Overview

The article delineates ten pivotal benefits of industrial air to air heat exchangers for electronics, underscoring their critical role in optimizing thermal management, enhancing energy efficiency, and promoting sustainability. These benefits are substantiated by compelling evidence of substantial energy cost savings, augmented performance and longevity of electronic devices, and their contribution to minimizing carbon footprints. Such attributes render them indispensable for contemporary industrial applications.

Introduction

The rapid evolution of the electronics industry necessitates innovative solutions that not only enhance performance but also prioritize energy efficiency and sustainability. In this context, industrial air to air heat exchangers have emerged as a vital technology, offering numerous benefits that can significantly improve thermal management and reduce operational costs.

As organizations strive to adopt these advanced systems, critical questions arise:

- How can companies effectively integrate air to air heat exchangers into their existing infrastructures?

- What unique advantages do they provide in the competitive electronics market?

This article explores the ten key benefits of these heat exchangers, illuminating their essential role in optimizing electronics cooling solutions.

Gagner-Toomey Associates: Innovative Solutions for Electronics Cooling with Air to Air Heat Exchangers

Gagner-Toomey Associates leads the way in delivering innovative solutions for electronics cooling, particularly through the utilization of air to air thermal devices. These sophisticated systems are engineered to effectively transfer heat from electronic components to the ambient air, thus ensuring optimal performance and prolonging the lifespan of devices.

The incorporation of industrial air to air heat exchangers not only improves thermal management but also enhances energy efficiency, a vital consideration in the contemporary electronics landscape. With a diverse portfolio of manufacturers, Gagner-Toomey facilitates the adoption of that satisfy the stringent demands of the electronics industry.

Their commitment to excellence is evident in the customized solutions they provide, meticulously designed to tackle the unique challenges faced by engineers. As the electronics sector continues to evolve, the effectiveness of industrial air to air heat exchangers becomes increasingly critical, with research indicating substantial improvements in their thermal performance and energy conservation.

This positions Gagner-Toomey as an indispensable ally in advancing temperature regulation solutions that align with the industry’s escalating needs.

Energy Efficiency: Reducing Operational Costs with Air to Air Heat Exchangers

The industrial air to air heat exchanger is notable for its exceptional energy efficiency, which is a crucial factor in significantly reducing operational expenses for companies. By reclaiming waste energy from exhaust air and utilizing it through an industrial air to air heat exchanger to precondition incoming air, these systems markedly lower the energy required for both heating and cooling. This innovative strategy not only leads to but also enhances the overall sustainability of operations by incorporating an industrial air to air heat exchanger.

