Overview

Blower units serve as crucial mechanical devices engineered to transport air or gas by elevating their pressure and velocity. They play an indispensable role in cooling electronic components, effectively preventing overheating and ensuring optimal operational efficiency. This article underscores the significance of blower units by illustrating how proficient thermal management not only enhances the reliability of electronic systems but also extends their lifespan.

Furthermore, it delves into the historical evolution of these devices, detailing the key characteristics that influence their design and application. By understanding the intricate relationship between blower units and electronic thermal management, professionals can make informed decisions that drive performance and reliability in their systems.

Introduction

Blower units are pivotal in the electronics industry, acting as the unsung heroes that uphold optimal thermal conditions for devices. By efficiently transporting air and dissipating heat generated by components such as CPUs and GPUs, these mechanical systems not only enhance performance but also significantly extend the lifespan of electronic equipment.

As the demand for compact and efficient devices continues to grow, engineers face a pressing challenge: how can they ensure that their cooling solutions are both effective and reliable? A comprehensive understanding of the intricacies of blower units is essential for navigating this complex landscape of thermal management.

Define Blower Unit: Core Functionality and Purpose

A fan assembly serves as a mechanical apparatus specifically engineered to transport air or gas by increasing its pressure and speed. It operates by drawing air through an inlet and expelling it through an outlet, typically utilizing a rotating impeller or fan.

In the electronics sector, maintaining optimal thermal conditions is indispensable with blower units. They facilitate airflow and effectively disperse heat generated by electronic components, which is critical for ensuring devices operate efficiently and prolonging their lifespan. Statistics reveal that overheating can diminish the lifespan of electronic components by as much as 50%, highlighting the urgent need for effective cooling solutions.

Furthermore, fans generally have a lifespan of 15 to 20 years, underscoring the importance of employing reliable cooling methods to prevent overheating. As noted, ‘Understanding the distinctions between air movers and fans enables engineers to make informed decisions that enhance system efficiency and address specific cooling requirements.’ This highlights the in electronics cooling, where precise temperature control is vital.

Regular maintenance is essential for optimal fan performance, and comprehending airflow dynamics and fan types is crucial when selecting appropriate cooling solutions.

