Overview

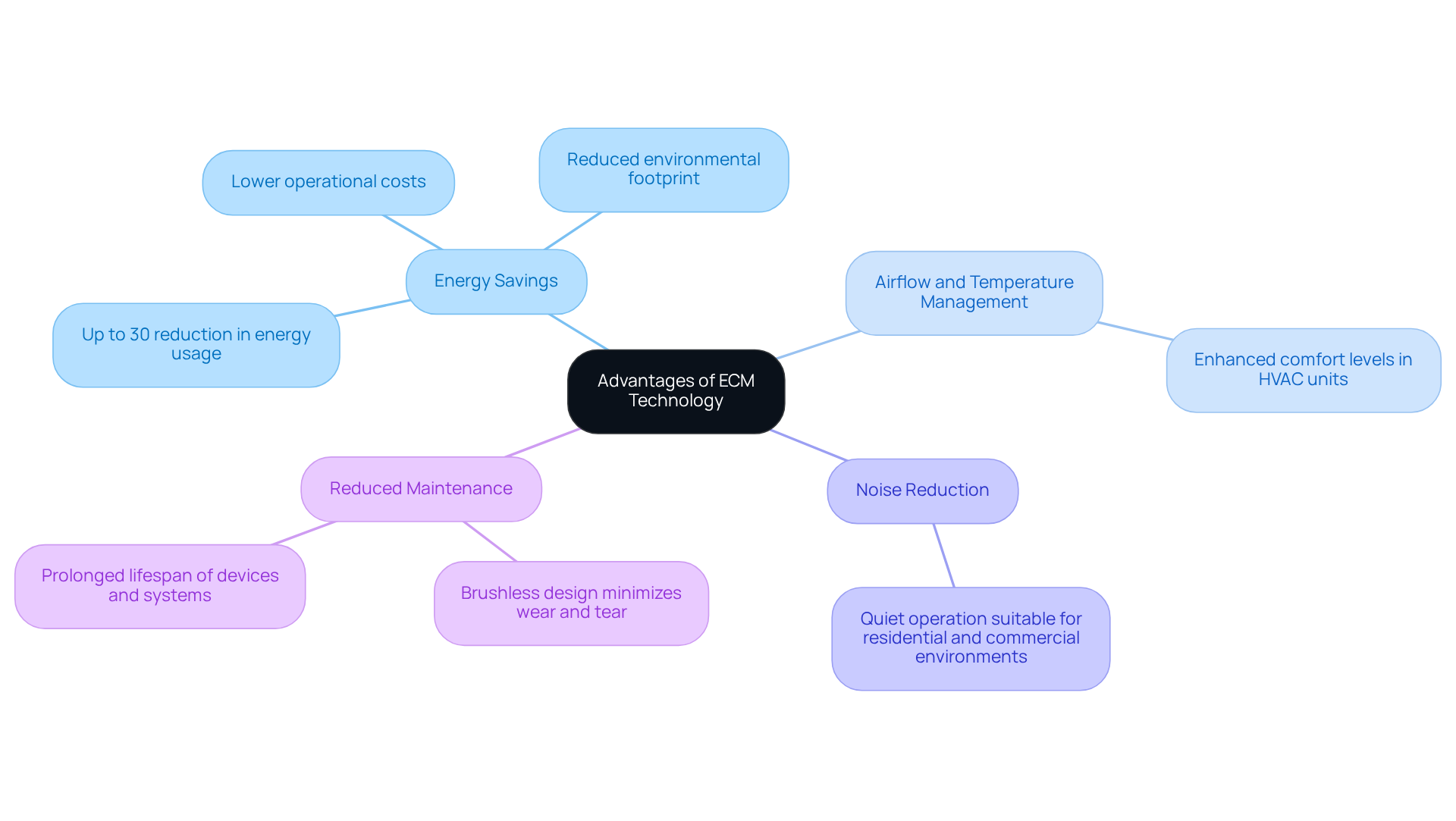

Electronically Commutated Motors (ECMs) represent a significant advancement in brushless DC technology, employing electronic control for precise speed and torque management. This innovation makes ECMs exceptionally efficient for applications such as HVAC systems. Notably, ECMs have the capability to adapt to real-time demands, which not only enhances energy efficiency but also improves user comfort.

Furthermore, they require significantly less maintenance compared to traditional motors like Permanent Split Capacitor (PSC) motors, which operate at a constant speed and exhibit lower efficiency.

In summary, the adoption of ECMs can lead to substantial operational benefits, positioning them as a superior choice in modern applications.