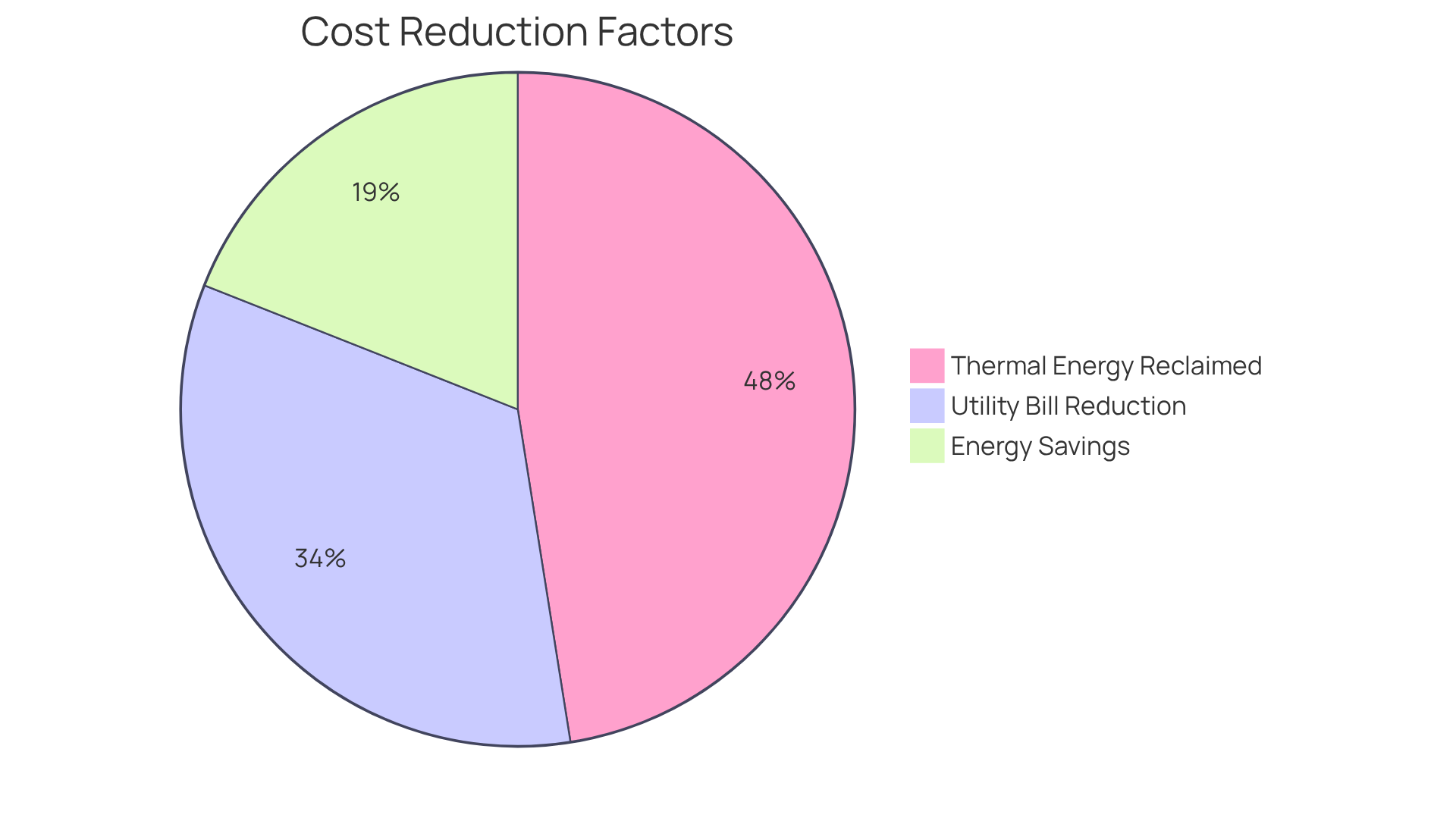

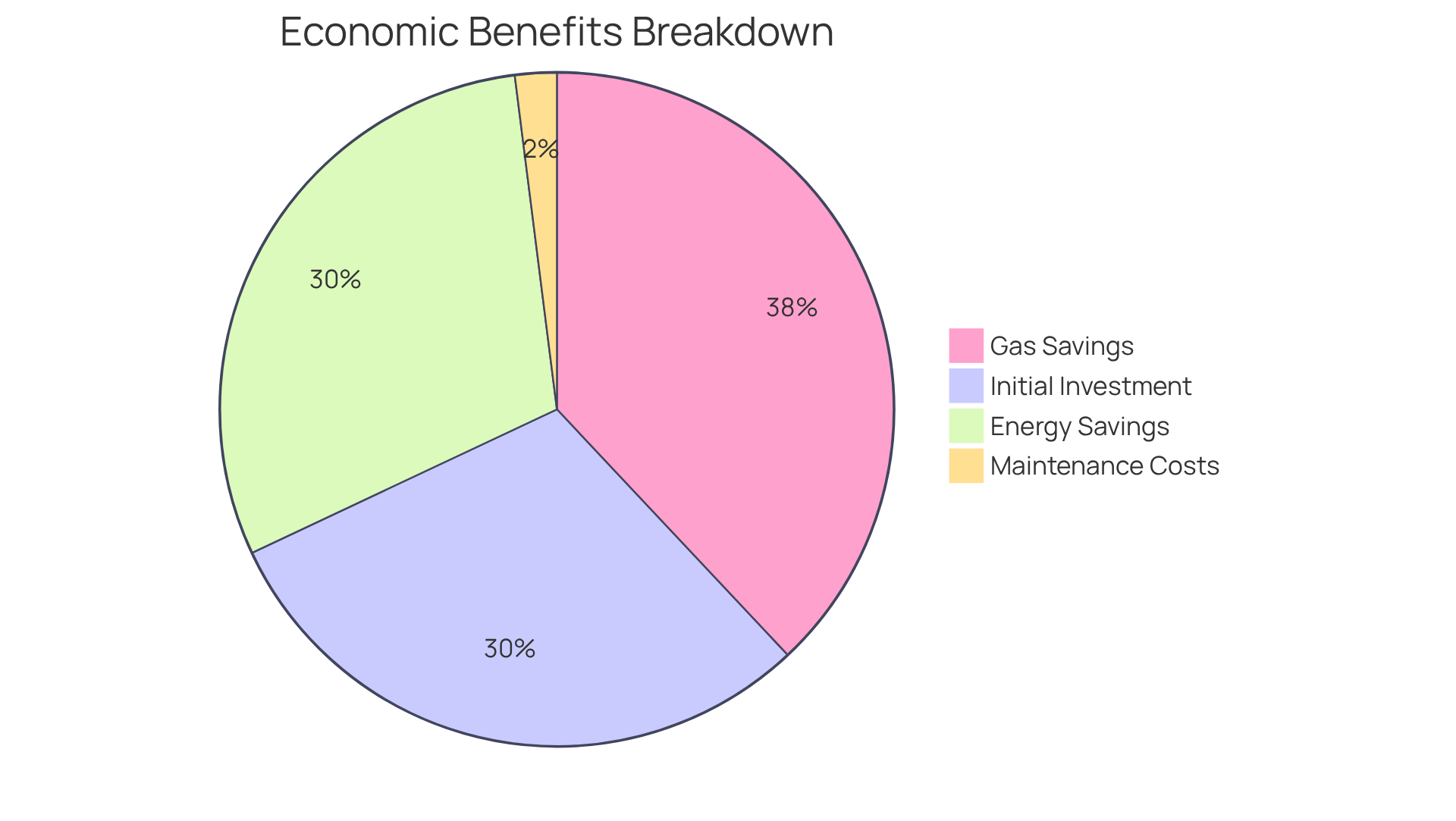

Businesses implementing air to air thermal devices can anticipate an average return on investment of approximately 38% on their gas expenses, based on systems boasting an efficiency of 70%. Many organizations experience payback periods of merely two years. Furthermore, the reduction in energy bills, attributed to decreased fuel consumption, serves as a direct advantage of investing in these systems.

Practical applications in sectors such as food processing demonstrate that industrial air to air heat exchangers can reclaim up to 94-95% of thermal energy, thereby further improving energy efficiency and diminishing operational costs. Regular maintenance of thermal devices is essential to maximize their benefits and ensure peak efficiency. Consequently, the industrial air to air heat exchanger emerges as a cost-effective solution for companies aiming to optimize energy usage while enhancing their profitability.

Enhanced Thermal Management: Optimizing Performance in Electronics Cooling

Improved thermal regulation stands out as a significant advantage of industrial air to air heat exchangers. These systems excel in efficiently dispersing thermal energy generated by electronic components, thereby maintaining optimal operating temperatures. By employing a closed-loop system, the industrial air to air heat exchanger effectively prevents the mixing of exhaust and incoming air, ensuring that only cooled air enters the enclosure. This precise control over temperature not only enhances the performance of electronic devices but also extends their lifespan, significantly reducing the need for costly replacements.

