Overview

The article delves into the mastery of design and maintenance strategies for liquid cooling plates, essential for optimizing thermal management in electronic systems. It underscores the critical nature of material selection, fluid pathway design, and consistent maintenance practices, which collectively enhance performance and reliability. Evidence illustrates significant advancements in efficiency and temperature regulation, particularly within high-density applications, prompting stakeholders to prioritize these strategies for superior outcomes.

Introduction

The escalating complexity and power demands of modern electronics render effective thermal management more critical than ever. Liquid cooling, recognized for its exceptional heat absorption capabilities, emerges as a highly efficient solution for sustaining optimal operating temperatures in high-performance applications. Nevertheless, the intricacies involved in designing and maintaining liquid cooling plates present significant challenges.

How can engineers adeptly navigate these complexities to ensure the reliable performance and longevity of their cooling systems?

Explore the Fundamentals of Liquid Cooling in Electronics

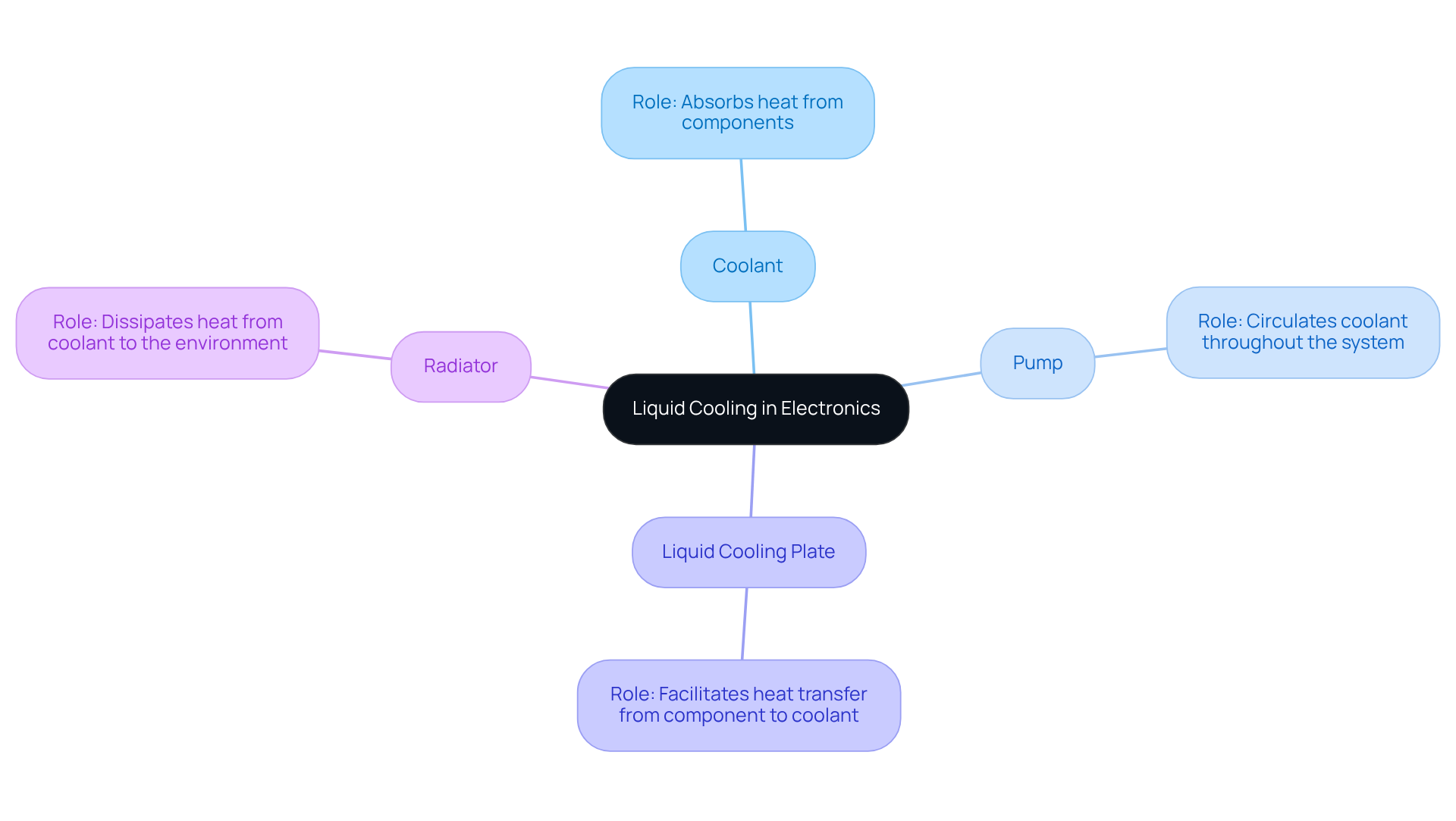

Liquid cooling is a technique employed to efficiently remove warmth from electronic components by circulating a coolant, typically water or a specialized fluid, through a closed-loop system. This method surpasses air cooling due to the superior thermal conductivity of liquids, which enables enhanced heat absorption and transfer. The key components of a liquid cooling system include:

- Coolant: The fluid responsible for absorbing heat from the components.

- Pump: Circulates the coolant throughout the system.

- Liquid Cooling Plate: A thermal exchanger that facilitates the transfer of heat from the component to the liquid coolant.

- Radiator: Dissipates heat from the coolant to the surrounding environment.

Understanding these components and their respective roles is essential for developing in high-performance electronics.

Understand Cold Plate Design Principles and Considerations

