors typically feature blades attached to a central hub, spinning at high velocities to generate a differential in force. Understanding the various types of centrifugal blower impellers—backward-curved, forward-curved, and radial—is vital for selecting the appropriate one for specific applications.

- Backward-curved fan blades are particularly valued for their energy-saving capabilities, achieving effectiveness levels of up to 85%, and their quieter operation, making them ideal for high static load applications such as HVAC systems and industrial exhaust.

- Conversely, forward-curved blades excel in low-pressure environments, attaining efficiencies ranging from 55% to 65%, facilitating substantial airflow with reduced resistance, which is beneficial in applications like clean room ventilation and air handling units.

Familiarity with these rotor types, particularly the centrifugal blower impeller, and their distinct characteristics—such as airflow capabilities, pressure handling, and efficiency—establishes a solid foundation for making informed decisions in your projects. Additionally, considering material options for harsh conditions, such as abrasion-resistant steel and stainless steel, is essential for ensuring durability in your applications.

Real-world examples indicate that backward-curved blades outperform forward-curved designs in noise-sensitive environments, while forward-curved alternatives are often favored for their cost-effectiveness in scenarios where initial investment is a priority. Understanding these distinctions enhances your ability to for optimal performance and durability in your systems. Regular preventive maintenance and inspections are also critical to ensuring the reliability and efficiency of the equipment in operation.

