Overview

This article examines the essential differences and applications of various fan bearing types, including sleeve bearings, ball bearings, fluid dynamic supports, and rifle supports.

- Sleeve bearings are noted for their cost-effectiveness and quieter operation; however, they tend to have a shorter lifespan.

- In contrast, ball bearings provide superior durability and performance in high-speed environments.

This analysis serves as a guide for engineers, aiding them in selecting the most appropriate bearing type tailored to specific cooling needs and operational requirements.

Introduction

Understanding the intricacies of fan bearings is essential for optimizing cooling system performance across diverse applications. With a range of options available—from sleeve bearings that emphasize quiet operation to ball bearings engineered for high-speed efficiency—engineers encounter the challenge of selecting the appropriate type for their specific requirements.

Key factors must be considered when navigating these choices to ensure the optimal balance between cost, lifespan, and noise levels. This article explores the critical differences, advantages, and applications of various fan bearing types, offering insights that empower informed decision-making in the field of cooling technology.

Define Fan Bearings: Types and Functions

Fan parts are essential components in cooling systems, facilitating the efficient rotation of fan blades and significantly impacting overall performance. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of both standard and custom air-movers, provides an extensive array of advanced cooling solutions. This includes fans and blowers meticulously optimized for superior performance, efficiency, and minimal noise.

The primary types of fan bearings include:

- Sleeve Bearings: These consist of a cylindrical sleeve that supports the shaft, offering a [quieter and more cost-effective solution](https://arrow.com/en/research-and-events/articles/the-pros-and-cons-of-fan-bearing-types). However, they typically exhibit a shorter lifespan compared to ball components, making them particularly suitable for applications where noise reduction is prioritized over durability.

- Ball Bearings: The use of ball components in fan bearings helps maintain separation between the inner and outer races, minimizing friction and extending lifespan. They excel in , rendering them ideal for environments that demand both efficiency and durability. Ball roller fans provide enhanced value over time due to reduced maintenance costs, despite higher initial expenses.

- Fluid Dynamic Supports: Among the fan bearings types, fluid dynamic supports utilize a thin film of fluid to sustain the shaft, offering superior performance and longevity. They are commonly found in high-end applications where efficiency and reliability are paramount.

- Rifle Supports: A specialized variant of sleeve supports, which are one of the fan bearings types, are designed for applications requiring low noise and minimal vibration, thereby improving user experience in sensitive environments.

Each type of support is vital to the efficiency and effectiveness of cooling systems in electronic devices. Industry experts emphasize that selecting the appropriate fan is critical for achieving thermal objectives. Recent innovations, such as the omniCOOL system from Gagner-Toomey Associates, which boasts extended fan life and improved performance, exemplify the continuous advancements in fan technology. This system effectively combines the benefits of both ball and sleeve designs to enhance operational longevity and efficiency. Additionally, design engineers must consider factors such as service life, mounting orientation, acoustic noise requirements, and cost when selecting support types, as highlighted in the guide on speed tolerance in cooling devices.

