Overview

The article provides essential insights into fan technologies specifically for electronics engineers, emphasizing the two primary types: axial and centrifugal fans, along with their critical applications in heat management. It elaborates on the operational principles governing these fans, explores the market dynamics influencing their use, and outlines best practices for installation and maintenance. These elements are vital for optimizing performance and ensuring the longevity of electronic devices.

Introduction

Fan technologies are crucial in the electronics sector, ensuring devices operate efficiently through effective heat dissipation. With the increasing demand for energy-efficient cooling solutions, it is imperative for engineers to grasp the distinctions between axial and centrifugal fans to enhance performance. As advancements in technology accelerate and the market expands, engineers must adeptly navigate the complexities of fan selection and maintenance to address the evolving requirements of their applications.

Explore the Fundamentals of Fan Technologies

Fan technologies are crucial for effectively managing heat within electronic devices. By generating airflow, fans facilitate the dissipation of heat produced by various components. The two primary categories of devices employed in electronics are axial and centrifugal fans.

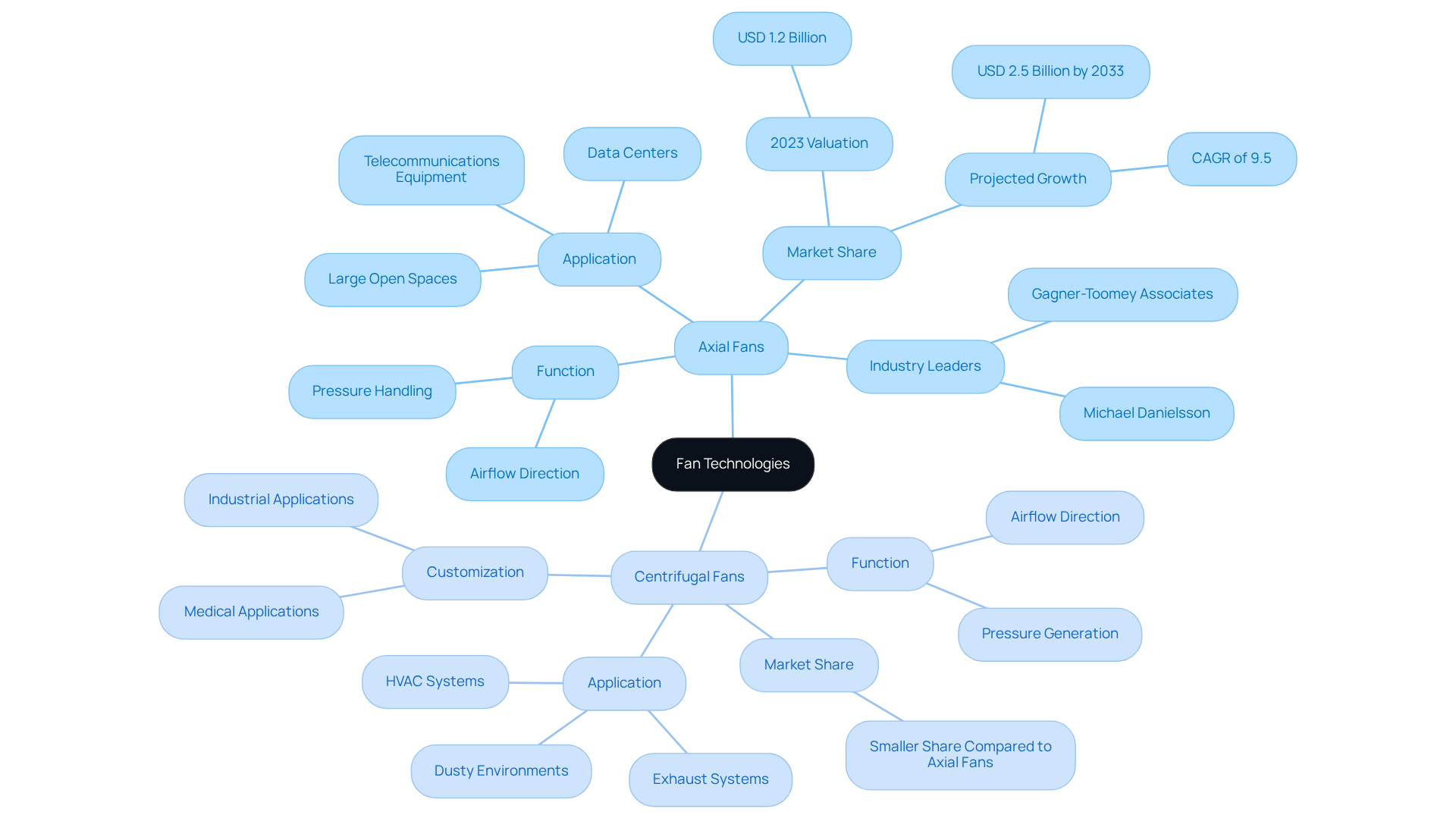

- Axial Fans: These devices effectively move air parallel to the unit’s axis, making them particularly suitable for applications that demand high airflow at low pressure. Their importance is underscored by industry leaders, such as Michael Danielsson, who emphasize that are essential for maintaining optimal temperatures in data centers and telecommunications equipment, where heat management is critical for performance. The growing demand for energy-efficient cooling solutions further accentuates the relevance of fan technologies, especially axial ventilation devices, in the contemporary market. Gagner-Toomey Associates, a global leader in power conversion products, offers a diverse range of standard and custom cooling solutions, including DC blowers tailored to meet the stringent requirements of various applications.

- Centrifugal Fans: In contrast, these fans draw air into their center and expel it at a right angle, thereby generating higher pressure. They are ideal for scenarios where airflow must navigate through ducts or where greater resistance is encountered. Commonly utilized in exhaust systems within dusty environments or in HVAC systems requiring air movement through intricate ductwork, centrifugal fans serve critical functions. Gagner-Toomey Associates also provides centrifugal blowers customized for industrial and medical applications, ensuring effective heat management in demanding environments.

