Overview

The title “7 Essential Features of Commercial Grade Fans for Engineers” addresses a critical question: what key characteristics must engineers consider when selecting commercial grade fans? This article delineates essential features, including:

- Durability

- Energy efficiency

- Airflow capacity

- Installation versatility

- Noise levels

- Maintenance requirements

- Safety features

Each of these aspects significantly influences performance, cost savings, and user safety across diverse applications, underscoring their importance in the decision-making process.

Introduction

The demand for commercial grade fans is surging as industries seek efficient and reliable cooling solutions to optimize their operations. Engineers are confronted with the challenge of selecting fans that not only meet stringent performance standards but also align with evolving technological advancements and sustainability goals. This article explores seven essential features of commercial grade fans, providing insights that empower engineers to make informed decisions. These decisions enhance durability, energy efficiency, and overall effectiveness across diverse environments.

What critical elements should engineers prioritize to ensure their cooling systems are both cost-effective and compliant with industry standards?

Gagner-Toomey Associates: Leading Provider of Commercial Grade Cooling Solutions

Gagner-Toomey Associates stands as a leading provider of commercial grade fans and temperature control solutions, specializing in advanced technologies meticulously designed to meet the specific needs of engineers in the electronics sector. By focusing on critical areas such as temperature regulation, power management, timing, RF, and interconnect technologies, the company collaborates with a diverse array of distinguished manufacturers. This strategic alliance empowers Gagner-Toomey to deliver that not only meet but consistently exceed industry standards, ensuring optimal performance and efficiency across a multitude of applications. Their unwavering commitment to excellence is evident in their customer service and product representation, establishing them as a dependable partner for engineers seeking efficient temperature control solutions across sectors including Telecom, Networking, IT/Data Center, and beyond.

The commercial refrigeration solutions market is projected to experience substantial growth, with a compound annual growth rate (CAGR) of approximately 7.7%, reflecting the increasing demand for energy-efficient technologies. Recent innovations, such as the integration of pulse-width modulation (PWM) technology, have revolutionized temperature control systems, facilitating power consumption reductions of up to 30% compared to traditional models. Industry experts highlight that the adaptability of PWM devices significantly enhances temperature management strategies, which is essential in high-performance environments.

Successful applications of advanced temperature regulation technologies, including high-pressure centrifugal fans, have showcased considerable energy savings and improved process efficiency, rendering them vital in various industrial contexts. Gagner-Toomey Associates guarantees that professionals gain access to these state-of-the-art solutions, reinforcing their role as a key partner in the evolving realm of commercial grade fans. Their consultative approach and responsiveness to customer needs further cement their status as leaders in delivering specialized solutions for engineers across diverse industries.

Durability: Essential for Long-Term Performance in Commercial Grade Fans

Durability is paramount for commercial grade fans, especially in demanding environments where continuous operation is the norm. Gagner-Toomey Associates, the world’s foremost manufacturer of standard and custom air-movers, guarantees that high-quality materials such as heavy-gauge steel and reinforced plastics are standard in fan housings. This commitment provides the .

The typical lifecycle of commercial quality units ranges from 2 to 4 years, underscoring the importance of investing in robust designs. Recent advancements in materials for 2025, including corrosion-resistant coatings and enhanced motor mounts, significantly bolster longevity and reliability. Devices constructed with these resilient materials can endure up to 4 years longer than those made with standard components.

Engineers must prioritize heavy-duty designs, as they not only minimize the frequency of replacements and repairs but also yield substantial cost savings over time. Consistent maintenance activities, such as inspections and sanitation, are crucial for extending the lifespan of these devices.

Statistics indicate that equipment crafted from premium materials, such as commercial grade fans, can reduce energy expenses by 15 to 30%, further emphasizing the value of investing in high-quality equipment from Gagner-Toomey Associates.

Energy Efficiency: A Key Feature for Cost-Effective Commercial Fans

Energy efficiency is paramount for commercial grade fans, as it significantly impacts operational expenses. Fans equipped with high-efficiency motors and innovative blade designs can achieve energy consumption reductions of up to 70%, all while ensuring optimal airflow. The integration of variable speed controls and intelligent technology facilitates real-time adjustments, tailored to specific conditions.

Engineers must prioritize units that meet or exceed ENERGY STAR ratings, as these models are engineered for superior efficiency without sacrificing efficacy. Notably, approximately 75% of commercial grade fans will necessitate redesigning within the next five years, highlighting the urgent need for businesses to embrace energy-efficient solutions.

By selecting advanced fan technologies, companies can realize substantial cost savings; for instance, a more efficient 20 horsepower fan has the potential to save over $1,000 annually in energy costs. As the demand for sustainable practices escalates, the transition towards energy-efficient temperature regulation solutions is not merely a trend but an essential strategy for operational excellence.