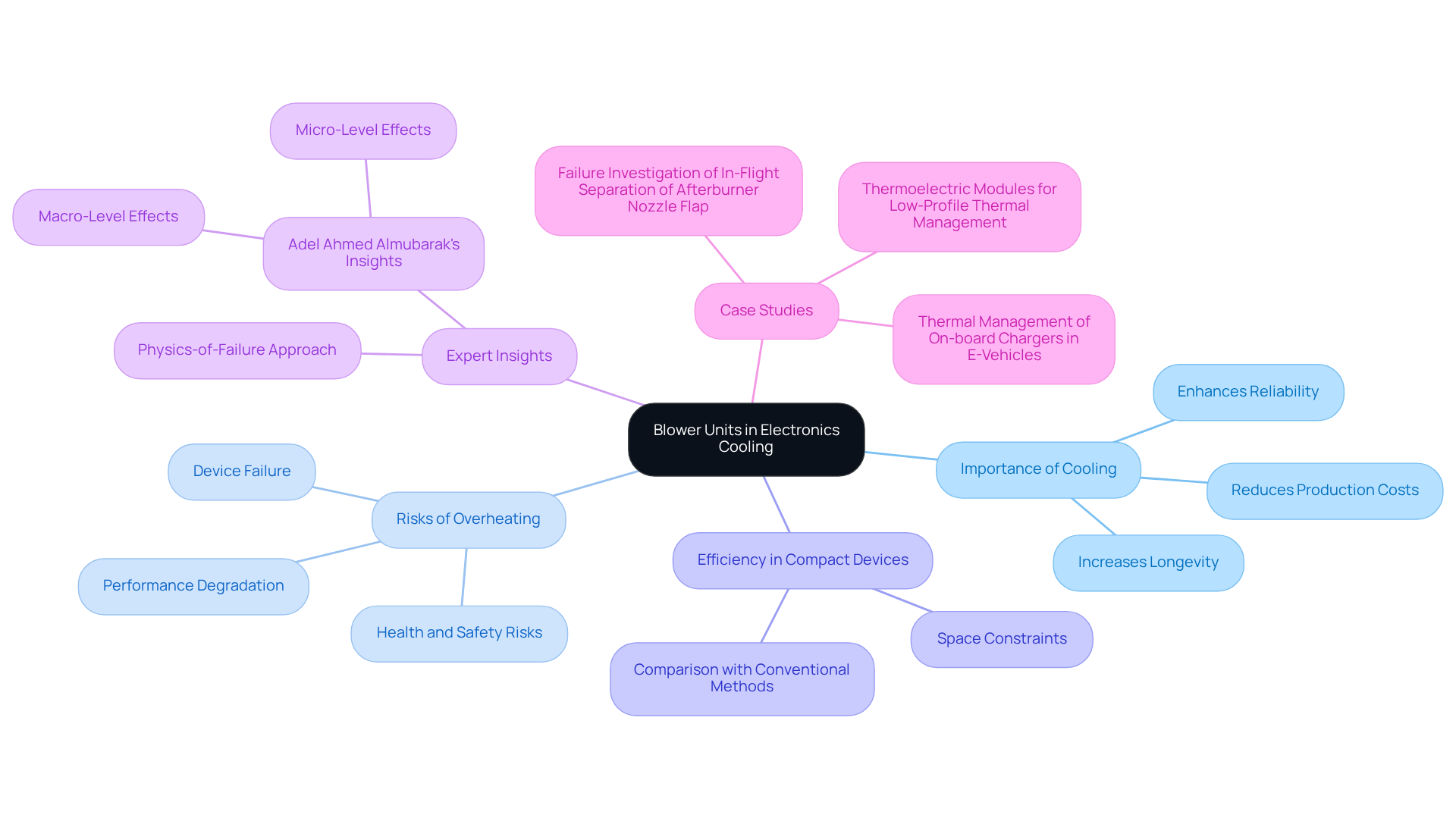

Contextualize Blower Units: Importance in Electronics Cooling

Blower units are integral to the cooling of electronics, ensuring the effective dissipation of heat generated by components such as CPUs, GPUs, and power supplies. Overheating poses significant risks, leading to performance degradation, reduced efficiency, and potential device failure. Statistics reveal that overheating is a predominant cause of electronic component failure; studies indicate that addressing thermal performance from the outset can result in lower production costs and expedited product development. By maintaining optimal temperatures, the blower unit significantly enhances the reliability and longevity of electronic systems.

In compact devices, where space constraints are prevalent, fans provide a more efficient cooling solution than conventional methods, establishing their necessity in modern electronics design. Expert insights, including those from Adel Ahmed Almubarak, highlight that both micro-level and macro-level consequences of overheating escalate health and safety risks for electronic assemblies. This underscores the importance of , which includes a blower unit and fan systems, to mitigate the risk of components reaching hazardous temperatures.

Case studies, such as those examining the effects of heat on electronic components, illustrate that effective thermal management through ventilation devices not only boosts performance but also contributes to the overall safety and reliability of electronic assemblies.

