Overview

This article highlights the essential electric motor parts that every engineer must be familiar with, focusing on critical components such as:

- Stator

- Rotor

- Commutator

- Windings

- Brushes

- Poles

- Bearings

- Housing

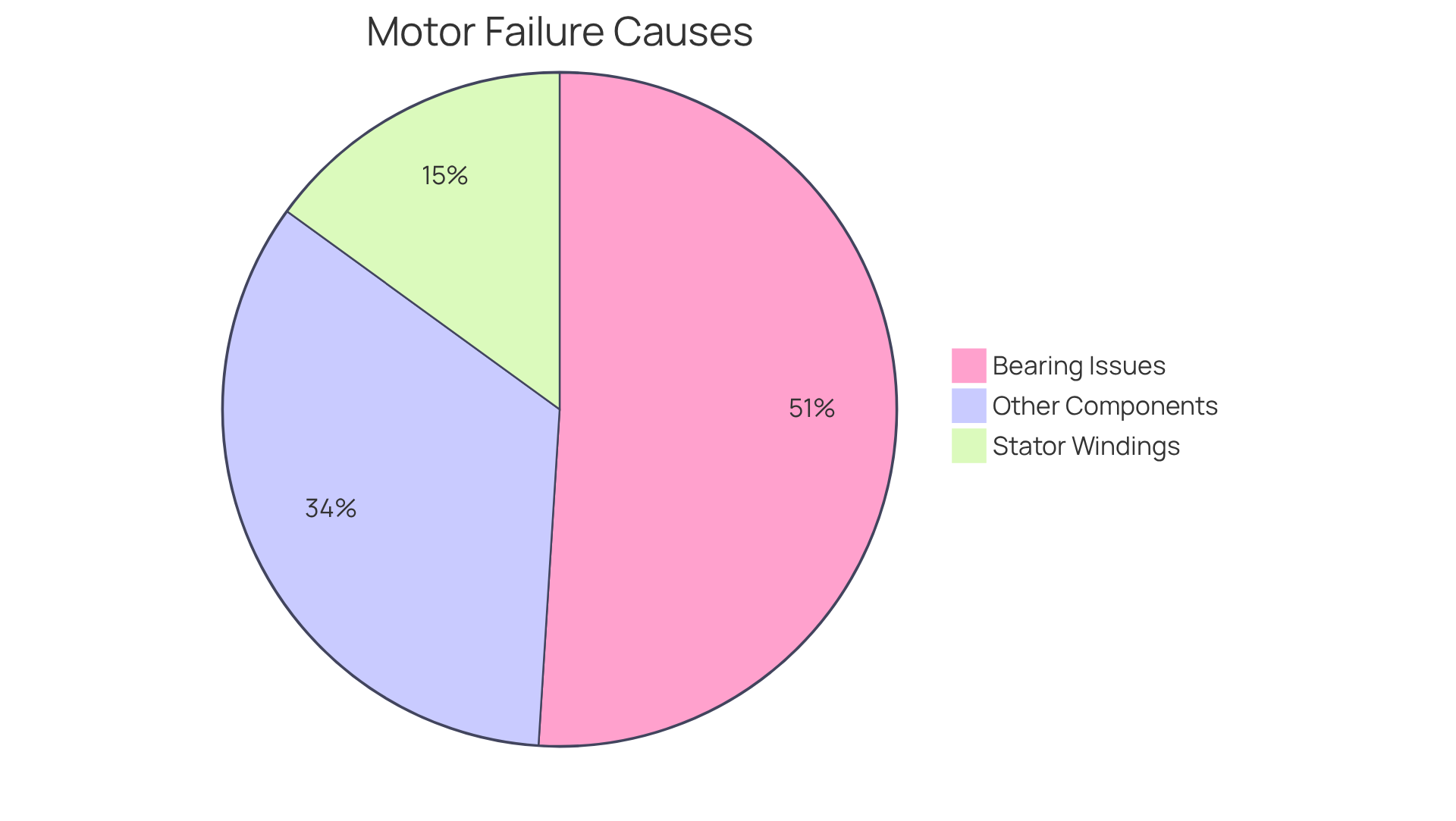

Each part is vital to the motor’s performance and reliability. Statistics reveal that a significant percentage of engine failures are attributable to specific components, underscoring the necessity for engineers to comprehend these parts thoroughly. By doing so, they can optimize designs and effectively reduce failure rates.

Introduction

Understanding the intricacies of electric motors is crucial for engineers navigating the rapidly evolving landscape of technology. The electric machinery market is projected to soar to USD 345.4 billion by 2034, making knowledge of fundamental components such as the stator, rotor, and commutator paramount. As the complexity of electric motor designs increases, engineers must ensure they are selecting the right parts to optimize performance and reliability. This article delves into the essential electric motor components every engineer should be familiar with, highlighting their functions and the critical role they play in enhancing machine efficiency.

Gagner-Toomey Associates: Innovative Solutions for Electric Motor Components

Gagner-Toomey Associates is at the forefront of supporting engineers in the electronics sector by delivering innovative solutions for electric component parts. Their expertise spans critical areas including:

- Cooling

- Power management

- Timing

- RF

- Interconnect technologies

By representing a diverse portfolio of leading manufacturers, Gagner-Toomey plays a pivotal role in the development and delivery of cutting-edge products and services. This commitment ensures engineers have access to the highest quality resources for their projects.

