Overview

Centrifugal fans function by employing a rotating impeller that draws air in axially and subsequently expels it radially. This mechanism results in an increase in air pressure and a significant directional change in airflow. The efficiency of these fans is notably influenced by several critical factors, including:

- Impeller design

- Rotational speed

- The physical characteristics of the air

Such considerations underscore their importance in diverse applications, particularly within HVAC systems and various industrial processes. Understanding these dynamics not only highlights the technical sophistication of centrifugal fans but also emphasizes their essential role in optimizing air management solutions.

Introduction

Centrifugal fans play a crucial role across various industries, adeptly converting mechanical energy into efficient airflow through their distinct operational principles. By harnessing the force generated by a spinning impeller, these fans not only elevate air pressure but also adeptly redirect airflow, rendering them indispensable for applications that span HVAC systems to industrial processes.

Nonetheless, a significant challenge persists in optimizing their design and performance—how can engineers guarantee that these fans function at peak efficiency while accommodating the diverse demands of different environments?

This article embarks on an exploration of the mechanics of centrifugal fans, examining their essential components, applications, and the myriad factors that influence their efficiency.

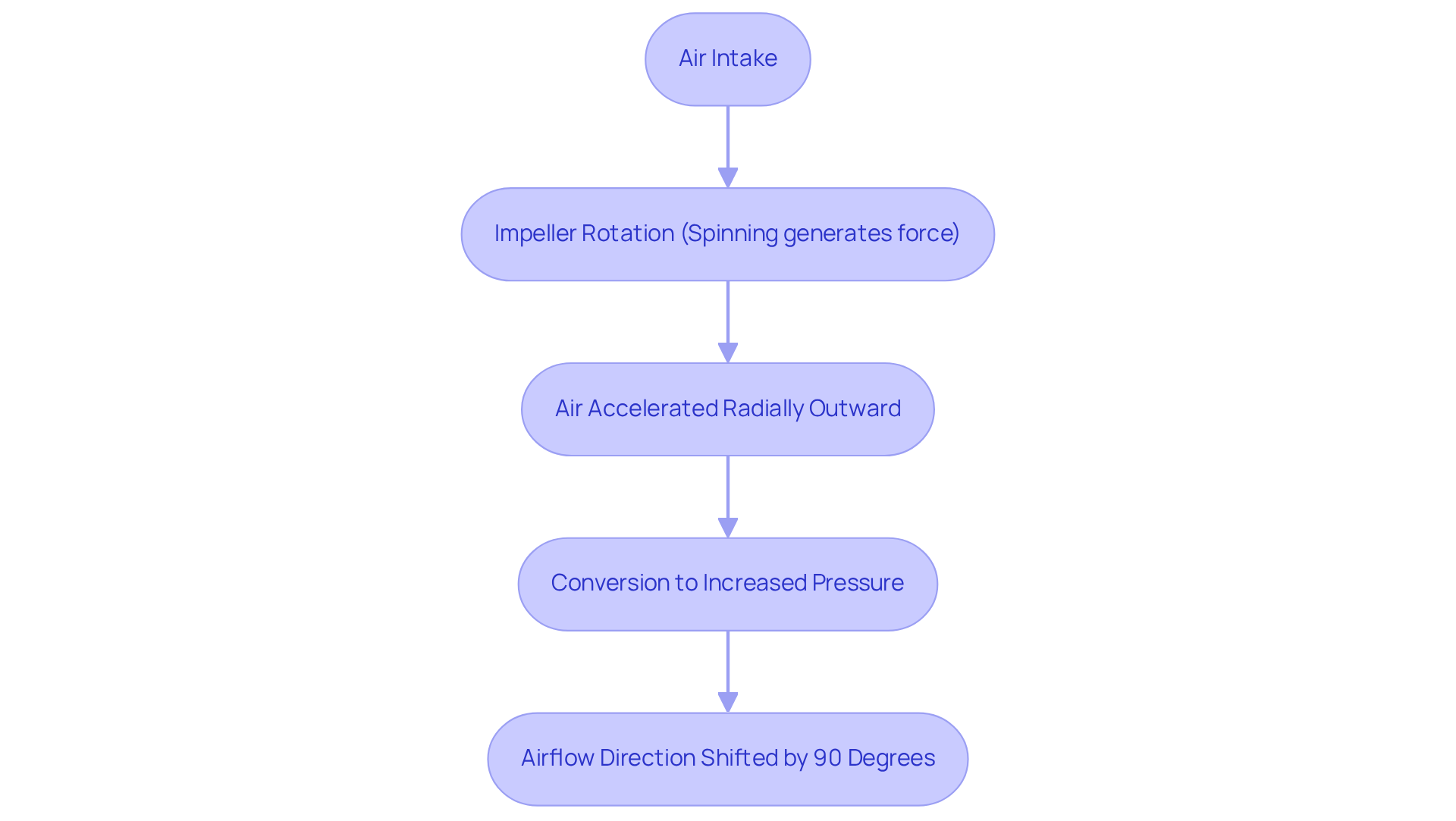

Understand the Principles of Centrifugal Fan Operation

These blowers illustrate how a centrifugal fan works by functioning based on the principle of force generated by a spinning impeller. To understand how a centrifugal fan works, it’s important to note that as the impeller rotates, it draws air into the fan through an axial inlet, accelerating it radially outward. This conversion of kinetic energy into potential energy results in increased air pressure. Notably, the airflow direction typically shifts by 90 degrees upon exiting the fan, underscoring the importance of this principle in applications requiring efficient air movement against resistance, such as HVAC systems and industrial processes.

The performance of rotating blowers is significantly influenced by various elements, including:

- Impeller design

- Rotational speed

- The physical characteristics of the air being displaced

For instance, backward-curved rotating devices are recognized for their high efficiency in converting mechanical energy into airflow, thereby reducing energy consumption and enhancing functionality in HVAC applications. Research indicates that optimizing impeller blade shape can yield enhancements of up to 4.5% at different operating points, emphasizing the critical role of design in achieving optimal performance.

Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, offers a comprehensive range of blowers and DC input devices optimized for performance, efficiency, and minimal noise. Their blowers range in size from 15 to 225mm, making them suitable for diverse applications across electronics, automotive, and industrial sectors. Case studies further elucidate the practical implications of these principles. In one instance, an industrial facility required consistent airflow through a complex duct system with high static pressure demands. The implementation of backward-curved turbines from Gagner-Toomey not only met these criteria but also minimized maintenance requirements due to their robust design. Furthermore, studies have shown that increasing the number of blades on a fan can enhance total pressure and performance, highlighting the vital importance of blade design in fan functionality.

Understanding how a centrifugal fan works and its applications is essential for engineers and designers aiming to in various environments, ensuring that fans operate efficiently and effectively in overcoming resistance.