Introduction

Understanding the intricacies of Electronically Commutated Motors (ECMs) is essential for professionals engaged in electronics engineering, particularly within HVAC systems. These advanced brushless DC devices revolutionize machinery operation by leveraging electronic control, resulting in enhanced efficiency and adaptability. As industries increasingly adopt ECM technology, it is crucial to address the advantages these motors hold over traditional counterparts, as well as the challenges related to their maintenance and replacement. This article delves into the mechanics, benefits, and troubleshooting of ECMs, providing valuable insights that will empower engineers and technicians alike.

Define Electronically Commutated Motors (ECMs)

Commutated motors, or Electronically Commutated Machines, represent a sophisticated category of brushless DC devices that leverage electronic regulation to manage machinery operations. Unlike traditional machines that rely on mechanical brushes for commutation, these advanced devices utilize a commutated motor with an that converts AC power to DC. This innovation enables precise management of speed and torque in a commutated motor, making it highly effective across a variety of applications. Notably, in heating, ventilation, and air conditioning systems, these modules adapt their performance based on real-time requirements, showcasing their versatility. Furthermore, the three-phase structure of electric machines significantly enhances their efficiency and performance compared to conventional motors.

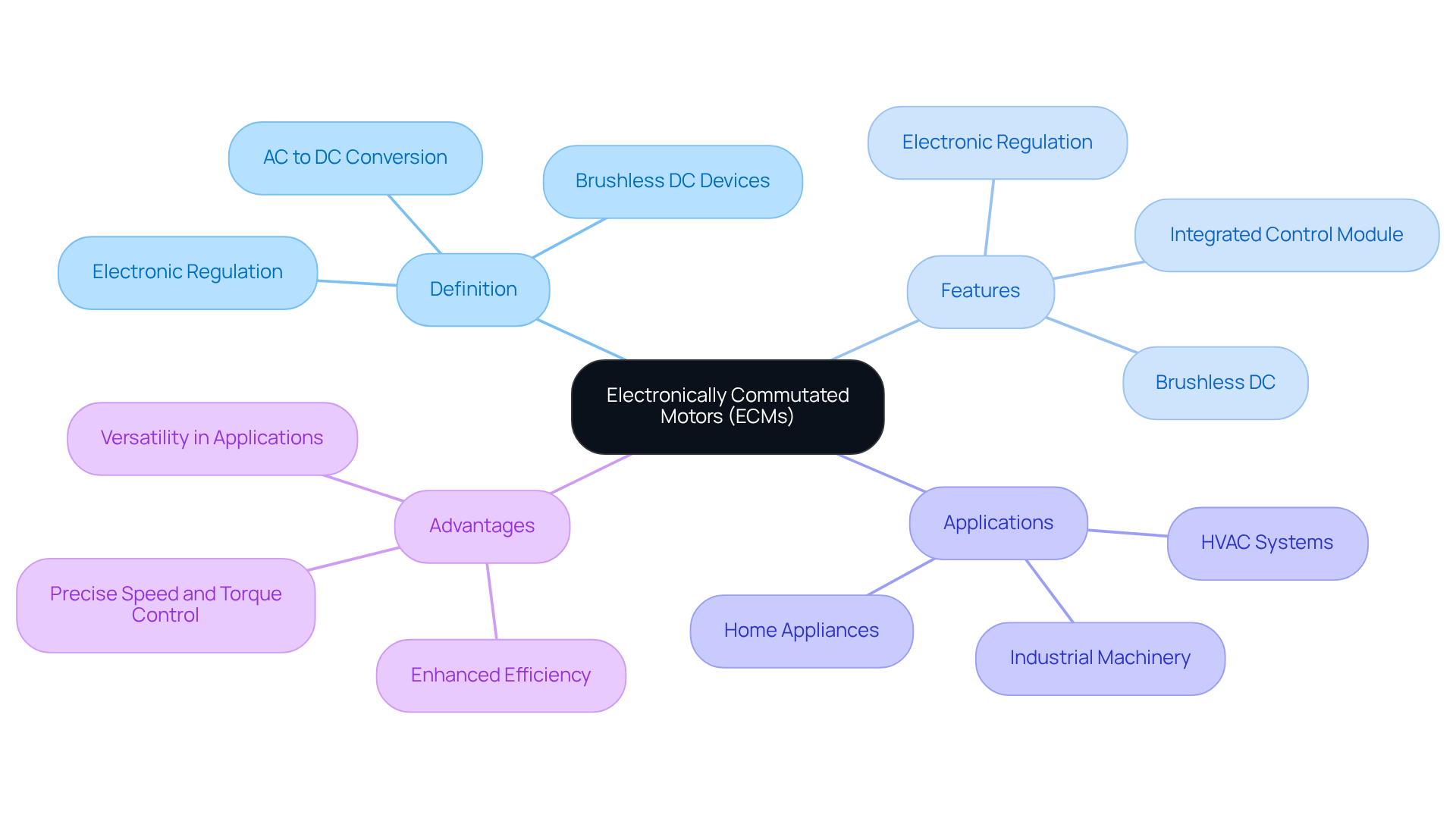

Explain How ECMs Operate in HVAC Systems

In HVAC setups, commutated motors play a crucial role by dynamically adjusting their speed to meet the heating or cooling demands of the environment. The electronic control module within the ECM receives input from a variety of sensors that continuously monitor temperature, humidity, and airflow. Utilizing this data, the system’s commutated motor fine-tunes its speed, ensuring that it operates with while maintaining optimal comfort levels. This capability not only enhances energy efficiency but also minimizes wear and tear on the system, ultimately leading to a longer operational lifespan and reduced maintenance costs. For example, during periods of low demand, the ECM can decrease its speed, thereby consuming less energy while still delivering sufficient airflow.

Compare ECMs with PSC Motors

When contrasting with permanent magnet machines, several key differences emerge.

- Permanent Split Capacitor (PSC) engines are characterized by their simpler design and typically operate at a constant speed. This design limitation restricts their efficiency, particularly under varying load conditions.

- Conversely, electronic management systems incorporate advanced electronic mechanisms that facilitate variable speed operation, allowing them to adapt to the specific requirements of the system.

- This adaptability results in electric machines achieving significantly higher energy efficiency, often reaching efficiency ratings of 80% or above, compared to PSC devices, which generally operate at approximately 60% efficiency.

- Moreover, commutated motors provide enhanced airflow management and quieter operation, making them more suitable for modern HVAC applications where comfort and efficiency are paramount.

