Overview

This article examines the critical features of large blower fans that enhance their performance, including:

- Airflow capacity

- Energy efficiency

- Durability

- Noise levels

- System compatibility

These characteristics are vital for achieving effective cooling, minimizing operational costs, and upholding rigorous standards of safety and efficiency across diverse applications. The detailed discussions elucidate how each element impacts performance and user satisfaction, providing actionable insights for informed decision-making.

Introduction

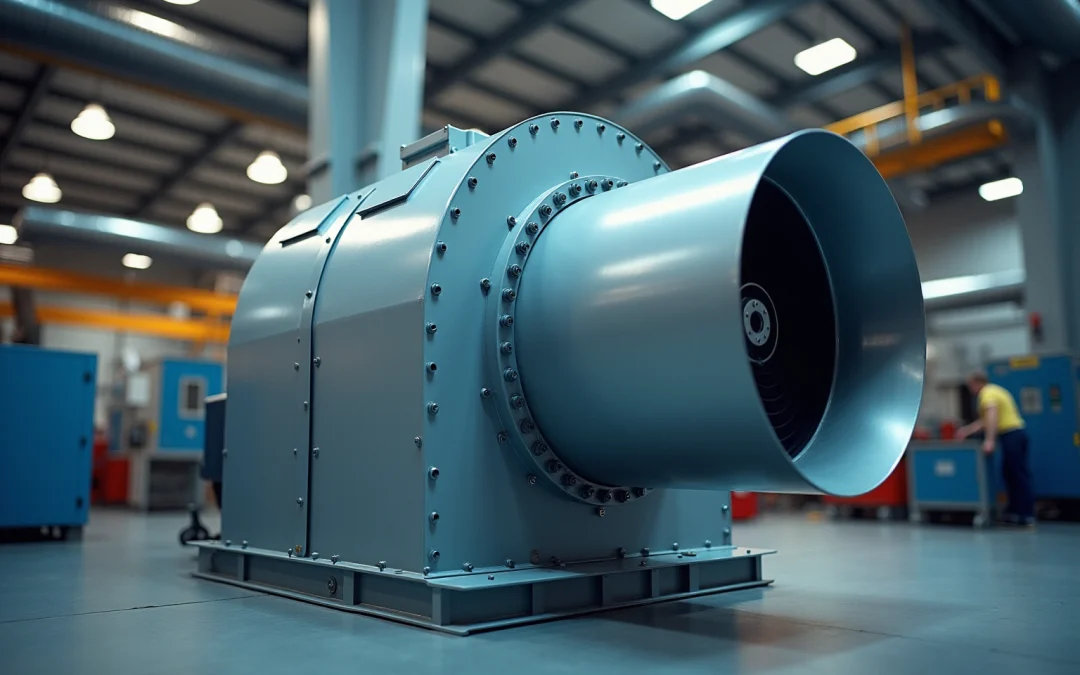

Large blower fans are essential for maintaining optimal airflow and temperature control across various industries, including data centers and manufacturing facilities. Their effectiveness relies on several critical features that not only enhance efficiency but also contribute to substantial energy savings and prolonged operational longevity.

However, with numerous options available, navigating the complexities of selecting the right blower fan can be challenging. This article explores nine fundamental characteristics that define large blower fans, offering insights that empower engineers and facility managers to make informed decisions for superior cooling solutions.

Gagner-Toomey Associates: Innovative Cooling Solutions for Large Blower Fans

Gagner-Toomey Associates excels in delivering innovative refrigeration solutions specifically designed for large blower fans. As the world’s largest manufacturer of standard and custom air movers, Gagner-Toomey seamlessly merges advanced technology with a profound understanding of the electronics sector, ensuring their products consistently surpass industry benchmarks. Their extensive portfolio features DC input tube axial units and centrifugal devices, optimized for performance, efficiency, and low noise, making them indispensable for various applications, including industrial ventilation and HVAC systems.

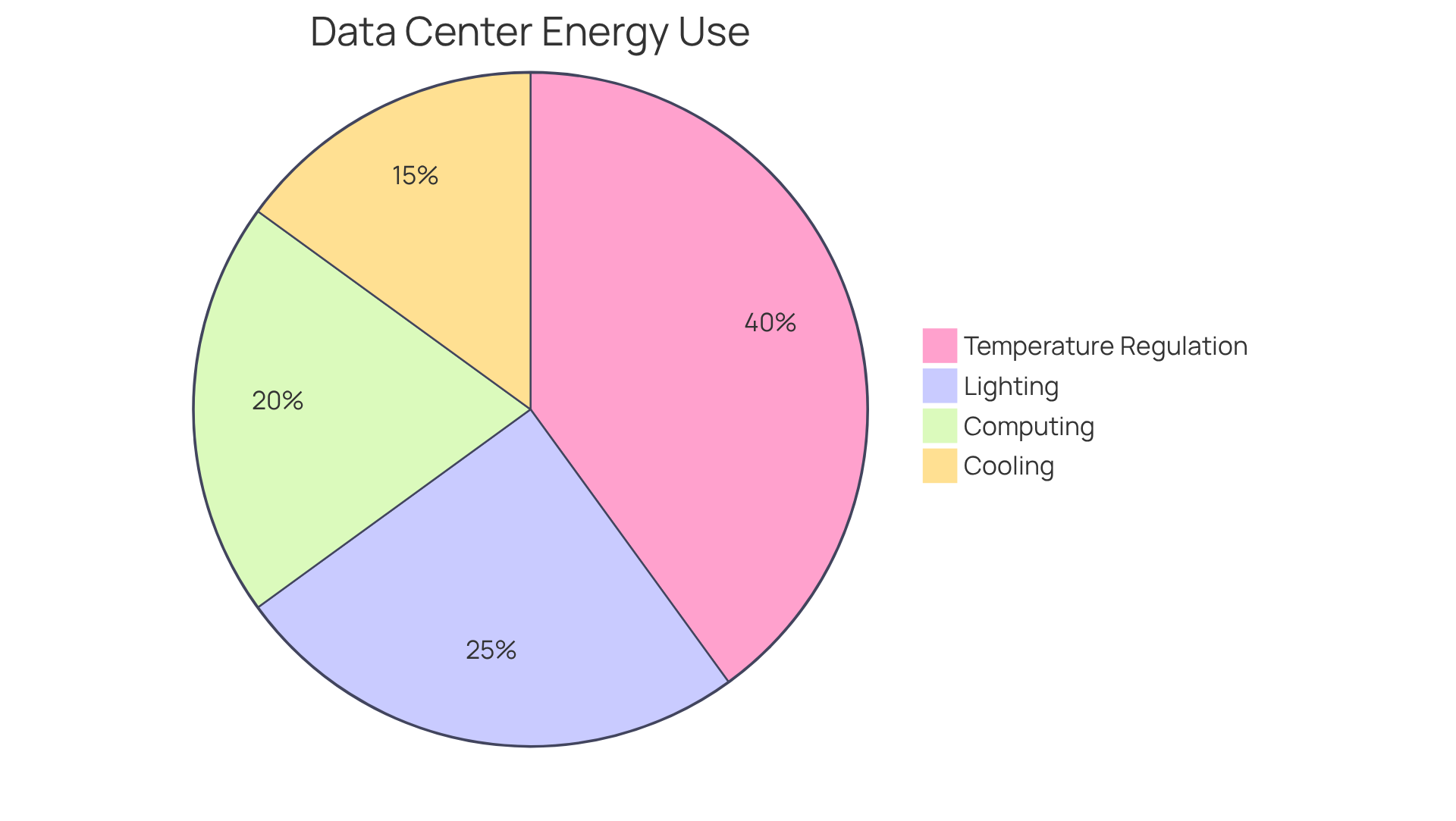

Large ventilation units are crucial for sustaining optimal airflow and thermal management in electronics. Efficient designs adeptly manage substantial heat loads while enhancing energy efficiency. Notably, statistics indicate that temperature regulation can account for up to 40% of a data center’s total energy consumption, and projections suggest that global energy use for temperature regulation could more than double by 2030. This underscores the urgent need for .