Market dynamics reveal that fan technologies, particularly axial blowers, dominate the electronics cooling sector, capturing a substantial market share due to their efficiency and effectiveness in high-volume airflow applications. In 2023, the market for axial devices in electronics cooling was valued at approximately USD 1.2 billion, with projections indicating growth to USD 2.5 billion by 2033, reflecting a compound annual growth rate (CAGR) of 9.5% from 2026 to 2033. Conversely, while centrifugal blowers are essential, they hold a smaller market share in this sector.

A thorough understanding of these fundamentals empowers engineers to make informed decisions regarding fan selection based on specific cooling requirements, thereby ensuring optimal performance and longevity of electronic devices.

Compare Axial and Centrifugal Fan Technologies

When comparing axial and centrifugal fans, several key factors warrant consideration:

- Airflow Direction: Axial fans move air in a straight line, while centrifugal fans alter the direction of airflow, a feature that proves advantageous in ducted systems.

- Pressure Generation: Centrifugal blowers excel in applications demanding higher pressure, making them particularly suitable for systems facing resistance, such as HVAC installations.

- Dimensions and Effectiveness: Axial fans are generally more compact and energy-efficient, ideal for high-volume, low-pressure applications. In contrast, centrifugal models are larger and more powerful, fitting for high-pressure scenarios.

- Noise Levels: Typically, axial fans operate more quietly at lower speeds, whereas centrifugal fans may generate more noise due to their design and operational characteristics.

The selection of the appropriate fan technologies hinges on the of the application, encompassing both airflow needs and spatial constraints.

Implement Best Practices for Fan Installation and Maintenance

To ensure the longevity and efficiency of fan systems, adherence to best practices is essential:

-

Installation:

- Proper alignment of the fan is crucial to prevent vibrations that can lead to mechanical failure.

- Utilize suitable mounting equipment to secure the fan, thereby reducing sound and enhancing stability.

- Consider airflow direction carefully and avoid any obstructions that could impede performance.

- Understanding is essential to ensure effective air circulation and comfortable working conditions.

-

Maintenance:

- Regular cleaning of fan blades and housing is vital to prevent dust buildup, which can significantly reduce airflow and efficiency.

- Inspect electrical connections and wiring for signs of wear or damage, as these can lead to operational failures.

- Lubricate moving parts according to the manufacturer’s recommendations to minimize friction and prolong lifespan.

- Continuously monitor fan performance and noise levels; any significant changes may indicate a need for maintenance or replacement.

- Preventive maintenance services are vital for ensuring the continuous dependability of fan units.