The company’s dedication to excellence is reflected in its exceptional customer service and consultative approach, which are integral to its corporate culture that respects and values the time and needs of its customers. Such a commitment solidifies Gagner-Toomey’s reputation as a trusted partner in the industry.

As the electric machinery market is projected to reach USD 345.4 billion by 2034, with a compound annual growth rate (CAGR) of 7.45%, Gagner-Toomey is strategically positioned to assist engineers in navigating the latest innovations and trends in electric technology. This foresight not only highlights their industry leadership but also underscores their role in in an evolving landscape.

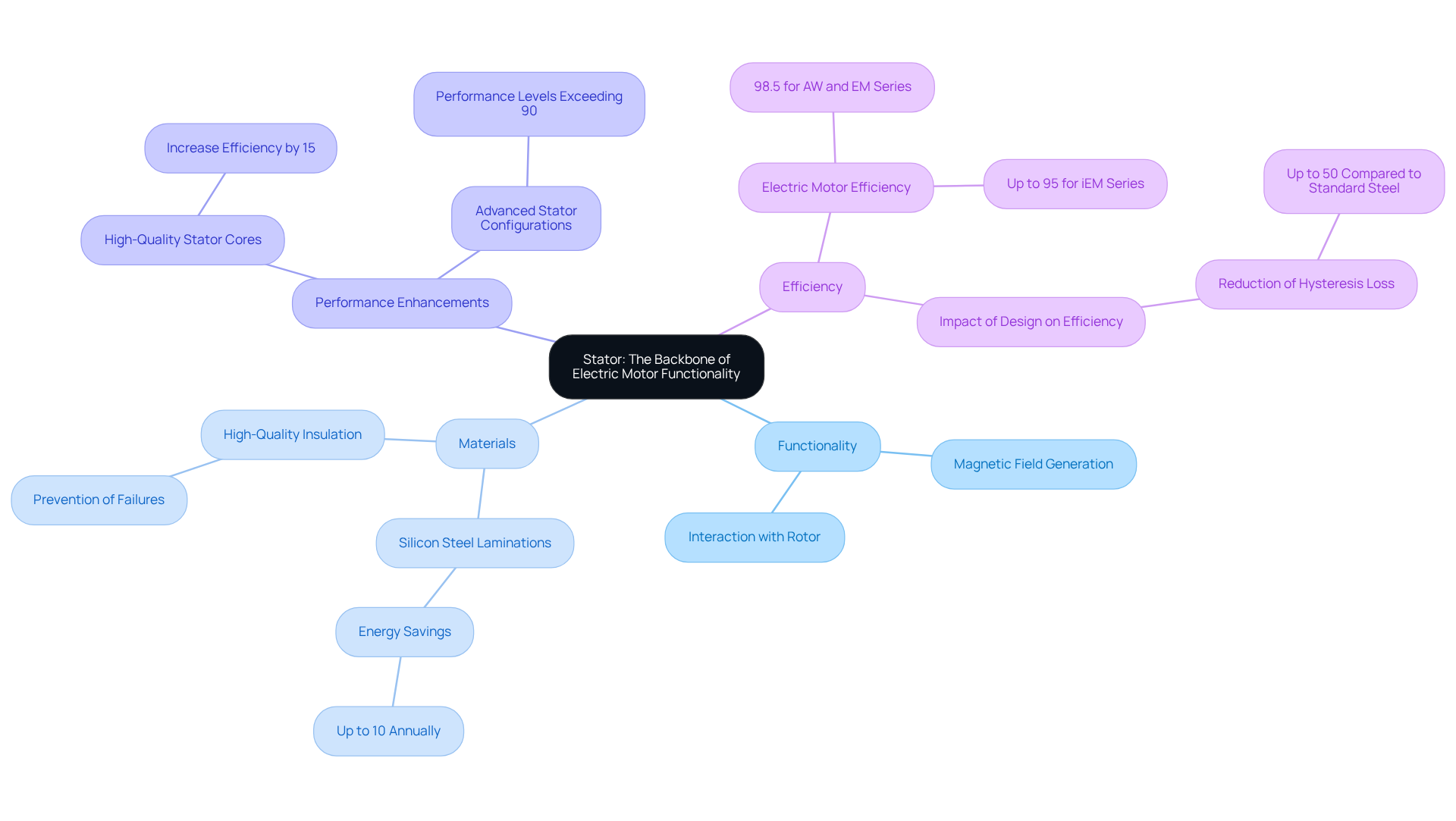

Stator: The Backbone of Electric Motor Functionality

The stator serves as the stationary component of an electric machine, comprising coils or windings that generate a magnetic field when energized. This magnetic field interacts with the rotor, enabling the transformation of electrical energy into mechanical energy. The significantly influence the engine’s effectiveness and performance.

For instance:

- High-quality stator cores can enhance machine performance by as much as 15%.

- Advanced materials, such as high-grade silicon steel laminations, have shown energy savings of up to 10% annually.

Siemens has underscored the importance of incorporating premium silicon steel laminations into stator cores, showcasing innovation in design that prolongs overall lifespan. Furthermore, electric engines from the iEM series can achieve efficiency levels of up to 95%, setting a benchmark for performance expectations.

Engineers must meticulously assess winding configurations and core materials to maximize the stator’s efficiency across diverse applications. Real-world examples illustrate that electric machines utilizing advanced stator configurations, such as laminated or segmented cores, achieve performance levels exceeding 90%.