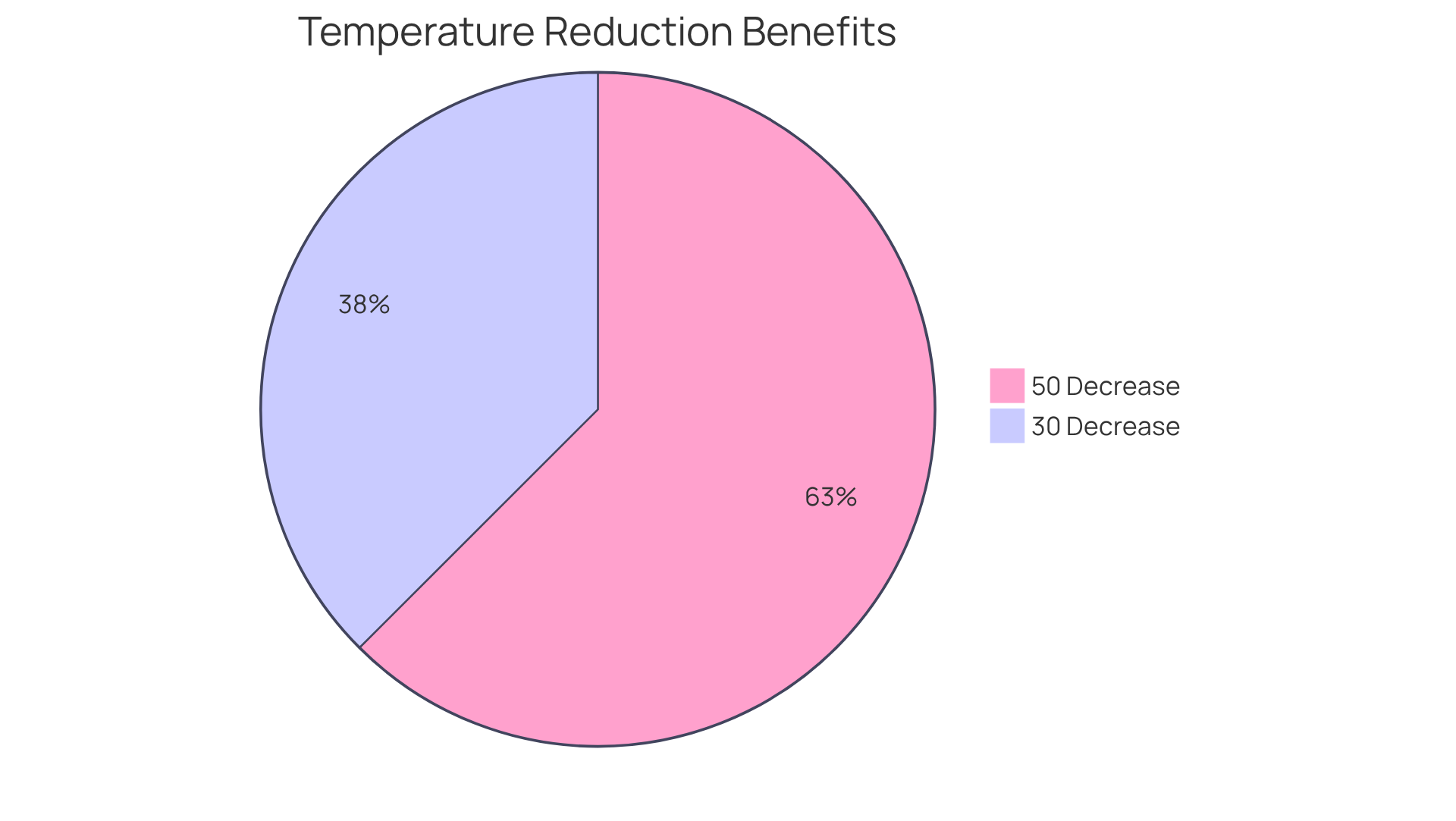

- Average Temperature Decrease: Engineers have indicated that utilizing air-to-air thermal devices can lead to average temperature decreases of 30% to 50%. This reduction is essential for of delicate electronic components.

- Performance Enhancement: In high-performance computing settings, for instance, these thermal devices have been shown to enhance operational reliability and energy efficiency, making them a crucial element in contemporary electronic temperature regulation solutions.

Integrating an industrial air to air heat exchanger into your temperature control strategy can substantially improve the efficiency and longevity of electronic systems. It is advisable to assess your current temperature control solutions to explore how these systems can be incorporated for optimal results.

Reliability: Ensuring Consistent Performance with Air to Air Heat Exchangers

Air to air heat exchangers are engineered for exceptional reliability, ensuring consistent performance even in the most demanding environments. These systems, devoid of moving components, require minimal upkeep, significantly reducing the likelihood of mechanical breakdowns compared to conventional temperature control methods. Their robust construction allows the industrial air to air heat exchanger to withstand harsh conditions, making it particularly suitable for industrial applications. This inherent reliability not only translates to reduced downtime but also results in lower maintenance costs, providing engineers and facility managers with peace of mind. Regular maintenance practices can further enhance their efficiency, with studies indicating that effective upkeep can reduce operational costs by up to 30%.

Moreover, the growing trend towards maintenance-free temperature control solutions reflects a shift in industry preferences, as organizations seek to streamline operations and minimize resource allocation for upkeep. Facility managers have observed that the simplicity of air to air heat exchangers facilitates straightforward maintenance protocols, which are crucial for maintaining optimal performance in challenging environments. As one facility manager wisely remarked, ‘The less we have to concern ourselves with temperature failures, the more we can concentrate on our core operations.’ This sentiment underscores the importance of investing in like the industrial air to air heat exchanger, which align with operational goals.