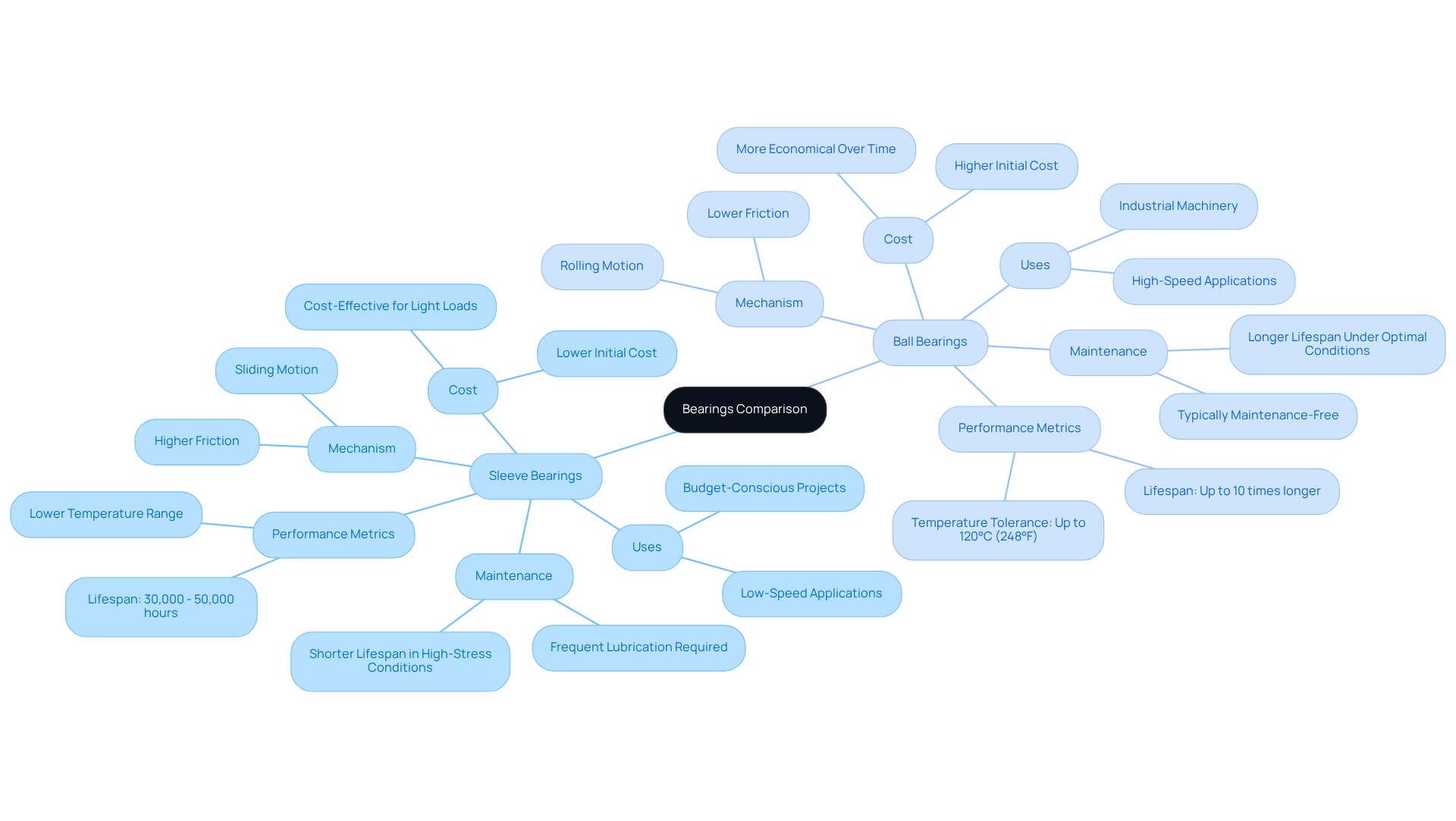

Examine Sleeve Bearings vs. Ball Bearings: Mechanisms and Applications

When comparing sleeve bearings and ball bearings, several critical factors emerge that warrant careful consideration:

- Mechanism: Sleeve bearings operate on a sliding motion, which can lead to increased friction. In contrast, ball bearings employ a rolling motion that significantly reduces friction, thereby enhancing efficiency.

- Uses: Sleeve supports are frequently utilized in low-speed, budget-conscious applications, such as computer case fans, blowers, and electric motors, where reducing noise is crucial. Conversely, ball components excel in high-speed environments, such as server cooling systems, due to their superior durability and efficiency.

- Performance Metrics: Ball components are specifically designed to handle higher speeds and loads, making them ideal for demanding applications in automotive and industrial machinery. They can function at temperatures reaching 120°C (248°F) and can endure up to ten times longer than sleeve components under optimal conditions, which typically last between 30,000 to 50,000 hours.

- Maintenance: Sleeve supports often require more frequent lubrication to maintain functionality, and adequate lubrication is essential for prolonging their lifespan. In contrast, ball components are typically maintenance-free, enhancing their appeal in high-performance environments.

- Cost: While sleeve supports are generally less costly initially, making them suitable for budget-conscious projects, ball supports may prove to be more economical in the long run within high-efficiency contexts due to their improved functionality, durability, and reduced upkeep and replacement costs.

Understanding these distinctions is vital for selecting the appropriate fan bearings types to meet specific cooling needs, thereby ensuring optimal performance and reliability across diverse applications.