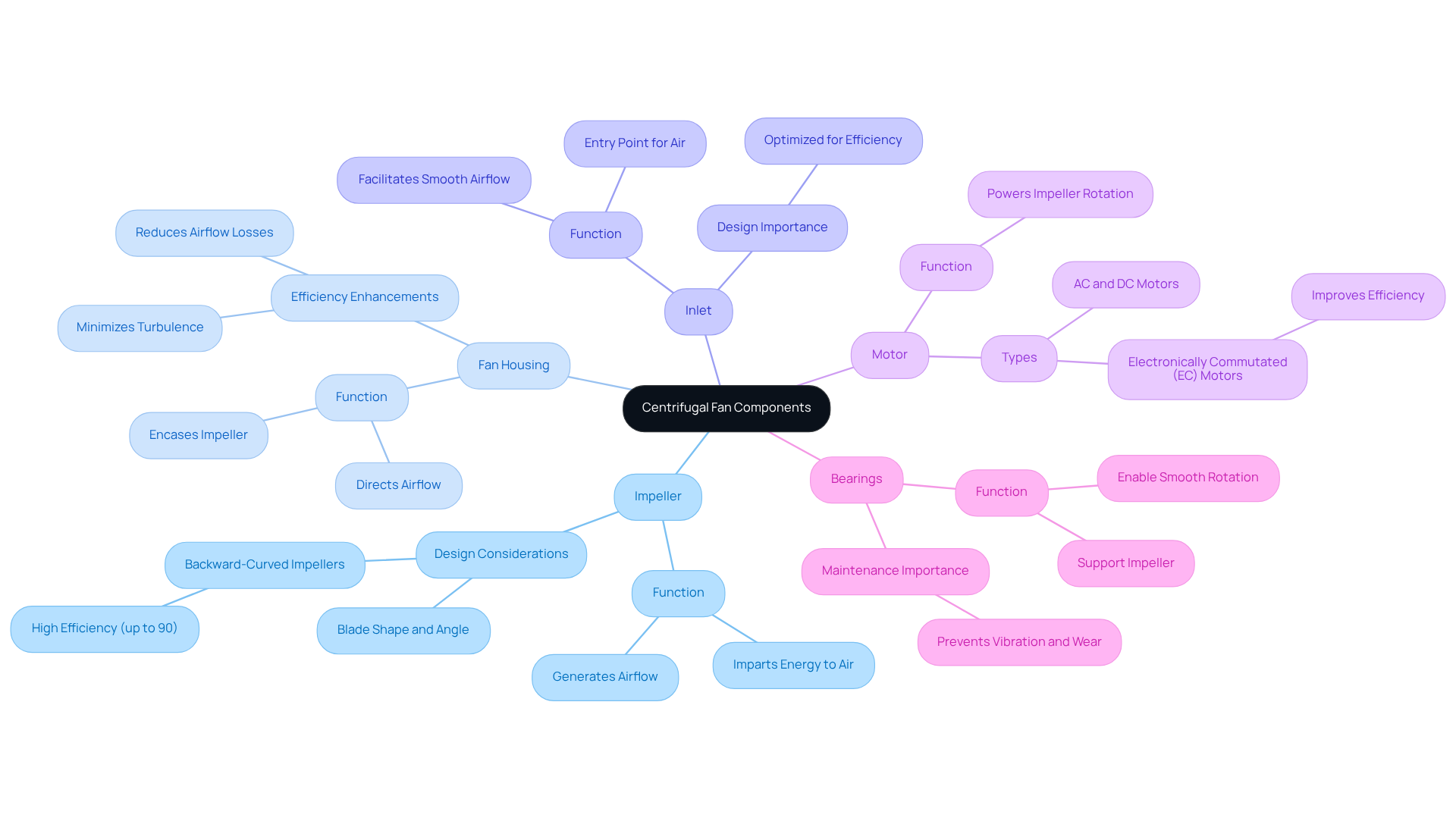

Explore Key Components and Their Functions

The primary components of a centrifugal fan are integral to its performance and efficiency.

- Impeller: This rotating element is essential for imparting energy to the air, generating the necessary airflow. The design of the impeller, particularly its blade shape and angle, significantly affects the fan’s performance and pressure generation. For instance, backward-curved impellers are recognized for their high performance, achieving up to 90% efficiency under optimal conditions.

- Fan Housing: The housing encases the impeller and directs airflow, designed to minimize turbulence and maximize efficiency. Well-engineered housings can enhance overall fan efficiency by minimizing airflow losses, which is crucial in applications requiring consistent air quality, such as cleanrooms and laboratories.

- Inlet: The inlet serves as the entry point for air into the fan, optimized to facilitate smooth airflow into the impeller. A well-constructed inlet can greatly enhance the fan’s efficiency by ensuring that air flows into the impeller without creating turbulence.

- Motor: The motor powers the impeller’s rotation, with options including AC and DC motors. Gagner-Toomey Associates provides a comprehensive range of DC input rotary blowers that improve efficiency by delivering precise speed control, resulting in reduced operational expenses. Electronically commutated (EC) motors are particularly advantageous in this context.

- Bearings: These elements support the impeller and enable smooth rotation, directly affecting the fan’s durability and efficiency. Appropriate bearing selection and maintenance are essential, as they can prevent excessive vibration and wear, common issues in rotating machinery.

Understanding is vital for selecting the appropriate fan for specific applications and ensuring effective maintenance. Engineers frequently emphasize the importance of balancing these elements to achieve optimal performance, particularly in high-pressure settings where backward centrifugal devices excel.