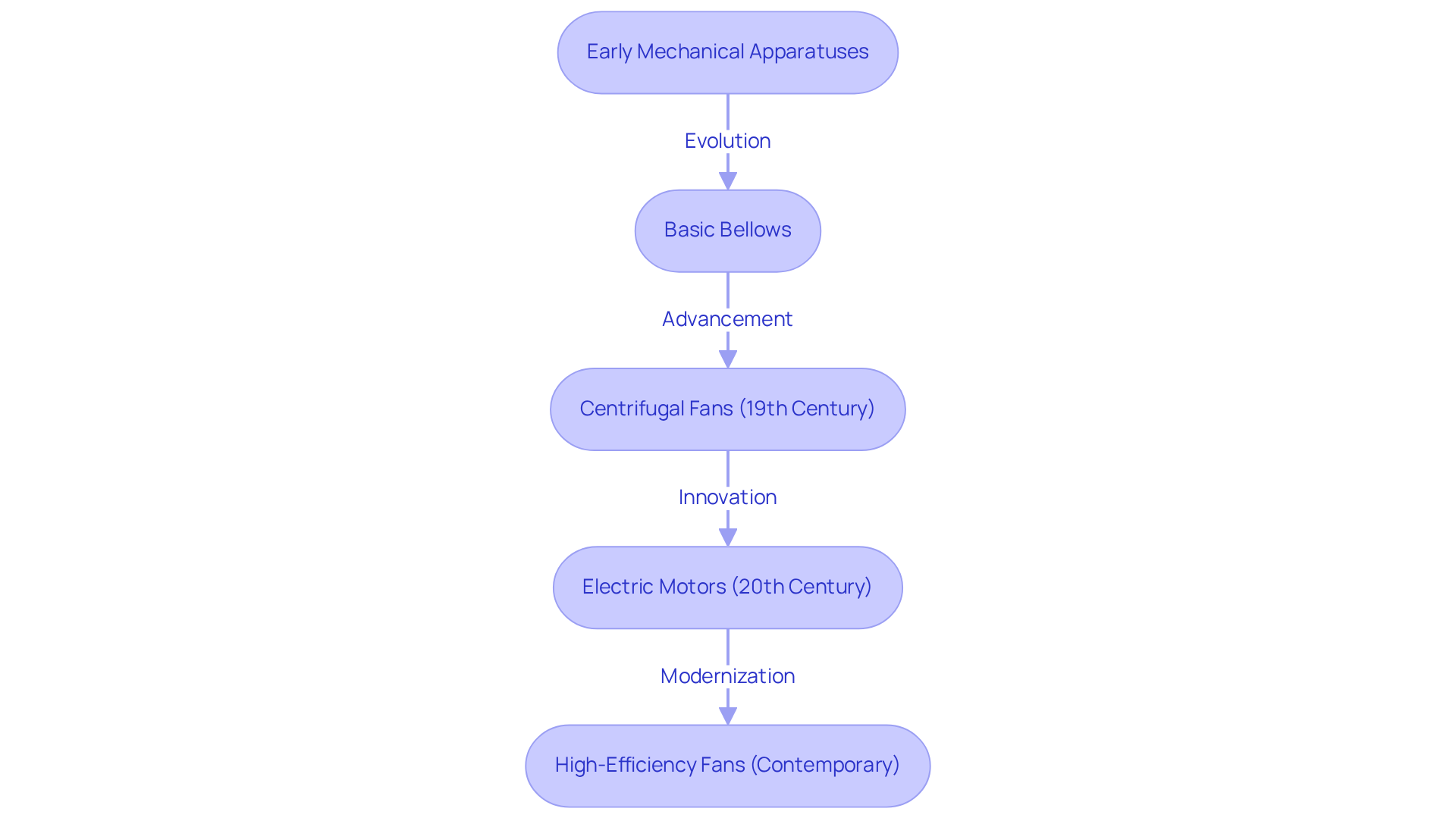

Trace the Evolution of Blower Units: Historical Development

The evolution of air-moving devices can be traced back to early mechanical apparatuses utilized for ventilation and air circulation. Initially, basic bellows served to circulate air; however, with technological advancements, centrifugal fans emerged in the 19th century, offering enhanced efficiency and performance. The introduction of in the 20th century revolutionized fan design, facilitating the development of more compact and powerful units. In contemporary times, advancements in materials and engineering have led to the creation of high-efficiency fans that operate more quietly, consume less energy, and manage greater forces, making them indispensable in various applications, particularly within the electronics sector. A significant case study highlights how the rapid expansion of data centers has escalated the demand for sophisticated ventilation technologies, particularly the blower unit, underscoring their critical role in modern infrastructure.

