Overview

The article examines best practices for the effective integration of axial blowers into cooling systems. It underscores the critical importance of proper sizing, positioning, and maintenance to optimize performance. By detailing how these practices enhance energy efficiency, mitigate noise and vibration issues, and ensure reliable operation, the article illustrates their role in achieving improved thermal management and sustainability across various applications.

Introduction

Axial blowers are integral to modern cooling systems, efficiently channeling air to sustain optimal temperatures across diverse applications. Their distinctive design facilitates high airflow rates with reduced energy consumption, rendering them an appealing option for engineers aiming to boost performance and minimize operational costs.

Nonetheless, the integration of these fans presents challenges; issues such as noise, vibration, and turbulence can compromise their efficacy.

How can engineers effectively navigate these hurdles to fully harness the advantages of axial blowers in their systems? This article explores best practices for successful integration, ensuring that axial blowers not only fulfill but surpass performance expectations.

Understand Axial Blowers: Principles and Functionality

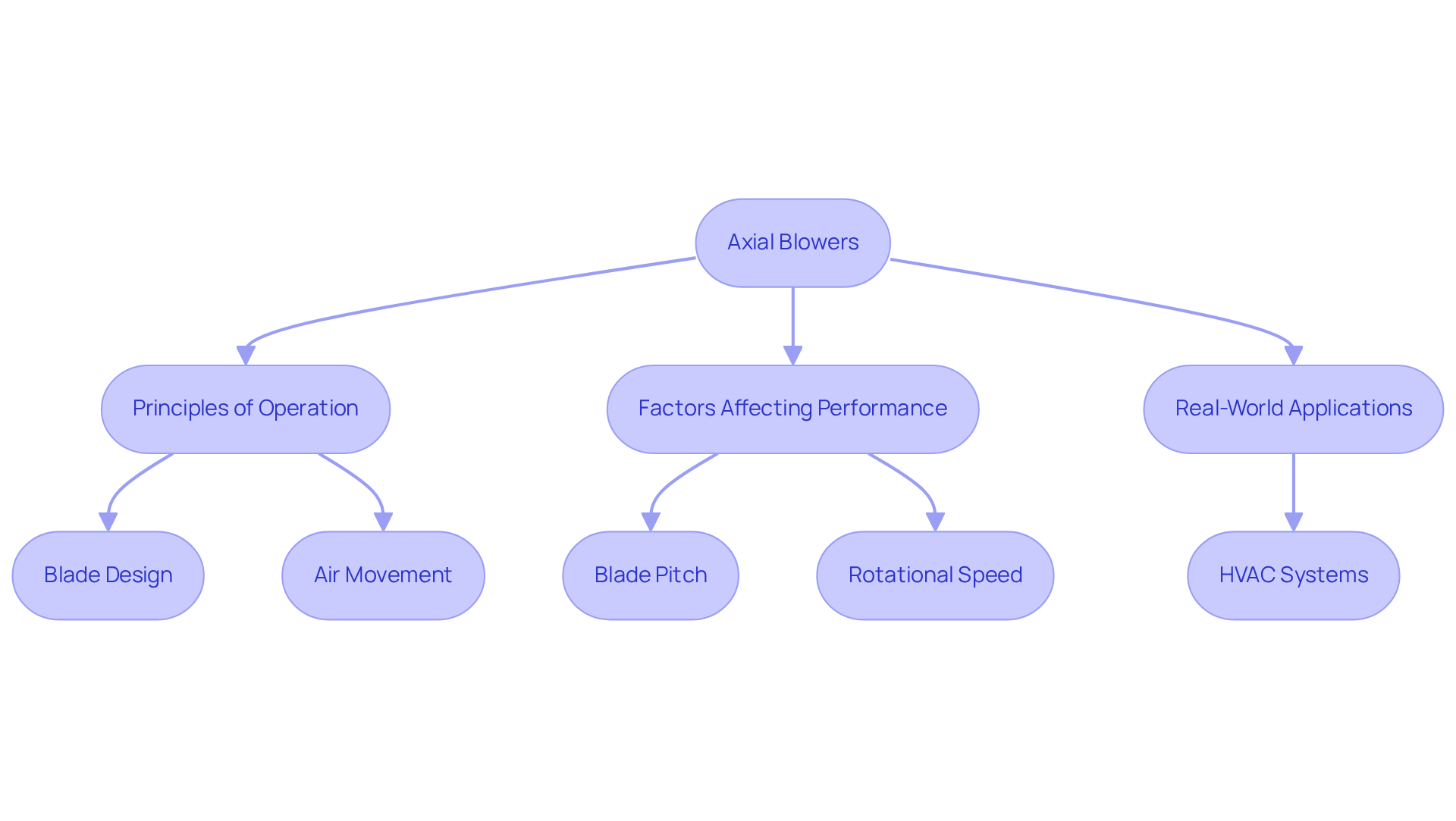

Axial fans are engineered to efficiently transport air in alignment with the fan’s axis, leveraging the transformation of rotational energy into air movement via blades that revolve around a central hub. This design enables them to achieve high air movement rates at low pressure, making axial blowers particularly suitable for applications that require substantial air circulation with minimal resistance.

Understanding ventilation dynamics is crucial for in cooling systems. Key factors such as blade pitch and rotational speed significantly influence flow characteristics. For example, an increase in blade pitch can enhance air movement; however, it may also lead to elevated noise levels and reduced efficiency. Likewise, the rotational speed has a direct impact on the volume of air displaced, necessitating meticulous calibration to fulfill specific application requirements.

Real-world applications underscore the significance of these dynamics. In HVAC systems, fan units are utilized to maintain comfortable indoor conditions through efficient air circulation. Their performance can be markedly affected by installation angles and proximity to other components, which, if not properly managed, can disrupt airflow and diminish efficiency. By mastering these principles, engineers are empowered to make informed decisions when selecting axial blowers, which ensures optimal thermal management in electronic systems and enhances overall operational effectiveness.

Leverage Advantages of Axial Blowers in Cooling Applications

Axial fans are increasingly favored in cooling applications due to their ability to efficiently move substantial volumes of air, which is vital for maintaining optimal temperatures in electronic components. In data centers, for instance, these fans are commonly utilized to cool server racks, where high airflow is critical to prevent overheating. Their compact design allows for seamless integration into confined spaces, making them particularly suitable for environments with limited space.

