Overview

This article delves into the intricacies of backward curved centrifugal fans, emphasizing their distinctive design features and diverse applications across industries such as HVAC. These fans are engineered to optimize airflow and static pressure, rendering them exceptionally effective for energy-efficient air circulation. This is particularly crucial in environments that demand high static pressure. Moreover, the article underscores the increasing importance of these fans in a multitude of industrial settings, highlighting their role in enhancing operational efficiency and sustainability.

Introduction

Backward curved centrifugal fans exemplify a remarkable fusion of design and functionality, serving a pivotal role in various industrial applications, particularly within HVAC systems.

With their unique blade architecture, these fans not only optimize airflow but also achieve impressive static performance levels, rendering them indispensable for environments that require consistent air pressure.

As industries increasingly prioritize energy efficiency and sustainability, it is essential to evaluate how these fans compare to their counterparts and to identify the challenges they face in maintaining performance.

Define Backward Curved Centrifugal Fan

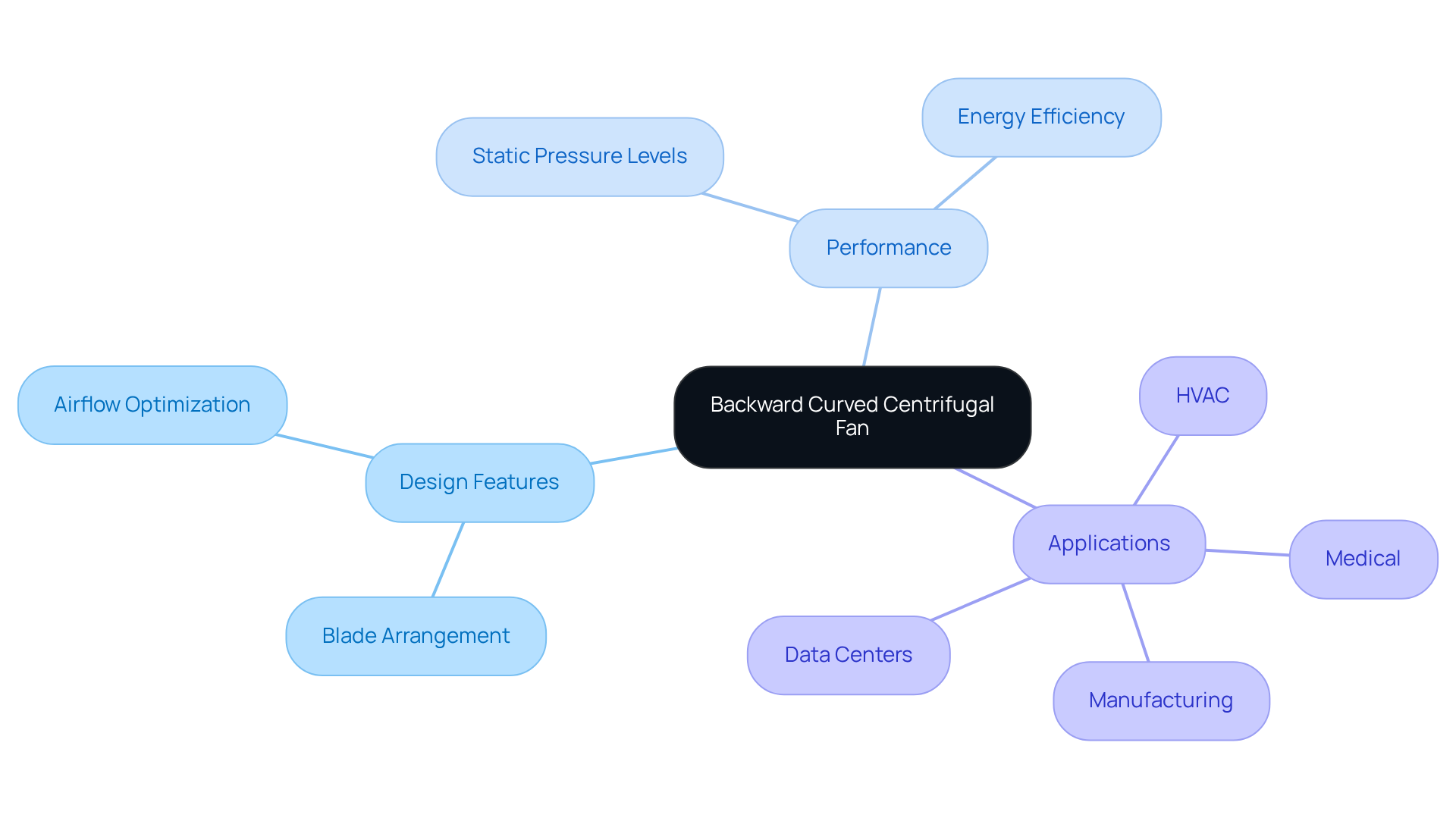

A backward bending centrifugal fan features blades that arch away from the direction of rotation, optimizing airflow through centrifugal force. This innovative design effectively draws air into the fan’s center and expels it outward, facilitating the generation of high static pressure. Backward curved centrifugal fans excel in various industrial applications, especially within heating, ventilation, and air conditioning (HVAC) systems. Their distinctive blade arrangement significantly minimizes turbulence, resulting in smoother airflow and enhanced energy performance. With static performance levels reaching up to 85%, the backward curved centrifugal fan is ideal for environments requiring , establishing it as a preferred choice in industries such as HVAC, medical, manufacturing, and data centers.

Gagner-Toomey Associates offers a comprehensive range of DC input centrifugal blowers, which includes backward curved centrifugal fans optimized for performance and efficiency, available in sizes ranging from 15 to 225mm. Recent technological advancements have further improved their performance, ensuring they meet the growing demands for energy conservation and sustainability in industrial applications.