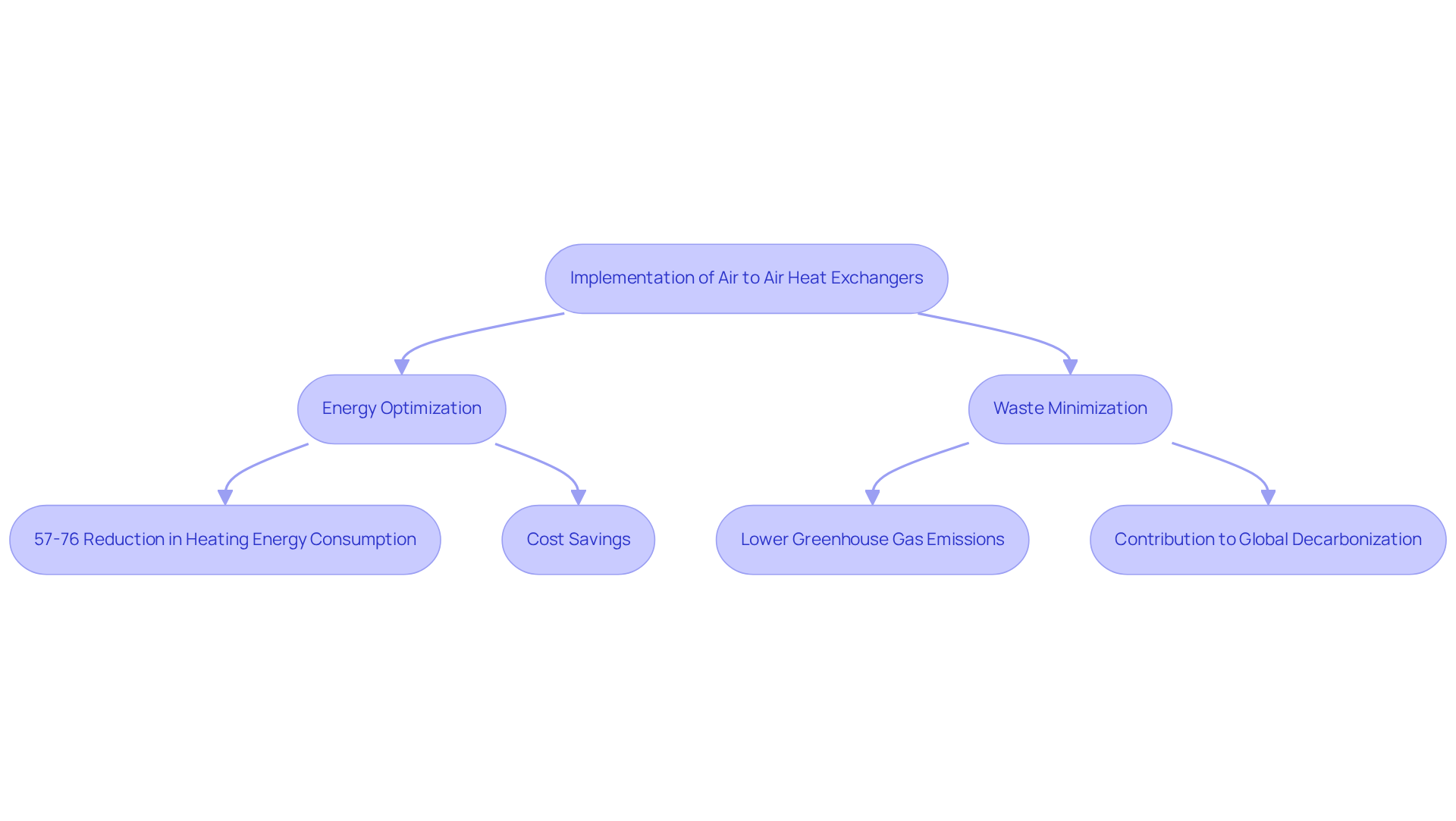

Environmental Sustainability: Reducing Carbon Footprint with Air to Air Heat Exchangers

The industrial air to air heat exchanger is pivotal in enhancing environmental sustainability by markedly reducing the carbon footprint associated with industrial activities. These systems optimize energy utilization and minimize waste, thereby effectively lowering greenhouse gas emissions tied to cooling processes. For instance, the implementation of air-to-air thermal devices has been shown to decrease heating energy consumption by 57% to 76%, leading to a substantial decline in local heating-related CO emissions. This aligns with , making the industrial air to air heat exchanger an attractive option for companies committed to environmental responsibility.

Furthermore, the integration of these systems facilitates energy recovery and reuse, significantly bolstering efficiency. In practical applications, companies like Silver Fern Farms have reported notable reductions in coal consumption and greenhouse gas emissions following the adoption of high-temperature thermal pumps, which often function in conjunction with air-to-air thermal devices. As highlighted by Rafael Martinez-Gordon, “Heat pumps, powered by low-emissions electricity, are the central technology in the global transition to secure and sustainable heating.” These technologies can deliver thermal energy ranging from 300% to 500% of the electrical energy supplied, resulting in considerable cost savings and emissions reductions.

As the industry progresses towards more sustainable technologies, the adoption of industrial air to air heat exchangers is not just a tactical choice; it represents a crucial step in mitigating the impacts of climate change. By prioritizing these systems, businesses can improve their operational efficiency while making significant contributions to global decarbonization initiatives.