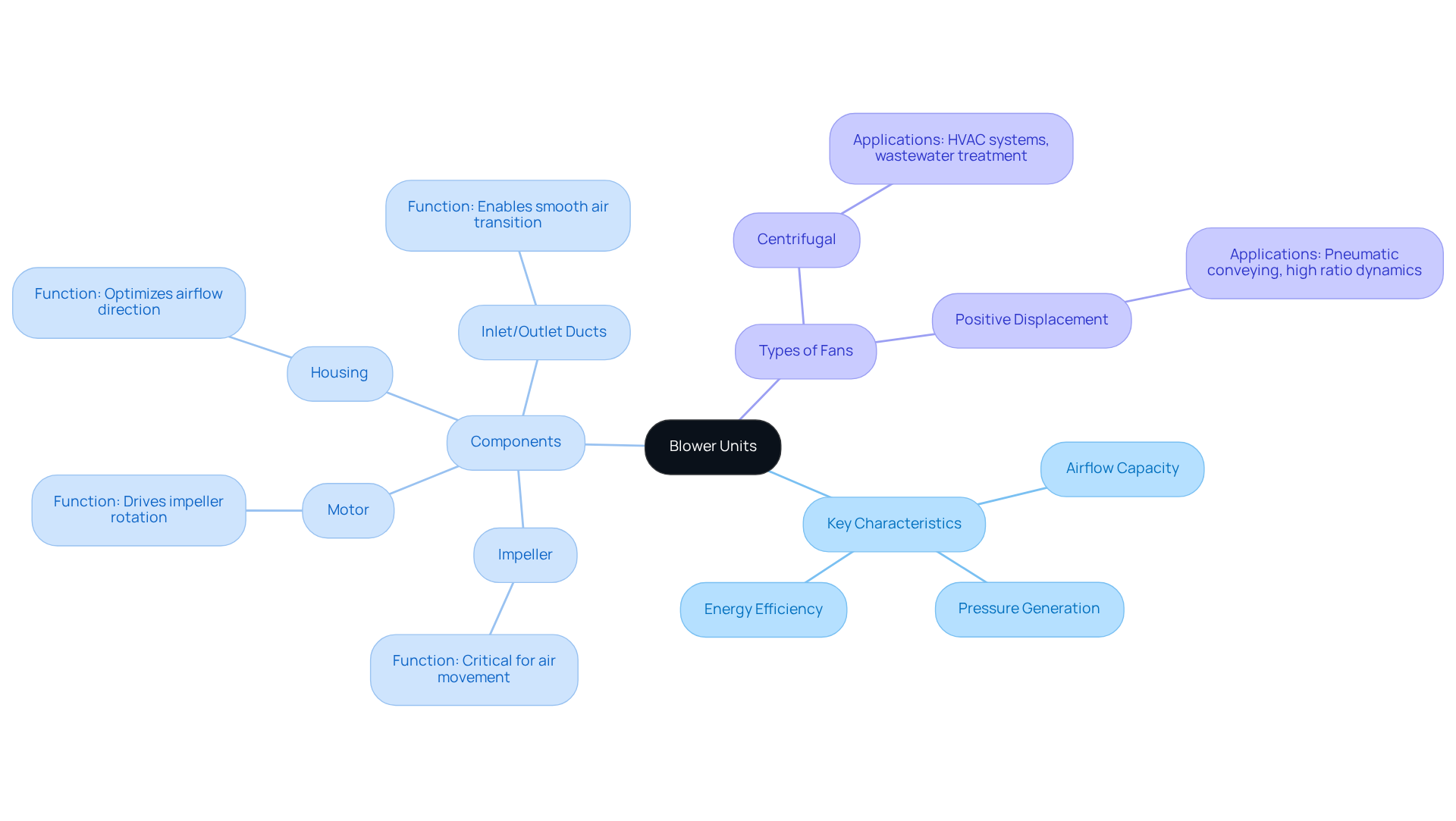

Identify Key Characteristics: Components of Blower Units

Blower systems are essential components across a variety of applications, characterized by their design, airflow capacity, pressure generation, and energy efficiency. The primary components of a ventilation system include the impeller, motor, housing, and inlet/outlet ducts. The impeller is critical for air movement, while the motor drives its rotation, ensuring effective airflow. The housing contains these elements, optimizing airflow direction, and the inlet/outlet ducts enable smooth air transition.

Fans can be categorized into two main types: centrifugal and positive displacement. Centrifugal fans are known for their high flow rates coupled with relatively low pressure levels, making them suitable for HVAC systems and wastewater treatment. Conversely, positive displacement devices are ideal for applications requiring high ratio dynamics and consistent flow rates, such as pneumatic conveying.

Understanding the characteristics of is crucial for engineers who need to select the right model for specific cooling requirements. For instance, at an operating point of 1000 CFM, the pressure drop across a media filter measures 0.15 inches w.c., underscoring the importance of selecting appropriate components to minimize static pressure while maintaining airflow capacity. Additionally, a 10% increase in airflow can lead to a 21% rise in static pressure, emphasizing the need for careful design considerations.

A case study examining static pressure fundamentals demonstrates how thoughtful component selection can significantly lower system static pressure while preserving capacity. This understanding is vital for optimizing the performance of the blower unit and ensuring durability across various applications, from HVAC systems to industrial processes.

Conclusion

The significance of blower units in electronics is paramount, as they play a crucial role in maintaining optimal thermal conditions for devices. By effectively transporting air and dissipating heat, these mechanical systems ensure that electronic components operate efficiently and enjoy extended lifespans. The ability of blower units to mitigate overheating risks underscores their essential function in modern technology.