Successful applications of these devices in industrial environments have demonstrated significant energy savings and improved operational efficiency, aligning with the increasing market demand for energy-efficient solutions. Furthermore, models representing 75% of all GFB shipments will require remodeling within the next five years to comply with evolving standards, emphasizing the necessity for ongoing innovation in temperature management technologies.

As highlighted by industry specialist Snehal Singh, ‘The demand for energy-efficient industrial air circulators is rising because these devices assist in regulating airflow, eliminating impurities, and enhancing the temperature regulation process.

Airflow Capacity: Essential for Optimal Performance

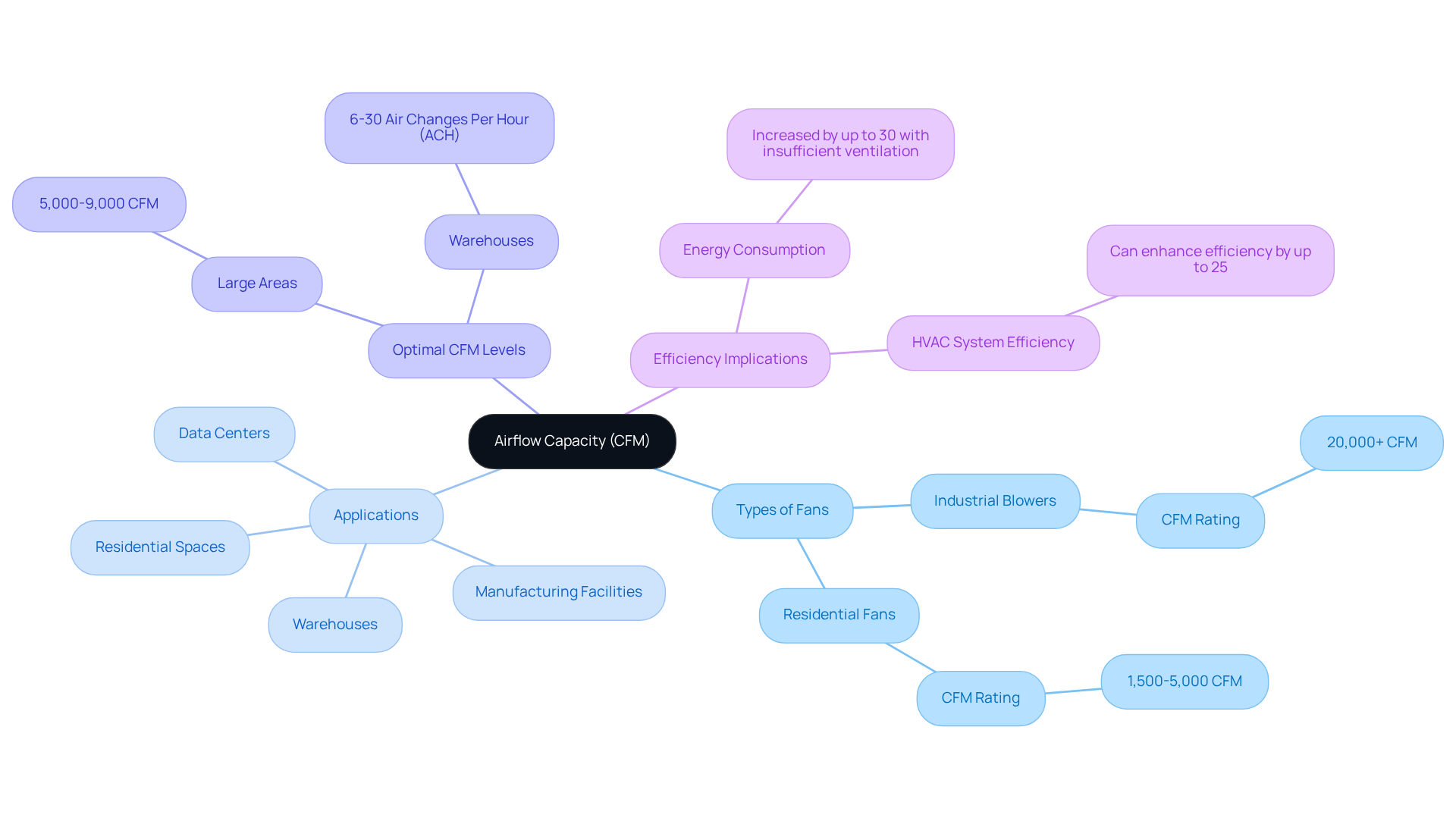

Airflow capacity, quantified in cubic feet per minute (CFM), is a pivotal characteristic of large blower fans, significantly influencing their effectiveness in cooling applications. Gagner-Toomey Associates, recognized as the world’s largest producer of both standard and custom air-movers, presents an extensive array of blower units meticulously optimized for performance, efficiency, and minimal noise. A higher CFM rating is indicative of the fan’s capacity to displace greater volumes of air, a critical factor for effective heat dissipation. This capability not only mitigates the risk of overheating but also considerably enhances the lifespan of electronic components.

For instance, industrial blowers can surpass 20,000 CFM, rendering them ideal for expansive environments such as manufacturing facilities and data centers, where the maintenance of optimal temperatures is paramount. In contrast, residential fans typically operate within a range of 1,500 to 5,000 CFM, making them suitable for smaller spaces. Selecting a fan with an appropriate CFM rating tailored to the specific temperature regulation needs of an application is essential for ensuring efficient operation and prolonging the lifespan of sensitive electronic devices.

Understanding the significance of airflow capacity empowers engineers to make informed decisions that improve cooling systems and elevate overall efficiency. For areas exceeding 450 square feet, CFM requirements generally span from 5,000 to 9,000, while warehouses necessitate between 6 and 30 Air Changes Per Hour (ACH), contingent upon their dimensions. Moreover, the P12 Max fan from Gagner-Toomey is equipped with dynamic speed adjustment via PWM, facilitating quiet operation during idle periods, exemplifying how technology can optimize airflow management.