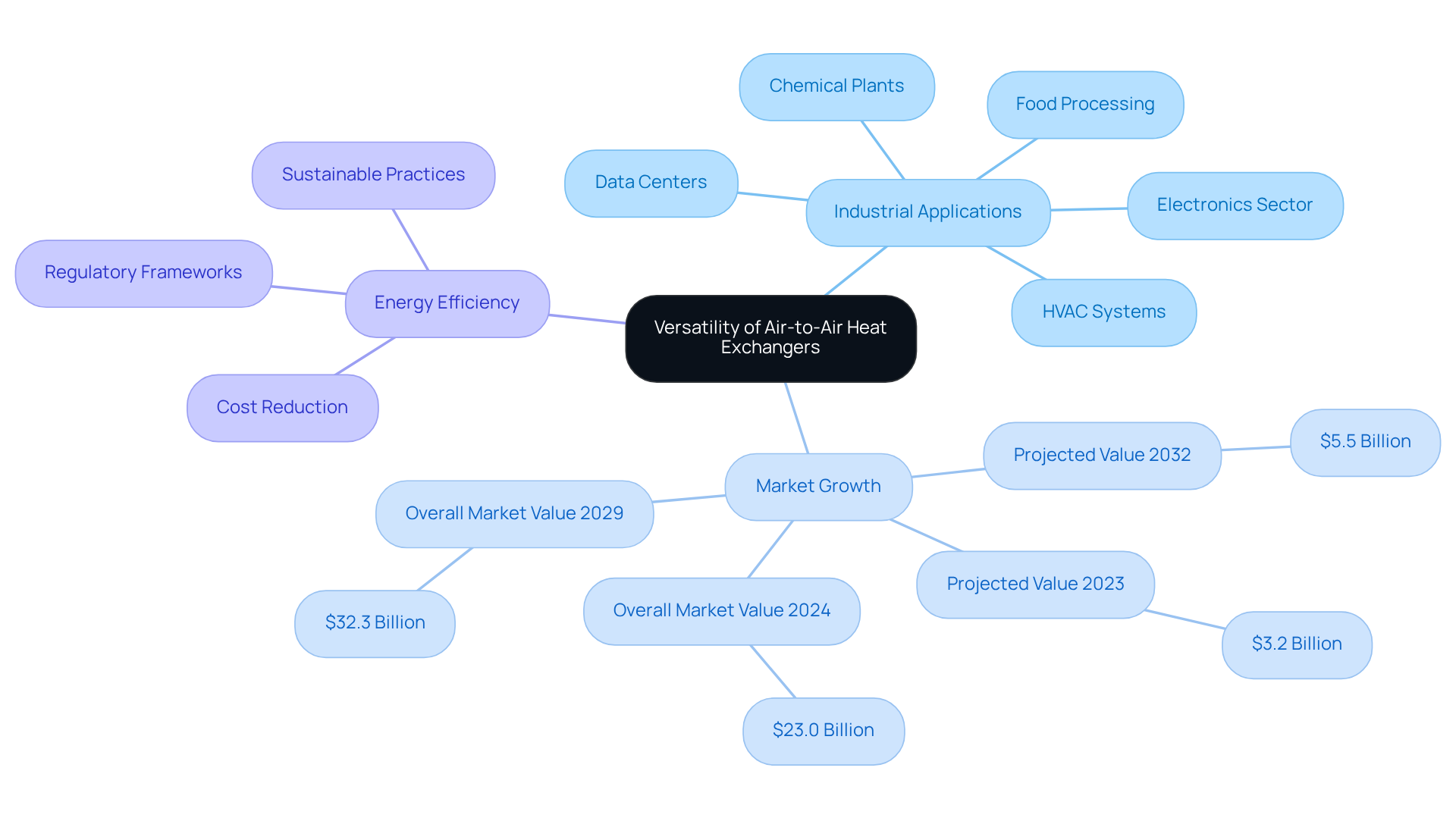

Versatility: Adapting Air to Air Heat Exchangers for Diverse Industrial Applications

Air-to-air thermal devices, such as industrial air to air heat exchangers, are renowned for their exceptional flexibility, making them suitable for a diverse array of industrial applications. The industrial air to air heat exchanger systems excel in maintaining optimal conditions for sensitive electronic devices and regulating temperatures in manufacturing processes. Their modular design allows for seamless integration of the industrial air to air heat exchanger into existing infrastructures, facilitating effective deployment in environments such as data centers, food processing facilities, and chemical plants. This flexibility is crucial, enabling companies to tailor air-to-air thermal devices to their specific cooling requirements.

For instance, in the electronics sector, industrial air to air heat exchangers adeptly manage thermal loads, ensuring that high-powered equipment operates at peak performance. Furthermore, the global air-to-air thermal transfer market is projected to grow from $3.2 billion in 2023 to $5.5 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.1%. In a broader context, the overall thermal transfer market was valued at USD 23.0 billion in 2024 and is anticipated to reach USD 32.3 billion by 2029, expanding at a CAGR of 7.0%. This growth highlights the rising demand for across various sectors, driven by regulatory frameworks and the necessity for sustainable practices.

As industries continue to evolve, the adaptability of air-to-air thermal devices will be vital in enhancing operational efficiency and reducing energy consumption. Engineers must consider the specific temperature regulation needs of their applications when selecting air-to-air thermal devices to optimize their efficiency.