By implementing these practices, engineers can significantly enhance the reliability and efficiency of their cooling mechanisms, particularly through the use of fan technologies, ensuring optimal performance in electronic applications. As pointed out by industry specialists, “Electricity is the lifeblood of contemporary existence, and electricians are the protectors of its flow,” emphasizing the significance of sustaining structures that support this essential resource.

Enhance Performance: Noise Reduction and Efficiency in Fan Systems

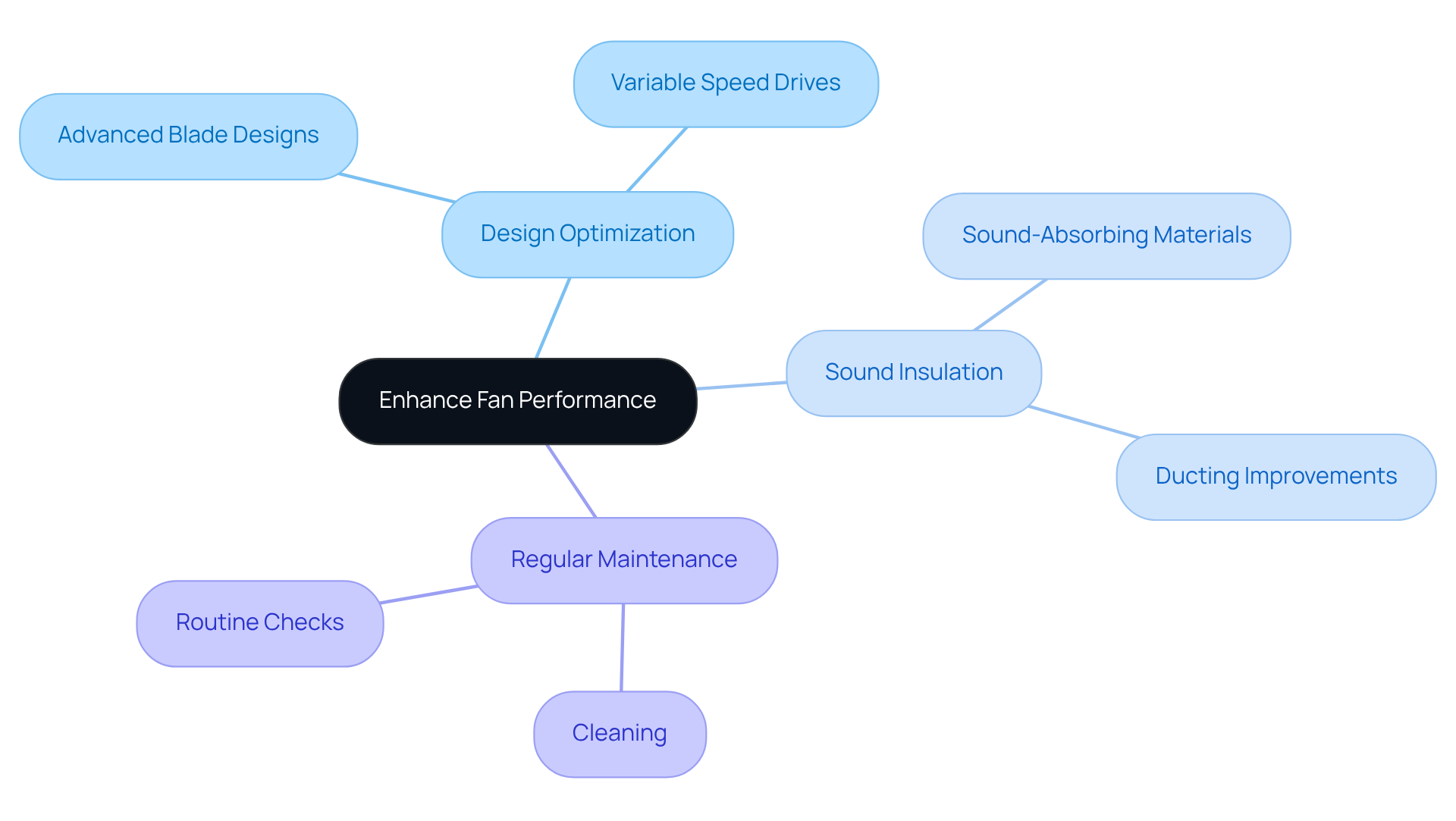

To enhance the performance of fan technologies while minimizing noise, engineers can implement several effective strategies.

