Overview

PWM fans demonstrate superior efficiency compared to traditional DC fans, primarily due to their capability to dynamically adjust speed and significantly reduce energy consumption by up to 30%. This makes them particularly suitable for applications that demand precise temperature control and lower noise levels. The article substantiates this claim by illustrating that PWM fans not only enhance cooling performance but also extend the lifespan of components and lower operational costs. Consequently, this establishes their dominance in contemporary thermal management solutions.

Introduction

The debate between PWM and DC fans extends beyond mere technical specifications; it embodies a crucial decision regarding energy efficiency and operational effectiveness within contemporary cooling systems. As industries increasingly prioritize sustainability alongside performance, grasping the nuances of these fan technologies is essential. This article explores the intricacies of PWM and DC fans, illuminating their distinct advantages and applications. Which technology truly stands out in terms of efficiency, noise reduction, and adaptability to diverse engineering needs?

Define PWM and DC Fans: Core Concepts and Mechanisms

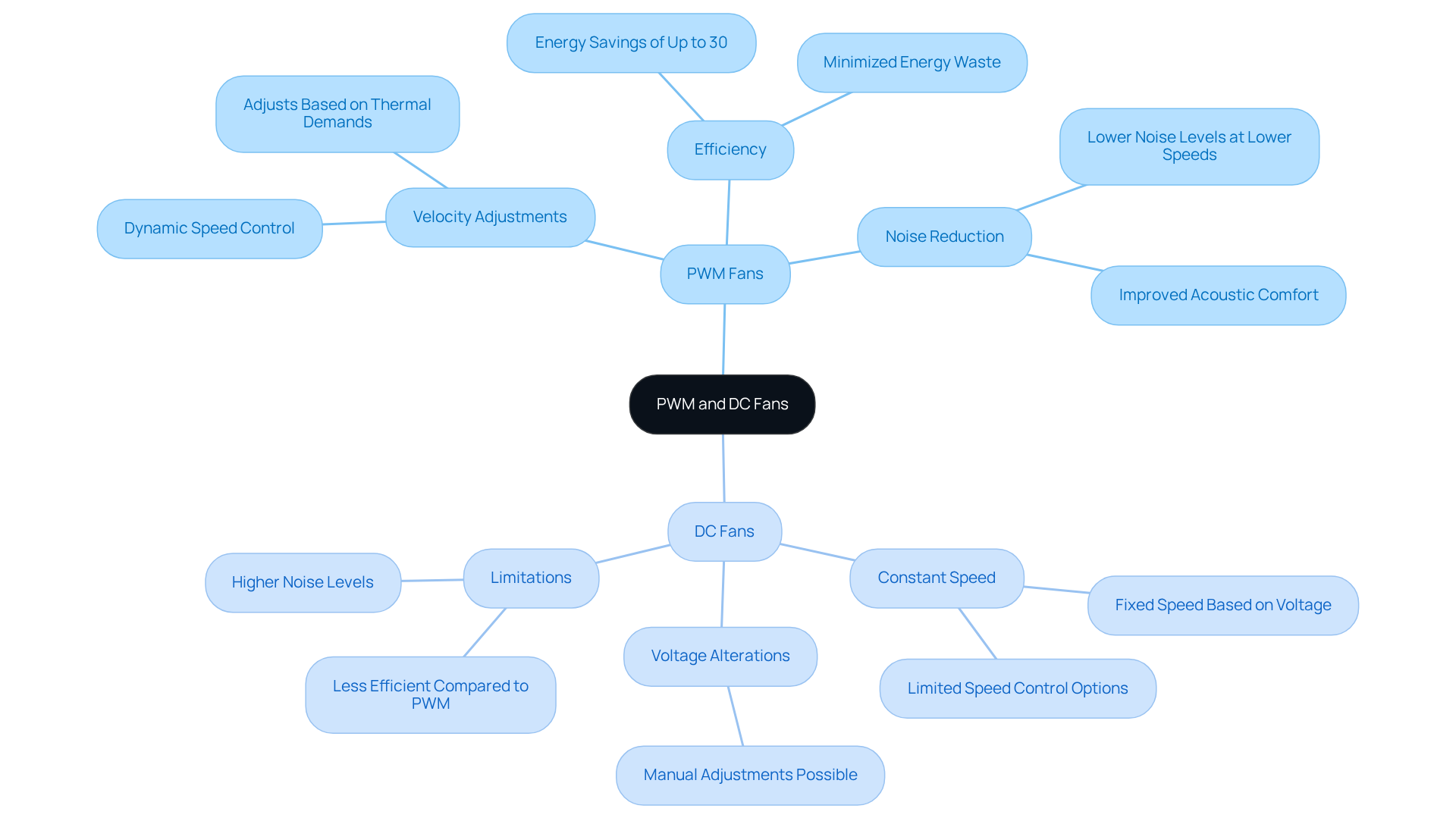

PWM or DC fan motors operate by adjusting the width of electrical pulses directed to the motor, which facilitates precise velocity adjustments. This capability enables PWM devices to function efficiently at lower rates, significantly reducing both noise and energy consumption. In contrast, DC (Direct Current) devices typically maintain a constant speed dictated by the supplied voltage. Although some DC models can be modified through voltage alterations, they do not offer the dynamic control that PWM systems provide.

The primary distinction lies in PWM’s capacity to modulate power delivery, resulting in across diverse applications. Research indicates that using a PWM or DC fan can achieve energy savings of up to 30% compared to traditional DC models, making them a superior choice for modern temperature regulation solutions. Furthermore, case studies reveal that systems employing PWM technology can realize noise level reductions of up to 30%, thereby improving acoustic comfort in sensitive environments.

Gagner-Toomey Associates offers an extensive array of PWM or DC fan Tube Axial devices and Centrifugal Blowers, engineered for efficiency and minimal noise, with sizes ranging from 15 to 280mm and IP protection available upon request. This comprehensive portfolio also features innovative thermal management solutions, including extruded aluminum heatsinks and integrated systems, which complement their fan offerings and effectively address the intricate temperature regulation needs of electronics.