Moreover, the critical nature of selecting appropriate stator materials cannot be overstated, as they directly affect not only the device’s operational efficiency but also its durability and reliability. Insulation failures frequently lead to equipment malfunctions, underscoring the necessity for high-quality insulation materials to prevent catastrophic winding failures.

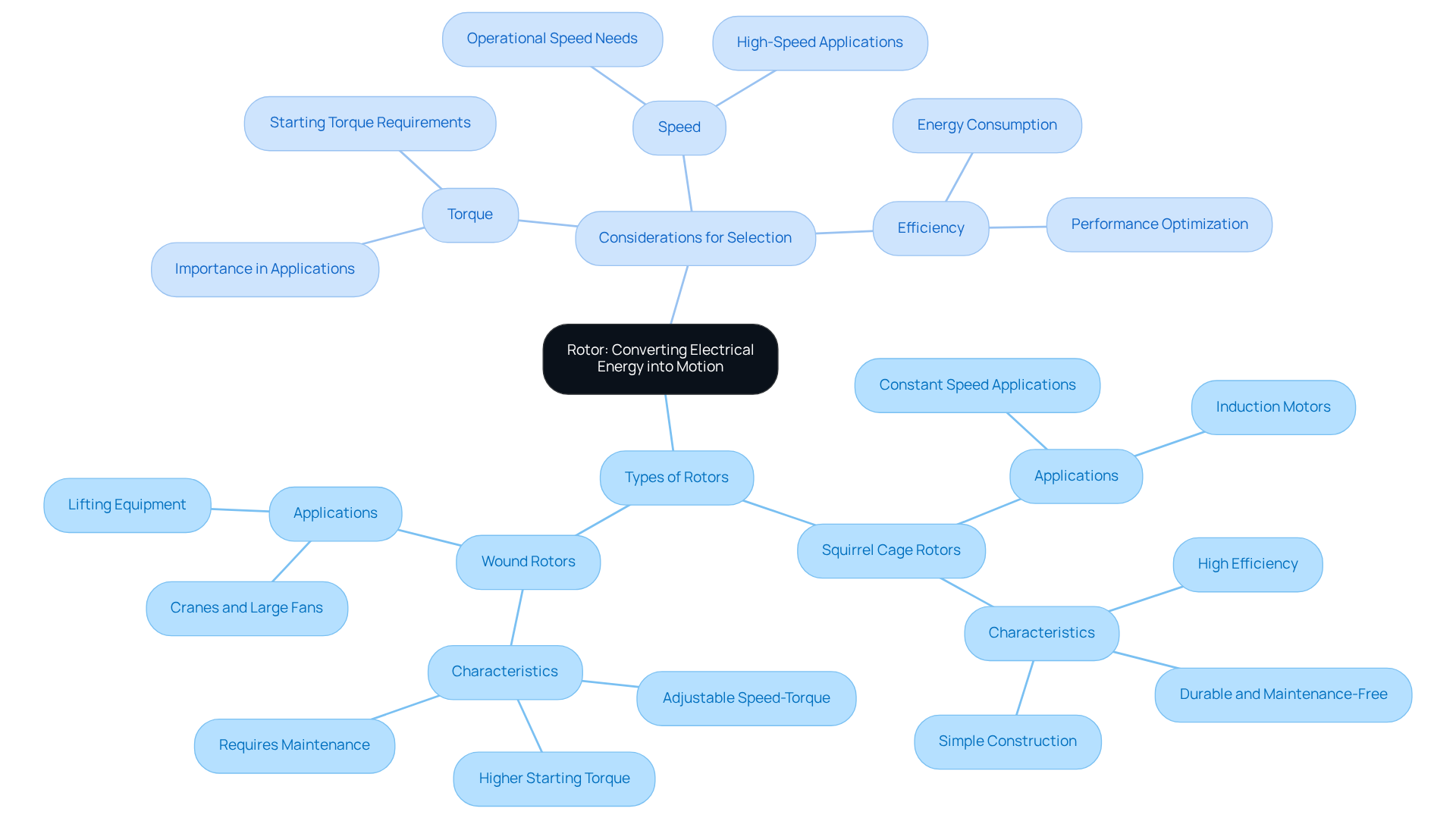

Rotor: Converting Electrical Energy into Motion

The rotor is one of the and serves as the pivotal rotating component of an electric motor, positioned within the stator. Its primary function is to convert electrical energy into mechanical energy, which is achieved through the basic electric motor parts and their interaction with the magnetic field generated by the stator.

The design of the rotor can vary significantly, with options such as:

Each presents distinct performance characteristics. Engineers are tasked with selecting the appropriate rotor type, carefully considering specific application requirements, including:

- Torque

- Speed

- Efficiency

This decision-making process is crucial for optimizing motor performance in various operational contexts.

