Overview

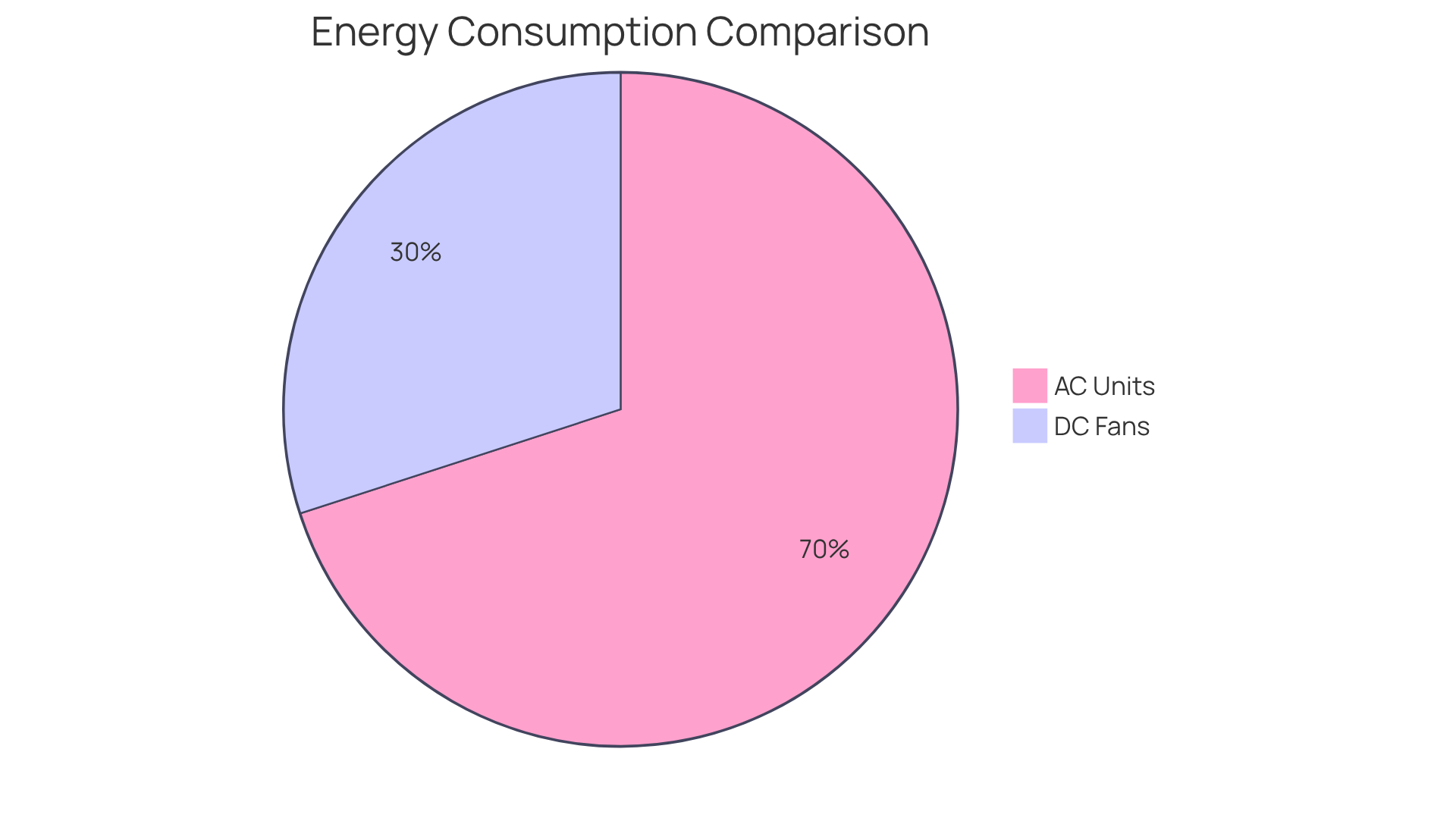

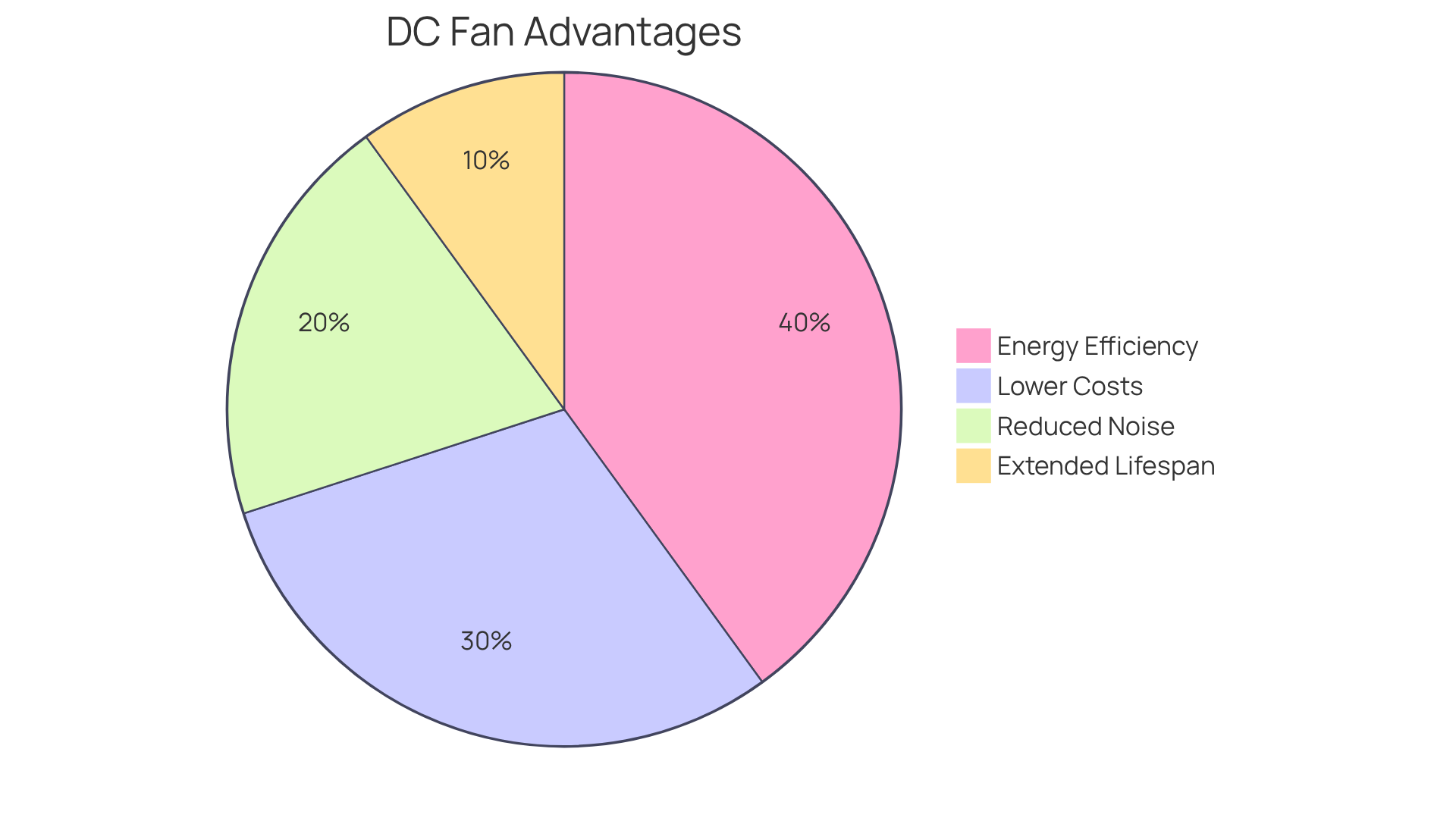

The primary advantages of utilizing DC cooling fans in electronics are their energy efficiency, variable speed control, low noise operation, durability, and versatility across diverse applications. Notably, DC fans consume up to 70% less power than their AC counterparts, which underscores their energy efficiency. Furthermore, these fans operate quietly, making them suitable for environments where noise reduction is critical. Their ability to provide tailored cooling solutions positions them as the ideal choice for modern electronic systems, effectively addressing the limitations of traditional cooling methods.

Introduction

DC cooling fans have emerged as a transformative force in the electronics industry, presenting substantial advantages over traditional AC models. Their capacity to consume up to 70% less energy not only leads to reduced operational costs but also fosters a more sustainable approach to thermal management.

As engineers confront the dual challenges of escalating energy demands and the necessity for quieter, more efficient systems, a critical question arises: how can DC cooling fans adeptly address these evolving requirements while ensuring reliability and performance across a diverse array of applications?