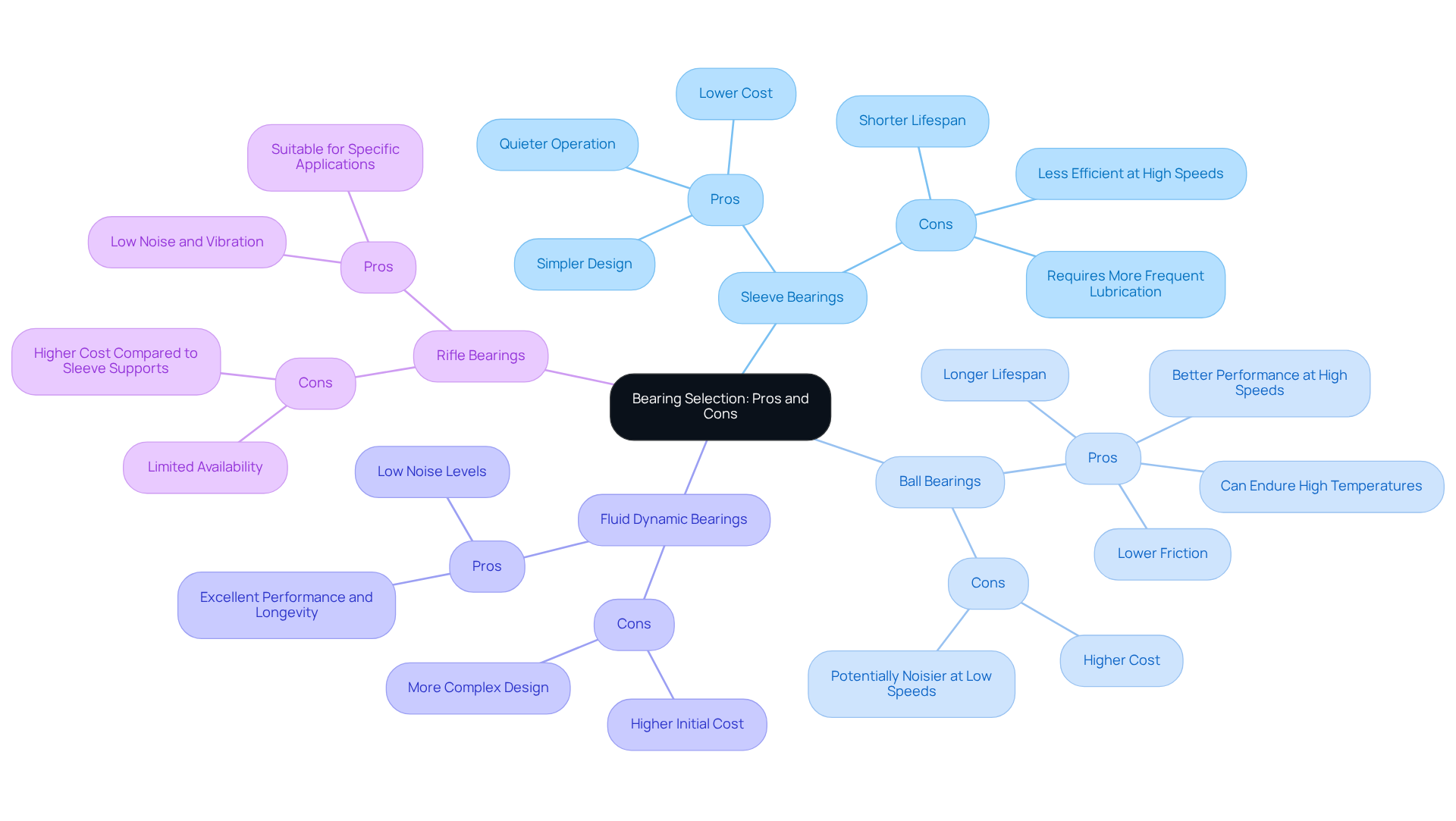

Evaluate Pros and Cons: Selecting the Right Bearing for Your Application

When selecting the right bearing for your application, it is essential to consider the following advantages and disadvantages:

-

- Pros: Quieter operation, lower cost, simpler design. Sleeve fan assemblies typically generate less noise during operation, making them ideal for tranquil environments such as offices.

- Cons: Shorter lifespan, less efficient at high speeds, and require more frequent lubrication due to their design.

-

- Pros: Longer lifespan, better performance at high speeds, and lower friction. Ball components can endure temperatures up to 120 °C (248 °F), making them suitable for high-temperature applications.

- Cons: Higher cost and potentially noisier than sleeve bearings, especially at lower speeds; however, the noise difference diminishes at higher speeds.

-

- Pros: Excellent performance and longevity, with low noise levels.

- Cons: Higher initial cost and more complex design.

-

Rifle Bearings:

- Pros: Low noise and vibration, suitable for specific applications.

- Cons: Limited availability and higher cost compared to sleeve supports.