Liquid cooling plates are designed to optimize heat transfer from electronic components to the coolant, utilizing several key design principles that are essential for high-performance applications.

- Material selection is critical; copper and aluminum are preferred due to their exceptional thermal conductivity, which is vital for efficient heat dissipation.

- The design of fluid pathways, or channel design, significantly impacts flow distribution and thermal transfer efficiency.

- Sophisticated configurations, such as topology-optimized channels, minimize flow resistance and enhance fluid throughput, resulting in superior thermal management.

- Additionally, it is imperative to consider the pressure drop across the network to ensure effective flow distribution.

Increasing the surface area of cold plates is another crucial factor for effective heat dissipation. This can be achieved through the incorporation of fins or other , facilitating greater contact with the coolant. Furthermore, the selection of appropriate thermal interface materials (TIMs) is vital for ensuring effective thermal contact between the electronic component and the cold plate. High-quality TIMs reduce thermal resistance, thereby enhancing overall thermal transfer performance.

The advent of microchannel technology represents a significant advancement in the design of liquid cooling plates. The use of ultra-thin microchannels, which can be as narrow as 100 microns, achieves exceptionally high thermal transfer coefficients and low thermal resistance, making them ideal for high-density electronic applications.

By meticulously evaluating these factors, engineers can create cold plates that excel in regulating temperature within high-density electronic applications, particularly in industries such as automotive and aerospace, where performance and reliability are paramount. The electric vehicle battery liquid cooling plate market, for instance, is projected to grow at a CAGR of 30.0% from 2024 to 2030, underscoring the increasing importance of effective thermal management solutions in this field. Moreover, case studies have indicated that the use of a liquid cooling plate is essential to battery thermal management setups, ensuring uniform temperature distribution and improving overall performance.