Upholding can enhance HVAC system efficiency by as much as 25%, whereas inadequate ventilation can lead to increased energy consumption of up to 30%, highlighting the broader ramifications of airflow capacity on energy usage and operational expenditures.

Energy Efficiency: Key to Cost-Effective Operation

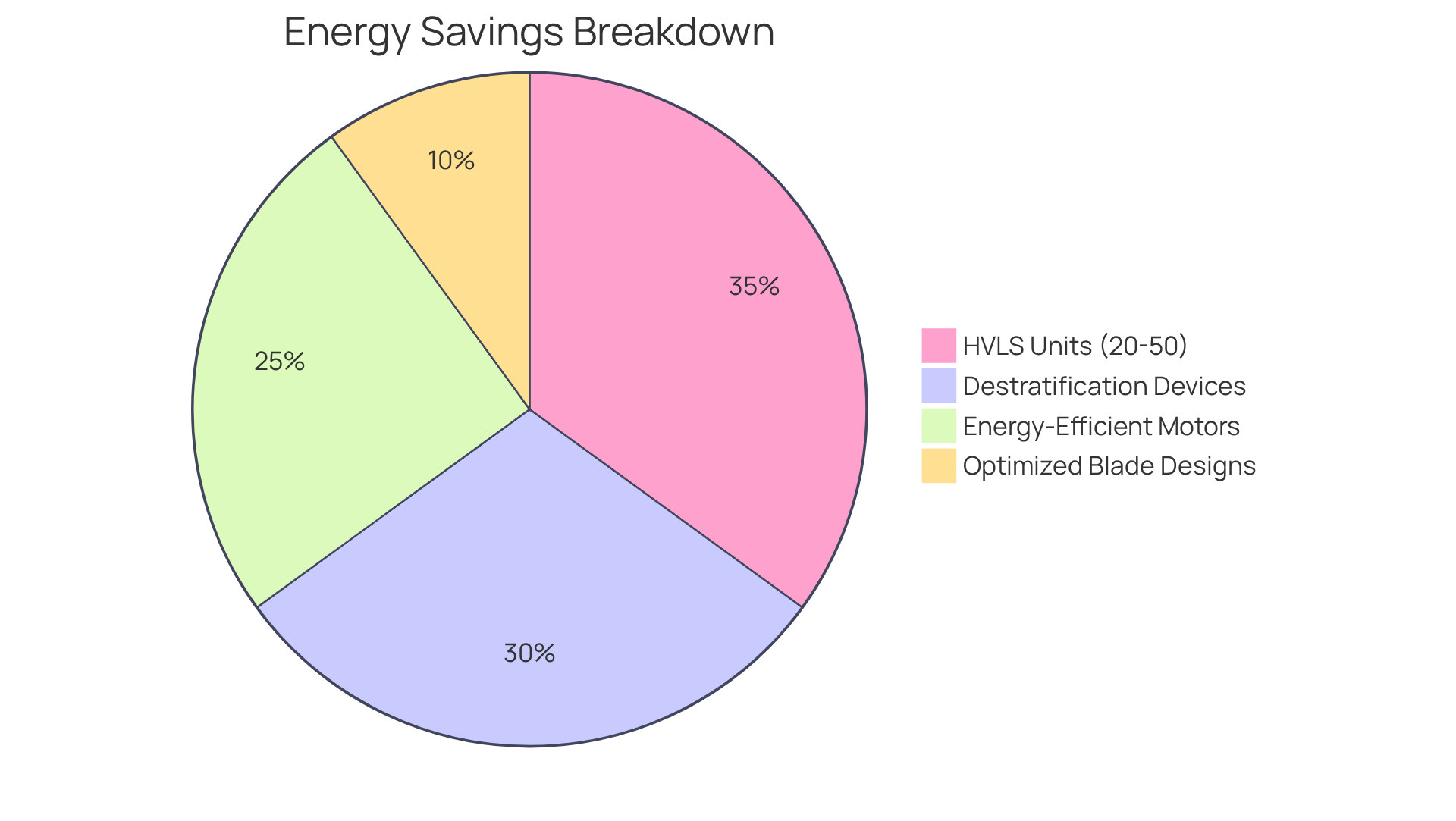

Energy efficiency stands as a pivotal element in the operation of a large blower fan, profoundly impacting both operational costs and environmental sustainability. Fans that incorporate energy-efficient motors and optimized blade designs are capable of significantly reducing power consumption while preserving or even improving airflow performance. This enhanced efficiency leads to ; research indicates that power usage can decrease by as much as 30% compared to conventional models, thereby reducing the carbon footprint associated with temperature regulation.

For instance, organizations utilizing high-volume, low-speed (HVLS) units can achieve energy savings ranging from 20% to 50% on cooling expenses, with a typical payback period of merely 12 to 24 months. Furthermore, destratification devices have the potential to save companies up to 30% on heating costs by efficiently redistributing warm air from the ceiling to occupied areas.

By committing to energy-efficient ventilation devices, such as a large blower fan, organizations not only secure substantial long-term savings but also contribute to the creation of a more sustainable future.