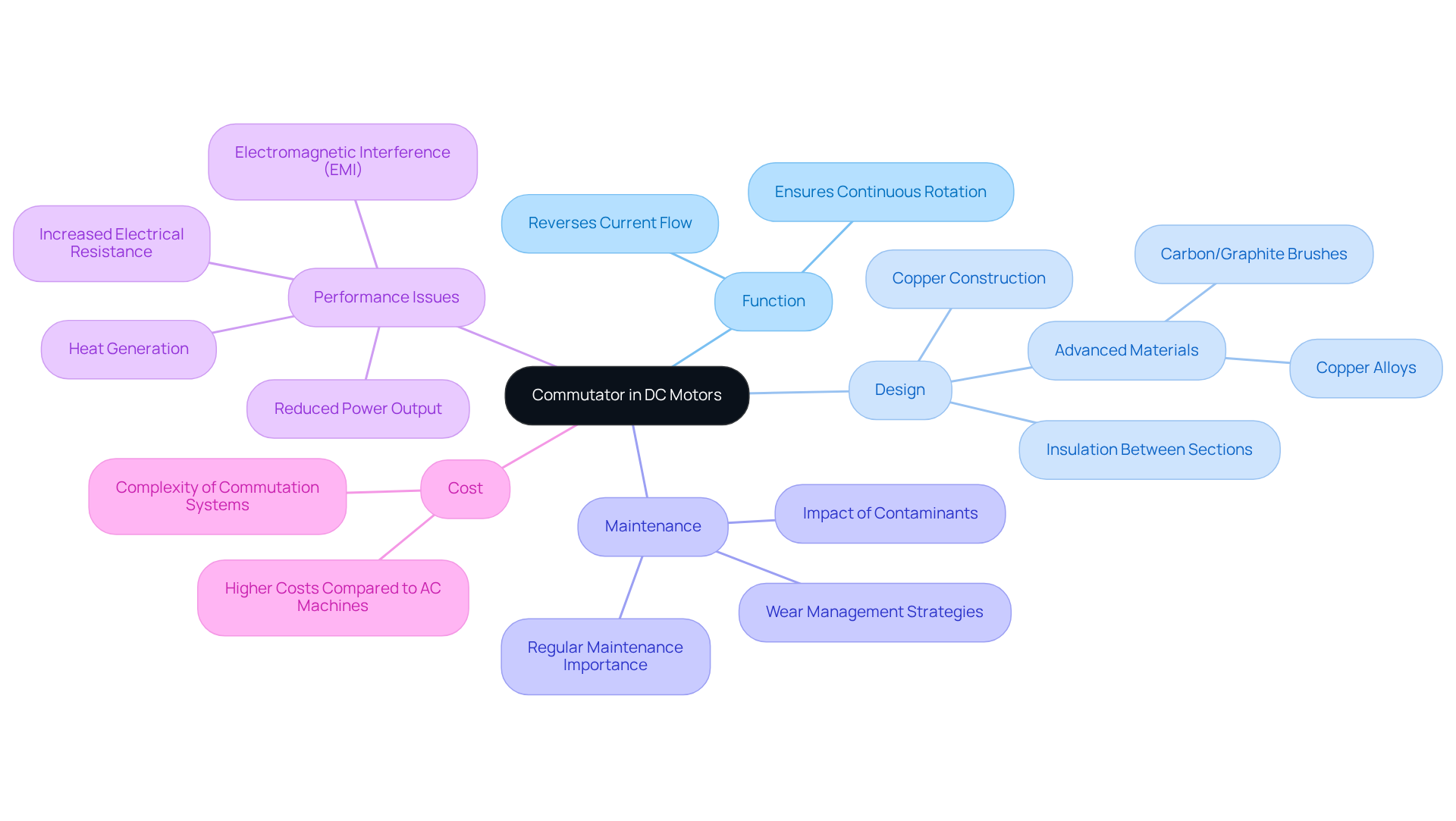

Commutator: Ensuring Directional Current Flow in DC Motors

The commutator serves as a crucial rotary switch in direct current devices, effectively reversing the direction of current flow within the rotor windings. This mechanism is vital for sustaining consistent torque, thereby enabling continuous rotation.

Typically constructed from copper sections that are insulated from one another, the significantly influences overall performance. Factors such as wear and maintenance are paramount; degraded commutators can lead to increased electrical resistance, reduced power output, and excessive heat generation, ultimately compromising performance.

Furthermore, commutation in DC machines can produce electromagnetic interference (EMI), rendering them less suitable for applications sensitive to such disturbances. The elevated costs associated with DC machines, stemming from the complexity of their commutation systems and manufacturing intricacies, are also critical considerations for engineers.

The use of advanced materials and precision engineering is essential in minimizing wear and ensuring reliable operation. Regular maintenance can greatly extend the lifespan of the engine, facilitating optimal performance across a range of applications.

Contaminants such as dust and debris can accumulate on the commutator, adversely affecting its performance and leading to uneven wear. Therefore, engineers should prioritize commutator design and material selection, alongside rigorous quality control in switching environments, to enhance device performance and reliability.