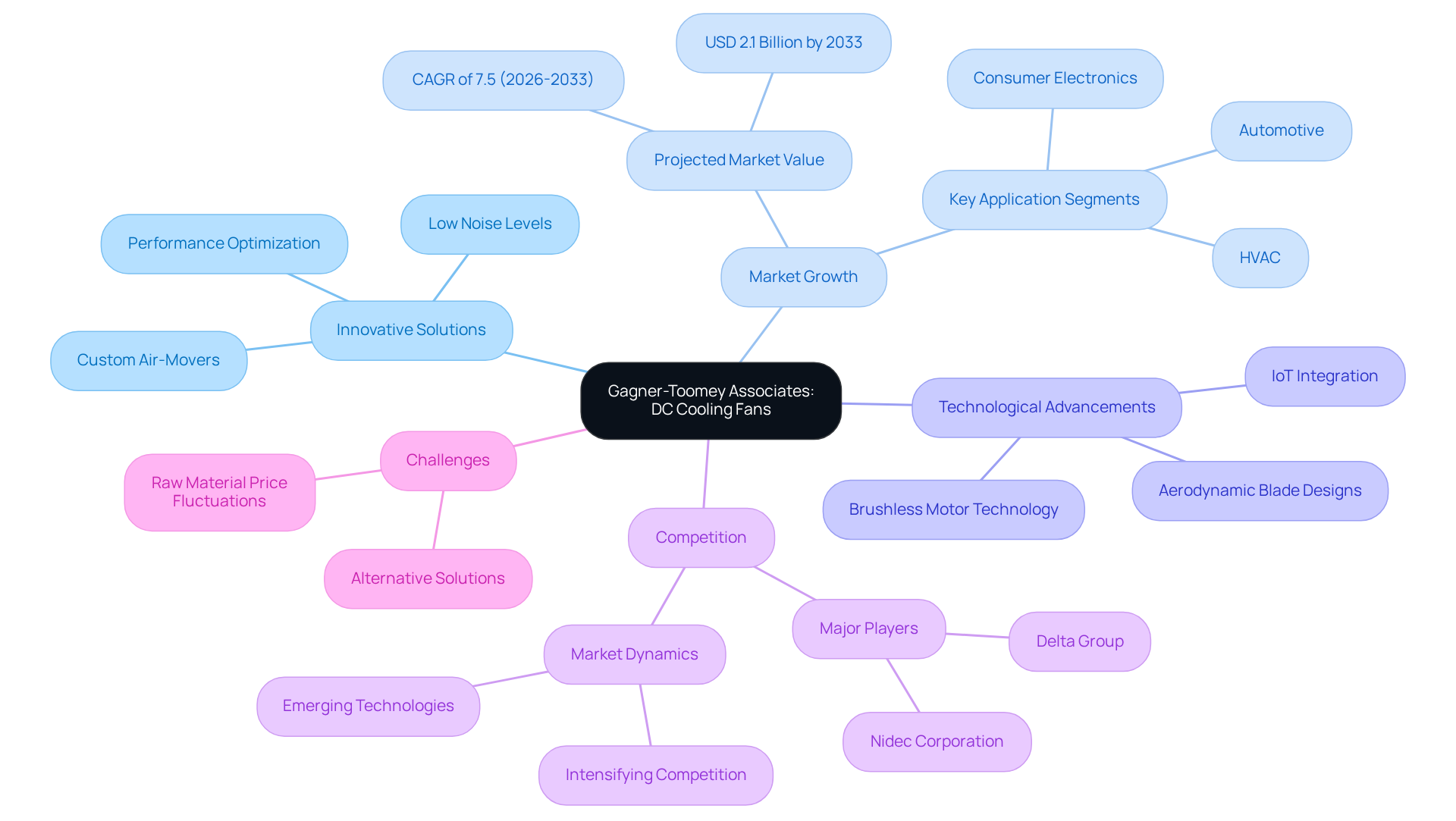

Gagner-Toomey Associates: Innovative Solutions for DC Cooling Fans

Gagner-Toomey Associates excels in delivering innovative solutions within the electronics sector, particularly in the realm of dc cooling fan technology. As the largest manufacturer globally of both standard and custom air-movers, Gagner-Toomey boasts a comprehensive portfolio that encompasses tube axial fans and centrifugal blowers, all meticulously optimized for performance, efficiency, and low noise levels. By representing a wide array of producers, they ensure engineers have access to cutting-edge technologies that enhance temperature regulation and overall performance.

Their unwavering commitment to excellence is reflected in their , which tackle the unique challenges engineers face across various applications, ranging from power management to RF technologies. Recent advancements in DC cooling fans, such as brushless motor technology and aerodynamic blade designs, are propelling market growth, facilitating quieter operations and improved thermal management. The market for DC cooling fans is poised to reach USD 2.1 billion by 2033, with a CAGR of 7.5% projected from 2026 to 2033, underscoring the increasing demand for energy-efficient temperature regulation solutions.

Moreover, the integration of IoT technologies and smart fan solutions is revolutionizing the industry, enabling enhanced monitoring and control capabilities. As competition intensifies, with prominent players such as Delta Group and Nidec Corporation leading the forefront, Gagner-Toomey Associates remains steadfast in equipping engineers with the essential tools to successfully implement these advanced technologies. Nonetheless, challenges persist, including competition from alternative temperature control solutions and fluctuations in raw material prices, which continue to influence market dynamics.

Energy Efficiency: Lower Power Consumption with DC Cooling Fans

DC ventilation devices are recognized for their remarkable energy efficiency, consuming up to 70% less power than conventional AC units. This significant reduction in power consumption not only results in but also promotes a more sustainable approach to cooling in electronic systems. The advanced brushless motor technology employed in DC devices minimizes energy loss, making them particularly suitable for energy-conscious applications. For instance, households that transition to DC devices can realize substantial savings over time, with some reports indicating reductions in energy expenses that can total hundreds of dollars annually. As Isaac Jamieson, founder of Tenmen Electrical, states, “DC devices use up to 70% less energy than their AC equivalents, making them an excellent choice for energy-conscious households.” This efficiency is further underscored by the fact that DC cooling fans can achieve the same airflow as AC motors while consuming considerably less energy, positioning them as an optimal choice for modern electronic cooling solutions. However, it is crucial to note that the installation of DC devices may necessitate a power converter, introducing some complexity compared to traditional AC setups. Moreover, although DC enthusiasts may encounter a higher upfront expense, their long-term savings and efficiency render them a valuable investment.

Key Benefits of DC Cooling Fans:

- Up to 70% less energy consumption compared to AC fans

- Significant long-term savings on electricity bills

- Advanced brushless motor technology for reduced energy loss

- Quieter operation, ideal for sensitive environments

- More advanced control options available

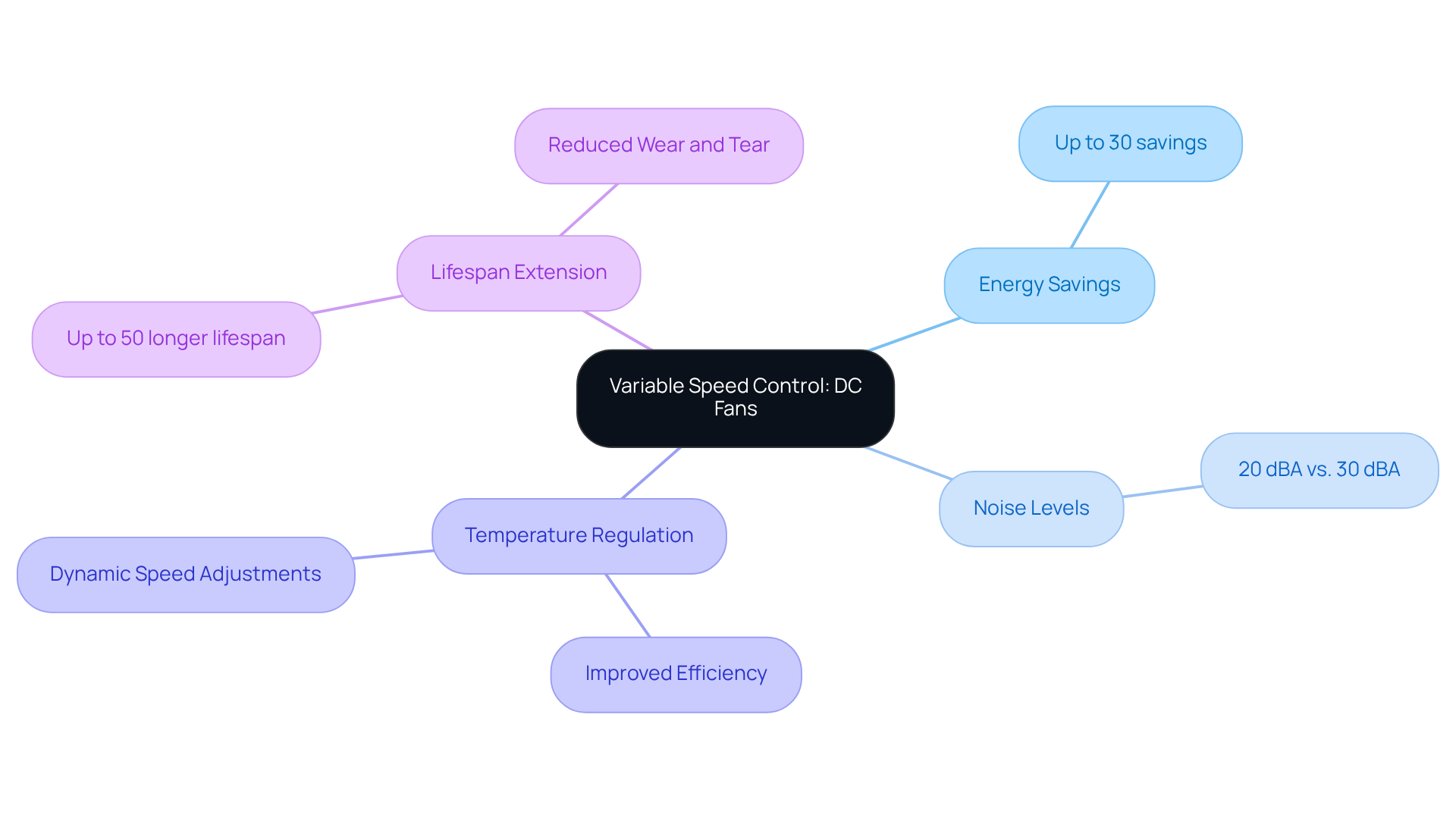

Variable Speed Control: Tailored Cooling Solutions with DC Fans

DC cooling fans are distinguished by their variable speed control, enabling engineers to adjust the cooling output to meet the exact thermal requirements of their systems. This capability facilitates meticulous adjustments in fan speed, optimizing both airflow and noise levels.

For example, PWM fan controllers can function at a mere 10% of peak speed, in stark contrast to conventional models that typically operate at a minimum of 50%. Such flexibility not only but also extends the lifespan of the devices, making them particularly advantageous in environments with frequent temperature fluctuations.

Notably, statistics indicate that employing variable speed DC devices can yield energy savings of up to 30% compared to traditional systems, rendering them an economical choice for modern electronic applications. Furthermore, PWM controllers for cooling can achieve noise levels as low as 20 dBA, significantly quieter than conventional models, which may surpass 30 dBA.

By fine-tuning fan speeds, engineers can markedly improve temperature regulation efficiency, diminish operational noise, and prolong the lifespan of electronic components, ultimately fostering more reliable and sustainable systems.

As Gagner Toomey aptly highlights, “PWM regulated blowers offer clear benefits compared to conventional units, positioning themselves as a vital option for modern electronic uses.

