Overview

This article identifies essential electronic fans that deliver optimal cooling solutions across various applications. It underscores the importance of advanced technologies, such as brushless DC motors and thermal fan clutches, which significantly enhance energy efficiency and reliability in temperature regulation. This focus addresses the increasing demand for effective thermal management in electronics, highlighting the necessity for innovative solutions in today’s technology-driven landscape.

Introduction

In an era where efficient thermal management is paramount for the performance and longevity of electronic devices, the demand for advanced cooling solutions has reached unprecedented heights. This article presents a curated list of seven essential electronic fans that not only promise optimal cooling but also integrate innovative technologies designed to enhance energy efficiency and reliability. As engineers navigate the vast array of options available, how can they select the best solutions tailored to their specific applications, ensuring they effectively address the evolving challenges of temperature regulation in 2025 and beyond?

Gagner-Toomey Associates: Leading Provider of Innovative Cooling Solutions

Gagner-Toomey Associates stands out as a premier provider of innovative temperature control systems tailored specifically for the electronics sector. In tackling complex thermal management challenges, the company partners with a diverse array of manufacturers to deliver state-of-the-art products across a broad range of electronic applications, including:

This commitment to excellence is not only reflected in the superior quality of their offerings but also in their , which is a core component of their organizational culture. This ensures that engineers have access to the most effective temperature control technologies on the market.

As the need for efficient thermal management continues to grow, Gagner-Toomey remains at the forefront, adapting to emerging trends and implementing successful strategies that meet the evolving demands of the industry. Their consultative approach emphasizes respect for clients’ time and needs, further solidifying their position as a trusted partner in the field.

Delta Brushless DC Axial Fans: High-Performance Cooling for Electronics

Delta Brushless DC Axial Fans are expertly engineered to provide high-performance cooling solutions specifically designed for a range of electronic applications, including the use of electronic fans. By leveraging advanced brushless motor technology, these fans significantly enhance energy efficiency, achieving up to a 70% reduction in power consumption compared to traditional AC motors. This remarkable efficiency not only lowers operational costs but also extends the lifespan of the devices, establishing them as a .

Featuring low noise operation alongside exceptional airflow capabilities, Delta units excel at maintaining optimal temperatures for sensitive electronic components, thereby ensuring both reliability and performance. Engineers consistently highlight the benefits of brushless motor technology, citing its superior efficiency and diminished maintenance requirements—factors that are crucial in high-demand environments. As the necessity for effective temperature control solutions continues to escalate in 2025, Delta’s electronic fans, specifically brushless DC axial fans, emerge as a leading option for achieving energy-efficient and reliable temperature regulation within the electronics sector.

3-Phase Brushless DC Motor Fan: Efficient Cooling for Complex Systems

3-phase brushless DC motor blowers are meticulously engineered to deliver enhanced temperature regulation for intricate electronic systems. These advanced devices significantly outperform conventional single-phase motors by providing improved efficiency, typically achieving energy savings of about 30% compared to their single-phase counterparts. This efficiency translates into . Their innovative design of the electronic fan ensures consistent airflow and minimal vibration, making it ideal for precision temperature control applications, particularly in data centers and high-performance computing environments.

Recent advancements in fan technology, exemplified by Delta’s introduction of 3-phase brushless DC fans and the high-efficiency filter (HEF) fans, underscore their pivotal role in next-generation server architectures. Furthermore, Delta’s E Series electronic fans, specifically the PFB-E and GFB-E models, are meticulously engineered to meet the demands of contemporary electronic temperature regulation solutions, further solidifying their importance in the sector.

Thermal Fan Clutches: Essential for Effective Cooling Management

Thermal fan mechanisms serve as essential components in efficient temperature regulation systems. These mechanisms engage and disengage in response to temperature fluctuations, facilitating optimal airflow only when required. This dynamic operation not only conserves energy but also extends the lifespan of the cooling system. By automatically adapting to varying thermal conditions, electronic fan devices ensure that electronic components remain within safe operating temperatures, thereby enhancing overall system reliability.

Recent advancements in materials and technology have markedly improved the performance and durability of these components, which are essential for modern electronic fan applications. The integration of advanced fan mechanisms, equipped with sensors and digital controls, not only refines temperature regulation but also promotes proactive maintenance. This proactive strategy enables the such as excessive heat, thereby preventing costly repairs and minimizing downtime.