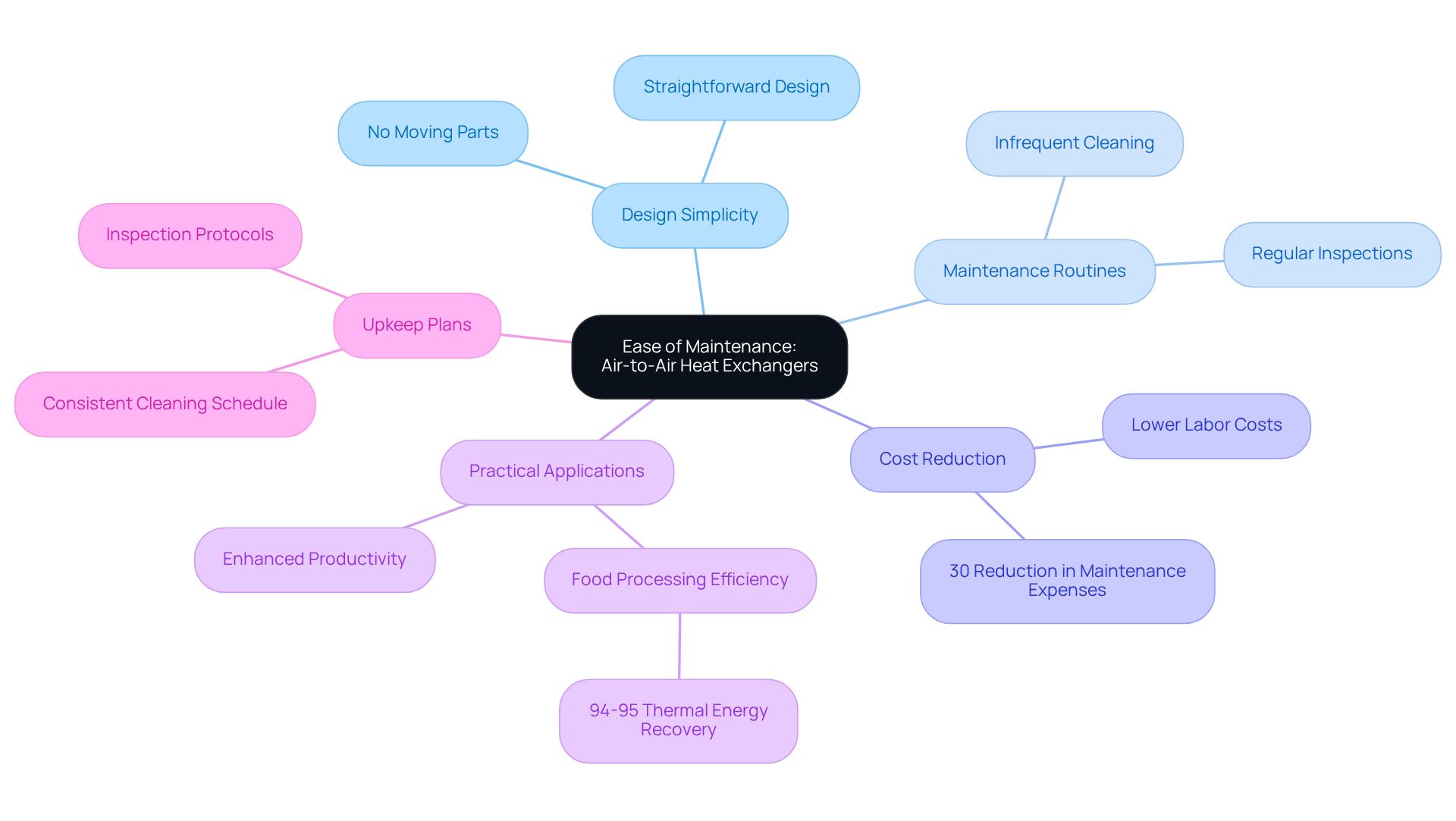

Ease of Maintenance: Simplifying Upkeep with Air to Air Heat Exchangers

Air-to-air heat exchangers, specifically industrial air to air heat exchangers, are meticulously engineered for optimal ease of maintenance, showcasing a straightforward design devoid of moving parts. This simplicity translates into maintenance routines that are not only infrequent but also uncomplicated compared to traditional temperature control systems. Generally, regular cleaning and inspection are sufficient to uphold operational efficiency. Such an approach not only minimizes labor costs but also significantly reduces the likelihood of unexpected failures. As a result, companies can focus on their core operations without the encumbrance of intricate maintenance schedules.

In fact, the implementation of advanced reliability practices can result in up to a 30% reduction in annual maintenance expenses, further amplifying the attractiveness of these systems. Engineers have observed that simplifying upkeep for cooling systems is essential for operational efficiency, as it facilitates better resource allocation and curtails downtime. Practical applications illustrate that organizations utilizing industrial air to air heat exchangers experience smoother operations and heightened productivity.

For instance, in the food processing industry, thermal devices can reclaim up to 94-95% of the thermal energy from processes such as pasteurization, underscoring the practical benefits of this technology. As Leslie F. Sikos aptly notes, “Fouling should be analyzed as it has a significant impact on maintenance issues.”

To maximize the benefits of air-to-air systems, businesses are encouraged to establish a that incorporates regular cleaning and inspections to ensure peak functionality.

Cost-Effectiveness: Maximizing Value with Air to Air Heat Exchangers

Investing in air-to-air thermal transfer devices presents a compelling economic solution for companies. While the initial investment may exceed that of traditional cooling methods, the long-term savings on energy bills—potentially reaching 30%—and lower maintenance costs frequently outweigh these upfront expenses. The and reliability of these systems contribute to reduced operational costs over time.

For instance, a commercial thermal transfer system operating at an efficiency of 70% could yield approximately 38% savings on gas expenses, underscoring the significant financial advantages. Businesses can anticipate a notable return on investment, with certain systems achieving full ROI in as little as two years, as they capitalize on energy savings and minimize downtime associated with air-to-air thermal systems.

Furthermore, the industrial air to air heat exchanger systems‘ ability to recycle up to 95% of thermal content from processes enhances their economic appeal, making them an attractive option for industries focused on sustainability and cost efficiency.