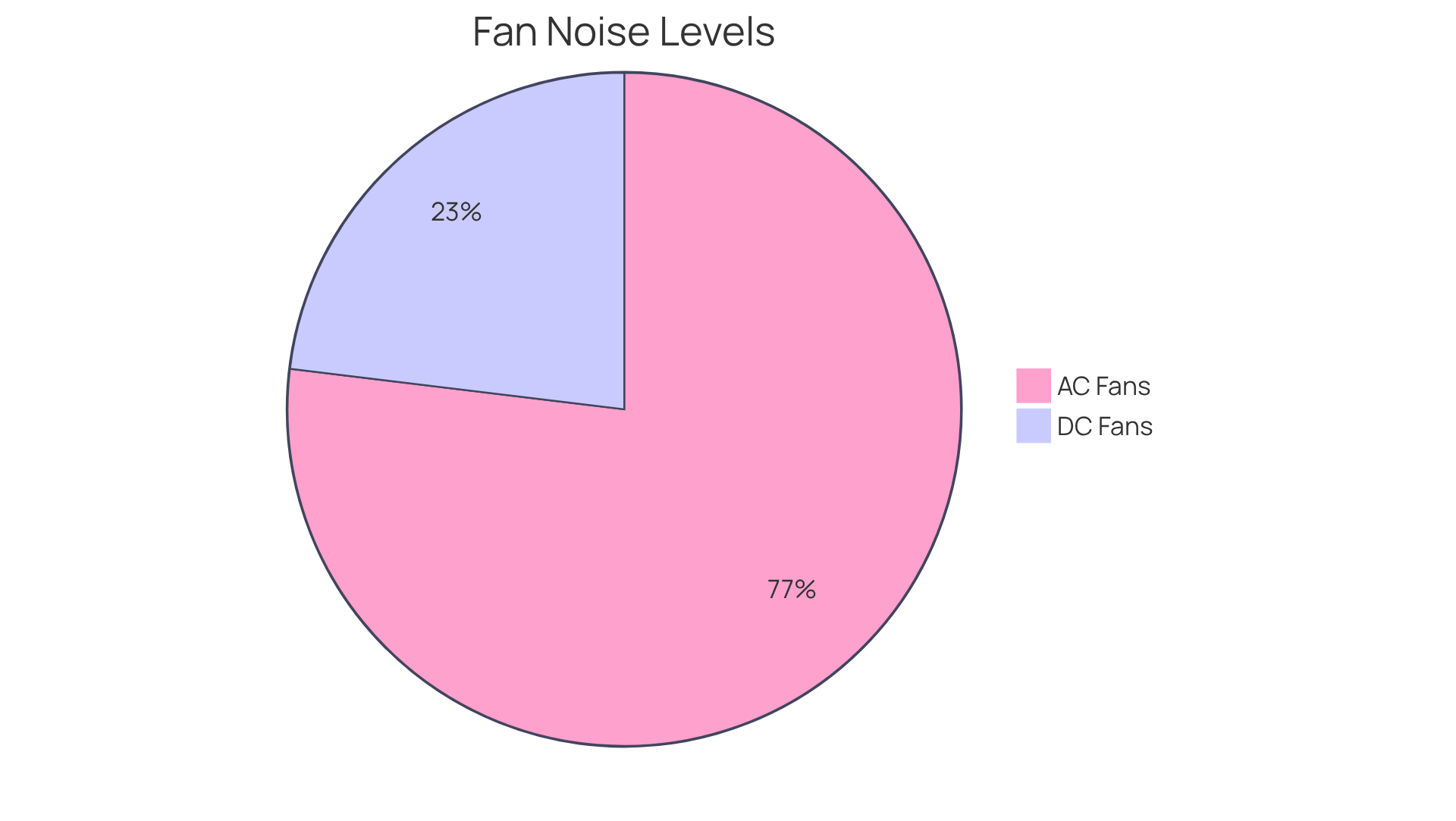

Low Noise Operation: Silent Performance of DC Cooling Fans

DC cooling fans are engineered for silent operation, making them ideal for environments where noise reduction is paramount. By utilizing advanced brushless motor technology, these devices markedly decrease operational noise compared to traditional AC models. This silent operation is especially advantageous in sensitive settings such as hospitals, data centers, and offices, where a is crucial for productivity and comfort. In fact, DC cooling fans can lower noise levels by as much as 70% compared to their AC counterparts, ensuring that electronic devices operate without disruptive sound.

As highlighted by EISKUHL, “We focus on producing high-quality DC axial devices and other advanced temperature control solutions, delivering efficient and dependable products for both the automotive and industrial sectors.” The ability of DC cooling fans to maintain low noise levels while effectively regulating temperature makes them a preferred choice for engineers seeking to enhance the performance of delicate electronic systems. Furthermore, DC devices offer superior control options, allowing for tailored temperature regulation that meets the specific demands of various applications.

Durability and Reliability: Robust Performance in Harsh Conditions

DC cooling fans from Gagner-Toomey Associates are engineered for durability, making them ideal for a variety of applications, particularly in industrial and outdoor settings. As the world’s leading producer of both standard and custom air-movers, Gagner-Toomey’s robust designs empower these devices to operate reliably under extreme temperatures, spanning from -40°C to 85°C, and in environments laden with dust and moisture. This durability is further augmented by features such as ball bearings and magnetic levitation bearings, which significantly extend their lifespan compared to conventional AC units. Under optimal conditions, the can reach up to 38,400 hours, whereas AC units generally fall short in terms of longevity and efficiency.

For example, a system deployed in Southeast Asia illustrated the effectiveness of Gagner-Toomey’s DC devices, functioning for over a decade without failure until corrosion issues arose due to environmental factors, including elevated levels of chlorine, potassium, and calcium in the dust. This underscores the importance of selecting devices with protective coatings, such as Pelgan Z, capable of safeguarding against corrosive elements and moisture. Moreover, the application of conformal coatings has been proven to significantly mitigate the risk of fan failure.

It is imperative to consider IP68 rated devices from Gagner-Toomey for extreme environments, as they offer complete protection against dust and water ingress. In summary, the integration of high-quality materials and advanced engineering in Gagner-Toomey’s DC cooling fan not only guarantees reliable performance but also leads to reduced maintenance costs, making it an exceptional choice for engineers in pursuit of long-term solutions.