Furthermore, the thermal fan engagement segment is projected to dominate the North America Thermal Fan Engagement sector, presenting substantial growth opportunities as the demand for fuel-efficient and reliable temperature regulation solutions continues to rise.

Standard Duty Fan Clutch: Reliable Cooling for Diverse Applications

Standard duty electronic fan mechanisms are engineered to provide reliable temperature regulation across a range of applications, including light trucks and passenger automobiles. These clutches activate at designated temperatures, and reducing unnecessary energy consumption. Their robust design and reliable functionality render them a preferred choice among engineers seeking efficient temperature control in diverse settings.

As automotive engineers emphasize, ‘the incorporation of dependable temperature regulation methods is essential for sustaining optimal vehicle performance, especially in challenging conditions.’ Successful implementations of these devices have demonstrated their capacity to enhance thermal management, ensuring that vehicles operate effectively while adhering to the demands of modern engineering.

Furthermore, managing under-hood temperatures is critical, and application engineers play a pivotal role in developing optimal temperature control solutions tailored for specific applications. The extensive array of electronic fan drives, electronic fans, and engine temperature control components available caters to various sectors, including trucking, construction, and agriculture, underscoring the adaptability and significance of standard duty electronic fan devices in today’s market.

Heavy Duty Fan Clutch: Optimal Cooling for Demanding Environments

Heavy-duty fan mechanisms are specifically engineered to meet the stringent temperature control demands of more rigorous applications, including heavy-duty trucks and industrial machinery. These devices activate at elevated temperatures, delivering superior airflow that ensures engines remain cool even under extreme conditions. Their robust durability and operational efficiency are critical for sustaining optimal performance in challenging environments, where the risk of overheating can result in significant operational disruptions. Understanding the role of these mechanisms underscores their essential nature in maintaining functionality and .

Severe Duty Fan Clutch: Cooling Solutions for Extreme Conditions

Robust duty fans are engineered to excel in extreme temperature environments, making them indispensable for heavy-duty applications in construction and agricultural equipment. These devices activate at high temperatures, delivering to prevent overheating, thereby ensuring effective equipment operation even in the most demanding conditions. Research indicates that these assemblies can enhance airflow by as much as 30%, significantly improving temperature regulation. Their durable design and reliable performance are crucial for upholding operational integrity in severe duty applications.

Engineers within the construction sector have recognized that efficient temperature control solutions, such as these fan clutches, are vital for prolonging equipment lifespan and boosting overall productivity. As we approach Bauma Munich 2025, scheduled from April 7 to 13, where innovations in temperature regulation will be showcased, the importance of reliable temperature management technologies in construction machinery becomes increasingly evident. Furthermore, SPAL Automotive will present its cutting-edge temperature regulation solutions at the event, underscoring the industry’s dedication to innovation.