Compare Performance Efficiency: PWM vs. DC Fans in Cooling Applications

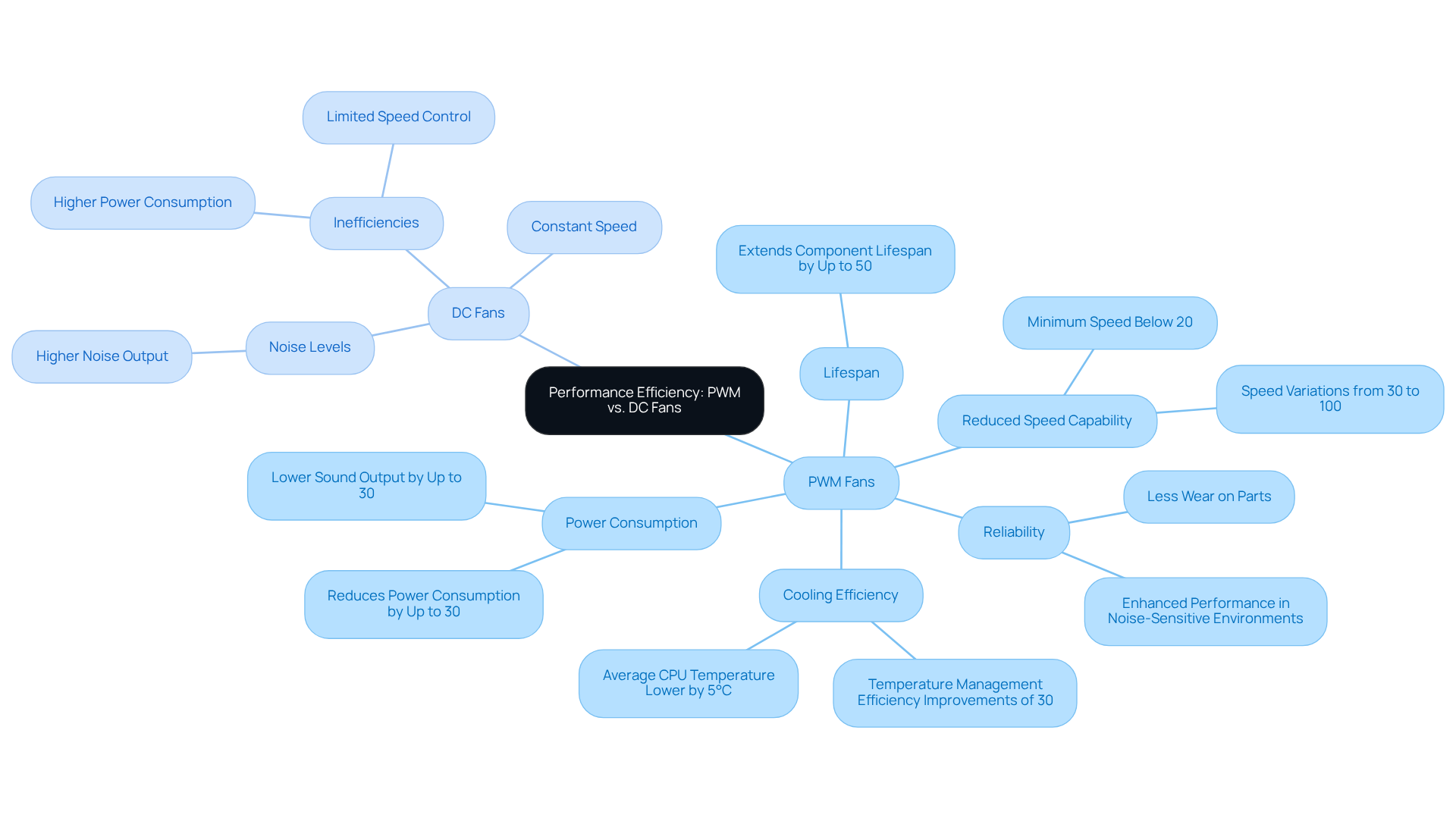

In temperature regulation applications, PWM or DC fan devices significantly outperform traditional DC units due to their ability to dynamically adjust rates according to thermal demands. Research indicates that a PWM or DC fan can maintain optimal cooling efficiency while operating at reduced rates, achieving a minimum speed below 20% of its specified velocity—a notable advantage over DC units.

For example, systems employing PWM or DC fan units have been shown to keep an average CPU temperature 5°C lower than those equipped only with DC fan units. Furthermore, PWM units can extend component lifespan by up to 50% and exhibit enhanced reliability, as they experience less wear on parts by operating at reduced rates when full power is unnecessary.

In contrast, PWM or DC fans typically run at a constant speed, which can lead to inefficiencies and increased noise levels under low-load conditions. This adaptability positions PWM devices as superior to traditional thermal management systems in both performance and efficiency, a sentiment echoed by who are increasingly integrating PWM thermal devices into their designs.

Additionally, PWM or DC fan units can reduce power consumption by as much as 30% compared to traditional DC models, further underscoring their energy efficiency. This adaptability reinforces the superiority of PWM devices over conventional cooling systems in terms of performance and efficiency.