Key insights regarding the functionality, importance, and evolution of blower units have been highlighted throughout this discussion. From their historical development to critical components and characteristics, it is evident that these devices are meticulously designed to meet the demands of contemporary electronics. The exploration of airflow dynamics and the necessity for regular maintenance further emphasizes the importance of careful consideration when selecting cooling solutions.

In light of these insights, it is imperative for engineers and designers to prioritize the integration of effective blower units in their thermal management strategies. The ongoing advancements in blower technology promise to enhance their efficiency and performance, making them indispensable in safeguarding electronic systems. Embracing these innovations will not only improve device reliability but also contribute to the broader goal of sustainable and efficient electronic design.

Frequently Asked Questions

What is a blower unit and what is its core functionality?

A blower unit is a mechanical apparatus designed to transport air or gas by increasing its pressure and speed. It works by drawing air through an inlet and expelling it through an outlet, typically using a rotating impeller or fan.

Why are blower units important in the electronics sector?

Blower units are essential in the electronics sector for maintaining optimal thermal conditions. They facilitate airflow and effectively disperse heat generated by electronic components, which is critical for ensuring devices operate efficiently and prolonging their lifespan.

What impact does overheating have on electronic components?

Overheating can reduce the lifespan of electronic components by as much as 50%, making effective cooling solutions a necessity.

What is the typical lifespan of fans used in blower units?

Fans generally have a lifespan of 15 to 20 years, emphasizing the importance of employing reliable cooling methods to prevent overheating.

How can understanding airflow dynamics and fan types benefit engineers?

Understanding the distinctions between air movers and fans enables engineers to make informed decisions that enhance system efficiency and address specific cooling requirements.

Why is regular maintenance important for blower units?

Regular maintenance is essential for optimal fan performance, ensuring that the blower unit operates effectively and prolongs its lifespan.