Airflow Capacity: Maximizing Cooling Effectiveness in Commercial Settings

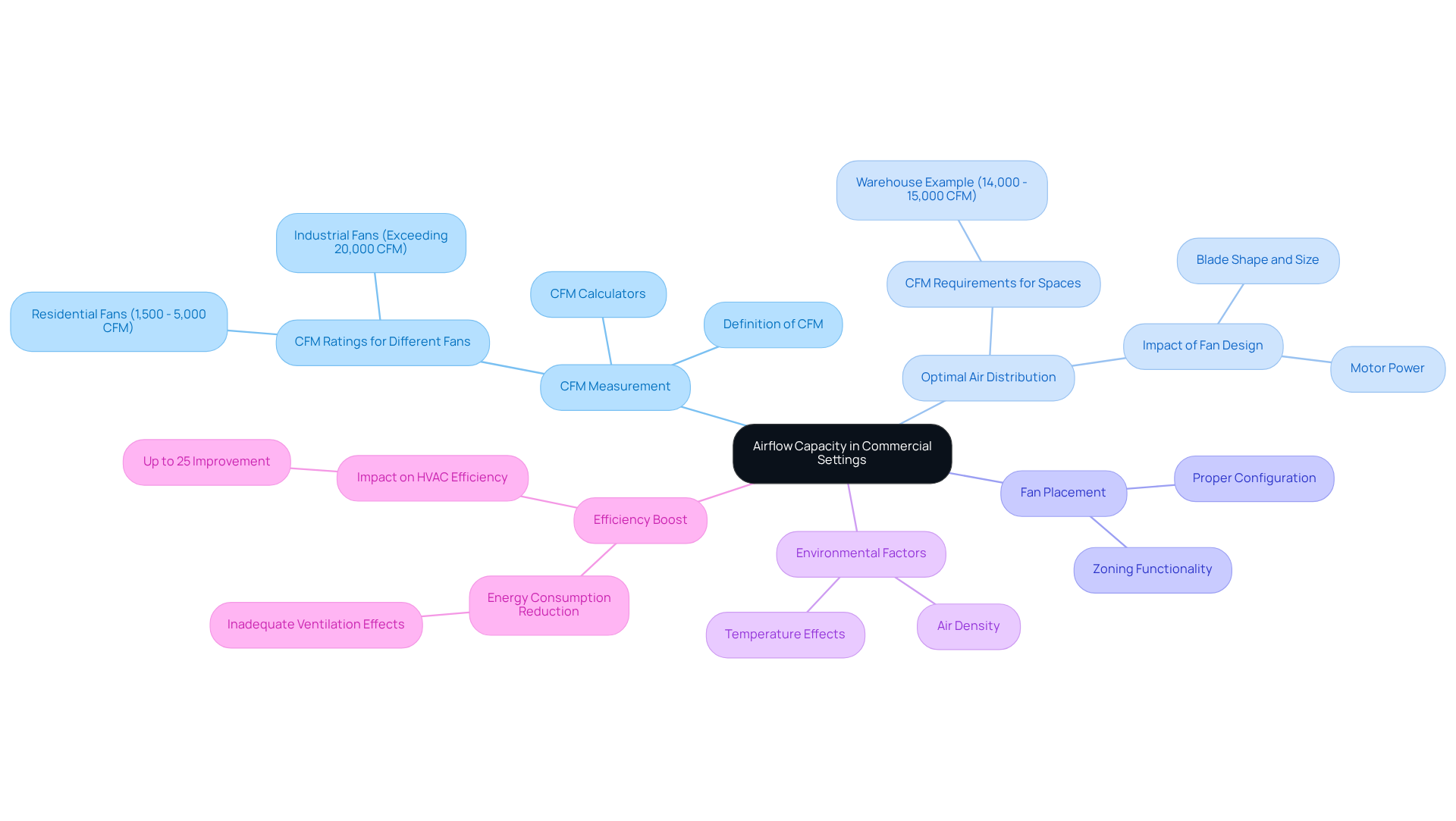

Airflow capacity, measured in cubic feet per minute (CFM), is vital for evaluating the effectiveness of commercial grade fans. Engineers must conduct a thorough assessment of the temperature control requirements specific to their applications to select devices that deliver adequate airflow. Commercial grade fans, which are high-capacity and capable of moving over 20,000 CFM, are particularly well-suited for expansive environments such as warehouses and manufacturing facilities, where effective air circulation is paramount. For example, a warehouse measuring 25 feet by 50 feet by 75 feet necessitates between 14,000 and 15,000 CFM for optimal air distribution.

Richard Boothman, Director of North American Sales for Modine, asserts that “consistent circulation promotes a safer, healthier, and more welcoming environment, ensuring productivity in industrial and commercial settings.”