Evaluate Energy Consumption: Efficiency and Cost Implications of PWM and DC Fans

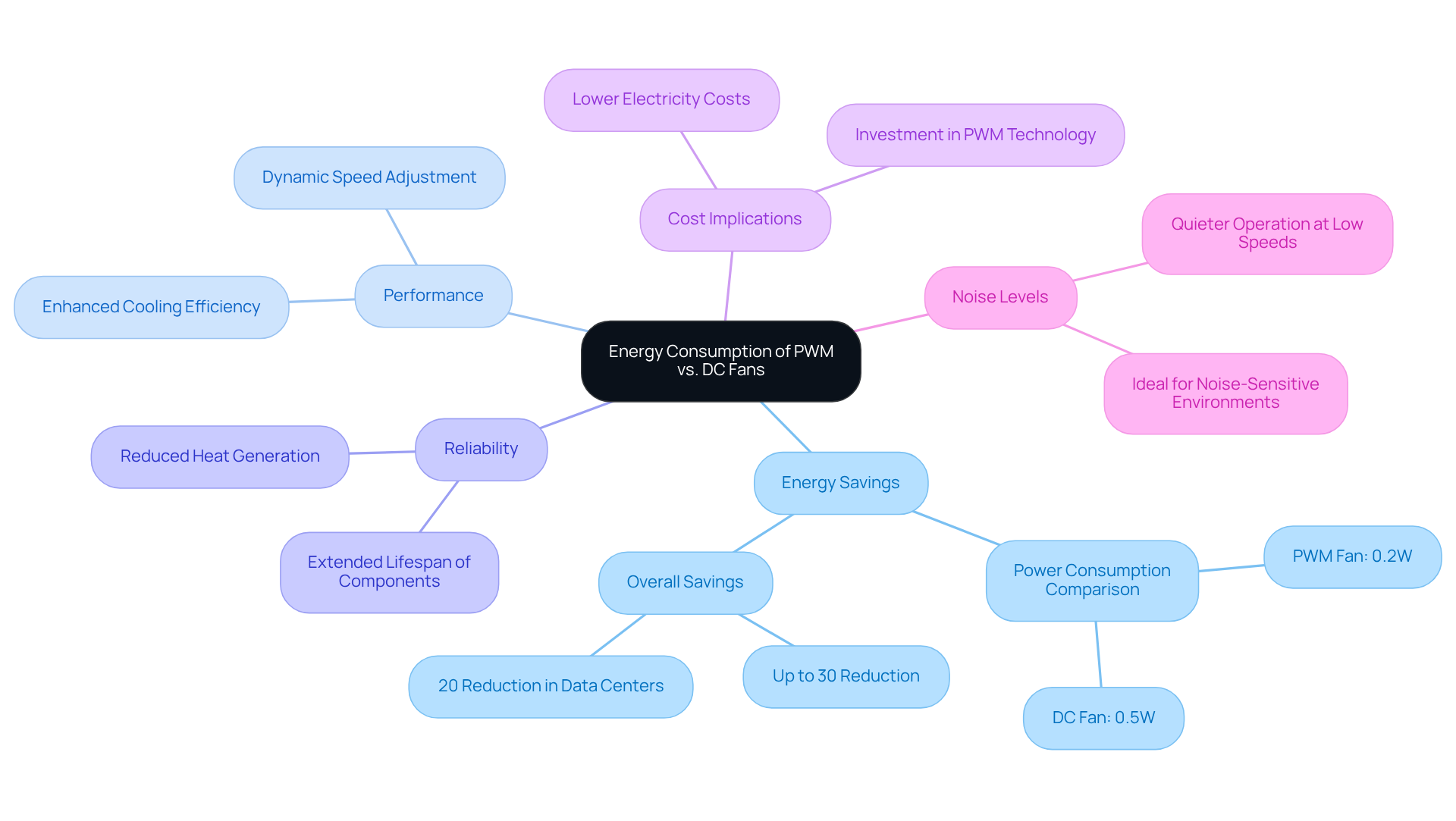

When considering energy consumption, PWM or DC fans offer substantial advantages over traditional DC counterparts. By enabling devices to operate at reduced rates without compromising performance, PWM or DC fan technology achieves energy savings of up to 30% compared to traditional units, as evidenced by a University of Toronto study.

For example, a PWM or DC fan can consume as little as 0.2W at lower speeds, while a standard PWM or DC fan may draw 0.5W or more, even when not fully utilized. These savings accumulate over time, leading to , particularly in applications requiring continuous operation.

Moreover, the lower energy consumption of PWM devices results in decreased heat generation, enhancing overall system reliability and extending the lifespan of electronic components. Experts assert that ‘this adaptability makes PWM devices superior to conventional temperature regulation systems in terms of both performance and efficiency.’

Additionally, PWM or DC fans excel in noise-sensitive environments, operating quietly at reduced speeds. However, for budget-conscious builds or moderate cooling needs, transitioning to PWM may not be essential.

Case studies indicate that implementing PWM technology not only optimizes energy usage but also contributes to cost savings in large systems, reinforcing its importance in contemporary thermal management strategies.