Examine Design Characteristics and Mechanisms

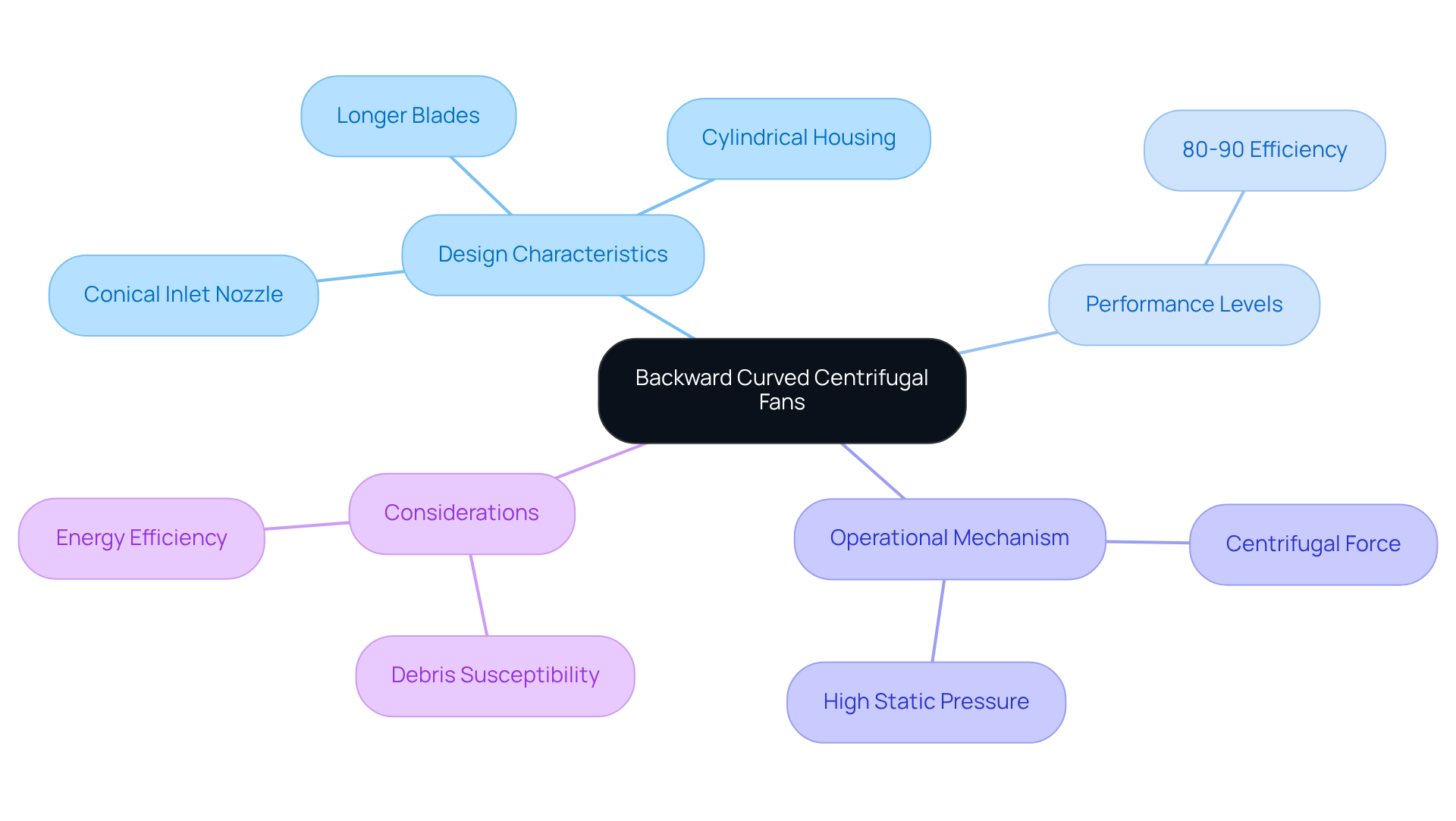

Backward curved centrifugal fans exemplify advanced design features that significantly enhance performance. These backward curved centrifugal fans, with longer blades and a more pronounced curvature than their forward curved counterparts, excel in airflow control. Typically achieving , backward curved centrifugal fans are exceptionally effective across a range of applications.

The design of the backward curved centrifugal fan with a cylindrical housing reduces airflow resistance, promoting a smoother operation. Furthermore, the backward curved centrifugal fan features a conical inlet nozzle that efficiently draws air into the fan, improving intake performance. Often equipped with high-performance motors, backward curved centrifugal fans minimize energy consumption, thereby boosting overall energy efficiency.

Their operational mechanism relies on the impeller’s rotation, which generates centrifugal force to propel air outward, creating high pressure. This configuration of the backward curved centrifugal fan is particularly advantageous in situations that demand high static pressure and exceptional airflow efficiency, making these blowers suitable for diverse industrial applications.

However, it is crucial to recognize that backward inclined ventilators may be susceptible to debris in the airstream, a consideration that should be addressed in industrial environments.

Explore Applications in Industry and HVAC Systems

Backward curved centrifugal fans are indispensable in a wide range of industrial applications, particularly in HVAC systems. Their innovative design facilitates , dust collection, and fume extraction in settings such as manufacturing plants, laboratories, and commercial buildings. Notably, the backward curved centrifugal fan is adept at managing high static pressures, making it ideal for air handling units, clean rooms, and exhaust systems.

In HVAC applications, bent impellers proficiently transport substantial volumes of air while ensuring quiet operation, a crucial factor for both residential and commercial environments. Moreover, backward curved centrifugal fans are employed in processes requiring precise airflow control, such as printing presses and laser cutting machines.