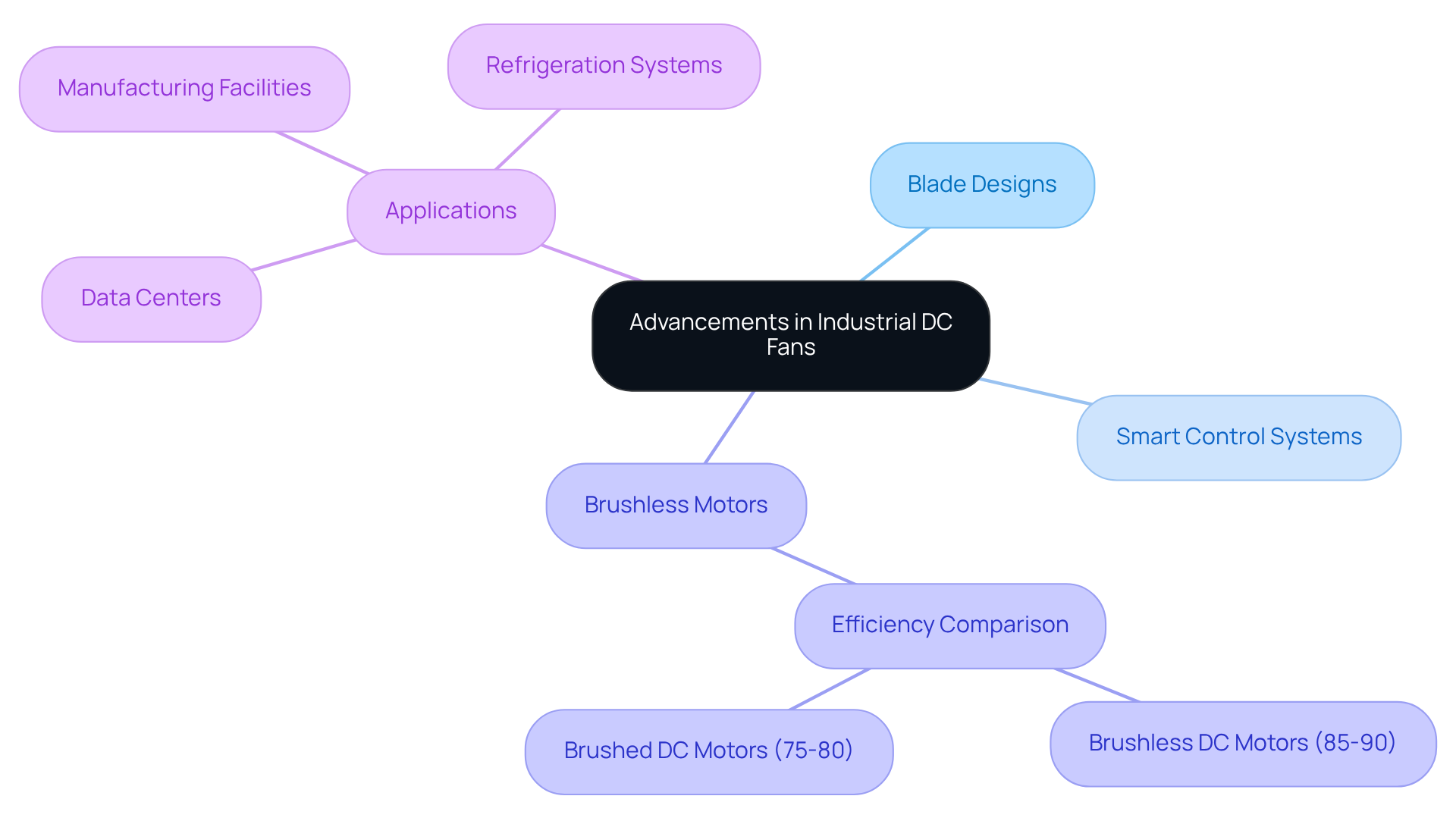

Latest Industrial DC Fans: Advancements for Modern Electronics

Recent advancements in industrial direct current devices have significantly enhanced temperature regulation and performance, making them indispensable in modern electronics. Innovations such as optimized blade designs, smart control systems, and energy-efficient brushless motors have resulted in improved airflow and substantial noise reduction. Notably, brushless DC motors typically achieve efficiencies ranging from 85-90%, compared to 75-80% for conventional brushed motors. This improvement reduces energy loss and bolsters thermal effectiveness. Such advancements are critical for applications spanning data centers to manufacturing facilities, where an electronic fan is essential for to sustain optimal performance and reliability. As the demand for quieter and more efficient temperature regulation solutions grows, the integration of intelligent controls in DC fans is revolutionizing refrigeration systems, enabling real-time adjustments that enhance energy savings and operational efficiency.