Windings: Generating Magnetic Fields for Motor Operation

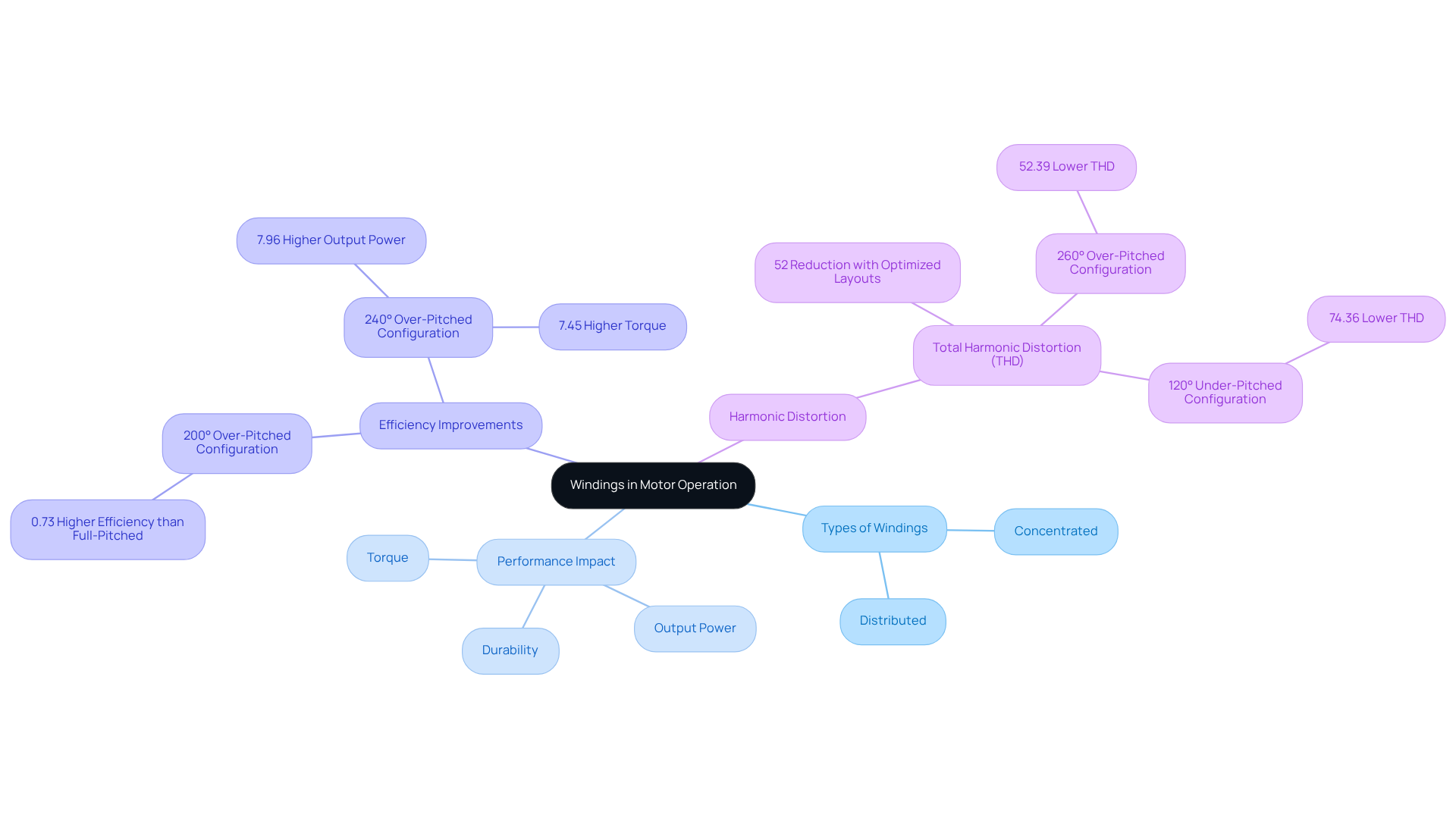

Windings, constructed from wire coils that encircle the stator or rotor, are essential for generating the necessary for operation. The choice between concentrated and distributed winding arrangements significantly influences the machine’s performance, torque, and overall effectiveness.

For instance, optimized winding layouts can lead to substantial performance improvements; research indicates that specific configurations can reduce total harmonic distortion (THD) by over 52% compared to full-pitched layouts. Notably, the highest efficiency is achieved with a 200° over-pitched configuration, which surpasses the efficiency of the full-pitched design by 0.73%.

Engineers must meticulously design these windings to enhance magnetic field strength while minimizing losses, ensuring efficient operation across varying load conditions. Experts emphasize that the correct winding arrangement not only boosts output power and torque but also contributes to the durability and reliability of electric machines.

Furthermore, specific coil-pitch adjustments can eliminate particular harmonic elements, underscoring the importance of precise winding structures. This comprehensive analysis of winding design is vital for advancing electric machinery technology and achieving optimal performance across diverse applications.