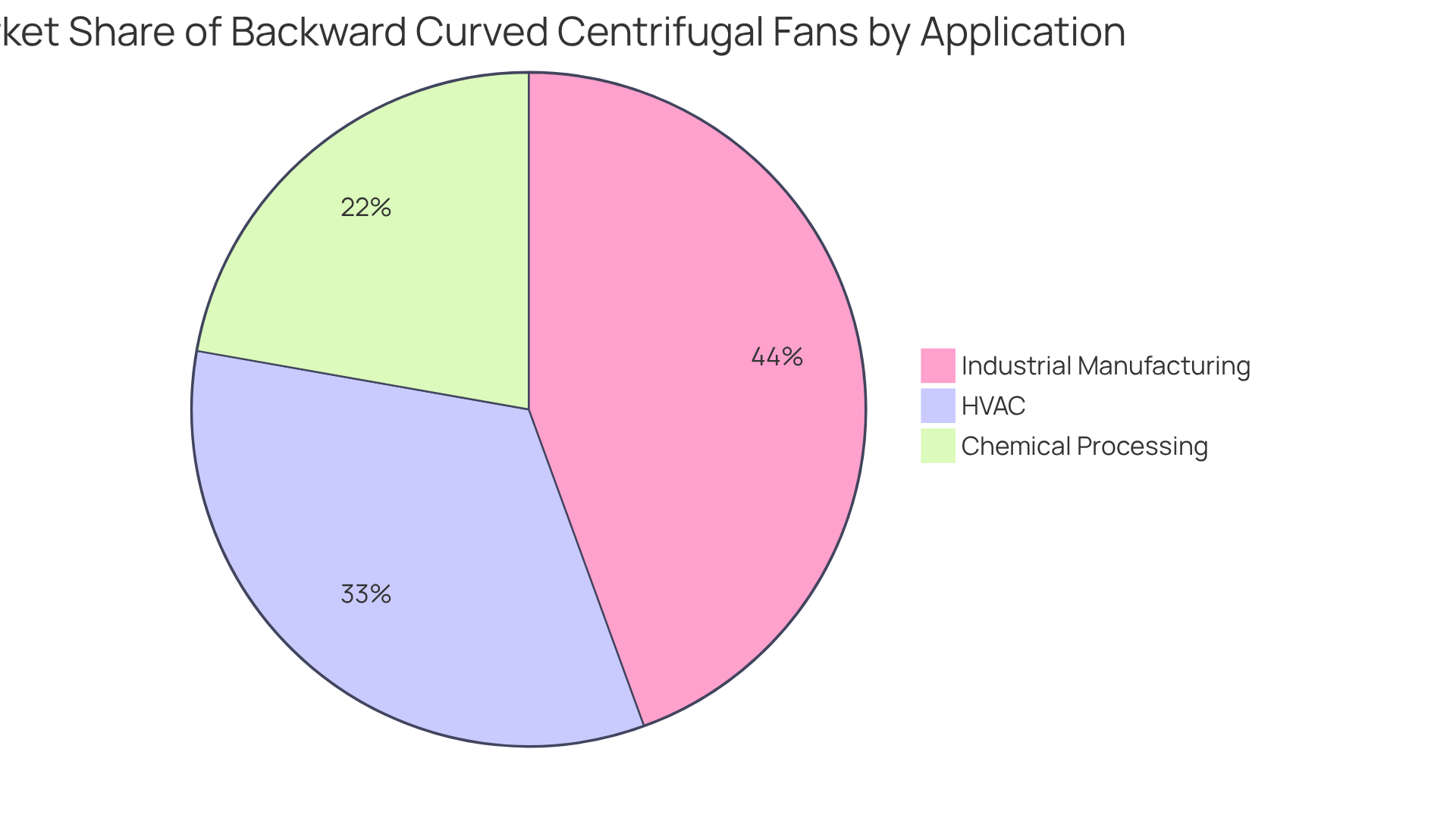

According to a 2022 assessment, the global market for reverse centrifugal blowers is projected to reach USD 4,454.3 million by 2033, underscoring their growing importance in energy-efficient systems. Additionally, the significant market utilization of backward curved centrifugal fans in HVAC systems is reinforced, with:

- Industrial manufacturing representing 40%

- HVAC accounting for 30%

- Chemical processing comprising 20%

This distribution emphasizes the critical role of backward curved centrifugal fans in enhancing operational efficiency and sustainability across various sectors. Furthermore, backward bent blades are recognized for their superior performance compared to forward bent blades due to reduced air resistance. Their application is also expanding in medical settings, where they help maintain sterile airflows in operating rooms. The integration of IoT technology for intelligent management and predictive maintenance is an emerging trend that further optimizes the performance of these devices.