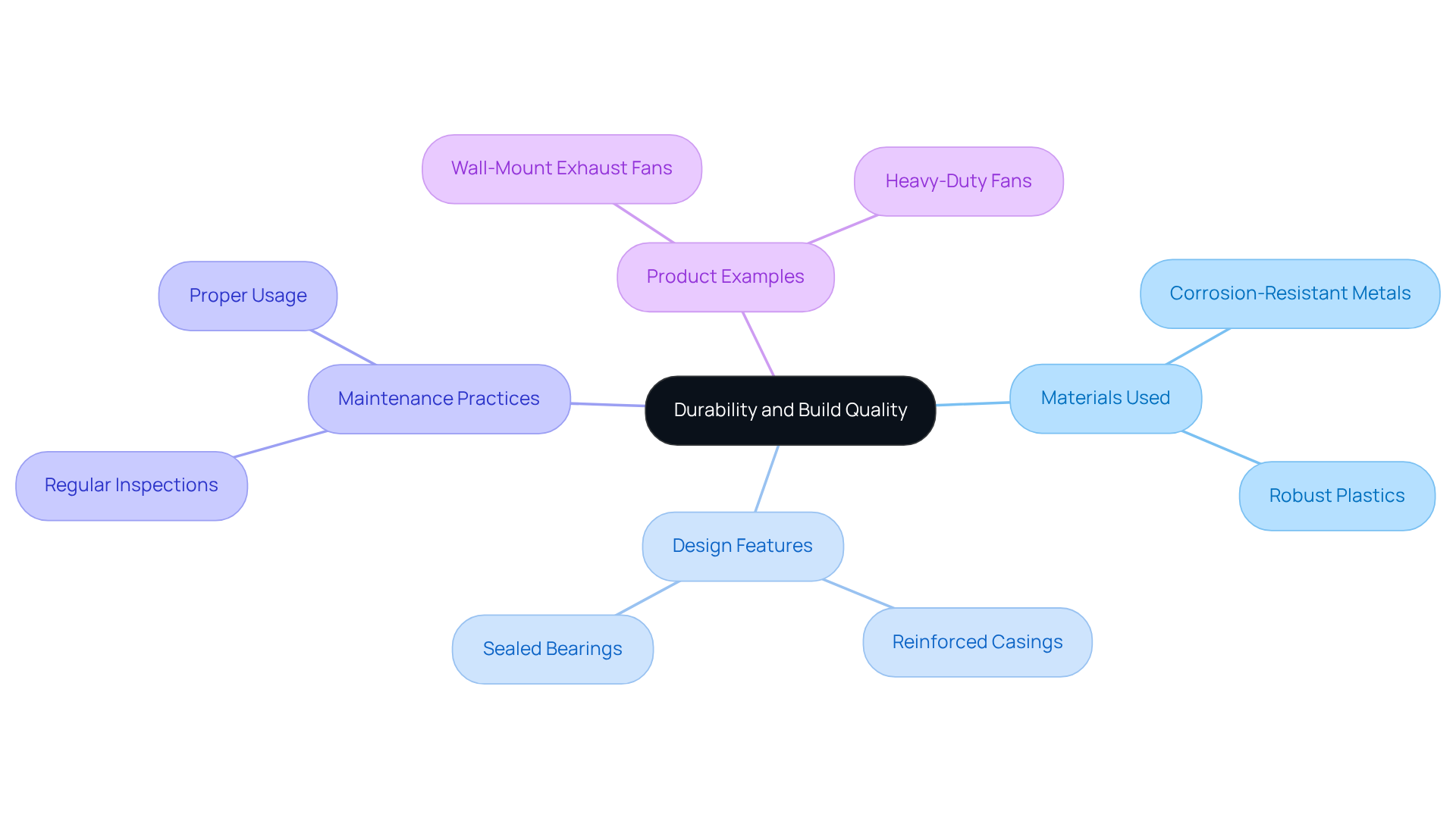

Durability and Build Quality: Ensuring Longevity

The of large blower fans are critical factors in determining their lifespan and reliability. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, guarantees that its devices are crafted from high-quality materials, including corrosion-resistant metals and robust plastics, specifically designed to endure the demanding conditions of industrial environments.

For example, heavy-gauge steel and aluminum casings not only provide structural integrity but also resist environmental factors that could impair performance. Key characteristics such as reinforced casings and sealed bearings play a vital role in protecting against dust and moisture, significantly extending the operational lifespan of these devices.

Statistics reveal that industrial fans can last anywhere from 10 to 25 years, contingent upon design and operational conditions, while the high-quality bearings in Gagner-Toomey Associates’ industrial fans can achieve service lives surpassing 50,000 hours, highlighting the critical importance of material selection.

Regular inspections, proper maintenance, and appropriate usage are essential for maximizing longevity. Selecting high-quality air circulators ensures consistent functionality and diminishes the need for replacements, ultimately yielding cost savings and enhancing operational efficiency.

Notable examples of high-quality ventilation devices from Gagner-Toomey Associates include wall-mount exhaust units, frequently employed in warehouses and manufacturing plants, which provide effective ventilation and improve indoor air quality.

By prioritizing build quality, engineers should opt for a large blower fan made from superior materials and establish regular maintenance schedules to ensure optimal performance.

Noise Levels: Critical for Quiet Operation

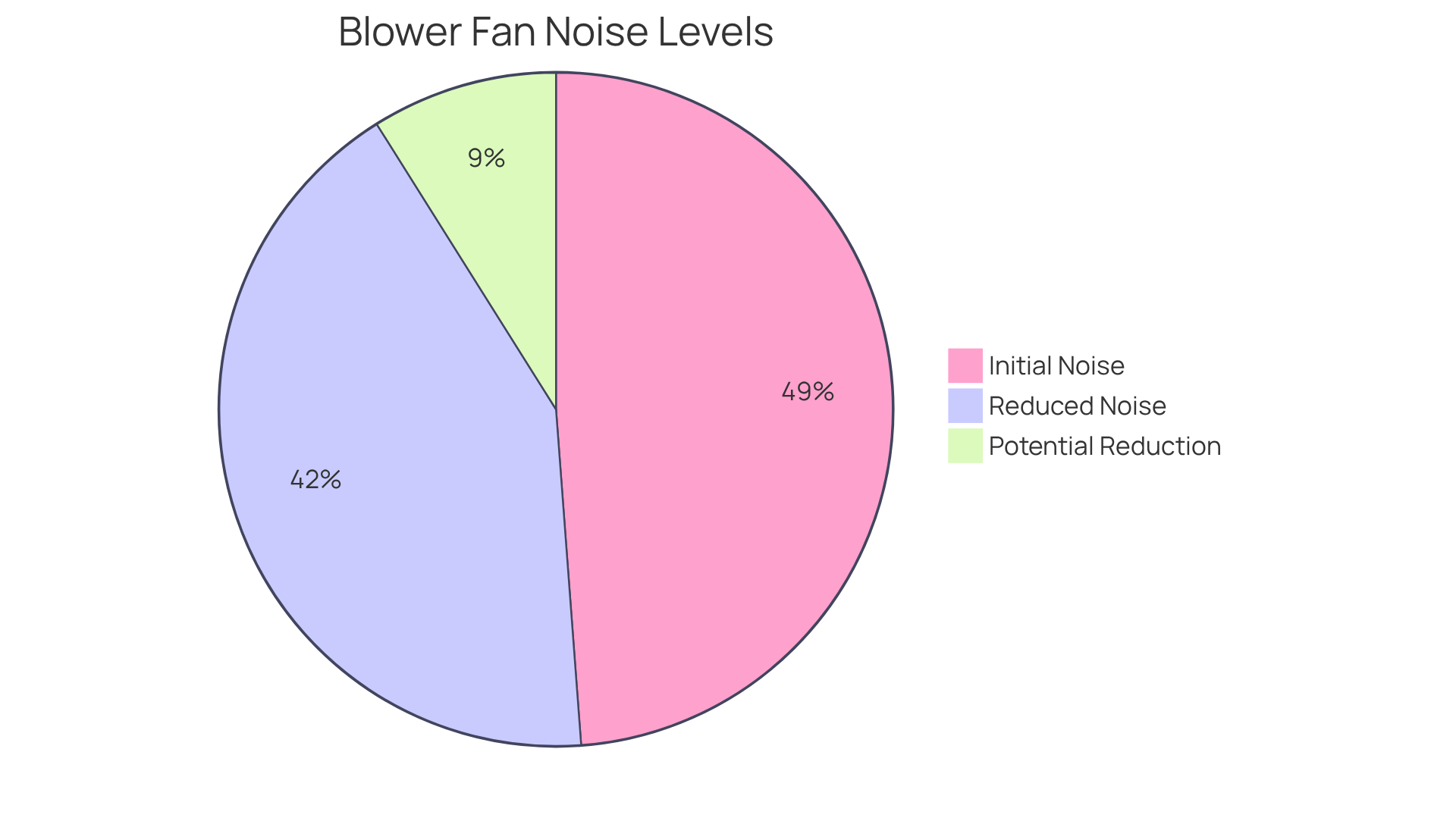

Noise levels generated by large blower fans pose a significant challenge to the comfort of their operating environments. Fans equipped with advanced noise reduction technologies, including sound-dampening materials and optimized blade designs, can achieve considerably lower decibel levels. For instance, a Qatar client successfully reduced warehouse fan noise from 82 dB to 71 dB by implementing innovative housing designs, resulting in a noise reduction exceeding 2 dB(A). This enhancement not only improves airflow but also minimizes user discomfort, which is particularly crucial in sensitive settings such as offices, hospitals, and residential areas, where and adversely affect well-being.