Implement Best Practices for Deploying Liquid-Cooled Systems

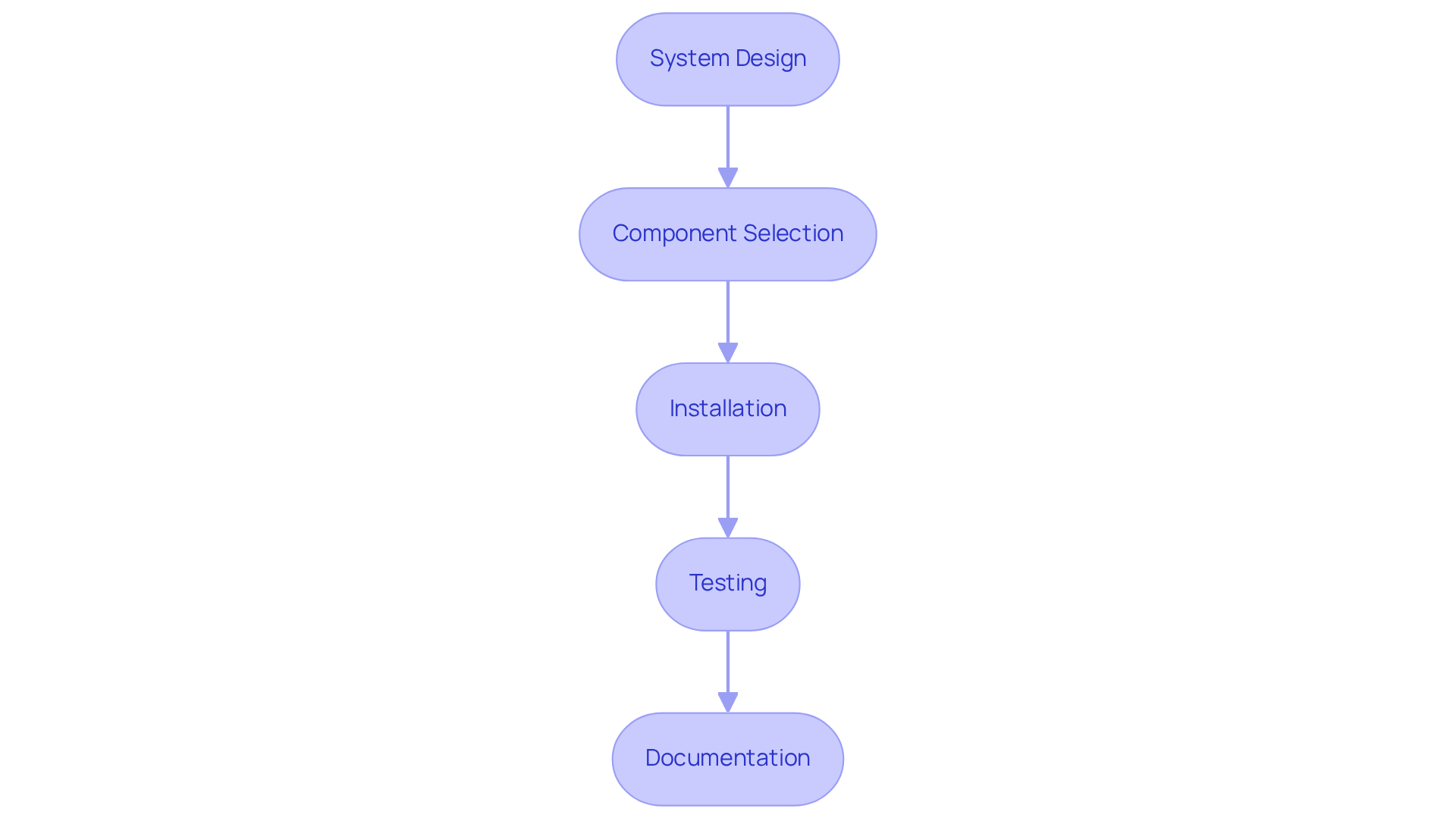

To ensure the successful deployment of liquid-cooled systems, it is essential to adhere to several best practices that address common challenges in this field:

- System Design: The cooling system must be meticulously designed to meet the specific thermal requirements of the application, taking into account component heat loads and environmental conditions.

- Component Selection: Opt for high-quality components, including pumps, cold plates, and radiators, as these enhance the reliability of the entire setup.

- Installation: Adhering to proper installation procedures for the liquid cooling plate is critical to prevent leaks and ensure optimal coolant flow. This includes securing all connections and verifying the integrity of seals to maintain system efficiency.

- Testing: A thorough evaluation of the setup prior to full deployment is vital. This process should identify potential issues, such as leaks or inadequate cooling performance, allowing for timely adjustments.