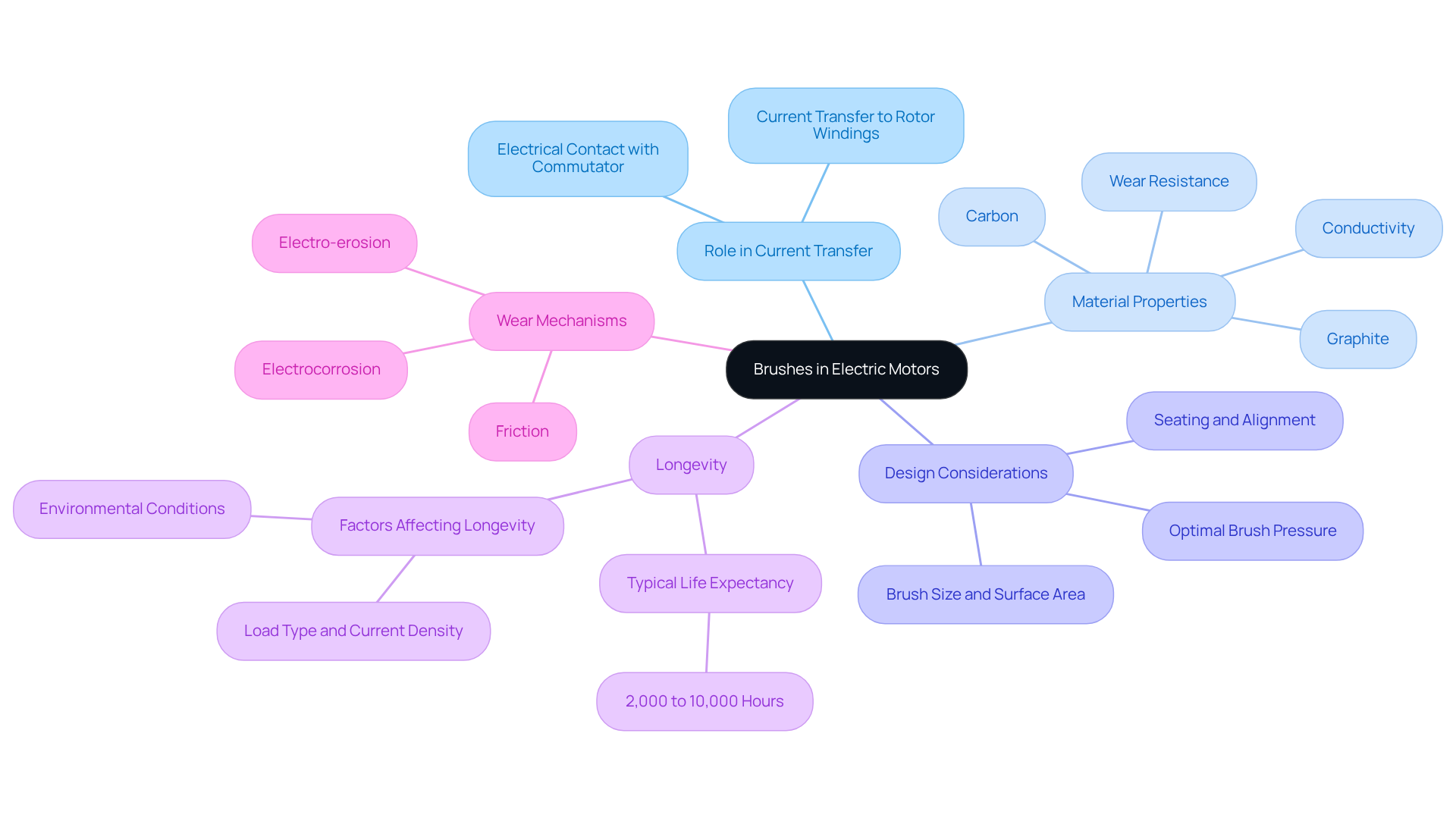

Brushes: Facilitating Current Transfer in Electric Motors

Brushes serve as essential conductive elements in DC machines, ensuring reliable electrical contact with the rotating commutator. Their role in transferring current to the rotor windings is crucial for the device’s operation. Typically made from carbon or graphite, these materials are chosen for their and wear resistance. The choice of brush material significantly influences performance; for instance, larger brushes provide an increased surface area for current transfer, enhancing conductivity and reducing heat generation. Selecting the appropriate material and design is vital for minimizing wear and extending the operational lifespan of the device. Notably, the longevity of brushes can vary considerably, with a typical life expectancy ranging from 2,000 to 10,000 hours under optimal conditions.

Engineers must prioritize these considerations to ensure efficient machine operation and to avert problems such as sparking and excessive wear, which can result from worn brushes, contaminated commutators, or voltage fluctuations. Understanding the dynamics of brush wear—encompassing friction, electrocorrosion, and electro-erosion—is essential for maintaining the reliability of DC devices throughout their service life. As Robert J. Hamilton stated, “Motor longevity depends on a good brush film that, in turn, depends on a lot of controllable factors.” Furthermore, environmental conditions can significantly affect brush wear, underscoring the necessity for engineers to account for these factors in their designs.

Poles: Influencing Torque and Speed in Electric Motors

The pole count in an electric machine is a crucial factor that significantly influences its torque and speed attributes. Motors with a higher number of poles, such as 6-pole or 8-pole configurations, excel in delivering greater torque at lower speeds. This characteristic makes them ideal for applications demanding high starting torque, such as cranes and industrial mixers.

For instance, a 6-pole machine operates at lower speeds while providing enhanced torque output, which is essential for heavy-duty tasks. Conversely, machines with fewer poles, typically 2-pole configurations, can achieve higher speeds, making them suitable for applications like fans and pumps, where speed is prioritized.

The relationship between pole count and performance is inversely proportional; as the number of poles increases, the maximum speed decreases. This principle is vital for engineers when selecting engines for specific applications. For example, a 2-pole device running at 10,000 RPM corresponds to a 4-pole machine running at 5,000 RPM and a 6-pole unit at 3,333 RPM.

Recent studies emphasize that the ideal pole count for high-speed applications typically ranges from 4 to 12 poles, depending on the specific needs of the device and its intended use. Additionally, higher pole counts contribute to smoother operation at lower speeds and improved torque characteristics, which are crucial for precision tasks.

However, it is important to note that devices with a higher pole count generally incur greater costs due to their enhanced torque capabilities. Understanding these dynamics enables engineers to effectively, ensuring that the chosen device meets operational demands while maintaining efficiency and reliability.