Highlight Advantages of ECM Technology

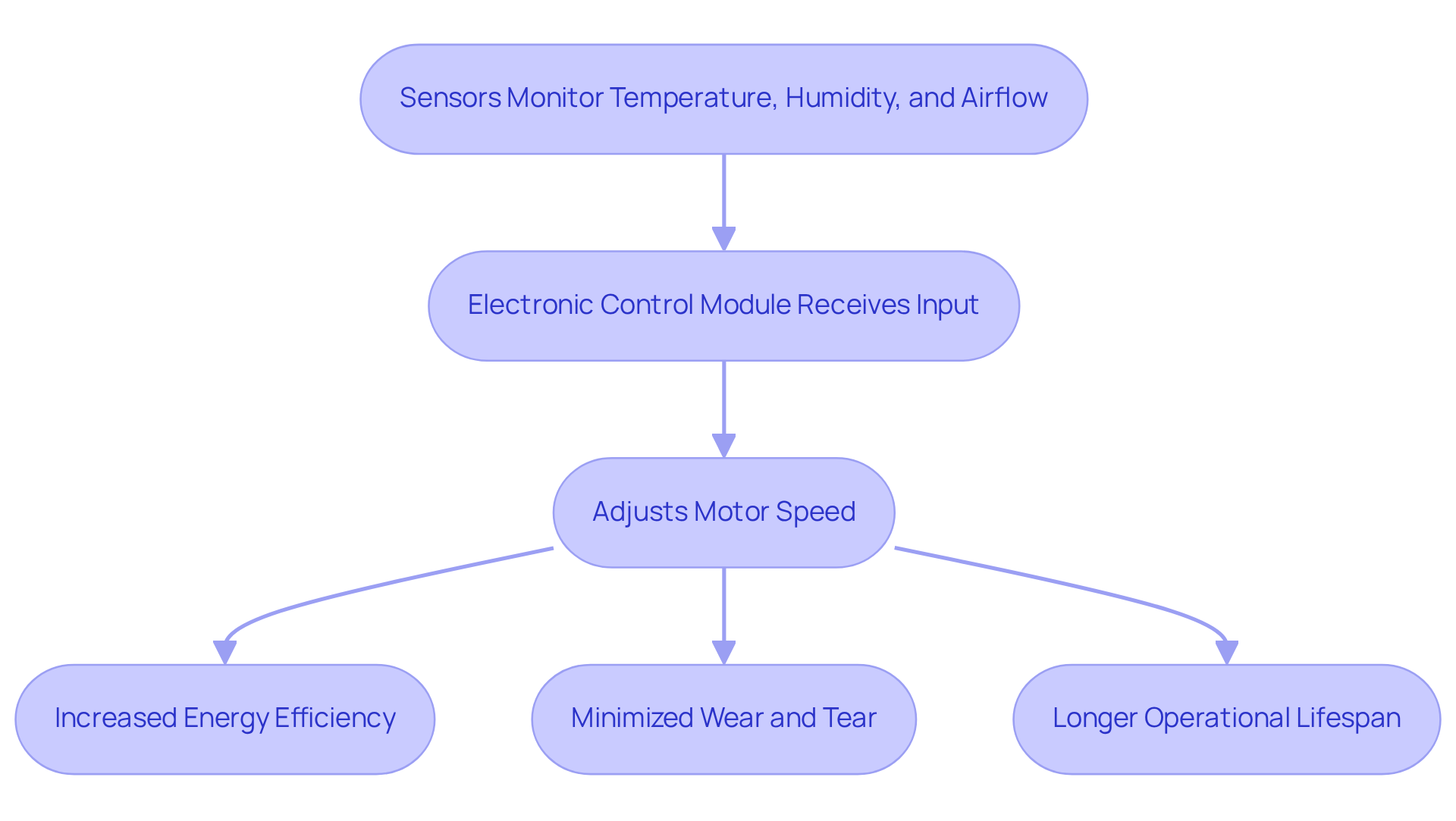

The advantages of ECM technology are both numerous and impactful.

- Firstly, electronic control mechanisms provide considerable energy savings, often decreasing energy usage by as much as 30% compared to conventional engines. This efficiency not only translates into but also contributes to a reduced environmental footprint.

- Secondly, energy control mechanisms enhance the management of airflow and temperature, resulting in elevated comfort levels in HVAC units.

- Their capability to operate quietly further underscores their suitability for residential and commercial environments where noise reduction is paramount.

- Additionally, electronic control modules require less maintenance due to their brushless design, which minimizes wear and tear, ultimately prolonging both the lifespan of the device and the systems they support.