Assess Application Suitability: Choosing Between PWM and DC Fans for Engineering Needs

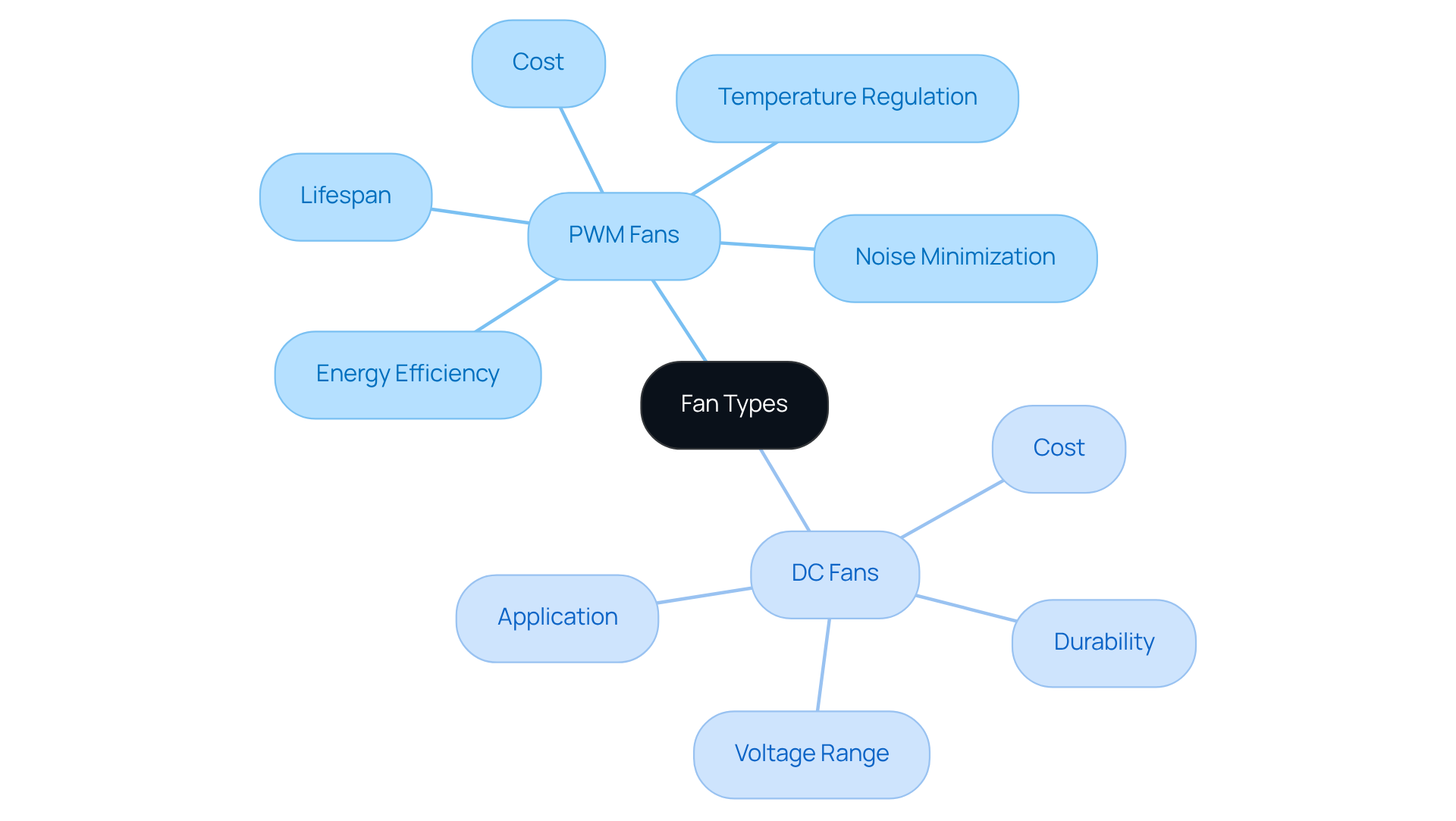

Choosing between a PWM or DC fan hinges on the specific requirements of the application. PWM or DC fan units excel in environments that demand precise temperature regulation and noise minimization, making them ideal for high-performance computing, medical devices, and sensitive electronic equipment. Their ability to dynamically adjust speeds in response to varying thermal loads significantly enhances operational efficiency. For instance, data centers employing PWM technology have reported a notable decrease in Power Usage Effectiveness (PUE) from 1.55 to 1.42, illustrating the effectiveness of PWM devices in optimizing energy consumption. Additionally, a PWM or DC fan necessitates four pins for connection and typically operates at a constant voltage of 12 volts, which is crucial for understanding its operational requirements compared to other DC devices. Furthermore, PWM units generally have a longer lifespan than DC models, making them a vital consideration for engineers focused on durability in their designs.