As noted, ‘the number of poles significantly affects a machine’s performance characteristics,’ underscoring the critical role of pole count in the selection process.

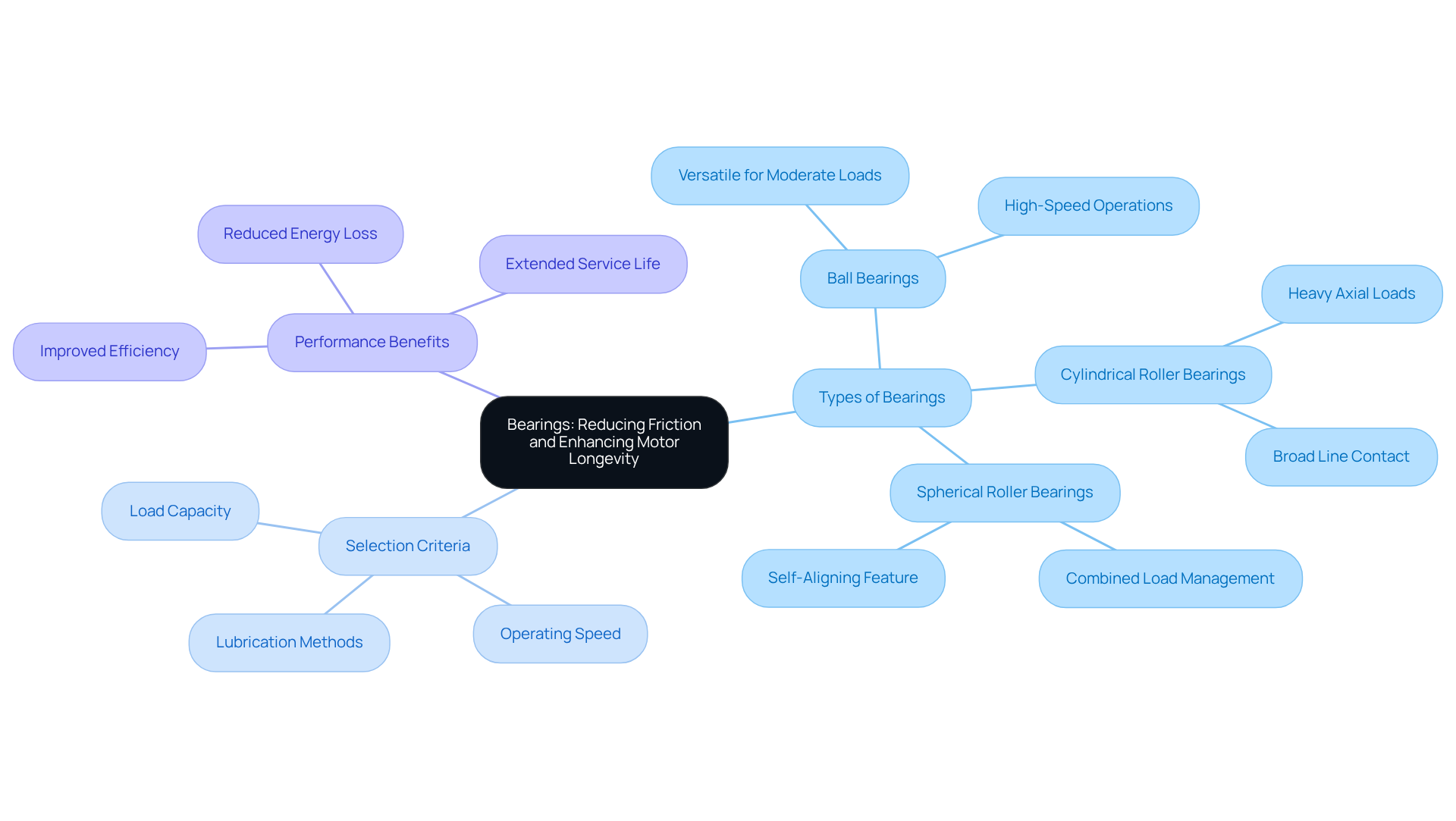

Bearings: Reducing Friction and Enhancing Motor Longevity

Bearings represent essential mechanical components that support the rotor and significantly reduce friction during operation, thereby enhancing the durability and reliability of electric machines. The selection of the appropriate type of support is vital, as it directly influences the motor’s performance and lifespan. Various types of supports, including ball types, cylindrical roller types, and spherical roller types, are utilized based on specific application requirements. For instance, ball components are versatile and suitable for moderate loads and high-speed operations, while cylindrical rollers excel at managing heavy axial loads.

When , engineers must consider multiple factors, such as load capacity, operating speed, and lubrication methods. The right component selection can lead to improved operational performance, reduced energy loss, and extended service life. As ENNENG states, “Bearing selection is one of the most critical items to determine overall efficiency and reliability of the machine.” Insulated components, for example, are particularly beneficial in high-frequency motors, minimizing electrical damage and enhancing reliability. TPI’s insulated supports are designed to reduce shaft currents, resulting in increased lifespan and improved performance.

Moreover, the implementation of hybrid ceramic components can significantly lower friction and prolong longevity, making them ideal for high-performance applications. Research indicates that proper support selection can enhance performance by 10-15% and improve power factor ratings. The case study titled “Conclusion on Motor Bearing Selection” underscores that appropriate selection fosters enhanced operational efficiency and durability. Furthermore, components engineered for specific load conditions can effectively manage both radial and axial forces, ensuring smooth operation even under challenging circumstances. Ultimately, understanding the nuances of bearing types and their applications is crucial for engineers aiming to optimize performance and longevity.