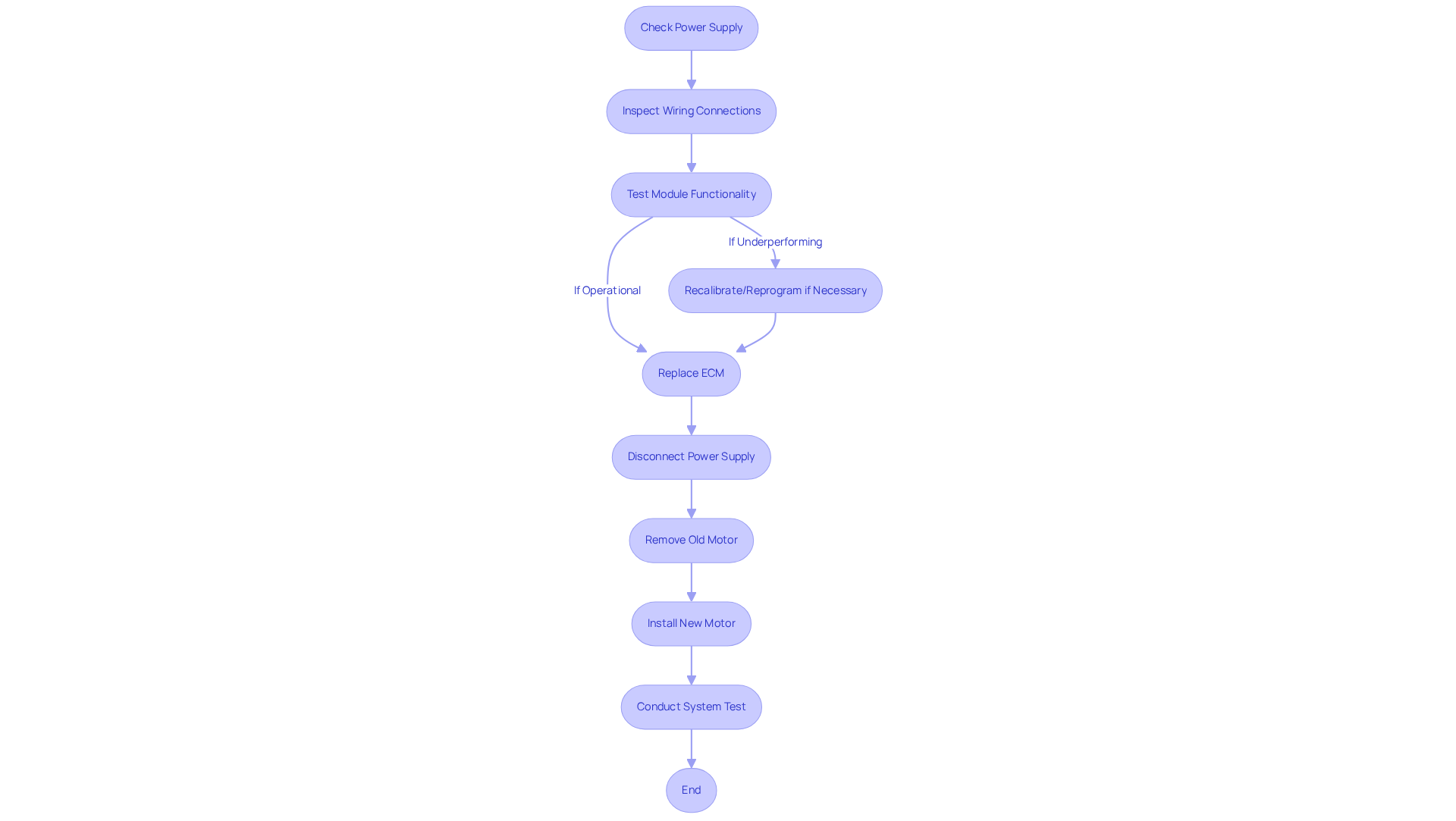

Guide on Troubleshooting and Replacing ECMs

Troubleshooting ECMs requires a systematic approach. Begin by checking the power supply to ensure the device is receiving the correct voltage. If the motor fails to start, inspect the wiring connections for signs of damage or corrosion. Next, confirm the module’s functionality by testing its output signals. Should the ECM be operational yet underperforming, recalibration or reprogramming may be necessary, often achievable through the control interface. When substituting an ECM, it is crucial to verify that the new engine is .

- Disconnect the power supply.

- Remove the old motor.

- Carefully install the new one, ensuring all connections are secure.

Finally, conduct a system test to confirm that the new ECM is functioning correctly and efficiently.

Conclusion

Electronically Commutated Motors (ECMs) represent a pivotal advancement in electronics engineering, particularly in their application within HVAC systems. By utilizing electronic control modules, these brushless DC devices offer enhanced efficiency and adaptability compared to traditional motors, effectively transforming how heating and cooling demands are met in modern environments.

This article explores key insights into the operation, advantages, and troubleshooting methods of ECMs. Their ability to adjust speed based on real-time environmental data, coupled with significant energy savings and reduced maintenance needs, positions ECMs as a superior choice over Permanent Split Capacitor (PSC) motors. The comparison highlights efficiency differences, with ECMs achieving ratings above 80%, while PSC motors typically hover around 60%. This underscores not only the technological superiority of ECMs but also their impact on operational costs and environmental sustainability.