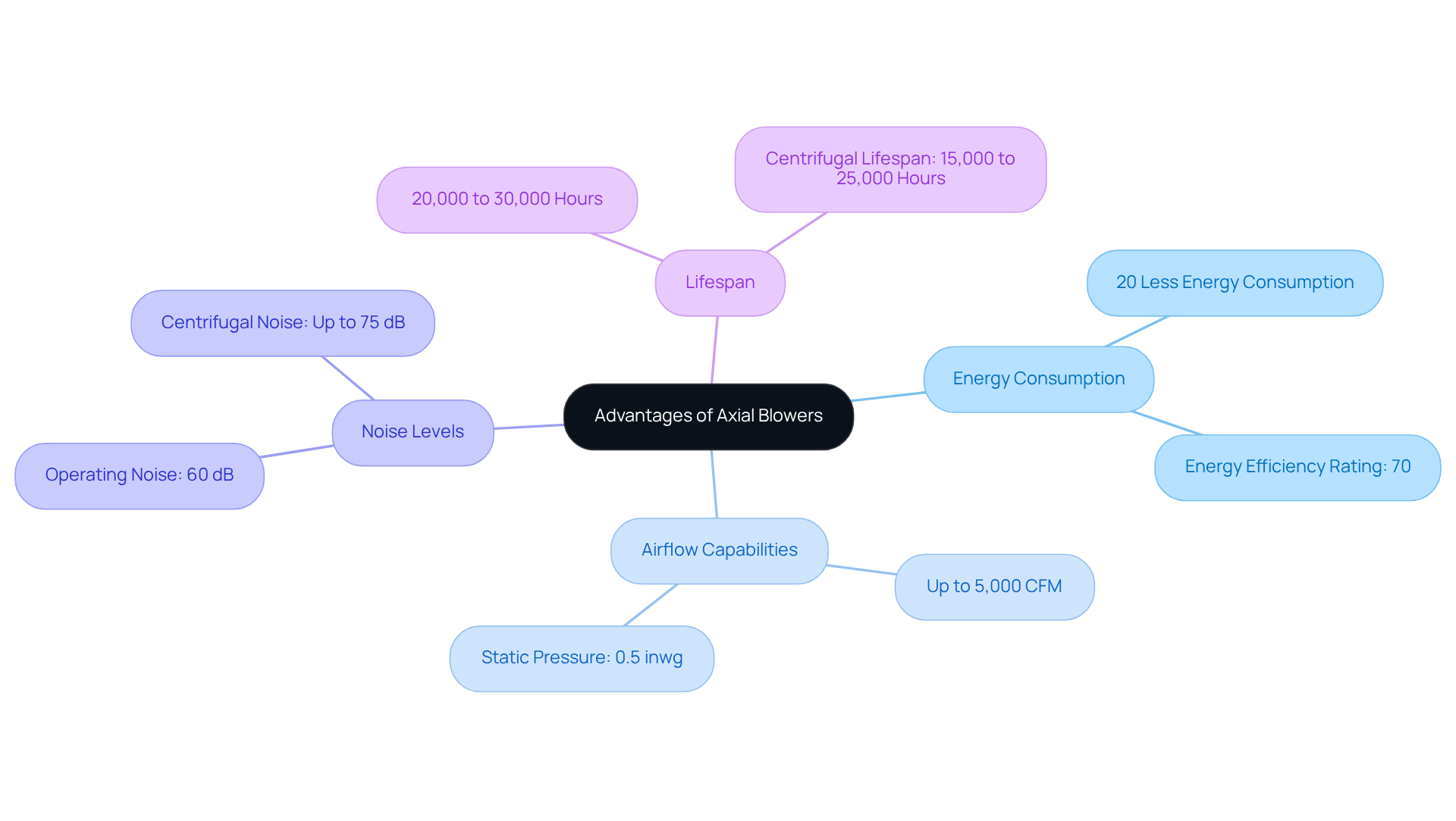

Notably, axial blowers typically consume up to 20% less energy compared to centrifugal devices, resulting in reduced operational costs. Their energy efficiency rating stands at approximately 70%, in contrast to centrifugal blowers, which achieve around 60%. This energy efficiency, coupled with their —up to 5,000 CFM at a static pressure of 0.5 inwg—empowers engineers to design cooling systems that not only meet performance standards but also support energy-saving initiatives.

Moreover, direct flow devices operate at a lower noise level of about 60 dB, compared to centrifugal models that can reach up to 75 dB, making them suitable for noise-sensitive environments. The anticipated lifespan of industrial units ranges from 20,000 to 30,000 hours, while centrifugal devices typically last between 15,000 to 25,000 hours, underscoring the long-term benefits of these systems.

Additionally, adherence to safety and environmental standards, such as RoHS and EMC, is essential for ensuring the reliability and efficiency of fans in electronic applications. By capitalizing on these advantages, organizations can enhance their cooling strategies while contributing to sustainability efforts.