Evaluate Key Selection Criteria

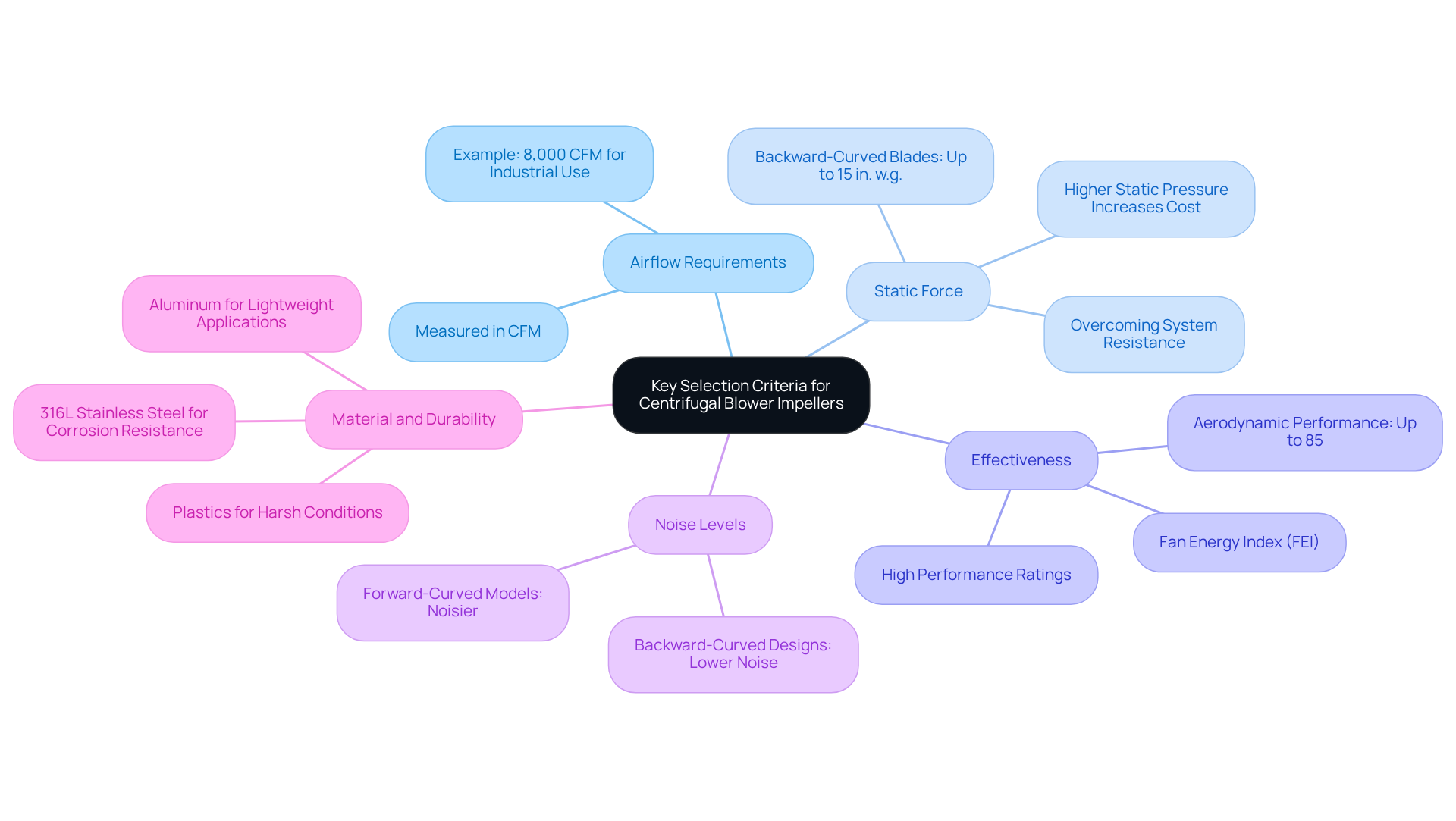

When selecting a centrifugal blower impeller, several key criteria must be considered to ensure optimal performance and efficiency:

- Airflow Requirements: Accurately determine the necessary airflow, measured in cubic feet per minute (CFM), for your particular use case. This measurement is essential as it directs the choice of a device capable of providing the . For instance, a fan producing 8,000 CFM is often sought for larger industrial applications; however, it is important to note that not all manufacturers provide this output.

- Static Force: Assess the static force required to surpass system resistance, which varies greatly among different rotor designs. Backward-curved blades, for instance, are recognized for their capacity to sustain high performance and functionality, achieving static ratings of up to 15 inches of water gauge (in. w.g.). It is also worth noting that higher static pressure requirements may raise the price due to reinforced construction needs.

- Effectiveness: Prioritize centrifugal blower impellers with high performance ratings, as this can lead to substantial [energy savings over time](https://gagner-toomey.com/10-benefits-of-centrifugal-exhaust-fans-for-engineers/). Centrifugal blower impellers with a backward-curved design can attain up to 85% aerodynamic performance, especially advantageous in medium to high-pressure applications. The Fan Energy Index (FEI) serves as a valuable metric for assessing efficiency.

- Noise Levels: Consider the operational noise produced by the rotor. Backward-curved designs generally create less noise than forward-curved models, which are noisier but appropriate for high-resistance uses. This comparison is essential for selecting the right impeller for noise-sensitive environments.

- Material and Durability: Choose materials that can withstand the operational environment, especially in situations involving corrosive or abrasive substances. Common materials include aluminum for lightweight applications, stainless steel (such as 316L) for corrosion resistance, and various plastics for durability in harsh conditions. Suggestions for particular materials according to environmental circumstances can improve the durability and dependability of the device.

By thoroughly evaluating these criteria, you can ensure that the chosen component not only meets the technical requirements of your project but also contributes to long-term operational efficiency and reliability.