By thoughtfully assessing these elements, engineers can select the most appropriate type of support for their specific cooling requirements.

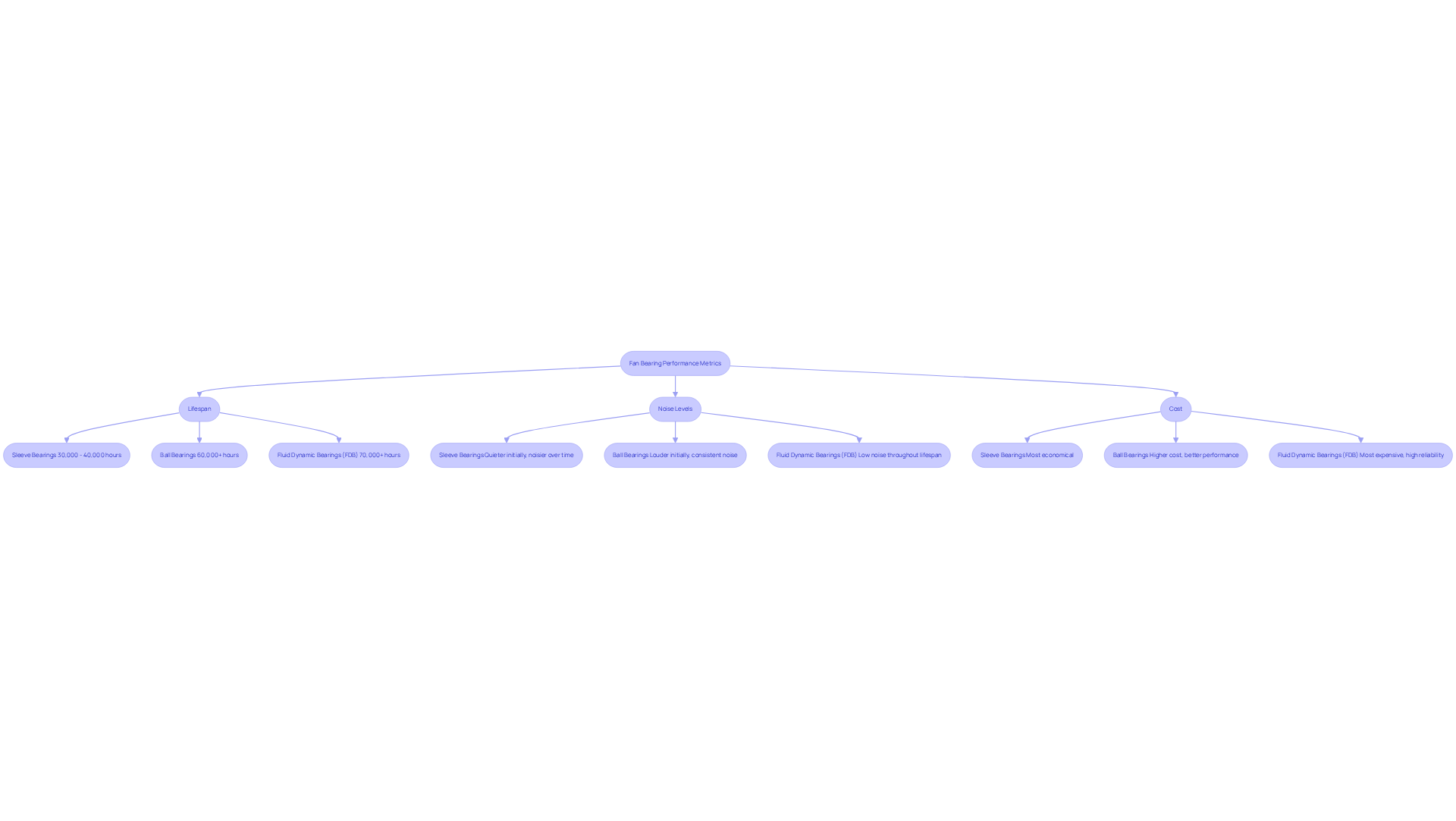

Analyze Performance Metrics: Lifespan, Noise, and Cost Considerations

Performance metrics are essential for evaluating different fan bearings types, particularly in terms of cooling system efficiency. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, offers a comprehensive array of cooling solutions that are optimized for performance, efficiency, and low noise, with options featuring IP protection available upon request. Key considerations include:

- Lifespan: Sleeve bearings typically last between 30,000 to 40,000 hours, whereas ball bearings can exceed 60,000 hours, particularly in configurations that combine one ball and one sleeve. Fluid dynamic supports (FDs), which are one of the fan bearings types, often surpass 70,000 hours, making them ideal for high-performance applications where durability is paramount. Gagner-Toomey’s extensive portfolio features fan bearings types like DC input Tube Axial fans and Centrifugal Blowers, ensuring a variety of options that cater to diverse lifespan requirements.