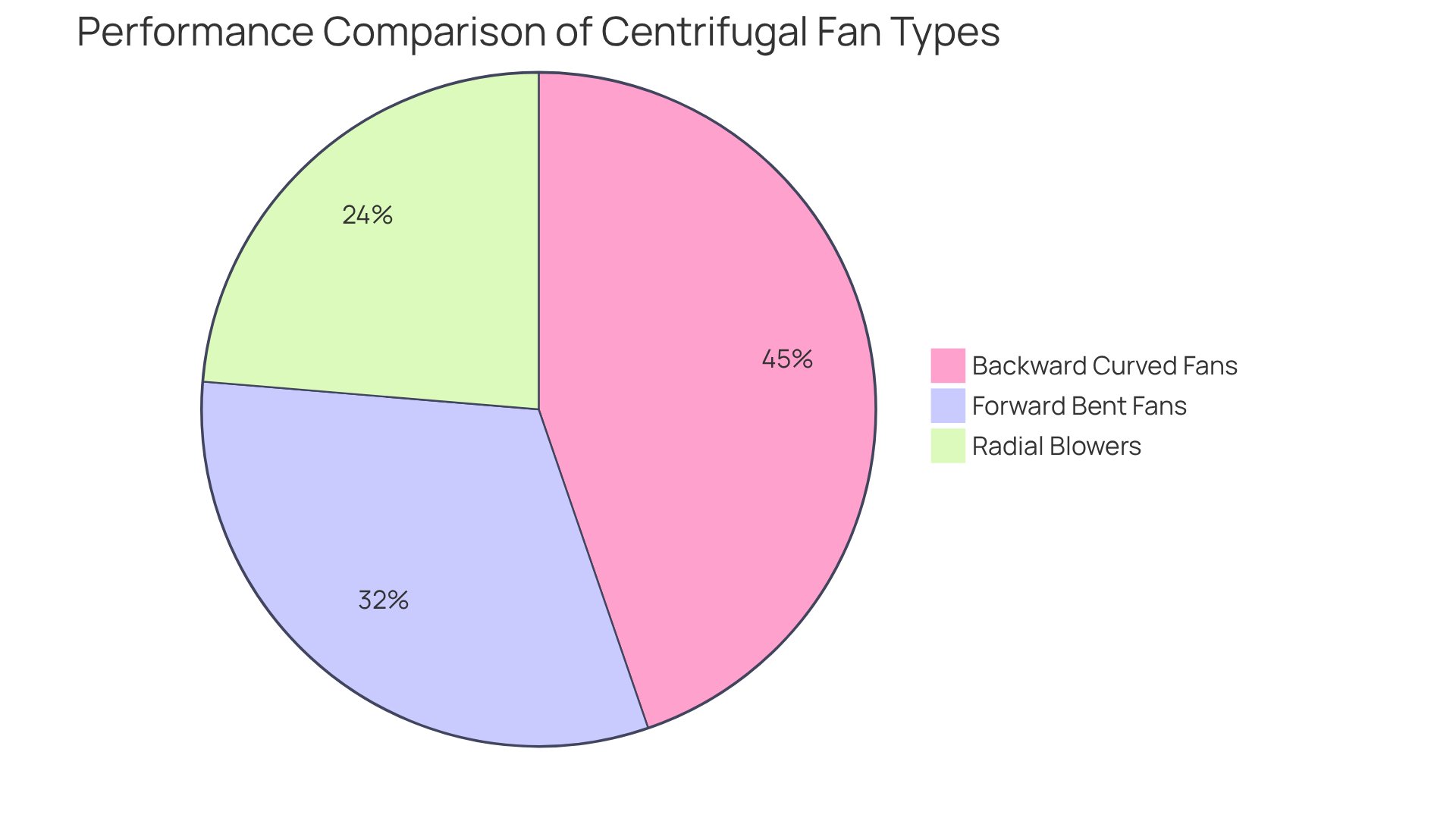

Compare with Other Centrifugal Fan Types

Backward curved centrifugal fans are noted for their superior effectiveness and performance in high-pressure scenarios, particularly when compared to other centrifugal types. They can achieve up to 85% static performance, which is significantly higher than forward bent blowers, typically yielding performances between 55% and 65%.

While forward bending blowers are optimized for high airflow at low pressures, reverse bending blowers excel in environments that demand . Their design minimizes turbulence, resulting in quieter operation, a crucial advantage in noise-sensitive settings.

According to the U.S. Department of Energy, enhanced performance can lead to substantial savings on electricity costs for businesses and contribute to reducing their carbon footprint. In contrast, radial blowers are generally suited for applications with lower pressure requirements and do not meet the performance standards of backward-angled blowers.

Common applications for the backward curved centrifugal fan include:

- HVAC systems

- Cleanrooms

- Data centers

where its ability to manage airflow efficiently is vital. Overall, backward curved centrifugal fans with a reverse design offer an optimal blend of high efficiency, low noise, and effective airflow management, making them a preferred choice across various industrial applications.

However, it is essential to acknowledge that reverse-bent blowers may generate higher noise levels compared to their forward-bent counterparts, which could be a consideration in noise-sensitive environments.

The global backward curved industrial fans market was valued at USD 2,557.4 million in 2024 and is projected to grow at a CAGR of 4.3% from 2024 to 2030, underscoring their increasing significance in the industry.

Conclusion

Backward curved centrifugal fans emerge as a critical component in various industrial applications, primarily due to their distinctive design that optimizes airflow and boosts energy efficiency. With blades that curve away from the direction of rotation, these fans excel at generating high static pressure while minimizing turbulence, establishing them as the preferred choice for HVAC systems and numerous other sectors.