Match Impellers to Project Requirements

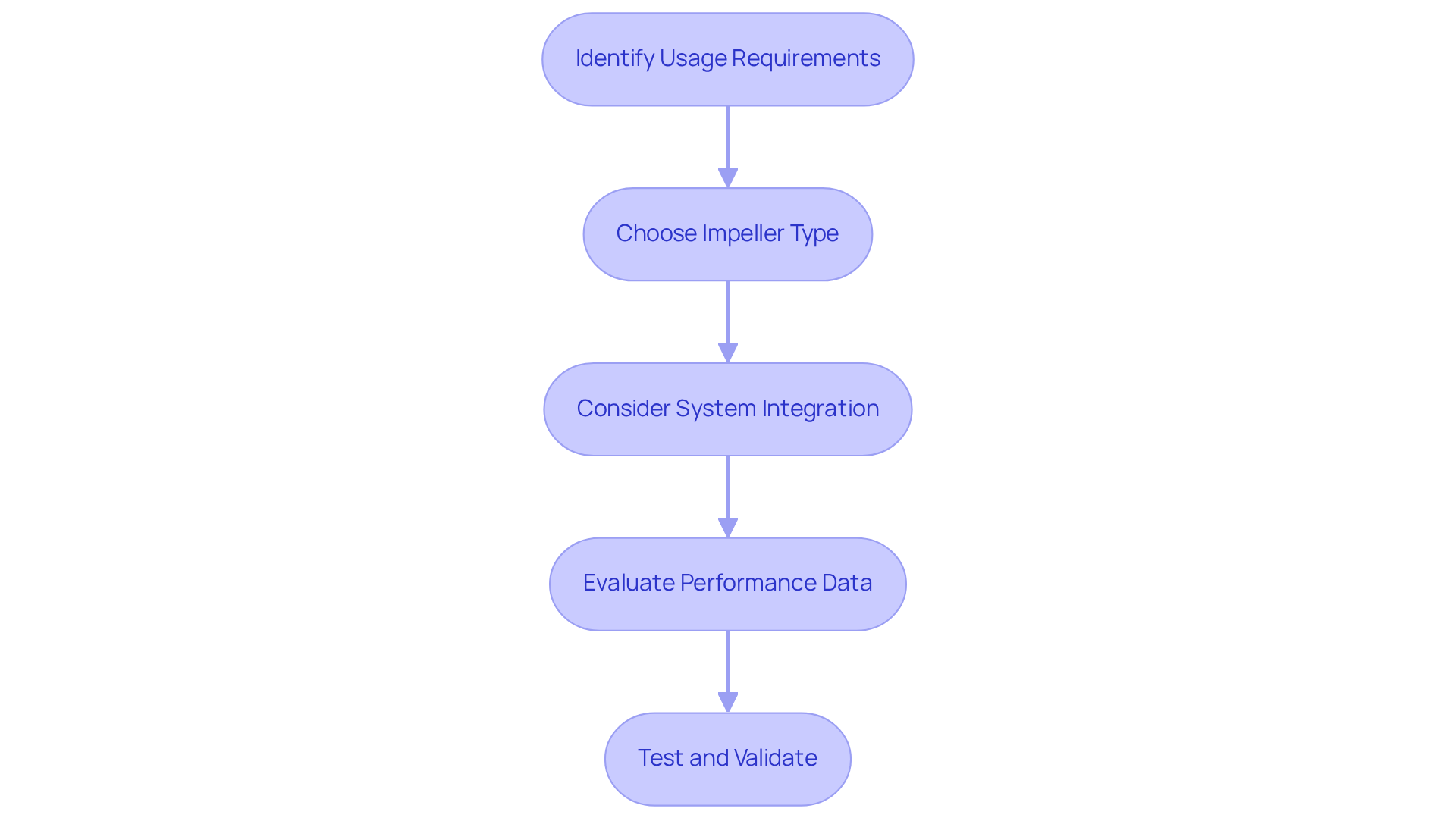

To effectively match impellers to your project requirements, consider the following steps:

- Identify Usage Requirements: Begin by clearly defining the purpose of the blower. Take into account factors such as the type of air being moved—whether it is clean, dusty, or hot—and the necessary airflow and pressure.

- Choose Impeller Type: Based on your usage requirements, select the appropriate rotor type. For high-pressure applications, backward-curved blades are often preferred due to their effectiveness and ability to manage increased resistance, achieving performance levels of 80-85%. Conversely, forward-curved blades are more suitable for high airflow at lower pressures, typically operating at 60-70% efficiency.

- Consider System Integration: Ensure that the selected component can be integrated into your existing system without significant modifications. This includes verifying compatibility with the blower housing and motor, as well as confirming that the align with your setup.

- Evaluate the performance data related to the centrifugal blower impeller by reviewing the performance curves and specifications provided by manufacturers to ensure that the component meets the required operational parameters. Notably, backward-curved rotor blades are recognized for their stable performance in high-demand environments, making them ideal for industrial applications.

- Test and Validate: If possible, conduct tests or simulations to verify that the chosen rotor operates as expected under actual conditions. This step is crucial for identifying potential issues before full-scale implementation, ensuring both reliability and efficiency in your system.