Understanding the interplay between airflow and static pressure is crucial for professionals aiming to . Proper fan placement and configuration can significantly enhance operational performance, with studies indicating that maintaining appropriate CFM levels can boost HVAC system efficiency by as much as 25%. Additionally, professionals must consider environmental factors, such as air density and temperature, which can impact fan performance. As the demand for efficient temperature control solutions continues to rise, a comprehensive understanding of CFM measurement will empower professionals to make informed decisions that enhance air quality and reduce energy consumption in environments utilizing commercial grade fans.

To determine airflow requirements for commercial applications, engineers can utilize CFM calculators that account for the specific dimensions, cooling needs, and the implementation of commercial grade fans in their spaces. The DSU fan, equipped with a high-efficiency EC motor, is engineered to combat air stratification and ensure reliable, all-season performance, making it an exceptional choice for optimizing airflow in large facilities.

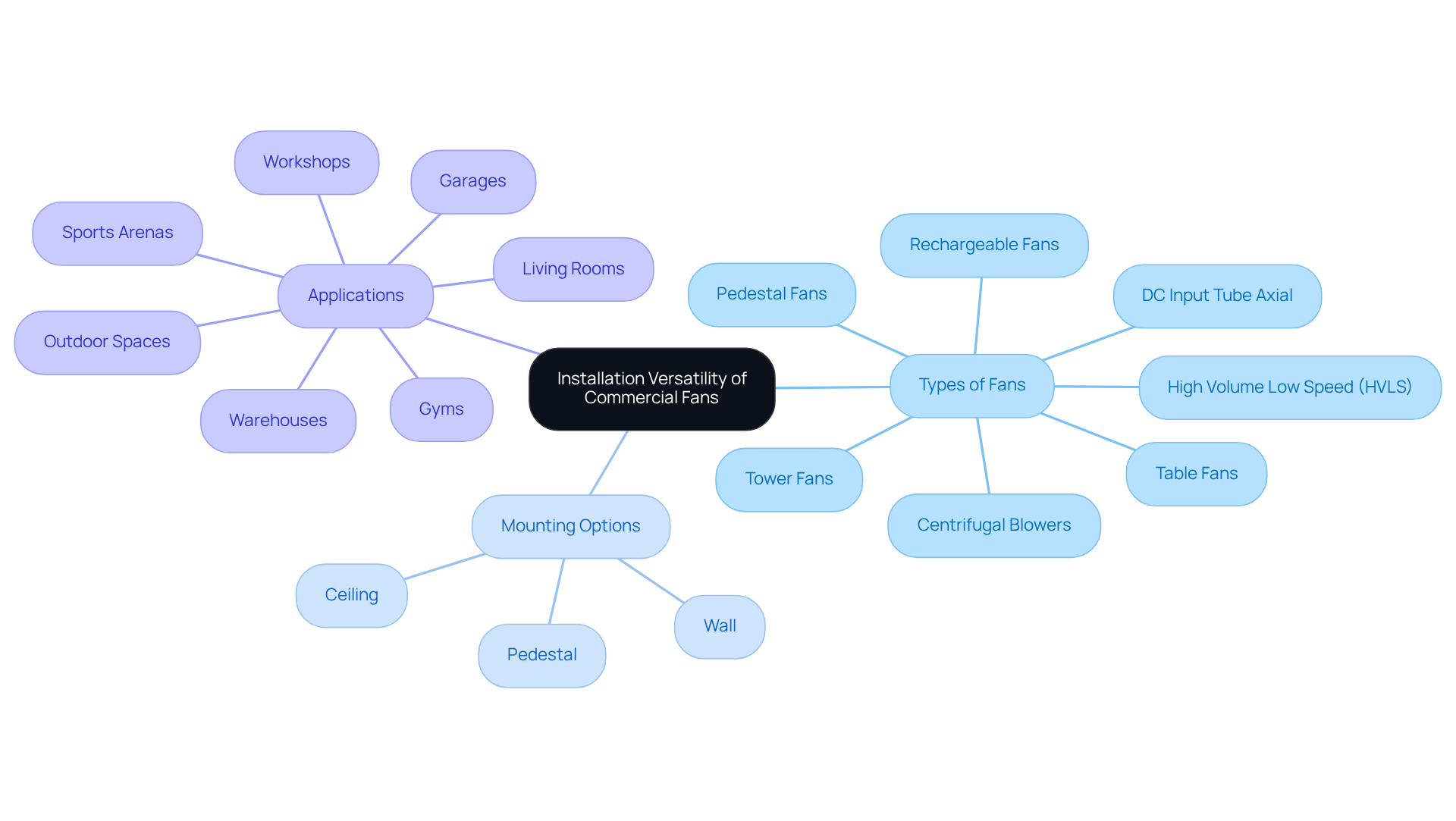

Installation Versatility: Adapting Commercial Fans to Diverse Environments

Installation versatility stands as a crucial characteristic of commercial grade fans, enabling their adaptation to diverse environments. Gagner-Toomey Associates offers an extensive selection of standard and custom air-movers, including DC input tube axial devices and centrifugal blowers, all optimized for superior performance and efficiency. These devices typically present various mounting options—ceiling, wall, and pedestal configurations—allowing engineers to determine the most effective installation method tailored to their specific applications.