Implement Best Practices for Integrating Axial Blowers

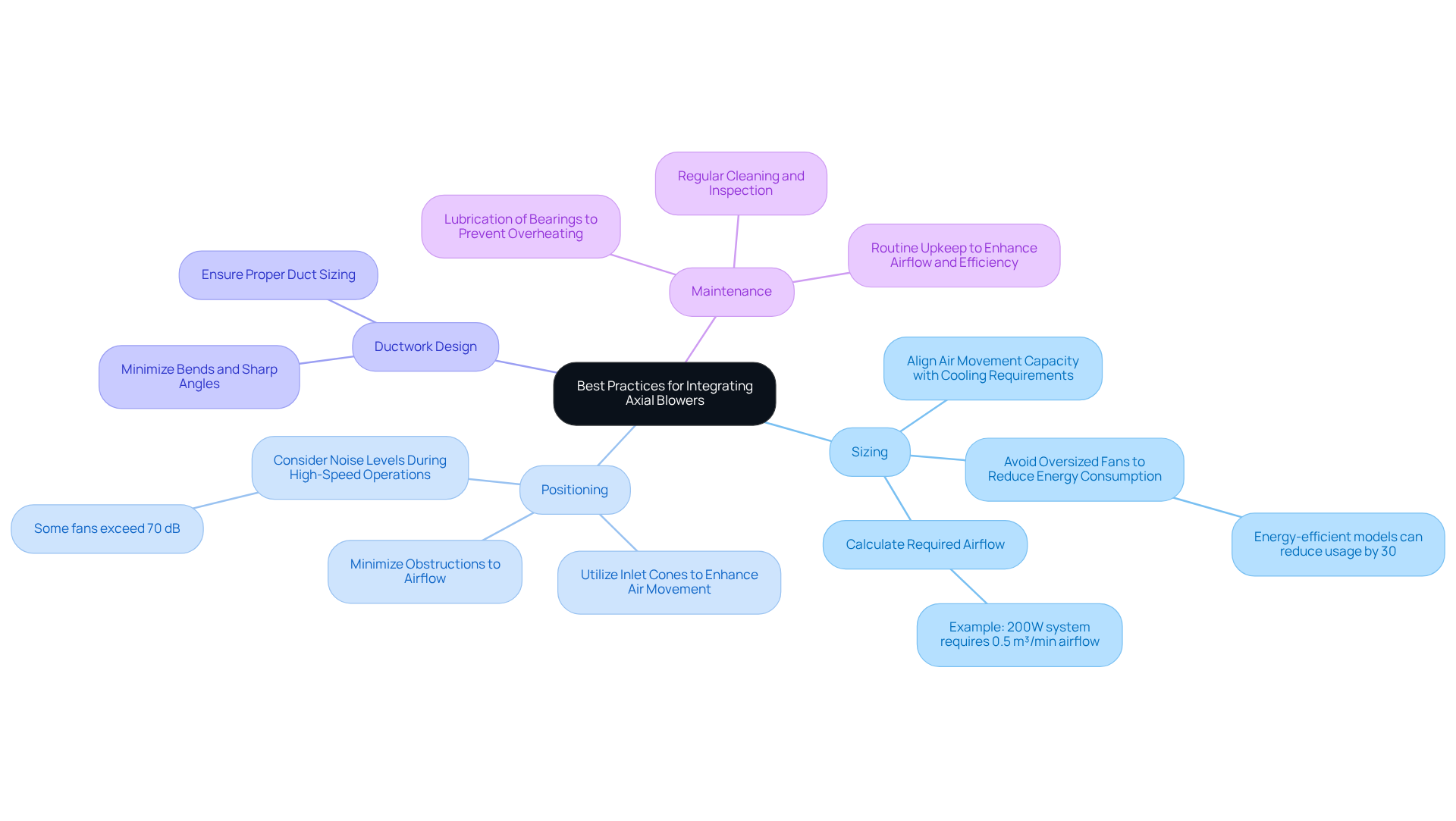

To successfully incorporate axial blowers into cooling systems, it is imperative to adhere to several best practices. First and foremost, appropriate sizing is essential; engineers must ensure that the fan’s air movement capacity aligns with the cooling requirements of the application. Oversized fans can lead to excessive energy consumption, with energy-efficient models reducing usage by as much as 30%. Conversely, undersized units may fail to provide adequate cooling. For instance, a system dissipating 200W requires an airflow of 0.5 m³/min to maintain a maximum temperature rise of 20°C. This underscores the critical importance of selecting the right ventilation device, particularly axial blowers, to enhance energy efficiency and overall performance.

Secondly, the strategic positioning of the fan is crucial. It should be installed to minimize obstructions to airflow and maximize operational efficiency. Utilizing inlet cones, for example, can enhance air movement and —an important consideration, as some fans can produce noise exceeding 70 dB during high-speed operations. Additionally, ensuring proper ductwork design is vital; minimizing bends and sharp angles in ducting can prevent flow restrictions that compromise performance.