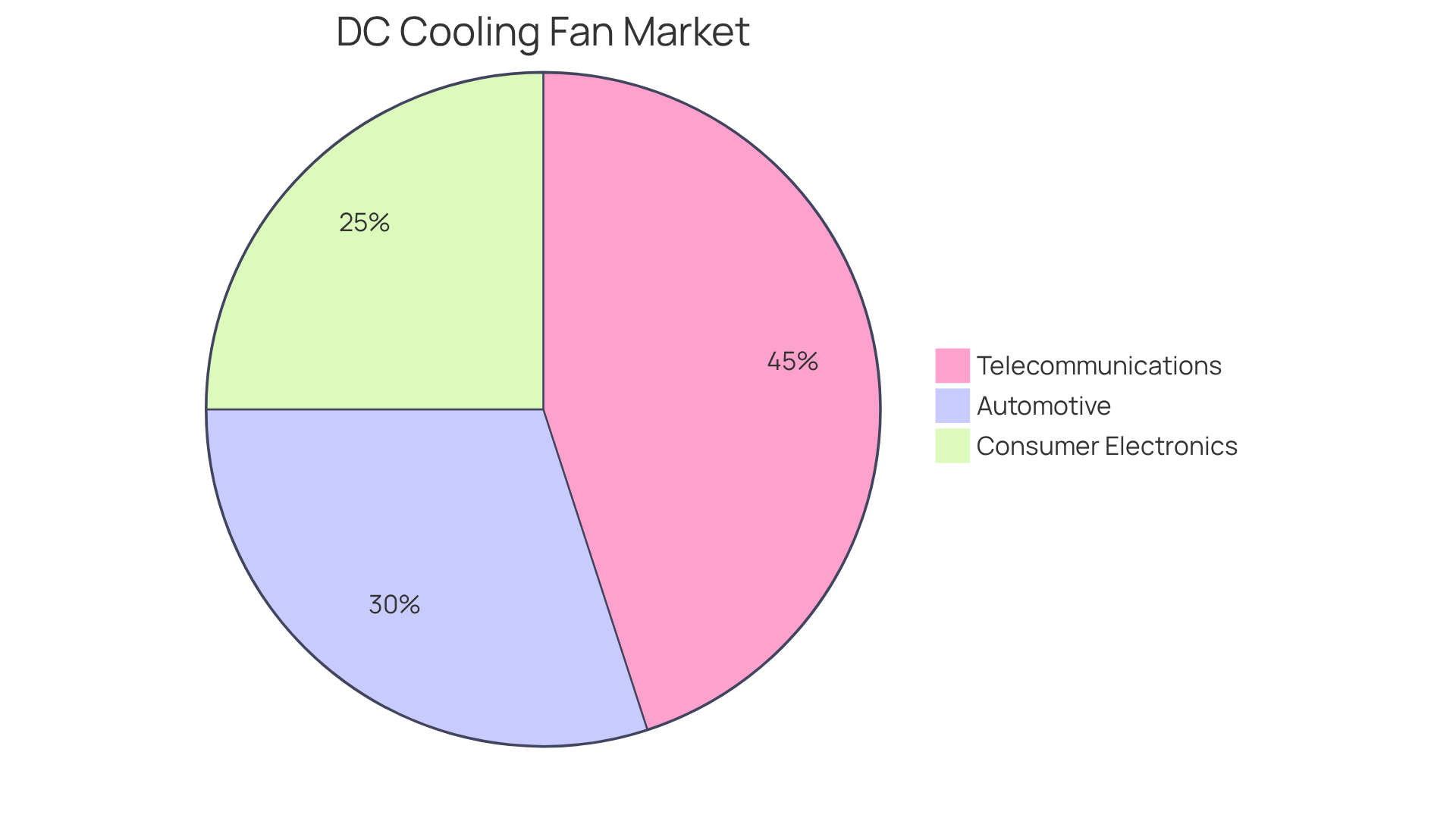

Versatile Applications: DC Cooling Fans Across Industries

DC ventilation units play a crucial role across various sectors, notably telecommunications, automotive, and consumer electronics. Their compact design and energy-efficient operation are particularly effective for temperature regulation in devices such as computers, servers, and medical equipment. In the telecommunications sector, DC devices are vital for maintaining optimal temperatures in network equipment, ensuring uninterrupted service delivery. Notably, the ICT sector represented 45% of the DC ventilation devices market in 2023, underscoring their essential function in this area.

The automotive industry also benefits significantly from direct current ventilation systems, especially with the rise of electric vehicles, where effective thermal regulation is critical for battery and power electronics performance. The DC cooling fan market is anticipated to grow from USD 1.2 billion in 2024 to USD 2.1 billion by 2033, reflecting the surging demand for these solutions. This adaptability allows engineers to employ DC motors for across diverse applications, addressing the escalating demands for energy efficiency and reliability.

DC vs. AC Fans: Understanding the Advantages of DC Cooling

When assessing cooling options, the advantages of DC models over AC variants become increasingly evident. DC cooling fans are recognized for their energy efficiency, consuming up to 70% less power than their AC counterparts for the same airflow output. Although DC models may entail a higher initial investment, their significantly reduced operational costs can lead to greater savings over time, with DC units costing approximately $3 in electricity compared to $10 for AC units. Furthermore, DC devices operate at lower voltages, with common models available at 5V, 12V, and 24V, enhancing safety and reducing the risk of electrical hazards.

The of DC units constitutes another compelling advantage. They utilize advanced brushless motor technology in their DC cooling fan, which minimizes noise, making it ideal for sensitive environments such as electronics and medical applications. Their design also contributes to a longer lifespan, decreasing maintenance requirements and bolstering overall reliability.

Real-world examples further underscore these advantages. In a warehouse case study, the installation of direct current blowers resulted in a 15% reduction in cooling expenses while improving air circulation and employee comfort. Experts emphasize that the appropriate selection and installation of ventilation devices are crucial for optimizing performance and durability. As one facility manager noted, “Selecting and installing ventilation devices properly results in improved performance and extended longevity.” HVAC and facility experts also highlight the significance of aligning fan airflow capacity with specific space measurements to ensure efficient air movement and safety.