Research indicates that proper installation and maintenance can further decrease noise levels by 10-15 decibels. As sound engineering professionals emphasize, “Proper installation and maintenance can reduce noise by 10-15 decibels.” Therefore, when making a selection, it is essential to consider the noise rating of a large blower fan. Additionally, sound engineering experts note, “The key factor affecting fan noise under normal working conditions is the shape design of the impeller,” underscoring the importance of thoughtful design in achieving quiet operation.

Moreover, it is vital to recognize the broader implications of noise reduction, as excessive noise can negatively impact children’s cognitive development and pose long-term health risks.

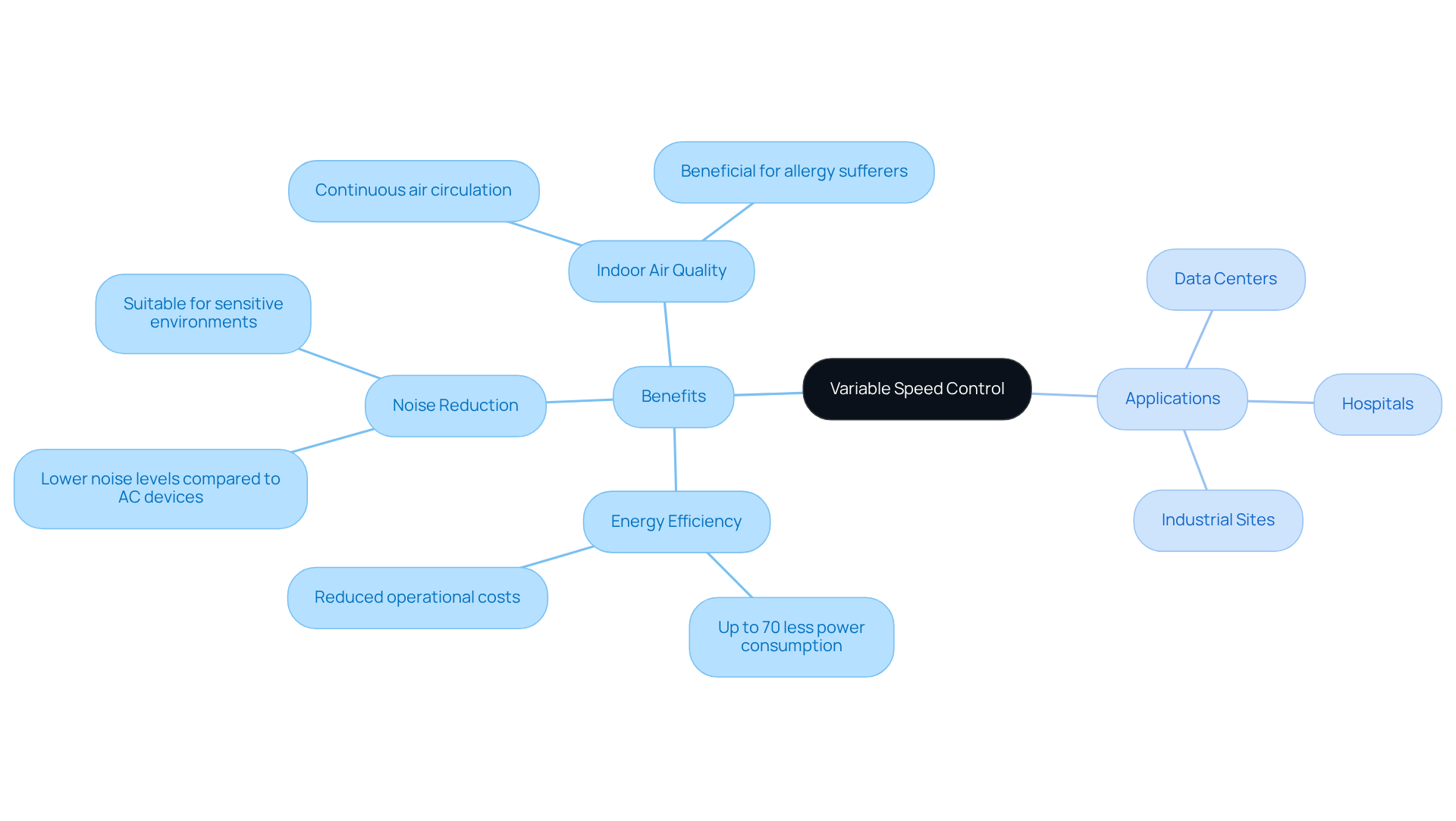

Variable Speed Control: Enhancing Operational Flexibility

Variable speed control is a crucial feature in large blower fans, allowing users to adjust the fan’s speed to satisfy specific temperature requirements. This adaptability significantly enhances energy efficiency and optimizes the performance of temperature control systems. By operating at reduced speeds during times of lower demand, users can realize substantial energy savings—blower DC devices can consume up to 70% less power than traditional AC devices—while simultaneously minimizing noise levels.

Large blower fans equipped with adjustable speed capabilities are particularly beneficial in environments where cooling needs vary, such as:

- Data centers

- Hospitals

- Industrial sites

This ensures optimal operation and consistent air circulation. This technology not only enhances indoor air quality, aiding allergy sufferers through continuous air circulation and filtration, but also bolsters energy conservation efforts, making it an indispensable consideration for contemporary electronic applications.