For instance, wall-mounted air circulators excel in maximizing floor space in workshops and gyms, while ceiling-mounted units facilitate extensive airflow distribution across larger areas. Heavy-duty air circulators, particularly High Volume Low Speed (HVLS) models with blade diameters ranging from 8 to 24 feet, demonstrate exceptional effectiveness in expansive environments such as warehouses and sports arenas. Furthermore, features such as adjustable height and tilt angles further enhance the versatility of these devices, ensuring optimal airflow distribution is customized to the unique requirements of each space.

Engineers must meticulously consider the layout and design of their environments, as these factors significantly influence both performance and aesthetics. Adhering to local building codes and following manufacturer instructions for safe installation is also paramount. With the appropriate installation method, Gagner-Toomey’s commercial grade fans can substantially , contributing to a more comfortable working environment.

Noise Levels: Ensuring a Quiet Operation in Commercial Fan Applications

Noise levels are a critical consideration when selecting commercial grade fans, especially in environments where silent operation is imperative. Fans engineered with noise reduction technologies—such as sound-dampening materials and optimized blade designs—effectively minimize operational noise. Engineers must prioritize devices that provide noise level specifications, typically quantified in decibels (dBA), to ensure compliance with the acoustic requirements of their applications. Opting for not only enhances comfort but also elevates productivity by reducing workplace distractions.