- Design Optimization: Engineers should employ fans with advanced blade designs that minimize turbulence and noise, leading to smoother airflow. Incorporating variable speed drives (VSDs) allows for dynamic modification of fan speed based on demand, which not only enhances energy efficiency but can also lessen sound levels by as much as 50% in specific scenarios. The installation of modern VSDs can by up to 50% in some applications, making them a crucial component in optimizing fan performance.

- Sound Insulation: Installing sound-absorbing materials around fan systems effectively dampens noise. Additionally, using ducting that reduces sharp bends and transitions can mitigate increased sound generation. Recent advancements in sound shield technology, which effectively blocks sound while allowing air to pass through, can be applied in various settings, including automotive and aerospace applications.

- Regular Maintenance: Keeping fans clean and free from debris is essential, as accumulated dirt can significantly increase noise and decrease efficiency. Routine checks for loose parts that may vibrate and create undesirable sounds are also necessary. It is essential to note that efficiency gains from VSDs in constant torque applications are likely not to surpass 10%, which is a significant consideration for engineers when optimizing fan performance.

By utilizing these methods, engineers can achieve significant enhancements in both the efficiency and sound performance of their fan technologies, ultimately improving the overall functionality of the system. The innovative HVAC solutions implemented at St. Nessan’s School demonstrate how effective design and maintenance strategies can lead to optimal indoor air quality while minimizing energy consumption and noise levels. Furthermore, quotes from industry experts, such as those from Quantum Controls, emphasize the importance of a data-driven approach to energy savings through VSDs, reinforcing the value of tailored solutions in optimizing fan performance.

Conclusion

Fan technologies are crucial in the effective management of heat within electronic devices, ensuring optimal performance and longevity. For engineers, understanding the distinctions between axial and centrifugal fans is essential, as these devices cater to different applications and cooling requirements. The insights provided herein emphasize the importance of selecting the appropriate fan technology based on specific airflow needs and the operational context.

Key arguments explored include:

- The unique characteristics of axial and centrifugal fans

- Their respective advantages in various scenarios

- The significance of proper installation and maintenance practices

By adhering to best practices, engineers can significantly enhance the reliability and efficiency of their cooling systems. Furthermore, this discussion underscores the growing market for these technologies, particularly the increasing demand for energy-efficient solutions within the electronics sector.

Ultimately, mastering fan technologies is vital for electronics engineers seeking to optimize cooling systems. As the industry continues to evolve, staying informed about the latest trends and best practices will empower engineers to make informed decisions that enhance performance and reduce energy consumption. Embracing innovative solutions and techniques will be key to driving advancements in fan technologies, ensuring that electronic devices operate effectively in an increasingly demanding environment.

Frequently Asked Questions

What is the primary function of fan technologies in electronic devices?

Fan technologies are crucial for managing heat within electronic devices by generating airflow that facilitates the dissipation of heat produced by various components.

What are the two main types of fans used in electronics?

The two primary types of fans used in electronics are axial fans and centrifugal fans.

How do axial fans operate and what are their applications?

Axial fans move air parallel to the unit’s axis and are particularly suitable for applications that require high airflow at low pressure, such as in data centers and telecommunications equipment for optimal temperature maintenance.

What is the significance of energy-efficient cooling solutions in the fan technology market?

The growing demand for energy-efficient cooling solutions highlights the relevance of fan technologies, especially axial ventilation devices, in the contemporary market.

What are centrifugal fans and where are they commonly used?

Centrifugal fans draw air into their center and expel it at a right angle, generating higher pressure. They are commonly used in exhaust systems within dusty environments and HVAC systems that require air movement through complex ductwork.

What market trends are observed for fan technologies in the electronics cooling sector?

Axial blowers dominate the electronics cooling sector, with a market value of approximately USD 1.2 billion in 2023, projected to grow to USD 2.5 billion by 2033, reflecting a compound annual growth rate (CAGR) of 9.5% from 2026 to 2033.

How can understanding fan technologies benefit engineers?

A thorough understanding of fan technologies enables engineers to make informed decisions regarding fan selection based on specific cooling requirements, ensuring optimal performance and longevity of electronic devices.