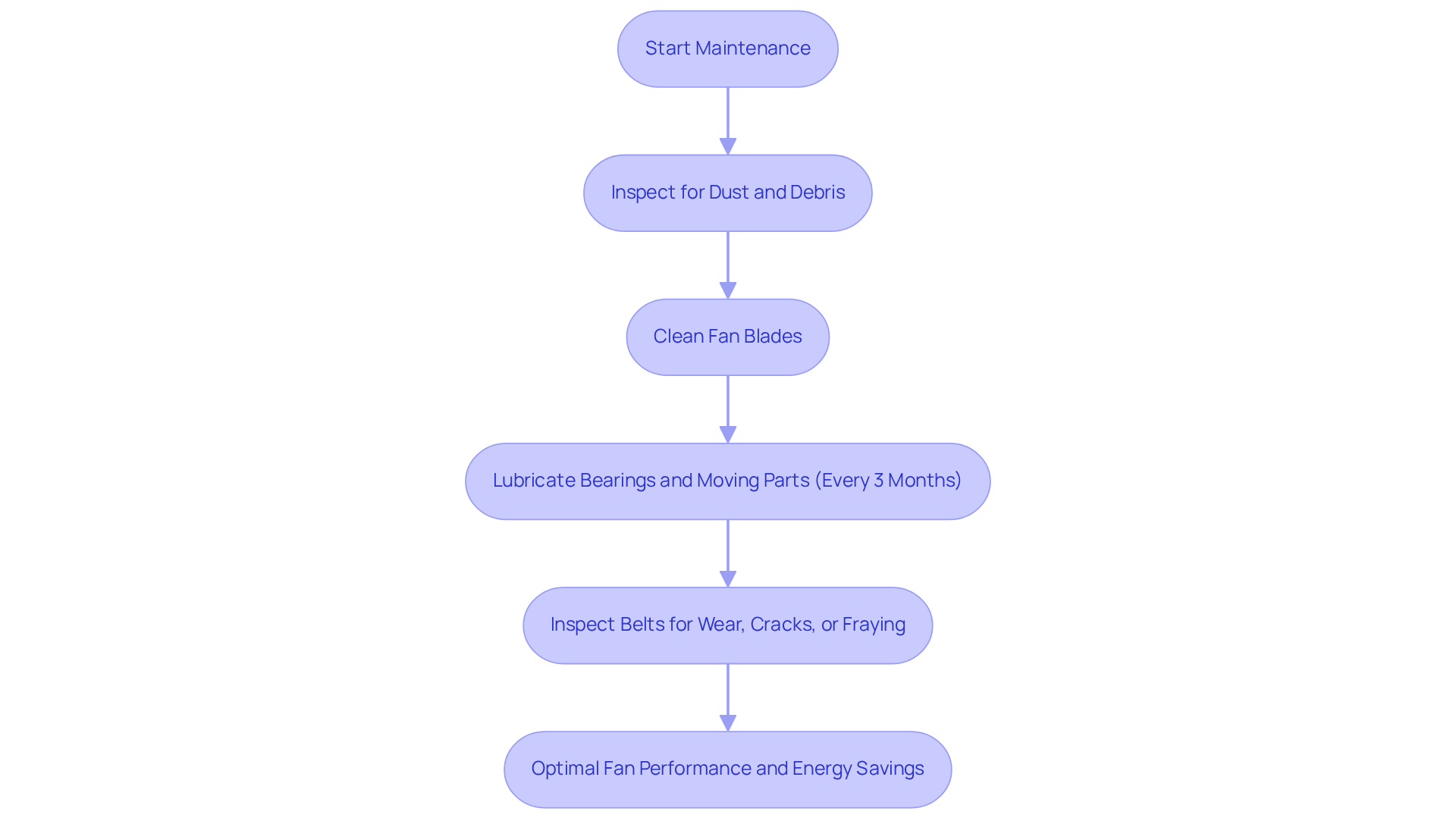

Ease of Maintenance: Simplifying Upkeep

The simplicity of is a critical consideration when selecting a large blower fan. Models engineered with accessible components, such as removable covers and easily replaceable filters, greatly facilitate routine maintenance. Regular upkeep, including thorough cleaning and inspections, is vital for ensuring optimal performance and extending the fan’s lifespan.

For example, proper lubrication of bearings and moving parts should be conducted every three months or as specified by the manufacturer to minimize friction and avert wear. Moreover, frequent checks for dust and debris are essential; dust accumulation on fan blades can elevate torque and obstruct airflow, resulting in increased energy consumption.

By prioritizing ventilation systems that allow for easy maintenance, users can minimize downtime and lower the total cost of ownership. As maintenance professionals underscore, a proactive approach to upkeep not only bolsters operational reliability but also fosters energy savings and mitigates environmental impact. Regular maintenance can yield significant savings on repairs or replacements, making it a strategic investment in operational efficiency.

Furthermore, it is crucial to routinely inspect belts for wear, cracks, or fraying to guarantee the fan operates smoothly.

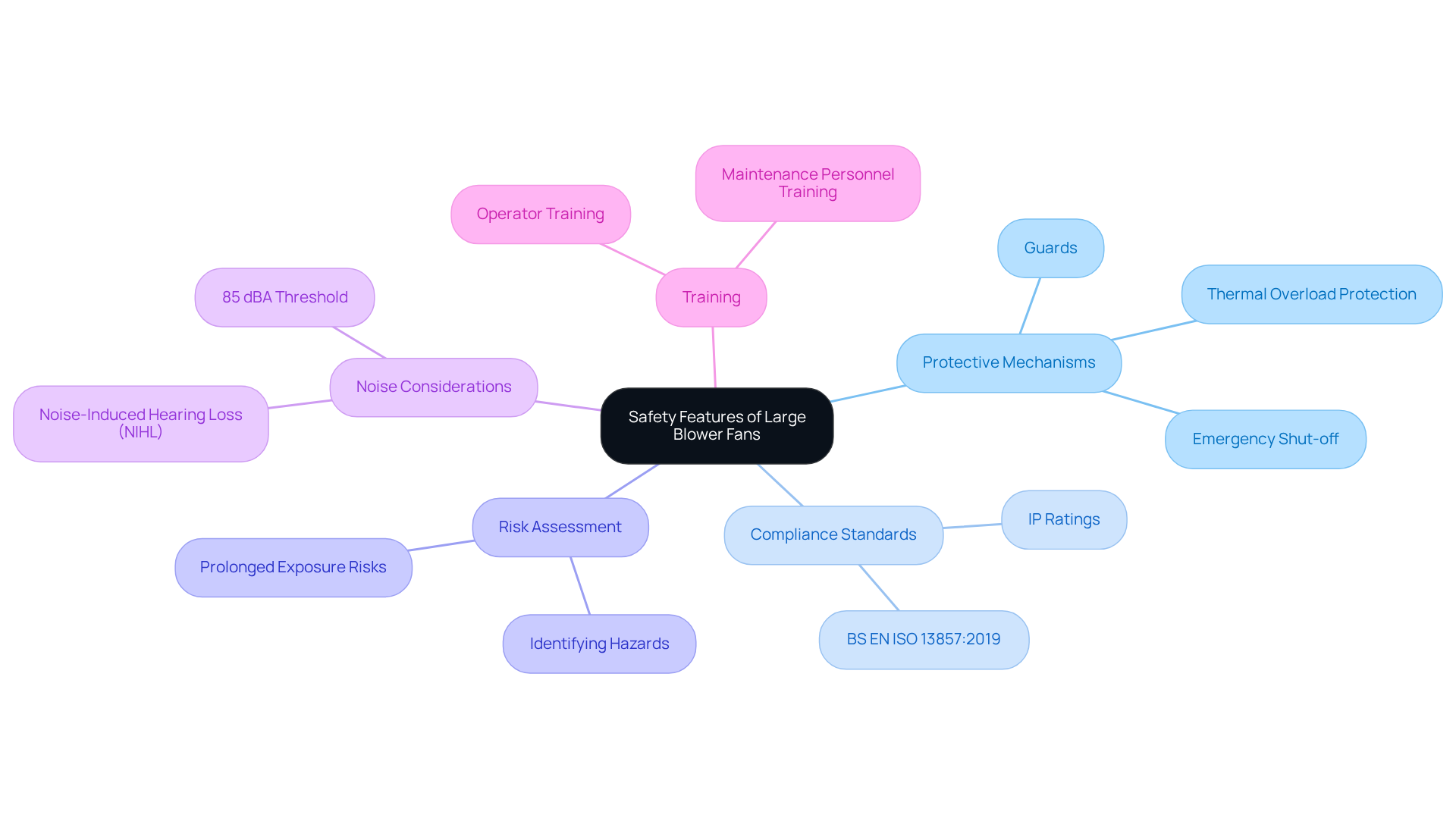

Safety Features: Protecting Users and Ensuring Compliance

Safety attributes in large blower fans are essential for safeguarding users and ensuring adherence to industry standards. Protective mechanisms, including guards, thermal overload protection, and emergency shut-off switches, are pivotal in preventing accidents and reducing injuries, thus cultivating a safer workplace for operators.