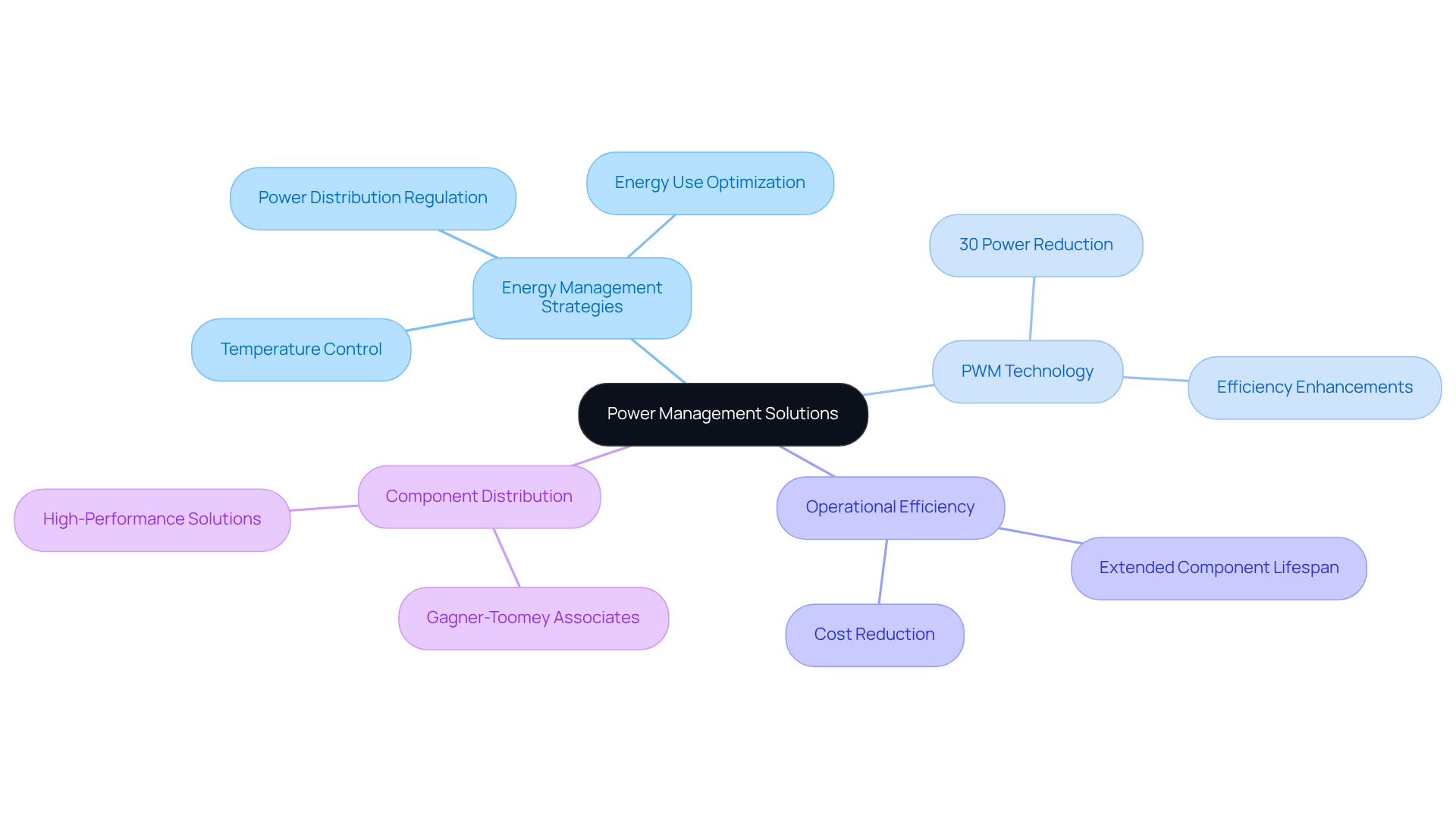

Power Management Solutions: Enhancing Cooling Efficiency in Electronics

Energy management strategies are essential for enhancing temperature control in electronic fan systems. By optimizing energy use and regulating power distribution, these approaches significantly reduce unnecessary energy waste, ensuring that cooling systems operate at peak performance.

For instance, the implementation of Pulse Width Modulation (PWM) devices can lead to power consumption reductions of up to 30% compared to conventional models, thereby greatly improving operational efficiency. Data centers that utilize PWM technology have reported efficiency enhancements in temperature management of up to 30%, demonstrating the effectiveness of these strategies across various applications.

Engineers have observed that the adoption of advanced power management strategies not only lowers operational costs but also extends the lifespan of electronic components. As one engineer aptly noted, “The adaptability of PWM devices makes them superior to conventional models in terms of both performance and efficiency.”

Furthermore, over 70% of electronics engineers are incorporating electronic fans with PWM technology into their designs, indicating a growing trend towards more efficient temperature regulation.