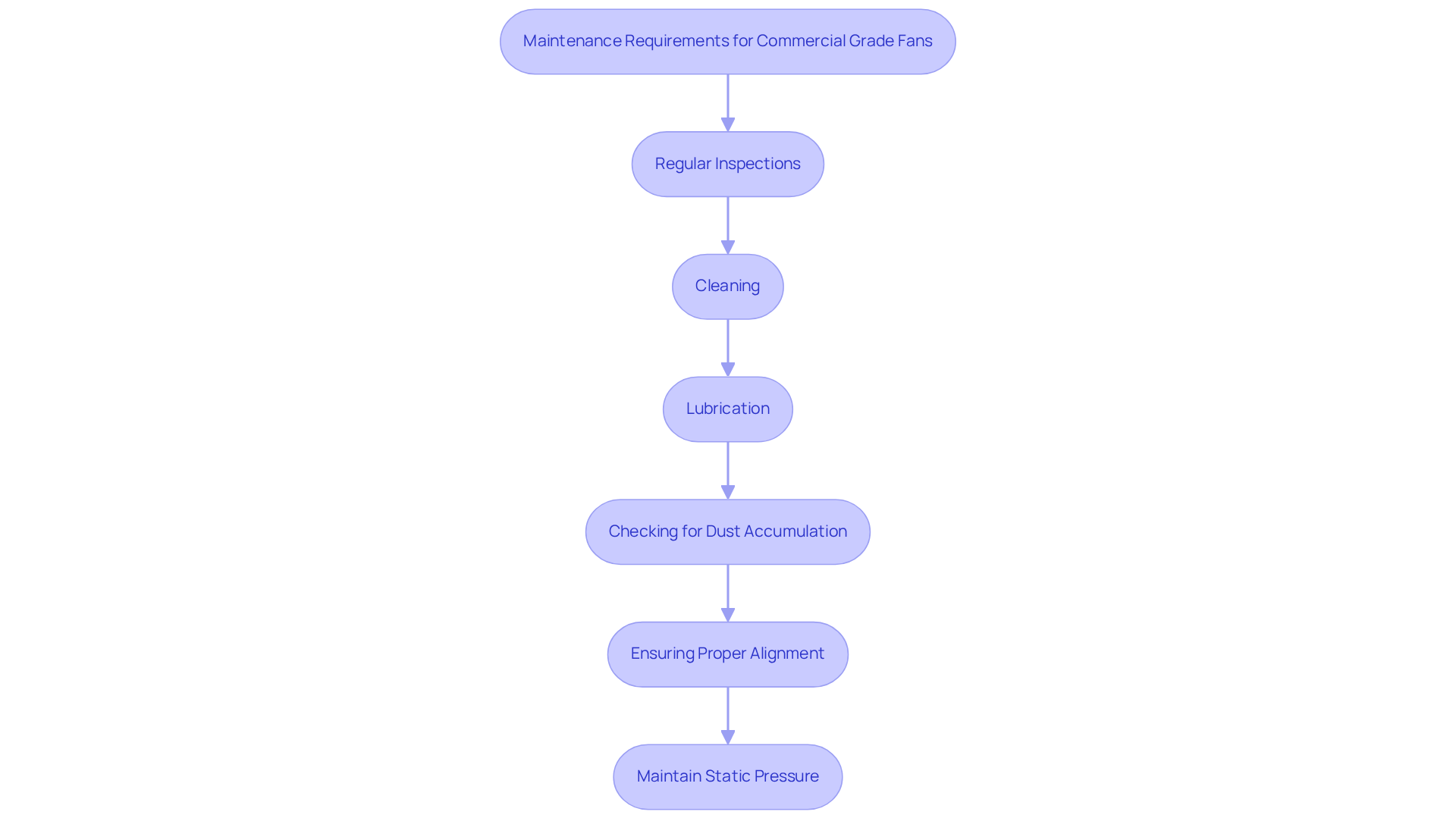

Maintenance Requirements: Keeping Commercial Grade Fans in Optimal Condition

Maintenance is crucial for ensuring the longevity and efficiency of commercial grade fans. Regular inspections, cleaning, and lubrication of moving parts are vital to mitigate wear and tear. Engineers must implement a structured maintenance schedule that includes:

- Checking for dust accumulation

- Ensuring proper alignment

- Verifying electrical connections

Furthermore, maintaining constant static pressure is necessary for the fan to overcome obstacles and sustain airflow. Notably, statistics reveal that facilities employing preventive maintenance programs experience a 31-50% reduction in service requests, underscoring the value of proactive strategies. Selecting devices with easily accessible components can , thereby enhancing optimal performance. For instance, a Vietnamese seafood processor achieved an impressive 14-year durability from stainless steel ventilators in a challenging environment by adhering to a strict maintenance routine. Additionally, effective maintenance practices can lead to a potential reduction in repair costs by distinguishing between repairable components and scrap. By prioritizing these best practices, engineers can significantly extend the lifespan of commercial grade fans and enhance their operational efficiency.