Housing: Protecting and Managing Heat in Electric Motors

The casing of an electric device is essential in safeguarding internal components from environmental hazards while effectively managing the heat generated during operation. A thoughtfully designed housing not only protects against dust, moisture, and other pollutants but also ensures that the device operates within safe temperature limits, thereby preventing overheating and prolonging its lifespan.

For instance, aluminum casing components are favored due to their high thermal conductivity, lightweight nature, and corrosion resistance, making them ideal for situations where efficient heat dissipation is critical. Conversely, while steel housings provide superior strength and durability, they may not dissipate heat as effectively as their aluminum counterparts.

Innovative structural features, such as fins and ventilation openings, enhance both passive and active cooling, further optimizing thermal management. Real-world examples, including case studies on aluminum housing, illustrate that using corrosion-resistant materials can extend the lifespan of housings by up to 25% in harsh environments, underscoring the importance of material selection in performance outcomes.

Moreover, advanced composites, known for their lightweight and high-strength properties, are increasingly being utilized in housing construction, offering significant benefits in terms of heat management and durability.

As the industry progresses toward sustainability, the adoption of recyclable materials like aluminum and steel is becoming more widespread, aligning with global energy efficiency objectives. Ultimately, the are pivotal in enhancing performance, reliability, and adaptability across a range of applications.

Understanding Electric Motor Parts: A Comprehensive Overview for Engineers

A comprehensive understanding of basic electric motor parts is essential for engineers involved in the development and application of electric machinery components. Each of the basic electric motor parts, including the stator, rotor, commutator, and supports, significantly influences the device’s performance and effectiveness. Notably, 15% of engine failures are attributed to stator windings, primarily due to overheating and overloading. In contrast, 51% of AC engine failures stem from bearing issues, underscoring the critical need for engineers to prioritize component knowledge in their projects.

By mastering the complexities of these components, engineers are empowered to make informed decisions that enhance performance and reliability. Real-world illustrations, such as those presented in the ” case study, exemplify how engineers have adeptly optimized machinery elements, resulting in reduced failure rates and improved operational efficiency.

As technology progresses, the significance of understanding electric motor parts will only increase, making it imperative for engineers to remain updated on the latest advancements and best practices in motor design. Historical data, including findings from the EPRI study, remains pertinent, highlighting the continuous necessity for engineers to integrate this knowledge into their work.

Conclusion

A thorough comprehension of electric motor components is vital for engineers focused on the design and application of electric machinery. This article highlights essential parts, including:

- Stator

- Rotor

- Commutator

- Windings

- Brushes

- Poles

- Bearings

- Housing

Each plays a critical role in determining the motor’s efficiency and reliability. Understanding these components enables engineers to make informed choices that enhance performance, reduce failure rates, and ensure longevity in electric motors.

Key insights reveal that:

- 15% of engine failures are linked to stator windings.

- 51% stem from bearing issues, underscoring the importance of prioritizing component knowledge.

By mastering these elements, engineers can optimize designs and implement best practices that align with technological advancements in electric motor design. Real-world examples illustrate how informed decision-making can lead to improved operational efficiency and reduced downtime.

As the electric machinery sector continues to evolve, engineers must stay abreast of the latest developments and innovations in motor technology. Emphasizing the significance of understanding electric motor parts not only empowers engineers to enhance their projects but also contributes to the overall advancement of the industry. Engaging with resources and case studies on electric motor components will further bolster expertise, ensuring that engineers are well-equipped to meet future challenges in this dynamic field.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for delivering innovative solutions for electric motor components, supporting engineers in the electronics sector with expertise in areas such as cooling, power management, timing, RF, and interconnect technologies.

How does Gagner-Toomey support engineers?

Gagner-Toomey supports engineers by representing a diverse portfolio of leading manufacturers, providing access to high-quality resources, and offering exceptional customer service through a consultative approach.

What is the projected growth of the electric machinery market?

The electric machinery market is projected to reach USD 345.4 billion by 2034, with a compound annual growth rate (CAGR) of 7.45%.

What role does the stator play in electric motors?

The stator is the stationary component of an electric motor that generates a magnetic field when energized, which interacts with the rotor to convert electrical energy into mechanical energy.

How can the design and materials of the stator affect performance?

High-quality stator cores can enhance machine performance by up to 15%, and advanced materials like high-grade silicon steel laminations can lead to energy savings of up to 10% annually.

What efficiency levels can electric engines from the iEM series achieve?

Electric engines from the iEM series can achieve efficiency levels of up to 95%.

Why is the selection of stator materials important?

The selection of stator materials is critical as it affects the operational efficiency, durability, and reliability of the electric motor. High-quality insulation materials are necessary to prevent equipment malfunctions due to insulation failures.

What is the function of the rotor in electric motors?

The rotor is the rotating component of an electric motor that converts electrical energy into mechanical energy through its interaction with the magnetic field generated by the stator.

What types of rotors are available for electric motors?

There are two main types of rotors: squirrel cage rotors and wound rotors, each with distinct performance characteristics.

What factors should engineers consider when selecting a rotor type?

Engineers should consider torque, speed, and efficiency when selecting the appropriate rotor type for specific application requirements to optimize motor performance.