For example, the installation of appropriate guards can significantly diminish the risks posed by fast-spinning impeller blades and other moving components. Moreover, compliance with safety standards, such as BS EN ISO 13857:2019, which outlines guidelines for assessing and minimizing the risk of crushing or shearing hazards related to machinery, not only protects employees but also boosts operational efficiency.

Conducting a comprehensive risk assessment is vital to identify potential hazards associated with rotating blades, belts, and shafts. Additionally, prolonged exposure to elevated noise levels can lead to noise-induced hearing loss (NIHL), underscoring the importance of considering noise levels as a safety factor in fan operation.

Training operators and maintenance personnel to recognize the risks associated with rotating components is crucial for fostering a culture of safety. When selecting a ventilation device, it is imperative to , including verifying that the large blower fan units meet specific IP (Ingress Protection) ratings to indicate their level of protection against dust and water intrusion.

This holistic approach not only contributes to a secure operating environment but also enhances the overall safety culture within the organization.

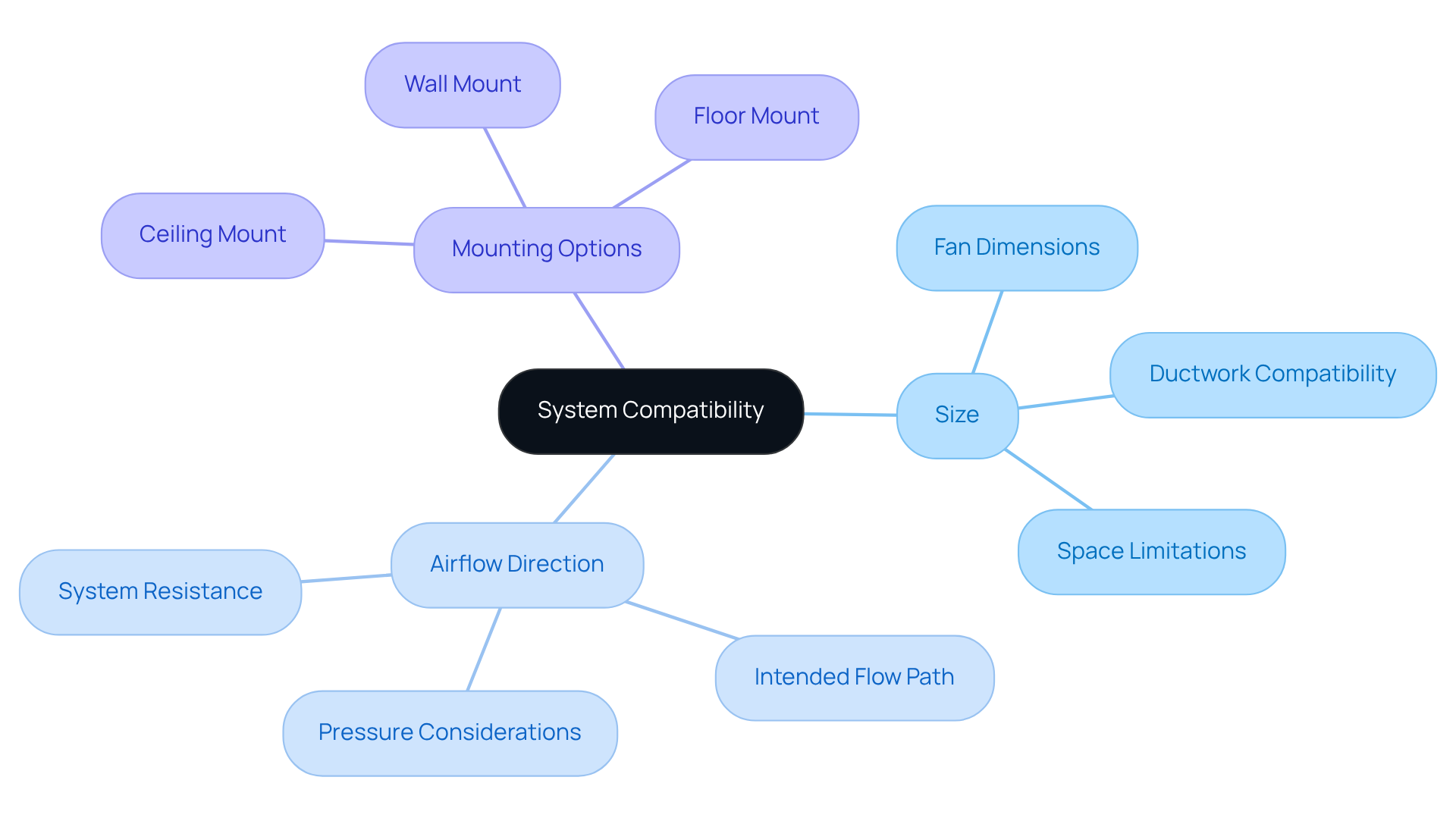

System Compatibility: Ensuring Seamless Integration

Ensuring system compatibility is paramount when selecting a large blower fan, as it profoundly impacts the operation and efficiency of the cooling system. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive array of DC input tube axial devices and centrifugal air movement equipment tailored for diverse applications, including electronics and automotive sectors.

Fans must seamlessly align with existing ductwork, control systems, and other components to function effectively. Key considerations for the large blower fan encompass:

- Size

- Airflow direction

- Mounting options

All of which are critical for smooth integration into the current setup. This compatibility not only but also streamlines installation, thereby minimizing potential issues. Engineers have observed that integrating Gagner-Toomey Associates’ fans into existing systems can lead to significant improvements in airflow and cooling effectiveness, underscoring the importance of meticulous selection and planning in achieving optimal outcomes.