In conclusion, the combination of energy efficiency, reduced noise, and extended lifespan positions DC devices as a superior choice for temperature control solutions across various applications, particularly where performance and reliability are paramount. Moreover, upgrading to efficient fans can yield a 10-20% reduction in annual power bills, reinforcing the financial advantages of transitioning to DC fans.

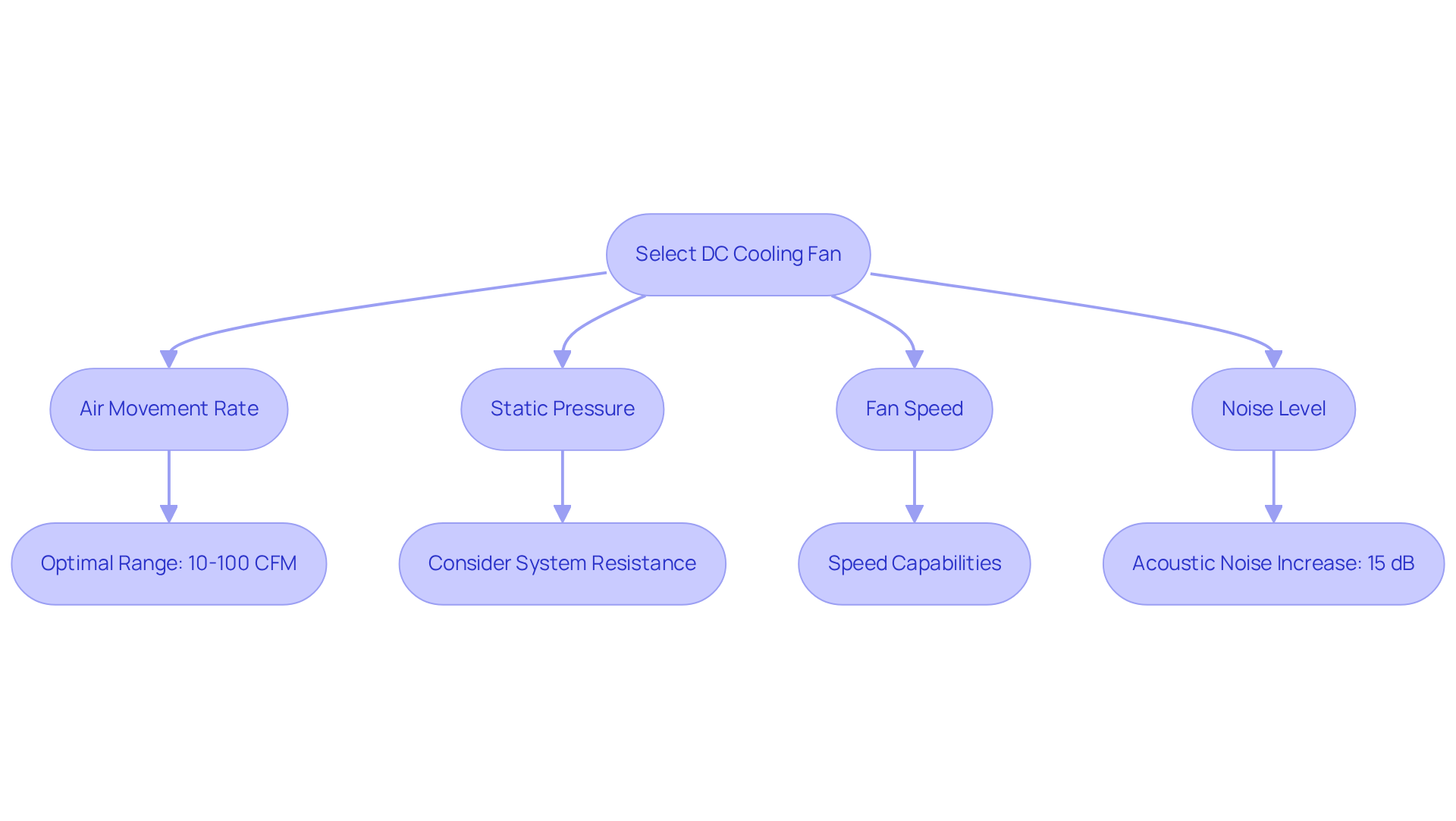

Airflow Fundamentals: Key Considerations for DC Fan Selection

Selecting the right DC cooling fan requires a comprehensive understanding of air movement principles, particularly the necessary air circulation rate and static pressure. Engineers must evaluate the specific thermal requirements of their applications, taking into account the fan’s operating curve and speed capabilities. A fan’s performance is often characterized by its ability to deliver air movement rates that meet or exceed the required specifications, with optimal air movement rates typically ranging from 10 to 100 CFM for effective electronic temperature regulation. Understanding the interplay between is crucial; as air movement increases, static pressure may decrease, necessitating careful selection to ensure that the fan can overcome system resistance.

In practical applications, engineers have successfully improved temperature regulation by selecting fans that closely align with their system requirements. For instance, the Same Sky’s CFM-6025V-131-167 model, which provides 16 CFM of air movement with no back pressure, exemplifies how matching fan specifications to temperature control needs can yield adequate thermal margins across various applications. Additionally, it is vital to consider the fan’s speed capabilities, as increasing fan speed can dramatically enhance airflow—tripling the speed results in a ninefold increase in pressure, underscoring the significance of fan affinity laws in the selection process.