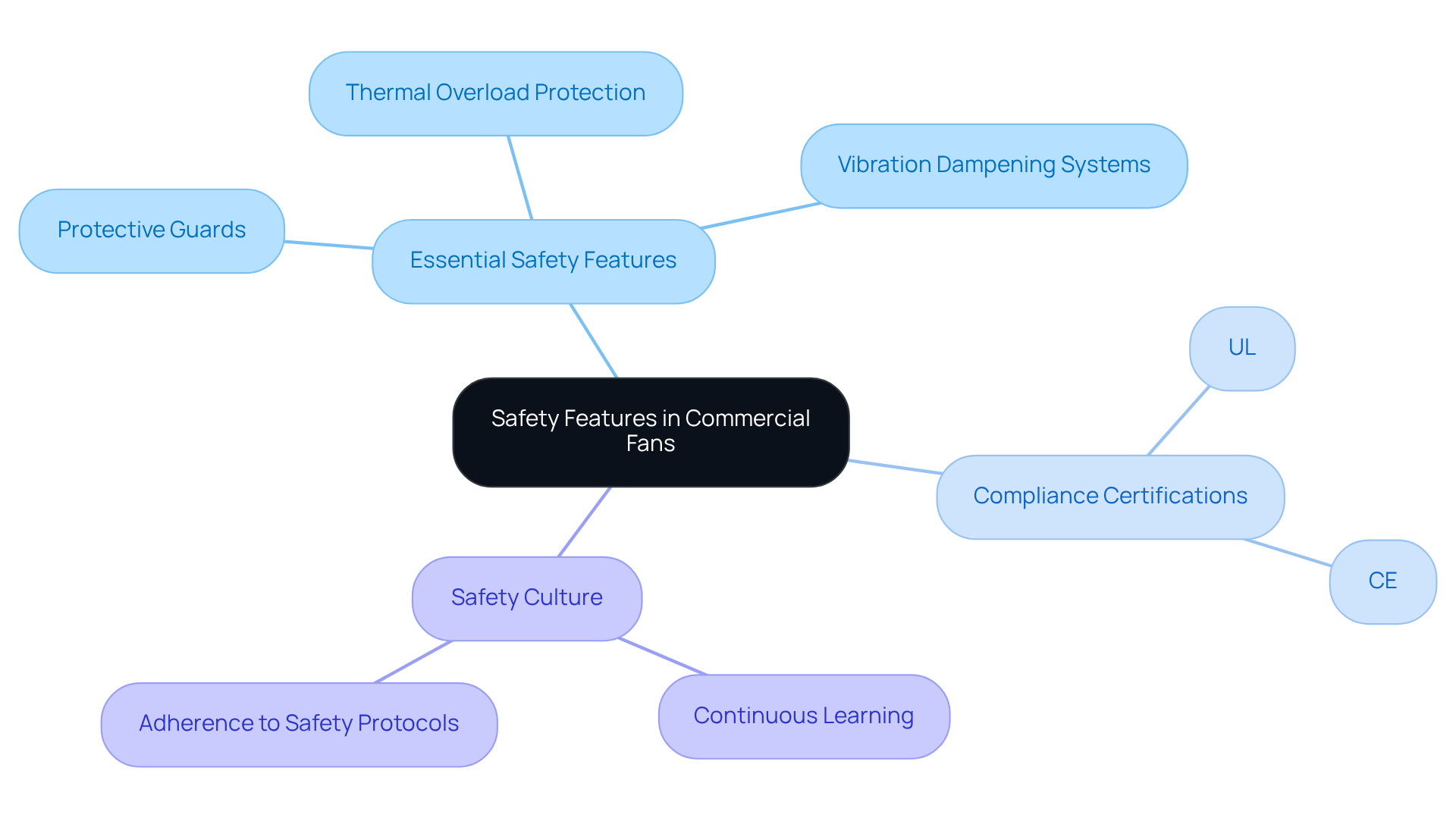

Safety Features: Protecting Users and Ensuring Compliance in Commercial Fans

Safety features are paramount in the design of commercial grade fans, ensuring user protection and compliance with industry regulations. Essential safety features encompass:

- Protective guards

- Thermal overload protection

- Vibration dampening systems

Engineers must prioritize commercial grade fans that meet relevant safety certifications, such as UL or CE, which signify adherence to stringent safety standards. Moreover, cultivating a culture of growth and education within the workplace is vital for promoting a safe environment, as it fosters continuous learning and strict adherence to safety protocols.

The cannot be overstated; prioritizing safety features in commercial grade fans not only mitigates risks associated with their operation but also enhances overall organizational performance. Statistics indicate that improper fan operation can lead to significant safety incidents, underscoring the importance of professionals proactively addressing safety concerns.

As Robert W. Campbell aptly noted, ‘Safety work is today recognized as an economic necessity.’ By emphasizing these safety features and nurturing a culture of safety, engineers can create a safer working environment and diminish the likelihood of accidents, ultimately benefiting both users and organizations.