Regular maintenance, including the cleaning and inspection of the fan and its components, is vital for ensuring long-term reliability and optimal performance. Routine upkeep significantly enhances airflow and reduces energy consumption, highlighting its importance as a fundamental practice for ventilation systems. By adhering to these best practices, engineers can improve the efficiency of cooling devices within their systems, resulting in extended lifespan, reduced maintenance needs, minimized downtime, and increased profitability.

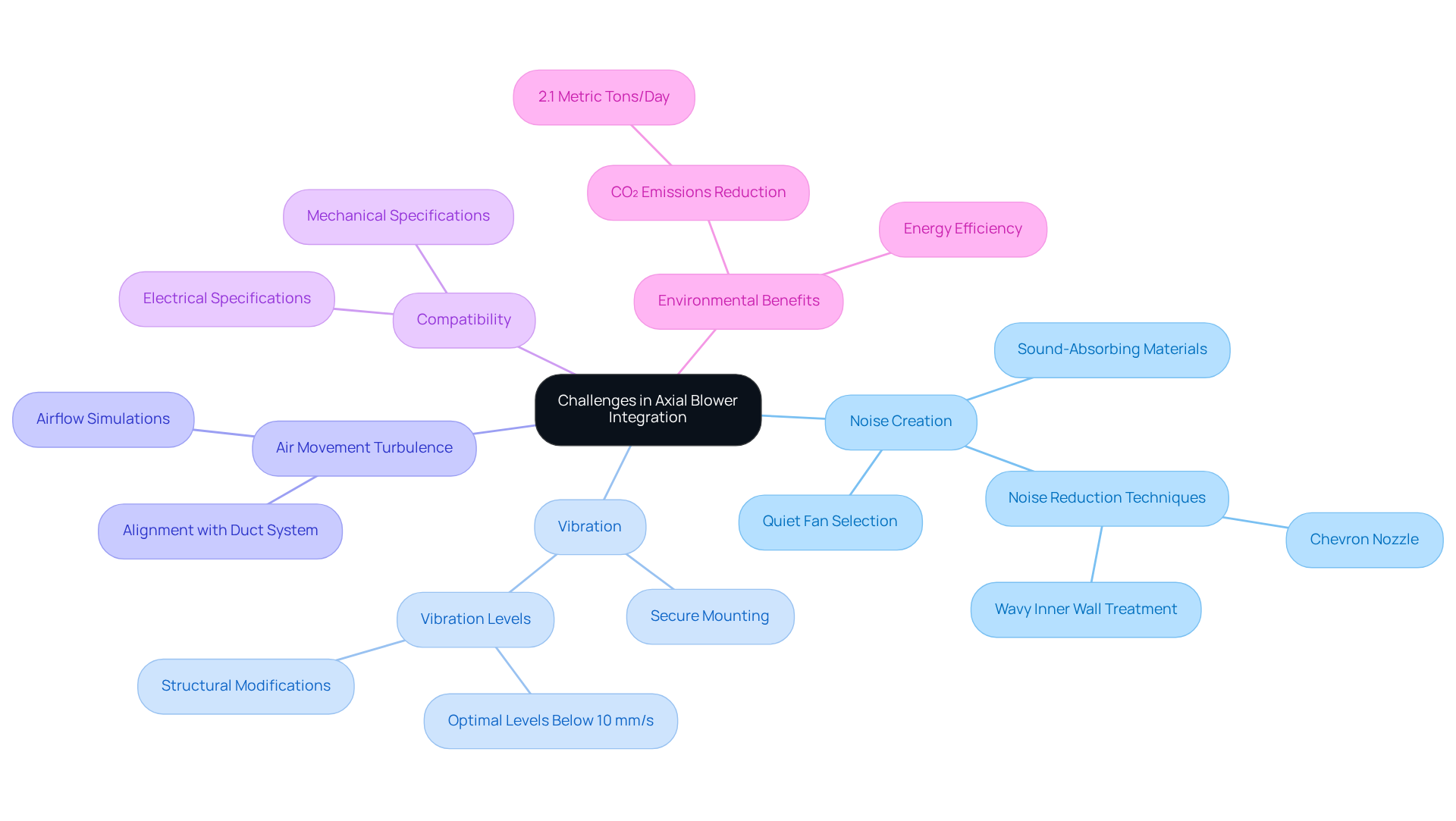

Address Challenges in Axial Blower Integration

Integrating axial blowers presents several challenges that engineers must navigate effectively. A primary concern is noise creation, which can be significantly minimized by selecting fans specifically engineered for quiet operation and incorporating sound-absorbing materials during installation. For instance, studies indicate that implementing design modifications, such as Chevron nozzles, can achieve noise reductions of up to 41.6% at the outlet. Furthermore, vibration poses a risk of mechanical failures; therefore, ensuring that the fan is securely mounted and balanced is essential. Excessive vibration levels can lead to potential bearing failures and increased operational costs. Engineers should aim for vibration levels below 10 mm/s to maintain optimal performance and longevity of the equipment. Notably, structural dynamic modifications have been shown to reduce vibration response levels from 11 mm/s to less than 2 mm/s, illustrating the effectiveness of vibration management strategies.

Another challenge is air movement turbulence, which may arise if the fan is misaligned with the duct system. Conducting airflow simulations during the design phase is crucial to identify and rectify potential turbulence issues before installation, ensuring smooth operation and efficiency. Moreover, compatibility with existing systems is vital; engineers must assess the electrical and mechanical specifications of the fan to ensure seamless integration with current infrastructure. This comprehensive approach not only enhances performance but also minimizes downtime and maintenance costs, ultimately leading to a more reliable and . Furthermore, the integration of effective axial blowers can yield significant environmental benefits, such as an estimated reduction of 2.1 metric tons of CO₂ emissions per day through energy-efficient operation. Additionally, early fault detection strategies can help avert substantial production losses, with one case study revealing that proper maintenance interventions prevented $9,600 in lost production.

Conclusion