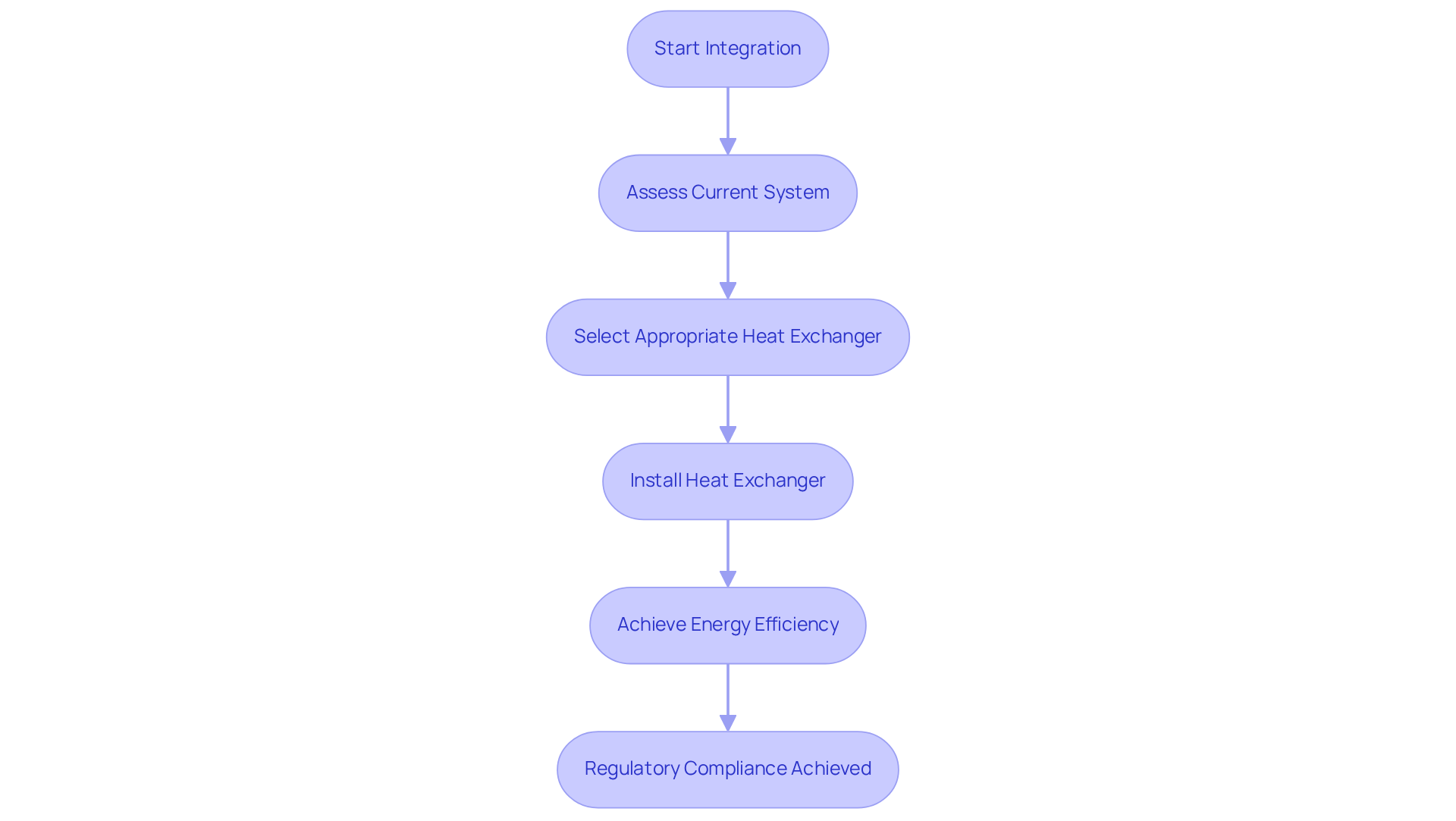

System Integration: Streamlining Electronics Cooling with Air to Air Heat Exchangers

The industrial air to air heat exchanger represents a pivotal advancement in thermal management, enabling seamless system integration and enhancing thermal solutions within existing electronic systems. Their modular design facilitates effortless installation alongside various temperature control technologies, including liquid systems and traditional HVAC units. This inherent flexibility empowers businesses to without necessitating a complete infrastructure overhaul.

By integrating an industrial air to air heat exchanger, companies can achieve a refrigeration solution that is not only efficient but also specifically tailored to their operational requirements. Notably, modern industrial air to air heat exchangers can reclaim up to 80% of warmth from exhaust air, resulting in significant reductions in heating and refrigeration costs.

Furthermore, the installation process is straightforward, typically completed in under a day, making these devices an attractive option for organizations seeking to enhance their temperature management practices. Engineers have underscored that the industrial air to air heat exchanger systems not only optimize energy efficiency but also play a crucial role in ensuring regulatory compliance, thereby rendering them indispensable in today’s industrial landscape.