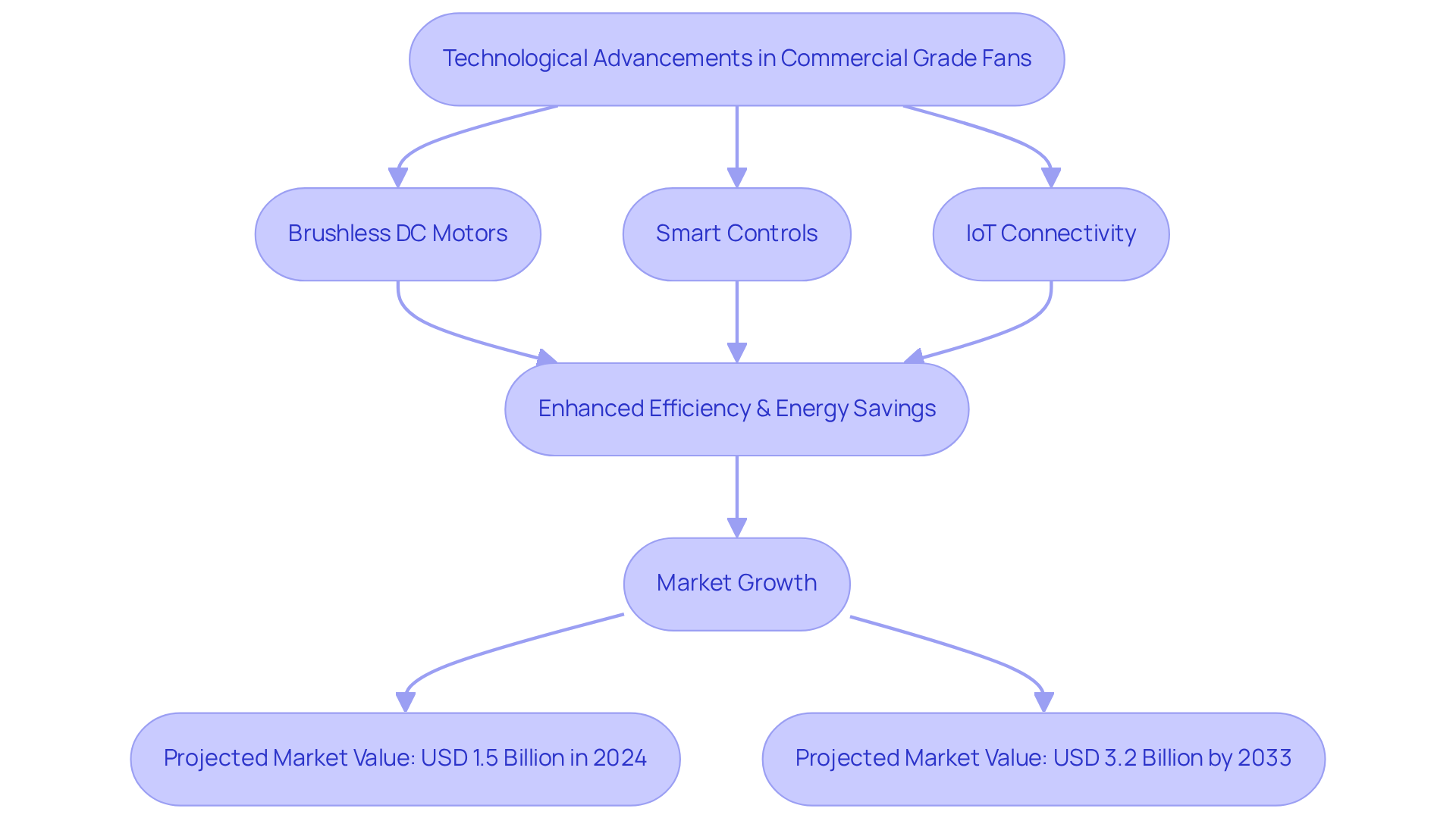

Technological Advancements: Enhancing Performance in Commercial Grade Fans

Technological progress is fundamentally transforming the design and functionality of commercial grade fans. Innovations such as brushless DC motors, smart controls, and IoT connectivity enable these devices to operate with enhanced efficiency, adapting seamlessly to varying environmental conditions. Features like remote monitoring and automated adjustments based on temperature and humidity levels significantly improve overall efficiency and energy savings.

Recent statistics reveal that the Smart Industrial Fan Market, valued at USD 1.5 billion in 2024, is projected to experience a CAGR of 9.3% from 2026 to 2033, ultimately reaching USD 3.2 billion by 2033. Engineers must stay abreast of these advancements to select devices that not only meet but exceed performance and efficiency criteria tailored for their specific applications.

As stated by the U.S. Department of Energy, energy-efficient devices can yield substantial operational cost savings for businesses, potentially reaching up to 50% compared to conventional models. The is not merely a trend; it is a critical component in achieving operational excellence and sustainability within the industry.