Mastering the integration of axial blowers into cooling systems is essential for optimizing performance and efficiency. These devices excel in delivering high airflow at low pressure, making them invaluable in various applications, particularly in environments where maintaining optimal temperatures is critical. By understanding their principles and functionality, engineers can leverage the unique advantages of axial blowers to enhance cooling strategies while ensuring energy efficiency and sustainability.

Key insights from this article highlight the importance of:

- Proper sizing

- Strategic positioning

- Regular maintenance

in the effective integration of axial blowers. Oversized or undersized fans can lead to inefficiencies, while thoughtful installation can mitigate noise and vibration challenges. Furthermore, adherence to safety and environmental standards ensures the reliability of these systems, ultimately contributing to reduced operational costs and improved longevity.

As organizations strive for enhanced cooling solutions, embracing best practices for axial blower integration becomes paramount. By prioritizing informed decision-making and proactive maintenance, engineers can not only optimize system performance but also contribute to broader sustainability goals. This commitment to excellence in cooling technology is crucial for fostering innovation and efficiency in today’s competitive landscape.

Frequently Asked Questions

What are axial blowers and how do they work?

Axial blowers are designed to transport air along the axis of the fan. They convert rotational energy into air movement through blades that revolve around a central hub, achieving high air movement rates at low pressure.

What applications are suitable for axial blowers?

Axial blowers are particularly suitable for applications that require substantial air circulation with minimal resistance, such as HVAC systems, where they help maintain comfortable indoor conditions.

How do blade pitch and rotational speed affect axial blower performance?

Blade pitch and rotational speed significantly influence airflow characteristics. Increasing blade pitch can enhance air movement but may also increase noise levels and reduce efficiency. Similarly, rotational speed directly impacts the volume of air displaced, requiring careful calibration for specific applications.

What factors can affect the performance of axial blowers in HVAC systems?

The performance of axial blowers can be affected by installation angles and proximity to other components. If not properly managed, these factors can disrupt airflow and decrease efficiency.

Why is understanding ventilation dynamics important for engineers?

Understanding ventilation dynamics allows engineers to make informed decisions when selecting axial blowers, ensuring optimal thermal management in electronic systems and enhancing overall operational effectiveness.