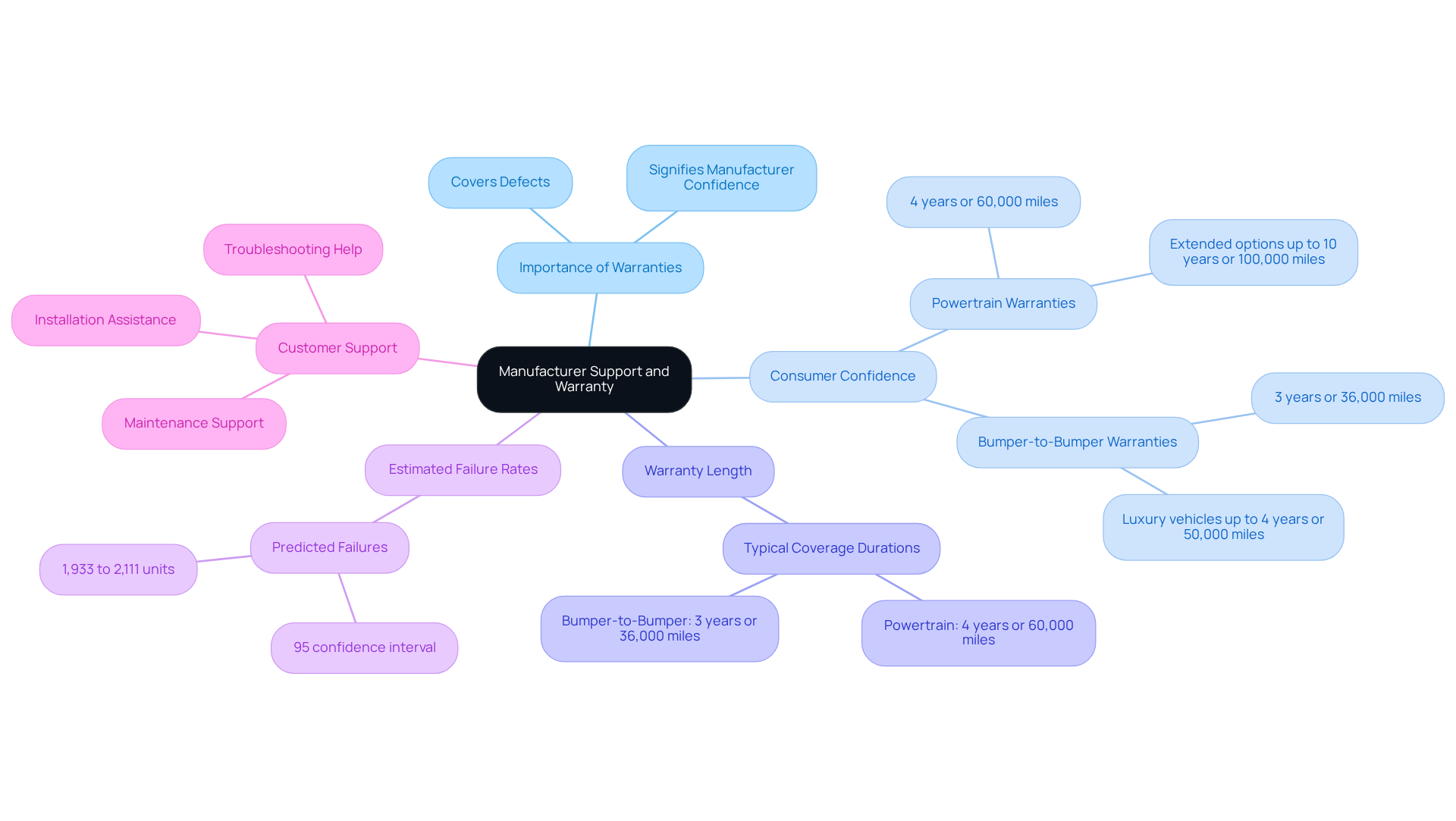

Manufacturer Support and Warranty: Assurance of Quality

Selecting a large ventilation fan from a reputable manufacturer, known for robust support and warranty options, is crucial for ensuring product reliability and customer satisfaction. A comprehensive warranty not only provides peace of mind by covering potential defects and performance issues but also signifies the manufacturer’s confidence in their product.

For example, powertrain warranties typically extend for four years or 60,000 miles, offering substantial protection for critical components, which in turn bolsters consumer confidence. Furthermore, the estimated failure rate for fan units ranges from 1,933 to 2,111 units with 95% confidence, underscoring the importance of warranties in safeguarding investments.

Effective customer support is integral to enhancing the user experience, assisting with installation, maintenance, and troubleshooting. As Henry Ford articulated, “Quality means doing it right when no one is looking,” a sentiment that resonates with the necessity for reliable products.

When selecting a large blower fan, it is imperative to assess the alongside the breadth of their support services. This strategic approach not only protects your investment but also ensures optimal performance and longevity of the fan.

Conclusion

The significance of large blower fans in optimizing airflow and enhancing temperature regulation is paramount. These devices are crucial for maintaining efficiency across various industrial applications, particularly in environments where effective heat management is essential. By integrating advanced technologies and innovative designs, large blower fans not only elevate operational performance but also contribute to substantial energy savings and sustainability.

Key features include:

- Airflow capacity

- Energy efficiency

- Durability

- Noise reduction

- Variable speed control

- Ease of maintenance

- Safety attributes

- System compatibility

- Manufacturer support

Each of these elements plays a vital role in ensuring that large blower fans operate effectively and efficiently, ultimately resulting in lower operational costs and improved user comfort.

As organizations increasingly prioritize energy efficiency and operational reliability, investing in high-quality large blower fans becomes indispensable. By selecting models that incorporate the latest advancements in technology and adhering to best practices in maintenance and safety, users can significantly enhance the performance of their cooling systems while also supporting broader environmental goals. Embracing these innovations is not merely a choice; it is an essential step towards achieving optimal performance in today’s demanding industrial landscape.

Frequently Asked Questions

What types of cooling solutions does Gagner-Toomey Associates provide?

Gagner-Toomey Associates specializes in innovative refrigeration solutions for large blower fans, offering both standard and custom air movers optimized for performance, efficiency, and low noise.

Why are large ventilation units important in electronics?

Large ventilation units are crucial for maintaining optimal airflow and thermal management in electronics, effectively managing substantial heat loads and enhancing energy efficiency.

How much energy consumption can temperature regulation account for in data centers?

Temperature regulation can account for up to 40% of a data center’s total energy consumption.

What is the significance of airflow capacity in large blower fans?

Airflow capacity, measured in cubic feet per minute (CFM), is essential for effective cooling applications, influencing the fan’s ability to displace air and mitigate overheating, thereby extending the lifespan of electronic components.

What are the typical CFM ratings for industrial and residential fans?

Industrial blowers can exceed 20,000 CFM, suitable for large environments, while residential fans typically operate between 1,500 to 5,000 CFM.

How does airflow capacity impact HVAC system efficiency?

Maintaining suitable CFM levels can enhance HVAC system efficiency by up to 25%, whereas inadequate ventilation can lead to increased energy consumption of up to 30%.

What role does energy efficiency play in the operation of large blower fans?

Energy efficiency is crucial as it significantly reduces operational costs and environmental impact, with energy-efficient fans capable of decreasing power consumption by up to 30% compared to conventional models.

What energy savings can organizations achieve with high-volume, low-speed (HVLS) units?

Organizations using HVLS units can achieve energy savings of 20% to 50% on cooling expenses, with a payback period of 12 to 24 months.

What benefits do destratification devices provide?

Destratification devices can save companies up to 30% on heating costs by efficiently redistributing warm air from the ceiling to occupied areas.