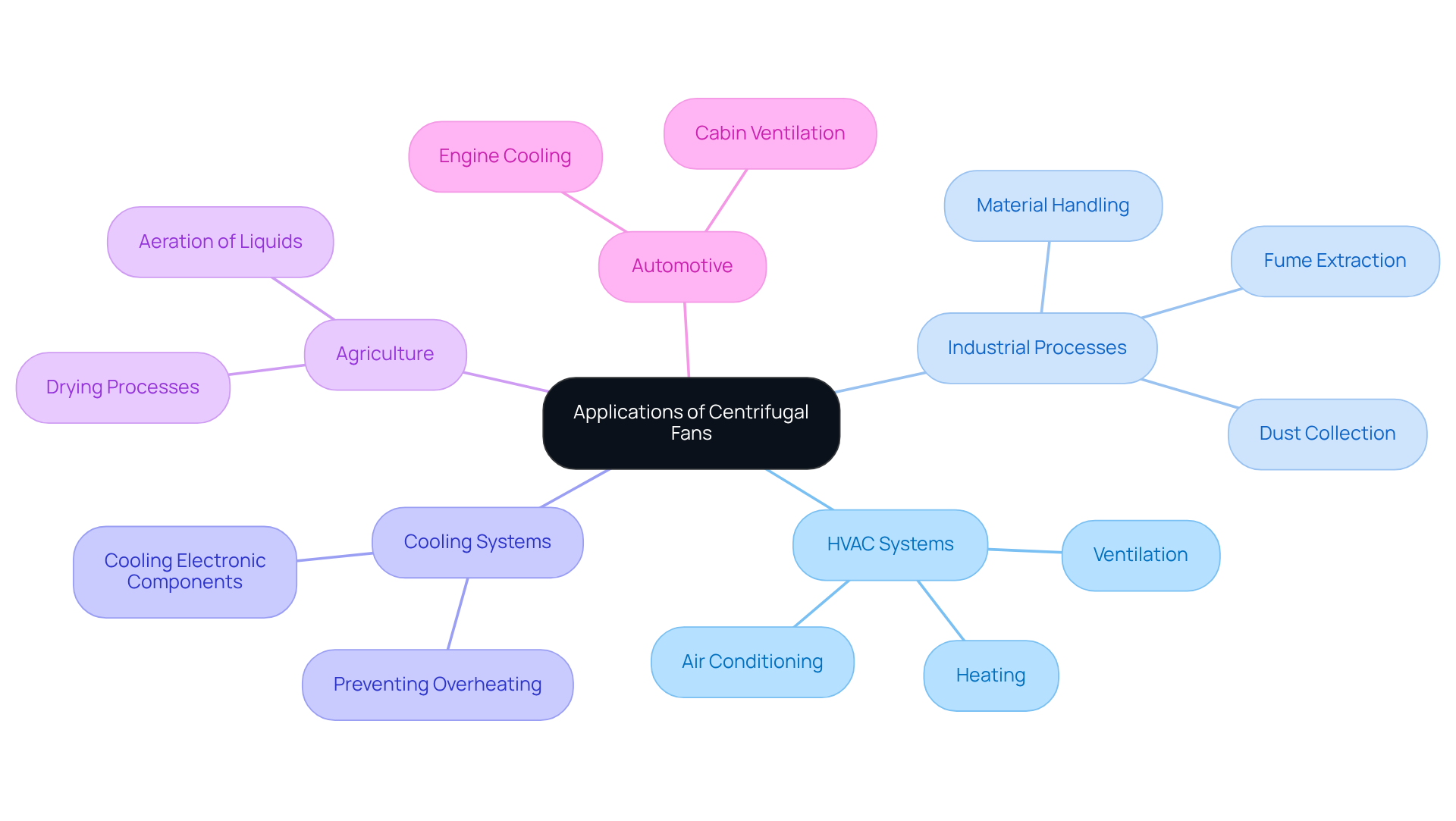

Examine Applications of Centrifugal Fans in Various Industries

Understanding is essential, as these blowers play a crucial role across various sectors, facilitating numerous applications that enhance operational efficiency and safety. Understanding their key areas of utilization is vital for engineers and decision-makers alike:

- HVAC Systems: These fans are indispensable for ventilation, air conditioning, and heating, ensuring optimal indoor air quality and comfort. The HVAC blower and fan systems market is projected to reach USD 2,096.2 million by 2035, driven by urbanization and energy conservation regulations.

- Industrial Processes: In sectors such as manufacturing and chemical processing, radial blowers are essential for dust collection, fume extraction, and material handling. Their implementation significantly boosts workplace safety and operational performance. The North America Industrial Centrifugal Fans/Blowers Market is expected to experience steady growth due to rising industrialization.

- Cooling Systems: Employed in cooling electronic components and equipment, rotary blowers mitigate overheating and ensure operational reliability. The incorporation of smart technologies within these systems is enhancing their efficiency while reducing energy consumption.

- Agriculture: In agricultural applications, centrifugal blowers are utilized for drying processes and aeration of liquids, thereby increasing productivity in farming operations. The growing demand for energy-efficient solutions in this sector reflects a broader trend towards sustainability.

- Automotive: These devices are integral to engine cooling and cabin ventilation systems, improving vehicle efficiency and comfort. The automotive industry is increasingly adopting advanced fan technologies to comply with stringent environmental regulations.