Gagner-Toomey Associates plays a crucial role in this landscape by connecting engineers with reliable component distribution, ensuring access to high-performance solutions such as solenoid pumps and rotary boost pumps that comply with industry standards like IATF 16969 and SAE. These pumps offer advanced capabilities, including low noise operation and , making them indispensable for achieving optimal temperature regulation in contemporary electronic applications.

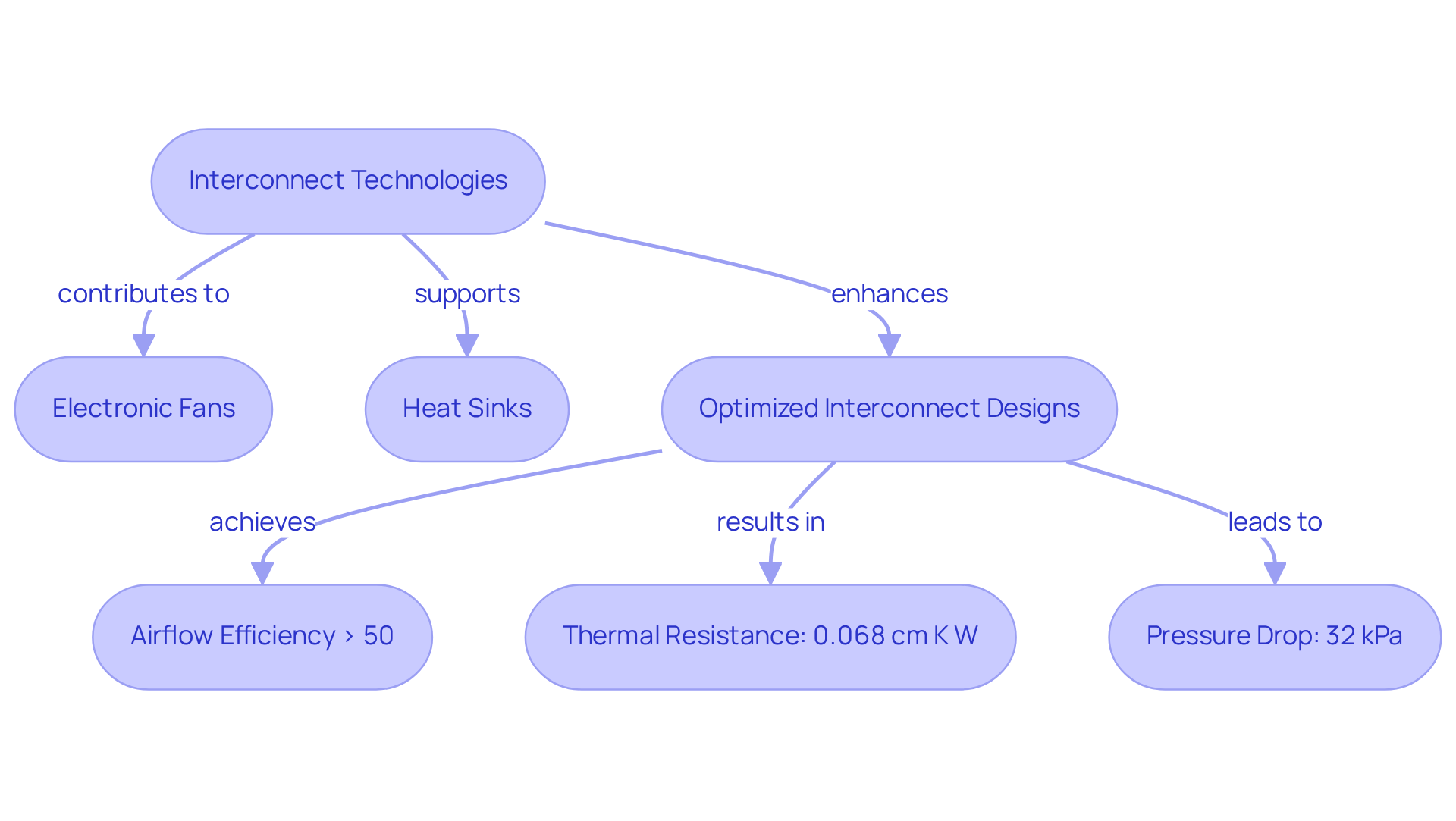

Interconnect Technologies: Ensuring Reliable Cooling Performance

Interconnect technologies are pivotal in ensuring reliable thermal management within electronic systems. By facilitating efficient airflow and heat dissipation, electronic fans are indispensable technologies for effective thermal management.