By adhering to these steps, you can ensure that the component you select will effectively meet your project’s demands.

Troubleshoot Common Selection Challenges

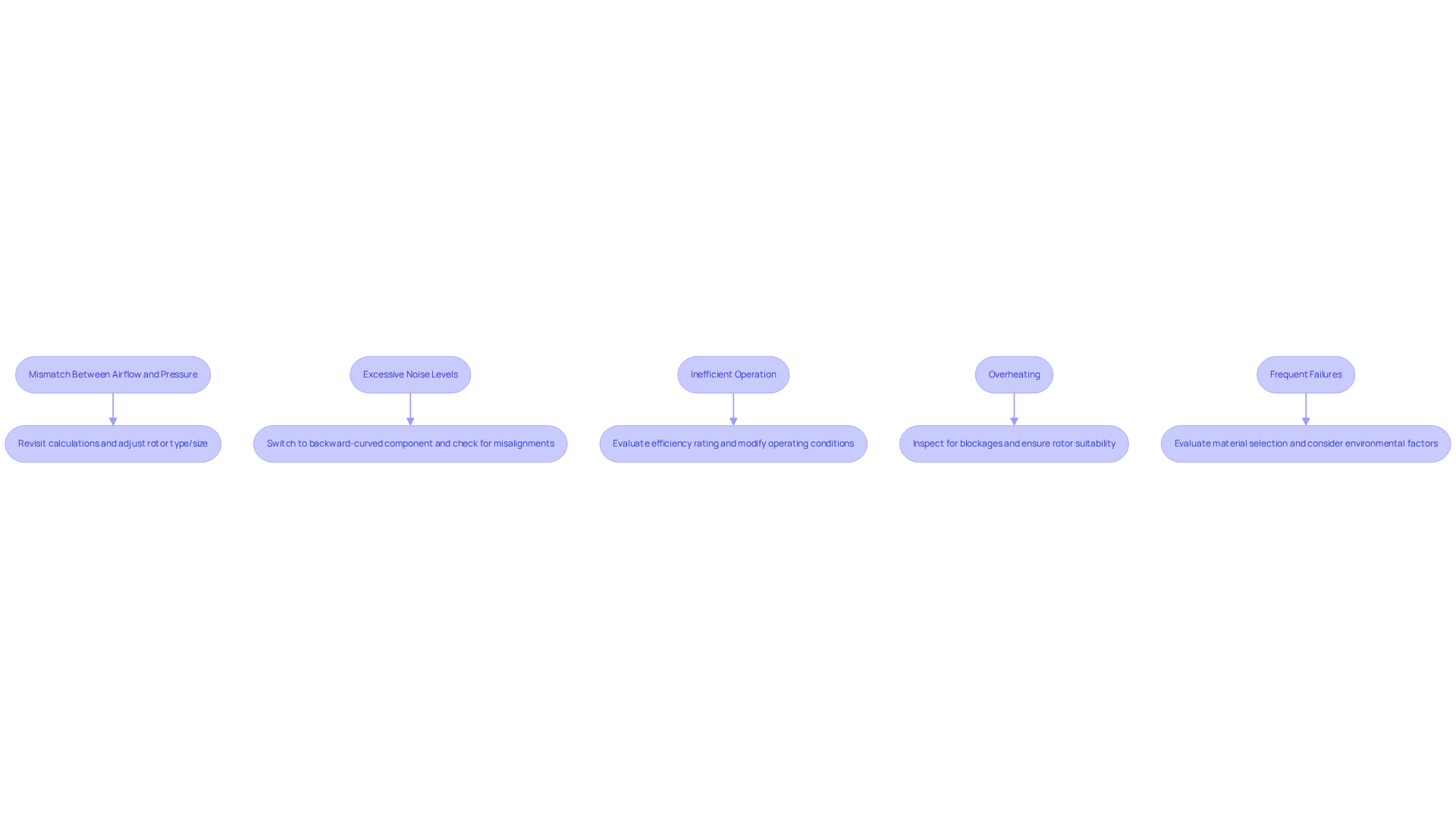

When selecting a , you may encounter several common challenges that require troubleshooting. Here’s how to effectively address them:

- Mismatch Between Airflow and Pressure: Should the selected rotor fail to meet the required airflow or pressure, it is essential to revisit your calculations. Ensure that you have accurately assessed the system’s needs, and adjust the rotor type or size as necessary.