In contrast, PWM or DC fan devices are often more suitable for simpler applications where cost is a primary factor. They are frequently utilized in basic ventilation systems or less demanding cooling tasks, providing reliable performance without the sophisticated control features found in a PWM or DC fan. With typical operating voltages ranging from 5 to 48 volts, DC motors present a , particularly in budget-sensitive projects. It is noteworthy that while PWM or DC fans are generally less expensive, the price gap is narrowing as PWM technology becomes increasingly prevalent. For example, a three-pack of PWM cooling devices can be found for under $12, indicating a trend towards cost-effectiveness in advanced cooling options. However, PWM or DC fan devices remain generally less expensive than their alternatives, which is an essential aspect to consider.

When evaluating the cost comparison, it is also crucial to recognize that DC units are durable and less prone to breakages due to their simpler design, offering a balanced perspective on their advantages. Ultimately, the decision should encompass performance requirements, budget constraints, and the operational environment. Engineers should consider scenarios where a PWM or DC fan is preferable, such as in high-demand applications that benefit from enhanced thermal management and quieter operation, while acknowledging that DC alternatives remain a viable option for straightforward cooling needs. Moreover, it is essential to note that a PWM or DC fan can reduce power consumption by up to 30% compared to standard DC fans, as highlighted by the University of Toronto, further substantiating their energy efficiency claims.

Conclusion

The comparison between PWM and DC fans reveals significant differences in efficiency, energy consumption, and application suitability. PWM fans stand out due to their ability to dynamically adjust speeds, offering enhanced performance and energy savings, making them a compelling choice for modern thermal management needs. In contrast, while DC fans provide reliable performance, they lack the sophisticated control mechanisms that PWM technology offers, which can lead to inefficiencies in varying load conditions.

Throughout the article, key insights highlight that PWM fans can reduce energy consumption by up to 30% compared to traditional DC models, while also minimizing noise levels and extending the lifespan of electronic components. This adaptability not only improves cooling efficiency but also results in substantial cost savings over time, particularly in applications requiring continuous operation. Furthermore, the choice between PWM and DC fans ultimately depends on the specific requirements of the application, with PWM fans being ideal for high-performance environments and DC fans serving as a cost-effective solution for simpler tasks.

In summary, the advantages of PWM fans in terms of efficiency, energy use, and application versatility underscore their growing importance in engineering design. As the demand for effective cooling solutions continues to rise, considering the specific needs of each project will be crucial in making informed decisions. Embracing PWM technology can lead to enhanced performance and sustainability, encouraging engineers and designers to prioritize these advanced solutions in their future projects.

Frequently Asked Questions

What is PWM in the context of fan motors?

PWM, or Pulse Width Modulation, is a technique used in fan motors to adjust the width of electrical pulses directed to the motor, allowing for precise velocity adjustments and efficient operation at lower rates.

How do PWM fans differ from DC fans?

PWM fans can modulate power delivery for dynamic control of speed, while DC fans generally maintain a constant speed based on the supplied voltage, with limited ability to adjust speed through voltage changes.

What are the energy savings associated with PWM or DC fans?

Research indicates that PWM or DC fans can achieve energy savings of up to 30% compared to traditional DC models.

How do PWM fans contribute to noise reduction?

Systems using PWM technology can realize noise level reductions of up to 30%, improving acoustic comfort in sensitive environments.

What products does Gagner-Toomey Associates offer related to PWM or DC fans?

Gagner-Toomey Associates offers a wide range of PWM or DC fan Tube Axial devices and Centrifugal Blowers, designed for efficiency and minimal noise, with sizes ranging from 15 to 280mm and optional IP protection.

What additional solutions does Gagner-Toomey Associates provide for thermal management?

They provide innovative thermal management solutions, including extruded aluminum heatsinks and integrated systems, to complement their fan offerings and address temperature regulation needs in electronics.