- Documentation: Maintain detailed records of the design, installation procedures, and maintenance schedules. This practice facilitates future troubleshooting and upgrades, ensuring long-term system reliability.

Maintain Liquid-Cooled Systems for Optimal Performance

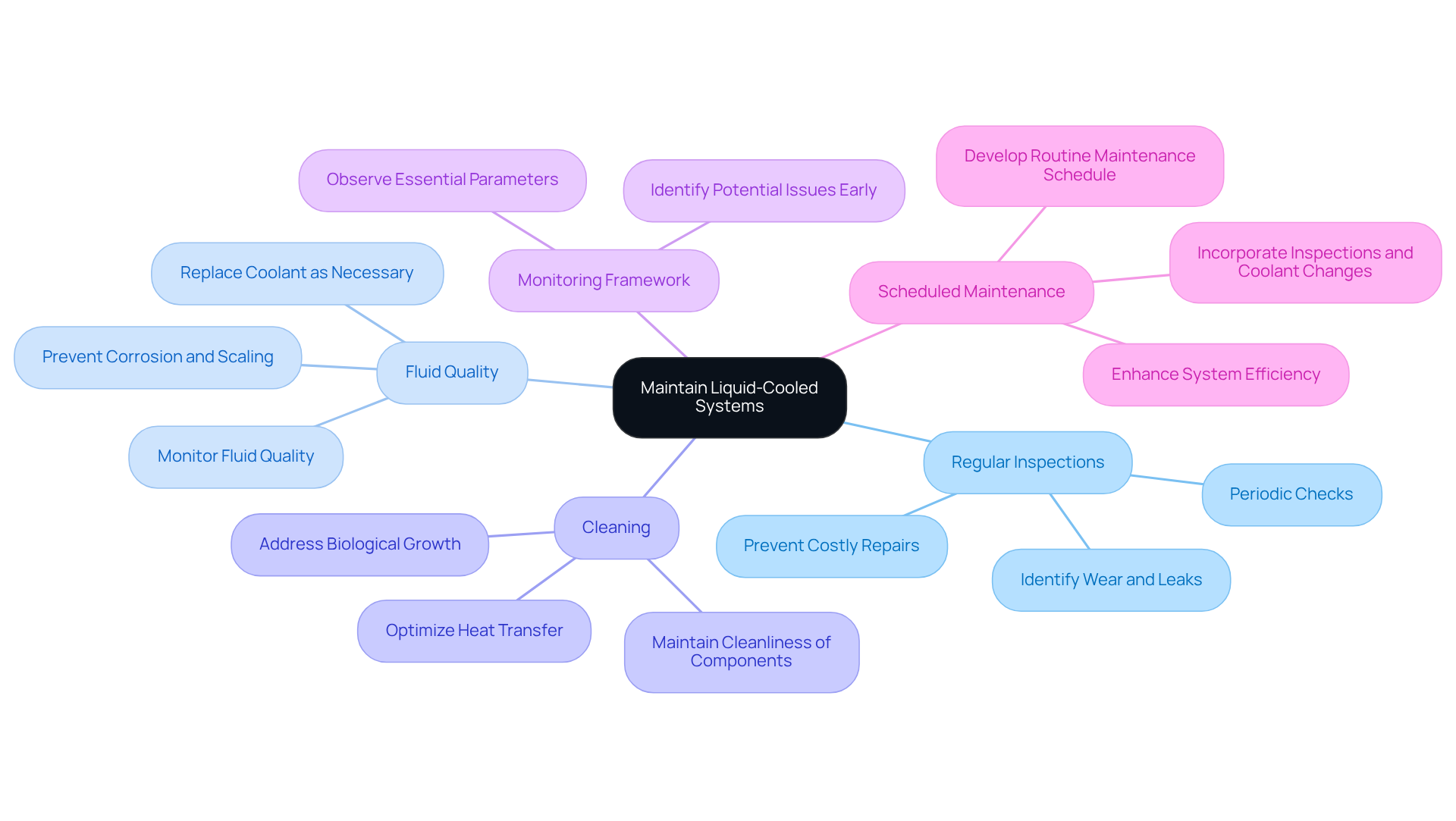

To ensure the effective maintenance of liquid-cooled systems, it is essential to implement best practices that enhance performance and reliability:

- Regular Inspections: Conduct periodic checks on all components, including pumps, cold plates, and radiators, to identify signs of wear, leaks, or blockages. Regular inspections are crucial as they can prevent minor issues from escalating into costly repairs. As Fred Rebarber pointed out, “In our completely optimized study, the introduction of liquid cooling resulted in a 10.2% decrease in total data center power and over a 15% enhancement in TUE,” emphasizing the significance of ensuring efficiency through regular checks.

- Fluid Quality: Vigilantly monitor and maintain fluid quality, replacing it as necessary to avert corrosion and scaling. Poor coolant quality can significantly diminish performance and lead to increased energy costs. Statistics suggest that poor water quality can raise energy expenses and shorten the lifespan of the cooling apparatus, underscoring the necessity for regular monitoring.

- Cleaning: Maintain cleanliness across all components, particularly the liquid cooling plate and radiators, to optimize heat transfer. Accumulated dust and debris can severely impair cooling efficiency, making regular cleaning essential. Furthermore, addressing biological growth through biocide treatment can prevent algae and bacteria from blocking pipes and decreasing efficiency.

- Monitoring Framework: Establish monitoring mechanisms to observe essential parameters such as temperatures, flow rates, and pressure levels. This data is invaluable for identifying potential issues early, thereby preventing failures in the network.

- Scheduled Maintenance: Develop a routine maintenance schedule that encompasses inspections, coolant changes, and component replacements. This proactive approach is essential for ensuring long-term reliability and operational efficiency of the cooling mechanism. A tailored water treatment plan, as discussed in the case study “Improving Cooling System Water Quality,” can enhance system efficiency and prolong the operational life of cooling systems.

Conclusion

Mastering the design and maintenance of liquid cooling plates is paramount for ensuring optimal performance in high-density electronic applications. This article has delved into the fundamental principles of liquid cooling, underscoring the significance of effective heat transfer mechanisms that outperform traditional air cooling methods. By comprehending the essential components and their functions—such as coolant, pumps, and radiators—engineers can devise efficient cooling solutions tailored to meet specific thermal requirements.

Key insights discussed encompass the critical aspects of cold plate design, including:

- Material selection

- Fluid pathway design

- Implementation of microchannel technology

These factors substantially enhance thermal management across various industries, particularly within the automotive and aerospace sectors. Furthermore, adopting best practices for system deployment and maintenance—such as:

- Regular inspections

- Fluid quality monitoring

- Scheduled maintenance

Ensures the longevity and reliability of liquid-cooled systems.

As the demand for effective thermal management solutions continues to escalate, especially in rapidly advancing fields like electric vehicle technology, the insights shared in this article serve as a vital resource for engineers and technicians. By embracing these strategies, one not only optimizes cooling performance but also fosters innovation and efficiency in electronic design, paving the way for breakthroughs in thermal management systems.

Frequently Asked Questions

What is liquid cooling in electronics?

Liquid cooling is a technique used to efficiently remove heat from electronic components by circulating a coolant, typically water or a specialized fluid, through a closed-loop system.

How does liquid cooling compare to air cooling?

Liquid cooling surpasses air cooling due to the superior thermal conductivity of liquids, which allows for enhanced heat absorption and transfer.

What are the key components of a liquid cooling system?

The key components include the coolant, pump, liquid cooling plate, and radiator.

What role does the coolant play in a liquid cooling system?

The coolant is the fluid responsible for absorbing heat from the electronic components.

What is the function of the pump in a liquid cooling system?

The pump circulates the coolant throughout the system.

What is a liquid cooling plate, and what does it do?

A liquid cooling plate is a thermal exchanger that facilitates the transfer of heat from the electronic component to the liquid coolant.

How does the radiator contribute to the liquid cooling process?

The radiator dissipates heat from the coolant to the surrounding environment, helping to maintain optimal temperatures in the system.