- Excessive Noise Levels: In cases where the blower operates with excessive noise, consider transitioning to a backward-curved component, which typically functions more quietly. Additionally, verify for any misalignments or vibrations that may contribute to elevated noise levels.

- Inefficient Operation: If the blower is consuming more energy than expected, evaluate the efficiency rating of the fan component and compare it with the system’s performance metrics. You may need to opt for a more efficient rotor design or modify the operating conditions to enhance performance.

- Overheating: If the blower experiences excessive heat, inspect the fan component for blockages or debris that may be hindering airflow. Ensure that the rotor is suitable for the temperature and material conditions relevant to your application.

- Frequent Failures: Should impellers fail frequently, evaluate the material selection to confirm its appropriateness for the specific application. Consider environmental factors such as humidity, temperature, and the presence of corrosive substances that may affect performance.

By proactively addressing these challenges, you can significantly enhance the reliability and performance of your centrifugal blower impeller system.

Conclusion

Selecting the right centrifugal blower impeller is essential for achieving optimal performance across various applications. Understanding the different types of impellers—such as backward-curved and forward-curved designs—tailored to specific operational needs is paramount. By grasping the unique characteristics and efficiencies of these impellers, individuals can make informed choices that significantly enhance the effectiveness of their systems.

Key insights include evaluating:

- Airflow requirements

- Static force

- Effectiveness

- Noise levels

- Material durability

Each of these factors plays a crucial role in ensuring that the selected impeller not only meets technical specifications but also contributes to long-term reliability and efficiency. Addressing common selection challenges, such as mismatched airflow and excessive noise, can markedly improve the operational success of centrifugal blower systems.

In conclusion, mastering centrifugal blower impeller selection transcends mere technicality; it embodies a strategic approach that can lead to improved energy efficiency and system longevity. By applying the guidelines and insights provided, individuals can navigate the complexities of impeller selection with confidence, ensuring that their projects meet both performance and durability standards. Embracing this knowledge empowers users to optimize their systems, contributing to a more efficient and sustainable operational environment.

Frequently Asked Questions

What are centrifugal blower impellers?

Centrifugal blower impellers are components that convert rotational energy into kinetic energy to propel air through a system. They consist of blades attached to a central hub, spinning at high velocities.

What are the different types of centrifugal blower impellers?

The main types of centrifugal blower impellers are backward-curved, forward-curved, and radial impellers, each with distinct characteristics suitable for various applications.

What are the advantages of backward-curved fan blades?

Backward-curved fan blades are known for their energy efficiency, achieving effectiveness levels of up to 85%, and they operate quietly, making them ideal for high static load applications like HVAC systems and industrial exhaust.

In what applications are forward-curved blades most effective?

Forward-curved blades are effective in low-pressure environments, with efficiencies ranging from 55% to 65%. They facilitate substantial airflow with reduced resistance, which is beneficial for applications like clean room ventilation and air handling units.

Why is it important to understand the characteristics of centrifugal blower impellers?

Understanding the characteristics of different rotor types, such as airflow capabilities, pressure handling, and efficiency, is essential for making informed decisions about which impeller to select for specific projects.

What materials are recommended for centrifugal blower impellers in harsh conditions?

For harsh conditions, materials such as abrasion-resistant steel and stainless steel are recommended to ensure durability and longevity of the impellers.

How do backward-curved blades compare to forward-curved designs in noise-sensitive environments?

Backward-curved blades generally outperform forward-curved designs in noise-sensitive environments due to their quieter operation.

What factors should be considered when selecting a centrifugal blower impeller?

Factors to consider include the specific application requirements, efficiency, airflow capabilities, pressure handling, material durability, and cost-effectiveness.

What is the importance of regular maintenance for centrifugal blower impellers?

Regular preventive maintenance and inspections are crucial to ensure the reliability and efficiency of the equipment in operation, helping to avoid potential failures and prolonging the lifespan of the components.