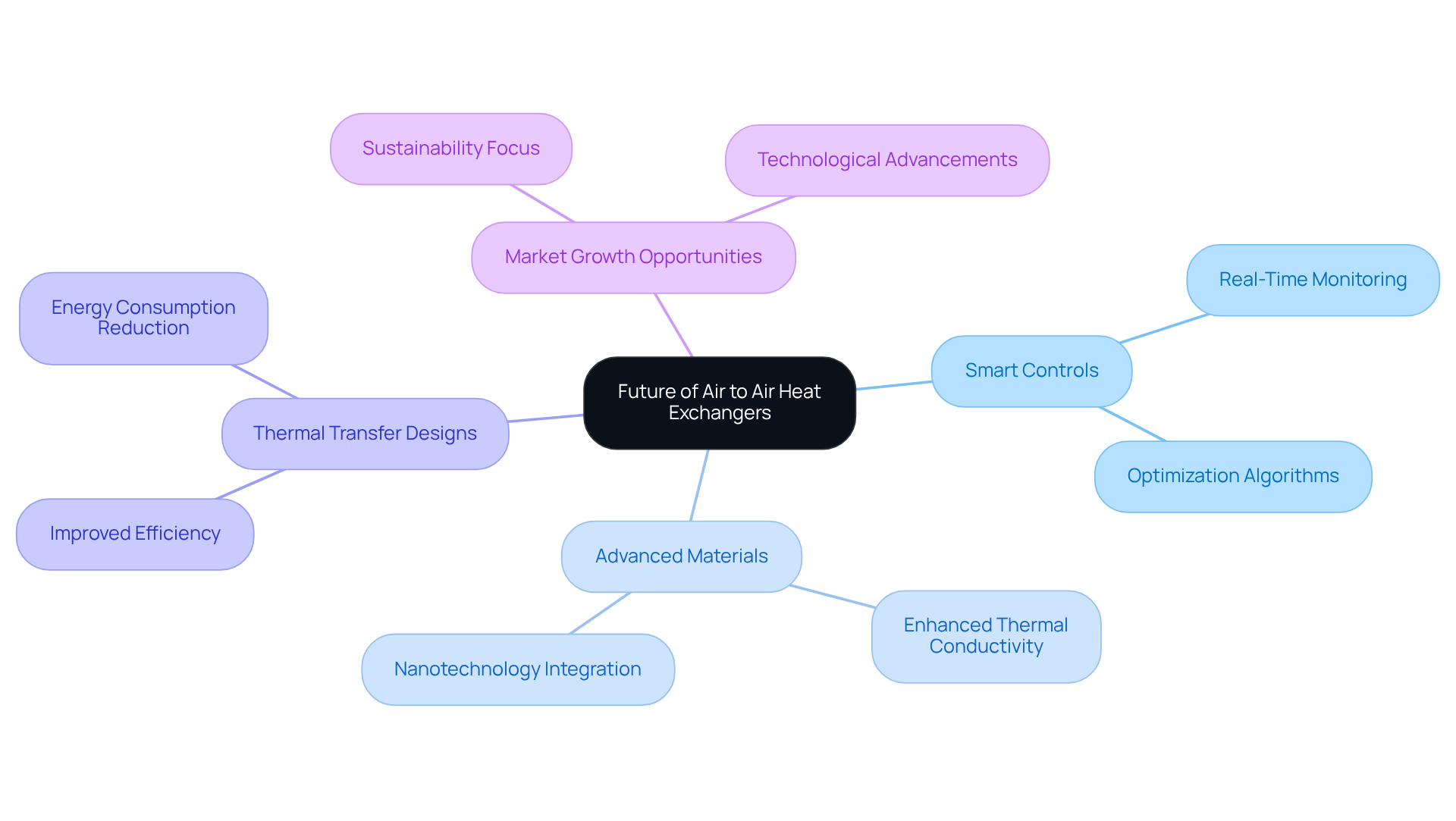

Technological Advancements: The Future of Air to Air Heat Exchangers in Electronics Cooling

The future of air-to-air thermal devices in electronics temperature management is undeniably promising, driven by continuous aimed at enhancing both efficiency and effectiveness. At the forefront of this evolution are innovations such as smart controls, which facilitate real-time monitoring and optimization, along with advanced materials that significantly enhance thermal conductivity.

Furthermore, improved thermal transfer designs are being developed to optimize performance while concurrently reducing energy consumption. As the demand for energy-efficient cooling solutions intensifies, air-to-air heat exchangers will play a crucial role in meeting these needs.

Companies that strategically invest in these emerging technologies will be exceptionally well-positioned to thrive in the competitive electronics market, leveraging the increasing focus on sustainability and efficiency.

Conclusion

The industrial air to air heat exchanger emerges as a transformative solution for electronics cooling, delivering a multitude of benefits that enhance performance, efficiency, and sustainability. By effectively managing thermal energy, these systems not only extend the lifespan of electronic devices but also yield significant cost savings and a diminished environmental footprint. The strategic implementation of air to air heat exchangers is crucial for companies seeking to optimize their operations in an increasingly energy-conscious market.

Key insights from the article underscore the exceptional energy efficiency of these systems, which can result in substantial reductions in operational costs through the reclamation of waste energy. Their reliability, ease of maintenance, and versatility across various industrial applications further emphasize their value. Moreover, the commitment to environmental sustainability through reduced carbon emissions positions air to air heat exchangers as an essential component of modern industrial practices.

As industries evolve, embracing innovative cooling technologies like air to air heat exchangers is not merely advantageous; it is imperative for ensuring competitiveness and compliance with sustainability goals. Organizations are urged to explore these advanced solutions to enhance their thermal management strategies, ultimately driving operational excellence and contributing to a more sustainable future.

Frequently Asked Questions

What is the primary function of air to air heat exchangers in electronics cooling?

Air to air heat exchangers are designed to effectively transfer heat from electronic components to the ambient air, ensuring optimal performance and prolonging the lifespan of devices.

How do air to air heat exchangers contribute to energy efficiency?

These systems reclaim waste energy from exhaust air to precondition incoming air, significantly lowering the energy required for heating and cooling, which reduces operational costs and enhances sustainability.

What is the expected return on investment for businesses using air to air heat exchangers?

Businesses can anticipate an average return on investment of approximately 38% on gas expenses, with many organizations experiencing payback periods of around two years.

How much thermal energy can industrial air to air heat exchangers reclaim in practical applications?

In sectors such as food processing, industrial air to air heat exchangers can reclaim up to 94-95% of thermal energy, improving energy efficiency and reducing operational costs.

What are the benefits of improved thermal management with air to air heat exchangers?

Improved thermal management helps efficiently disperse thermal energy, maintains optimal operating temperatures, enhances the performance of electronic devices, and extends their lifespan.

What is the average temperature decrease achievable by using air to air thermal devices?

Utilizing air to air thermal devices can lead to average temperature decreases of 30% to 50%, which is crucial for preserving the integrity and efficiency of delicate electronic components.

In what settings are air to air heat exchangers particularly beneficial?

These thermal devices are especially beneficial in high-performance computing settings, where they enhance operational reliability and energy efficiency.

Why is regular maintenance important for air to air heat exchangers?

Regular maintenance is essential to maximize the benefits of thermal devices and ensure they operate at peak efficiency.