Moreover, engineers should acknowledge that actual ventilation will typically be about half of the fan’s maximum output, suggesting that opting for a fan capable of generating double the required flow is prudent. Operating fans simultaneously can amplify maximum air movement, while running them sequentially can enhance maximum pressure, providing further strategies for optimizing performance based on specific system demands. Lastly, understanding the acoustic noise implications of fan speed alterations is crucial; doubling the fan speed leads to a 15 dB increase in noise, which can influence overall system design.

Ultimately, ensuring that the selected DC cooling fan meets the specific air movement and pressure requirements is vital for achieving optimal temperature regulation and efficiency in electronic systems.

Challenges with Traditional Cooling Solutions: Why Choose DC Fans?

Traditional cooling solutions frequently encounter challenges such as , excessive noise, and limited adaptability to varying thermal loads. For example, air conditioning units may cost around $10 for the same airflow that a direct current (DC) model achieves for merely $3, underscoring the substantial cost savings associated with DC technology. Furthermore, DC systems operate at lower voltages and utilize brushless motors, which not only diminish energy loss but also enhance reliability and durability. A 25-watt DC device can produce the same output as a 100-watt alternating current (AC) unit, further illustrating the efficiency of DC systems, particularly beneficial in commercial settings where they can consume up to 70% less energy than their AC counterparts.

Moreover, the quiet operation of DC units renders them ideal for sensitive environments, such as medical devices and telecommunications equipment, where noise reduction is paramount. Companies like Sugon have adopted immersion temperature regulation servers that leverage DC technology, resulting in over 30% lower energy usage compared to traditional air-cooled systems. This shift towards direct current devices is driven by the need for more effective and versatile temperature regulation solutions that can meet the demands of contemporary electronics.

In conclusion, the transition to DC cooling fan devices not only addresses the shortcomings of conventional methods but also paves the way for enhanced performance and reduced operational costs, positioning DC cooling fans as an attractive option for modern electronic applications.

Comprehensive Benefits: Why DC Cooling Fans Are Essential in Electronics

In summary, DC ventilation devices present a multitude of advantages that make them indispensable in the electronics sector. Their , variable speed control, low noise operation, durability, and versatility across applications position them as a superior choice for effective thermal management. By addressing the challenges posed by traditional cooling solutions, engineers can optimize both performance and reliability in their designs by utilizing a DC cooling fan. It is imperative for professionals in the field to consider integrating these advanced solutions to enhance their projects.

Conclusion

The advantages of DC cooling fans in electronics are not only evident but also essential, underscoring their critical role in modern temperature regulation solutions. These fans deliver remarkable energy savings, consuming up to 70% less power than traditional AC units, while also featuring superior performance attributes such as variable speed control and low noise operation. This synergy of efficiency and adaptability positions DC cooling fans as the optimal choice for a diverse range of applications, guaranteeing that electronic systems operate reliably and quietly.

Key insights throughout the article illuminate the myriad benefits of DC cooling fans. Their energy-efficient designs, advanced brushless motor technology, durability, and versatility across various industries are engineered to satisfy the demanding thermal management requirements of contemporary electronics. Furthermore, the integration of IoT technologies and smart solutions significantly enhances their functionality, rendering them indispensable in sectors spanning telecommunications to automotive.

Given these compelling advantages, it is imperative for engineers and industry professionals to contemplate the transition to DC cooling fans. By adopting these innovative solutions, they can optimize energy consumption, diminish operational noise, and bolster the overall reliability of electronic systems. The shift towards DC technology not only rectifies the shortcomings of traditional cooling methods but also paves the way for a more sustainable and efficient future in electronics.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in innovative solutions within the electronics sector, particularly in DC cooling fan technology, and is the largest global manufacturer of standard and custom air-movers.

What types of fans does Gagner-Toomey offer?

Gagner-Toomey offers a comprehensive portfolio that includes tube axial fans and centrifugal blowers, optimized for performance, efficiency, and low noise levels.

What recent advancements have been made in DC cooling fan technology?

Recent advancements in DC cooling fans include brushless motor technology and aerodynamic blade designs, which facilitate quieter operations and improved thermal management.

What is the projected market growth for DC cooling fans?

The market for DC cooling fans is projected to reach USD 2.1 billion by 2033, with a compound annual growth rate (CAGR) of 7.5% from 2026 to 2033.

How do DC cooling fans compare to conventional AC units in terms of energy efficiency?

DC cooling fans consume up to 70% less power than conventional AC units, resulting in lower electricity bills and a more sustainable approach to cooling.

What are the key benefits of using DC cooling fans?

Key benefits of DC cooling fans include up to 70% less energy consumption, significant long-term savings on electricity bills, advanced brushless motor technology for reduced energy loss, quieter operation, and more advanced control options.

What is variable speed control in DC cooling fans?

Variable speed control allows engineers to adjust the cooling output of DC fans to meet the exact thermal requirements of their systems, optimizing airflow and noise levels.

How much energy savings can be achieved with variable speed DC devices compared to traditional systems?

Employing variable speed DC devices can yield energy savings of up to 30% compared to traditional systems.

What noise levels can PWM controllers for cooling achieve?

PWM controllers for cooling can achieve noise levels as low as 20 dBA, significantly quieter than conventional models, which may exceed 30 dBA.

What challenges does Gagner-Toomey face in the market?

Gagner-Toomey faces challenges such as competition from alternative temperature control solutions and fluctuations in raw material prices, which influence market dynamics.