Gagner-Toomey Associates leverages its extensive network of local distributors, including industry leaders such as CONEC and Delta, to provide engineers with access to advanced interconnect options that significantly enhance cooling efficiency. For example, the implementation of optimized interconnect designs can yield airflow efficiency improvements exceeding 50%, which is critical for high-density applications such as AI accelerators and GPUs.

Furthermore, the achieved convective thermal resistance is 0.068 cm K W, accompanied by a total pressure drop of 32 kPa, underscoring the effectiveness of these technologies. As one engineer aptly stated, ‘Understanding where and how heat will flow through the system while running is fundamental to thermal engineering.’ This underscores the necessity of integrating robust interconnect solutions alongside , such as heat sinks and electronic fans, to sustain optimal performance and reliability in electronic systems.

Conclusion

Gagner-Toomey Associates stands at the forefront of innovative cooling solutions specifically designed for the electronics sector, demonstrating an unwavering commitment to excellence in temperature regulation and energy efficiency. This article highlights a variety of essential electronic fans, including Delta Brushless DC Axial Fans and 3-Phase Brushless DC Motor Fans, which not only enhance thermal management but also promote sustainability by significantly reducing energy consumption. Furthermore, the significance of thermal fan clutches and power management solutions is underscored, emphasizing their role in optimizing cooling efficiency across diverse applications.

Key insights reveal that advancements in electronic fan technology—such as smart control systems and improved designs—are crucial for addressing the increasing demands of modern electronics. The integration of interconnect technologies further enhances airflow efficiency, which is vital for high-density applications like data centers and AI systems. The article emphasizes the necessity of incorporating these advanced cooling solutions to ensure reliable performance and longevity of electronic components.

In conclusion, as the electronic cooling landscape continues to evolve, the adoption of innovative technologies and strategies is paramount. Engineers and manufacturers must prioritize efficient cooling solutions to meet the challenges posed by tomorrow’s applications. By embracing the advancements discussed, particularly those offered by Gagner-Toomey Associates, stakeholders can ensure optimal performance and sustainability within the rapidly changing electronics industry.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leading provider of innovative temperature control systems specifically tailored for the electronics sector, addressing complex thermal management challenges.

What types of applications do Gagner-Toomey Associates’ products serve?

Their products serve a broad range of electronic applications, including temperature regulation, power management, timing, RF, and interconnect technologies.

What is the company’s approach to customer service?

Gagner-Toomey Associates emphasizes exemplary customer service as a core component of their organizational culture, ensuring engineers have access to effective temperature control technologies.

How does Gagner-Toomey Associates adapt to industry trends?

The company remains at the forefront of efficient thermal management by adapting to emerging trends and implementing successful strategies that meet the evolving demands of the industry.

What are Delta Brushless DC Axial Fans designed for?

Delta Brushless DC Axial Fans are engineered to provide high-performance cooling solutions for a variety of electronic applications, particularly electronic fans.

What are the energy efficiency benefits of Delta Brushless DC Axial Fans?

These fans can achieve up to a 70% reduction in power consumption compared to traditional AC motors, which lowers operational costs and extends device lifespan.

What advantages do Delta Brushless DC Axial Fans offer in terms of operation?

They feature low noise operation and exceptional airflow capabilities, ensuring optimal temperatures for sensitive electronic components, thereby enhancing reliability and performance.

What are 3-phase brushless DC motor blowers used for?

They are designed for enhanced temperature regulation in intricate electronic systems, providing improved efficiency and thermal management compared to conventional single-phase motors.

How much energy savings can 3-phase brushless DC motor blowers achieve?

They typically achieve energy savings of about 30% compared to single-phase motors.

What recent advancements in fan technology have been made by Delta?

Delta has introduced 3-phase brushless DC fans and high-efficiency filter (HEF) fans, which play a crucial role in next-generation server architectures and contemporary electronic temperature regulation solutions.