This article explores the design characteristics and operational mechanisms of backward curved centrifugal fans, underscoring their superior performance compared to forward curved and radial fans. Notable insights include their capability to handle high static pressure, energy-efficient operation, and suitability for applications that demand precise airflow control, such as cleanrooms and medical environments. Additionally, the increasing market demand highlights their significance in energy-efficient systems, with projections indicating a substantial rise in utilization across diverse industries.

In conclusion, comprehending the advantages and applications of backward curved centrifugal fans is vital for industries striving to enhance operational efficiency and sustainability. As technology progresses and the necessity for energy conservation intensifies, investing in these innovative fans can yield significant operational improvements and cost savings. Embracing this technology not only optimizes performance but also contributes to a greener future in industrial and commercial environments.

Frequently Asked Questions

What is a backward curved centrifugal fan?

A backward curved centrifugal fan features blades that arch away from the direction of rotation, optimizing airflow through centrifugal force. This design effectively draws air into the fan’s center and expels it outward, generating high static pressure.

What are the advantages of backward curved centrifugal fans?

These fans excel in minimizing turbulence, resulting in smoother airflow and enhanced energy performance. They have static performance levels reaching up to 85%, making them ideal for environments requiring consistent airflow and pressure.

In what applications are backward curved centrifugal fans commonly used?

Backward curved centrifugal fans are commonly used in various industrial applications, particularly within heating, ventilation, and air conditioning (HVAC) systems, as well as in medical, manufacturing, and data center environments.

What range of sizes is available for backward curved centrifugal fans from Gagner-Toomey Associates?

Gagner-Toomey Associates offers backward curved centrifugal fans optimized for performance and efficiency in sizes ranging from 15 to 225mm.

How have recent technological advancements impacted backward curved centrifugal fans?

Recent technological advancements have improved the performance of backward curved centrifugal fans, ensuring they meet the growing demands for energy conservation and sustainability in industrial applications.