By understanding how does a centrifugal fan work in these applications, engineers can select the appropriate fan type and design tailored to specific operational needs, ensuring optimal performance and adherence to industry standards. As the market evolves, the focus on energy conservation and the integration of intelligent technology will continue to shape the future of industrial blowers.

Analyze Efficiency and Performance Factors in Centrifugal Fans

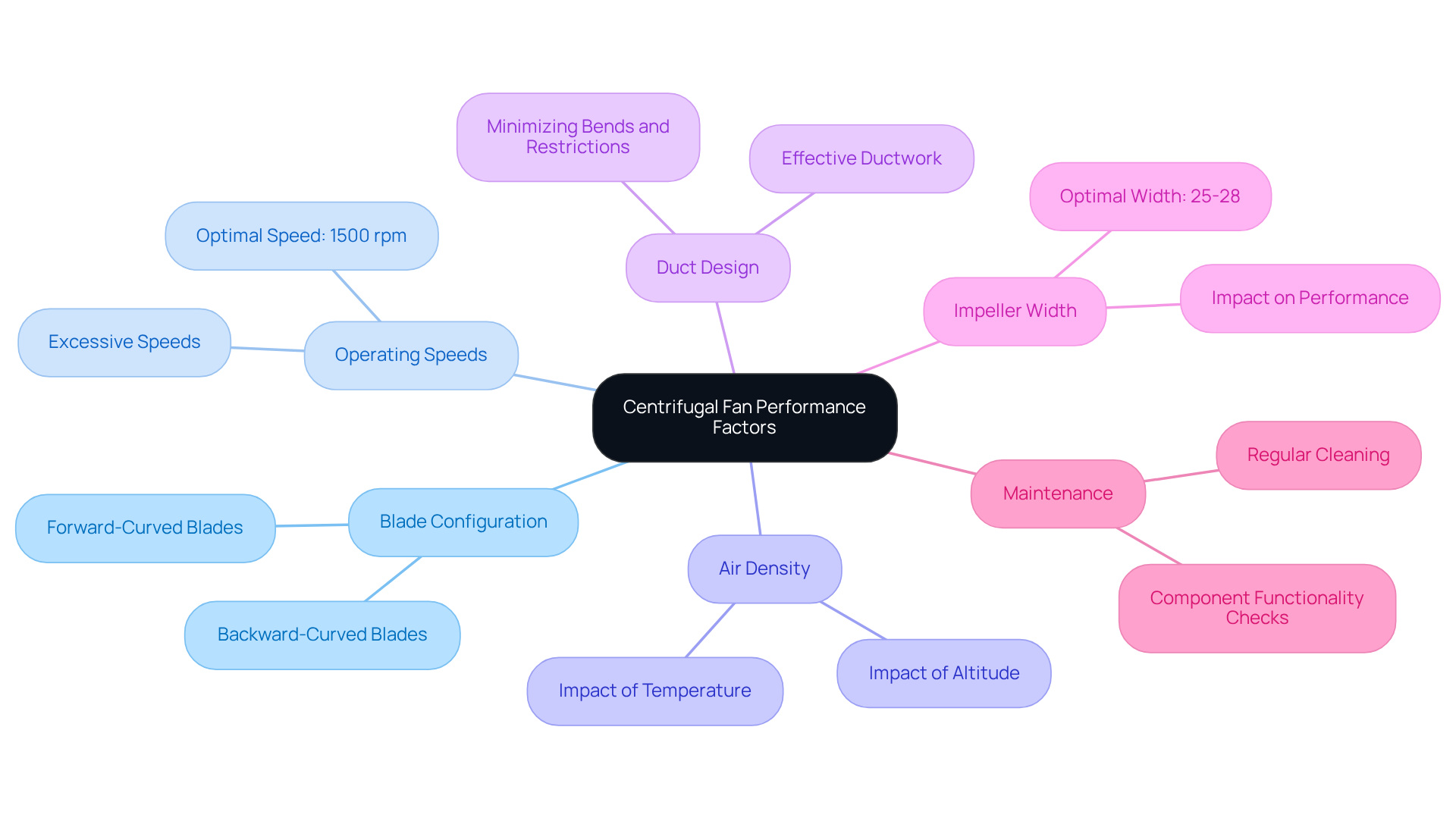

The performance of rotating blowers is significantly influenced by critical factors, particularly blade configuration, which plays a crucial role in determining airflow and energy consumption. Backward-curved blades are recognized for their superior performance compared to forward-curved designs, as they facilitate smoother airflow and reduce turbulence. This design choice can lead to substantial , given that centrifugal blowers are among the highest energy-consuming devices, accounting for approximately 300 TWh of electricity annually. The energy performance levels of fans have reached up to 92%, underscoring the potential advantages of proper design and maintenance.