- Noise Levels: Sleeve supports are generally quieter in their initial phase but may become noisier as wear progresses, particularly after 2-3 years. Conversely, among the fan bearings types, ball elements might start off louder but maintain consistent functionality over time, making them suitable for applications where noise levels are a critical factor. FDBs are one of the fan bearings types celebrated for their low noise levels throughout their operational lifespan, rendering them preferable for noise-sensitive environments. The fan bearings types used in Gagner-Toomey’s fans are engineered to , with specific models demonstrating this capability, thus ensuring optimal efficiency across various settings.

- Cost: Sleeve supports represent the most economical choice, making them ideal for budget-conscious projects. Although fan bearings types come at a higher price point, their cost is justified by enhanced functionality and durability, especially in demanding applications. FDBs, despite being the most expensive option, deliver exceptional effectiveness and reliability, making them worth consideration for essential systems where efficiency is critical. Gagner-Toomey’s diverse product range, showcasing different fan bearings types in standard and custom designs across multiple sizes, empowers engineers to select the best option tailored to their budget and project requirements.

By thoroughly analyzing these performance metrics, engineers can make informed decisions that align with their project specifications and budget limitations, ensuring optimal cooling system performance in 2025.

Conclusion

Understanding the various types of fan bearings is crucial for optimizing cooling system performance. Each bearing type—sleeve, ball, fluid dynamic, and rifle—offers unique advantages and challenges that can significantly impact efficiency, noise levels, and overall application suitability. Selecting the right bearing involves not only recognizing these differences but also considering the specific needs of the application, such as durability, cost, and noise tolerance.

The article delves into the mechanics and applications of sleeve and ball bearings, highlighting their respective performance metrics, maintenance requirements, and cost implications. Sleeve bearings are often favored for their quieter operation and lower initial costs, while ball bearings are recognized for their longevity and efficiency in high-speed environments. Fluid dynamic and rifle supports provide specialized solutions that cater to specific operational needs, further emphasizing the importance of informed selection based on application demands.

Ultimately, engineers and designers must carefully evaluate the performance metrics of each bearing type—spanning lifespan, noise, and cost—to ensure optimal functionality in their cooling systems. By making informed decisions grounded in the insights provided, stakeholders can enhance the reliability and efficiency of their projects, paving the way for superior thermal management solutions in the future.

Frequently Asked Questions

What are fan bearings and why are they important?

Fan bearings are essential components in cooling systems that facilitate the efficient rotation of fan blades, significantly impacting overall performance.

What are the primary types of fan bearings?

The primary types of fan bearings include sleeve bearings, ball bearings, fluid dynamic supports, and rifle supports.

What are sleeve bearings and their advantages?

Sleeve bearings consist of a cylindrical sleeve that supports the shaft, offering a quieter and more cost-effective solution. They are particularly suitable for applications where noise reduction is prioritized, although they typically have a shorter lifespan compared to ball bearings.

How do ball bearings differ from sleeve bearings?

Ball bearings maintain separation between the inner and outer races, minimizing friction and extending lifespan. They excel in high-speed applications and are ideal for environments that demand both efficiency and durability.

What are fluid dynamic supports and their benefits?

Fluid dynamic supports utilize a thin film of fluid to sustain the shaft, offering superior performance and longevity. They are commonly found in high-end applications where efficiency and reliability are paramount.

What are rifle supports and their specific use?

Rifle supports are a specialized variant of sleeve supports designed for applications requiring low noise and minimal vibration, thereby improving user experience in sensitive environments.

Why is it crucial to select the appropriate fan bearing type?

Selecting the appropriate fan bearing type is critical for achieving thermal objectives and ensuring the efficiency and effectiveness of cooling systems in electronic devices.

What recent innovations have been made in fan technology?

Recent innovations include the omniCOOL system from Gagner-Toomey Associates, which combines the benefits of both ball and sleeve designs to enhance operational longevity and efficiency.

What factors should design engineers consider when selecting fan bearings?

Design engineers should consider factors such as service life, mounting orientation, acoustic noise requirements, and cost when selecting fan bearing types.