Warranty and Support: Ensuring Reliability in Commercial Fan Purchases

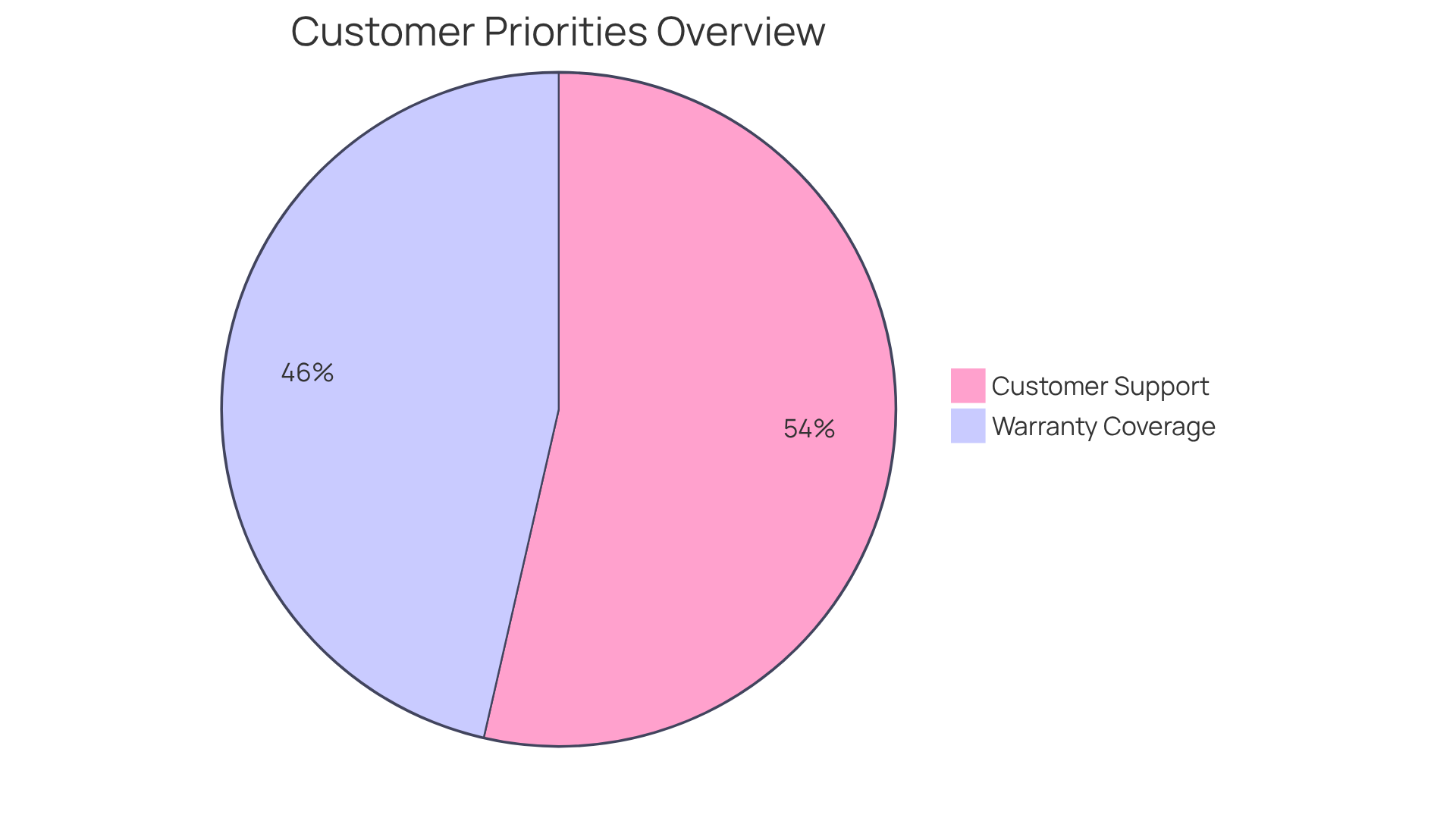

When selecting commercial grade fans, are paramount considerations. A comprehensive warranty not only protects the investment but also reflects the manufacturer’s confidence in the product’s durability and performance. Engineers should prioritize commercial grade fans that offer extensive warranty coverage, including both parts and labor, to safeguard against potential defects.

In 2025, the significance of warranty in electronics cooling solutions is highlighted by data showing that 78% of customers prioritize warranty coverage in their purchasing decisions. Additionally, dependable customer support is essential for addressing any issues that may arise during installation or operation.

For example, companies that offer dedicated support teams have recorded a 90% customer satisfaction rate, underscoring the positive influence of effective service on user experience. By emphasizing warranty and support, engineers can significantly enhance the long-term reliability and satisfaction of their purchases of commercial grade fans.

Conclusion

The exploration of commercial grade fans highlights their critical role in achieving effective temperature control and airflow across diverse industrial applications. By emphasizing key features such as:

- Durability

- Energy efficiency

- Airflow capacity

- Installation versatility

- Noise levels

- Maintenance requirements

- Safety features

- Technological advancements

- Warranty support

engineers are empowered to make informed decisions that significantly enhance operational efficiency and cost-effectiveness.

This article shares vital insights into:

- The necessity of selecting high-quality materials that extend the lifespan of fans

- The importance of energy-efficient designs to minimize operational costs

- The adaptability of fan installations to accommodate various environmental needs

Moreover, the focus on safety features and maintenance practices reinforces a commitment to user protection and the longevity of equipment.

Ultimately, prioritizing these essential features when selecting commercial grade fans not only leads to improved performance and reduced costs but also cultivates a safer and more comfortable working environment. As the demand for advanced cooling solutions continues to rise, engineers are encouraged to remain informed about the latest innovations and best practices to ensure they choose the most suitable fans for their specific applications. Investing in quality commercial grade fans transcends mere choice; it constitutes a strategic decision that can profoundly influence overall operational success.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in commercial grade fans and temperature control solutions, focusing on advanced technologies tailored for engineers in the electronics sector.

What industries does Gagner-Toomey Associates serve?

Gagner-Toomey Associates serves various industries, including Telecom, Networking, IT/Data Center, and more, providing efficient temperature control solutions.

What is the projected growth rate of the commercial refrigeration solutions market?

The commercial refrigeration solutions market is projected to grow at a compound annual growth rate (CAGR) of approximately 7.7%.

How does pulse-width modulation (PWM) technology benefit temperature control systems?

PWM technology can reduce power consumption by up to 30% compared to traditional models and enhances temperature management strategies in high-performance environments.

What materials does Gagner-Toomey Associates use for their commercial grade fans?

Gagner-Toomey Associates uses high-quality materials such as heavy-gauge steel and reinforced plastics in fan housings to ensure durability and withstand rigorous conditions.

What is the typical lifecycle of commercial quality fans?

The typical lifecycle of commercial quality fans ranges from 2 to 4 years.

How can engineers extend the lifespan of commercial grade fans?

Engineers can extend the lifespan of commercial grade fans through consistent maintenance activities, including inspections and sanitation.

What are the energy efficiency benefits of commercial grade fans?

Commercial grade fans equipped with high-efficiency motors and innovative blade designs can achieve energy consumption reductions of up to 70%, significantly impacting operational expenses.

What is the importance of ENERGY STAR ratings for commercial grade fans?

Fans that meet or exceed ENERGY STAR ratings are engineered for superior efficiency, ensuring optimal performance without sacrificing efficacy.

What potential savings can companies realize by using energy-efficient fans?

Companies can save over $1,000 annually in energy costs by using a more efficient 20 horsepower fan, highlighting the cost-effectiveness of energy-efficient solutions.