In conclusion, embracing ECM technology is essential for those seeking enhanced efficiency, comfort, and longevity in HVAC systems. As industries continue to prioritize energy conservation and operational excellence, understanding and implementing ECMs will be crucial. Whether troubleshooting existing systems or considering replacements, recognizing the value of ECMs can lead to significant improvements in both performance and sustainability.

Frequently Asked Questions

What are Electronically Commutated Motors (ECMs)?

Electronically Commutated Motors (ECMs) are advanced brushless DC devices that use electronic regulation to control machinery operations. They differ from traditional motors by utilizing an integrated electronic control module to convert AC power to DC, allowing for precise management of speed and torque.

How do ECMs differ from traditional motors?

Unlike traditional motors that rely on mechanical brushes for commutation, ECMs use an electronic control module for commutation, enhancing their efficiency and performance. This electronic approach enables better speed and torque management.

What applications are ECMs particularly effective in?

ECMs are particularly effective in heating, ventilation, and air conditioning (HVAC) systems, where they can adapt their performance based on real-time requirements.

How do ECMs operate in HVAC systems?

In HVAC systems, ECMs dynamically adjust their speed based on the heating or cooling demands of the environment. They receive input from sensors monitoring temperature, humidity, and airflow, allowing the motor to fine-tune its speed for maximum efficiency and comfort.

What are the benefits of using ECMs in HVAC systems?

The benefits of using ECMs in HVAC systems include enhanced energy efficiency, minimized wear and tear on the system, a longer operational lifespan, and reduced maintenance costs. For example, during low demand periods, ECMs can decrease their speed to consume less energy while still providing adequate airflow.