Operating at optimal fan speeds is vital; excessive speeds can lead to increased energy consumption and noise levels. For example, a fan’s operation can be optimized by maintaining a rotational speed of around 1500 rpm, where efficiency is maximized without compromising airflow.

Air density also impacts fan efficiency, with variations due to temperature and altitude necessitating adjustments for optimal performance. Engineers must take these factors into account when designing systems to ensure that fans operate efficiently under diverse conditions.

Furthermore, the overall system design, including effective ductwork and minimizing bends and restrictions, can enhance airflow and reduce energy losses. A well-designed duct system complements the fan’s capabilities, ensuring that airflow is maximized while minimizing resistance.

The influence of impeller width is also critical; ideal widths of approximately 25-28% of the blade system diameter can significantly enhance performance and effectiveness. Additionally, the use of advanced materials such as aluminum and composites in blade design contributes to weight reduction and improved performance.

Regular maintenance is another essential factor that can greatly enhance fan performance. Keeping the fan clean and ensuring all components function properly helps sustain optimal efficiency. Research has shown that regular maintenance practices can extend the lifespan of rotary blowers and enhance their performance.

By comprehensively understanding these elements, engineers can explore how a centrifugal fan works to implement effective strategies that boost performance, leading to improved operational efficiency and reduced energy costs. The integration of innovative blade designs and consistent maintenance routines can yield considerable energy savings and operational advantages.

Conclusion

Centrifugal fans are indispensable devices that harness the principles of physics to generate airflow efficiently across a multitude of applications. Understanding the mechanics behind their operation—including the pivotal role of the impeller and other essential components—enables engineers and designers to optimize performance tailored to specific needs. The efficiency of centrifugal fans transcends mere design; it also encompasses operational strategies and maintenance practices that can significantly elevate their functionality.

Insights from this exploration underscore that the design of the impeller, coupled with the integration of advanced materials and technologies, is crucial to the overall efficiency of centrifugal fans. Their applications span diverse industries, from HVAC systems that ensure air quality to manufacturing processes aimed at enhancing workplace safety. The significance of selecting the appropriate fan type and maintaining optimal performance cannot be overstated, as it directly correlates with energy savings and operational effectiveness.

As industries evolve, the demand for energy-efficient solutions will propel innovation in centrifugal fan design and application. Engineers and decision-makers must remain informed about the latest advancements and best practices, ensuring they harness the full potential of centrifugal fans in their operations. By embracing these insights, they will not only enhance performance but also contribute to a more sustainable and efficient future in air movement technology.

Frequently Asked Questions

How does a centrifugal fan operate?

A centrifugal fan operates based on the principle of force generated by a spinning impeller, which draws air into the fan through an axial inlet and accelerates it radially outward, converting kinetic energy into potential energy and increasing air pressure.

What is the typical airflow direction in a centrifugal fan?

The airflow direction typically shifts by 90 degrees upon exiting the fan.

What factors influence the performance of centrifugal fans?

The performance is influenced by impeller design, rotational speed, and the physical characteristics of the air being displaced.

What type of impeller design is known for high efficiency in HVAC applications?

Backward-curved rotating devices are recognized for their high efficiency in converting mechanical energy into airflow, which reduces energy consumption and enhances functionality in HVAC applications.

How can optimizing impeller blade shape impact fan performance?

Optimizing impeller blade shape can yield enhancements of up to 4.5% at different operating points, highlighting the importance of design in achieving optimal performance.

What range of blowers does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a comprehensive range of blowers and DC input devices ranging in size from 15 to 225mm, suitable for diverse applications across electronics, automotive, and industrial sectors.

Can you provide an example of centrifugal fan application in an industrial setting?

In one instance, an industrial facility required consistent airflow through a complex duct system with high static pressure demands. The implementation of backward-curved turbines from Gagner-Toomey met these criteria and minimized maintenance requirements due to their robust design.

How does the number of blades on a fan affect its performance?

Increasing the number of blades on a fan can enhance total pressure and performance, emphasizing the importance of blade design in fan functionality.

Why is understanding centrifugal fans important for engineers and designers?

Understanding how a centrifugal fan works and its applications is essential for engineers and designers to optimize airflow in various environments, ensuring fans operate efficiently and effectively in overcoming resistance.