Overview

The article delivers critical insights into fan PWM controllers, underscoring their pivotal role in enhancing energy efficiency, minimizing noise, and optimizing thermal management within electronic systems. It asserts that advanced PWM technology—encompassing both 2-wire and 4-wire configurations—facilitates precise speed control and adaptability across diverse applications. This makes PWM controllers indispensable for engineers striving to refine cooling solutions effectively.

Introduction

The evolution of cooling technology is rapidly transforming the landscape of electronic systems, with Pulse Width Modulation (PWM) fan controllers leading this change. These innovative devices not only enhance energy efficiency and reduce noise but also adapt dynamically to real-time thermal conditions, rendering them indispensable for engineers across various applications.

As the demand for smarter and more efficient cooling solutions continues to grow, a critical question emerges: how can engineers effectively navigate the complexities of PWM technology to optimize performance and reliability in their designs?

This article explores ten essential insights that illuminate the pivotal role of PWM controllers in modern engineering, providing valuable guidance for maximizing their benefits.

Gagner-Toomey Associates: Leading Provider of PWM Fan Control Solutions

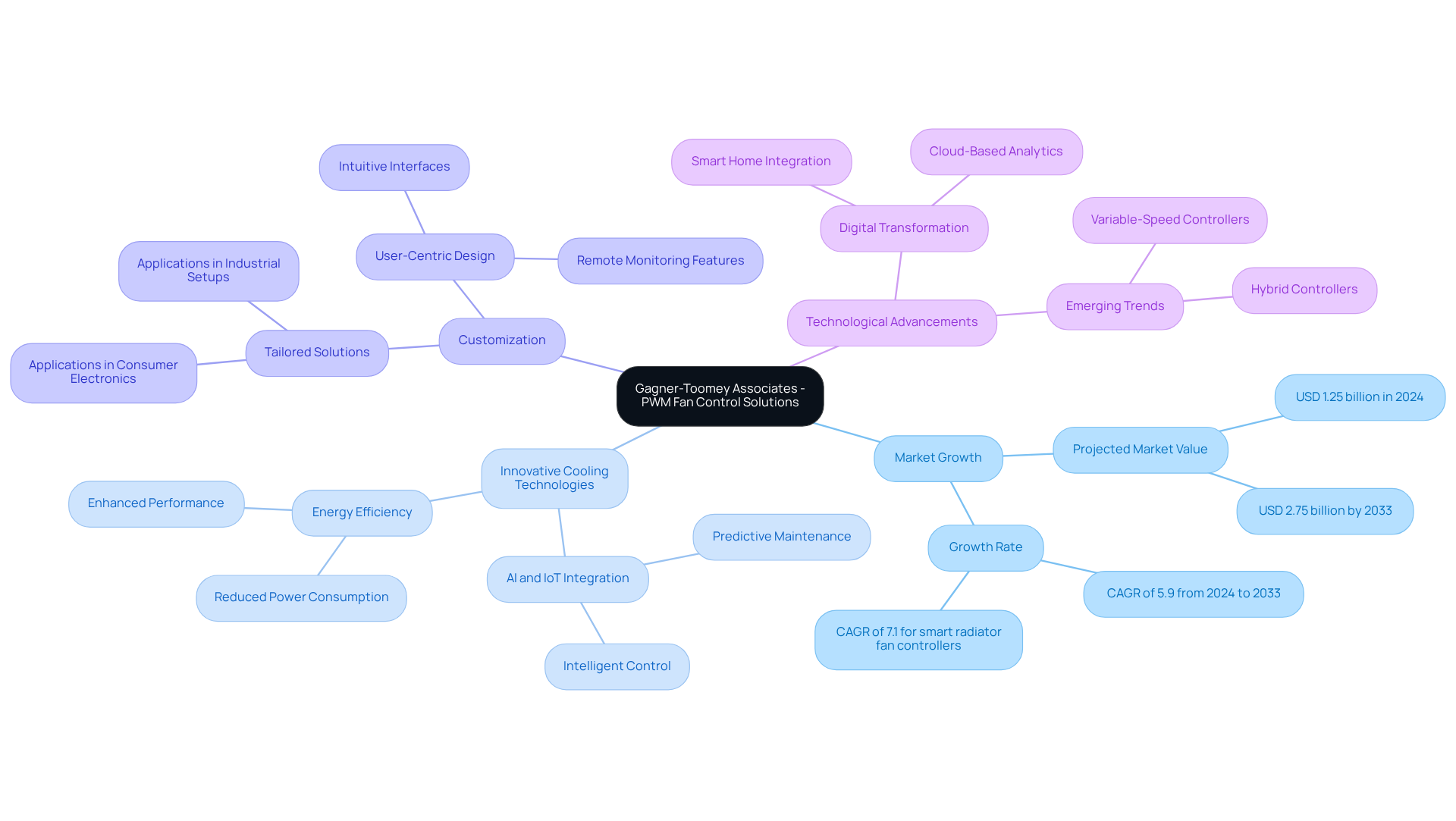

Gagner-Toomey Associates is recognized as a premier provider of fan PWM controller solutions, specializing in innovative cooling technologies that significantly enhance efficiency and performance. By collaborating with top manufacturers, the company delivers advanced PWM fan devices meticulously designed to meet the dynamic needs of engineers in the electronics field.

With the global projected to grow from USD 1.25 billion in 2024 to USD 2.75 billion by 2033, Gagner-Toomey is strategically positioned to capitalize on this trend. Their customized solutions improve thermal management across a diverse array of applications, ranging from consumer electronics to industrial setups.

Recent advancements in PWM technology, including the integration of AI and IoT for intelligent control, further underscore the company’s unwavering commitment to providing cutting-edge solutions. As industry leaders emphasize the critical importance of innovative cooling technologies, Gagner-Toomey Associates remains at the forefront, ensuring clients benefit from the latest developments in thermal management.

Understanding PWM Technology: The Basics of Pulse Width Modulation

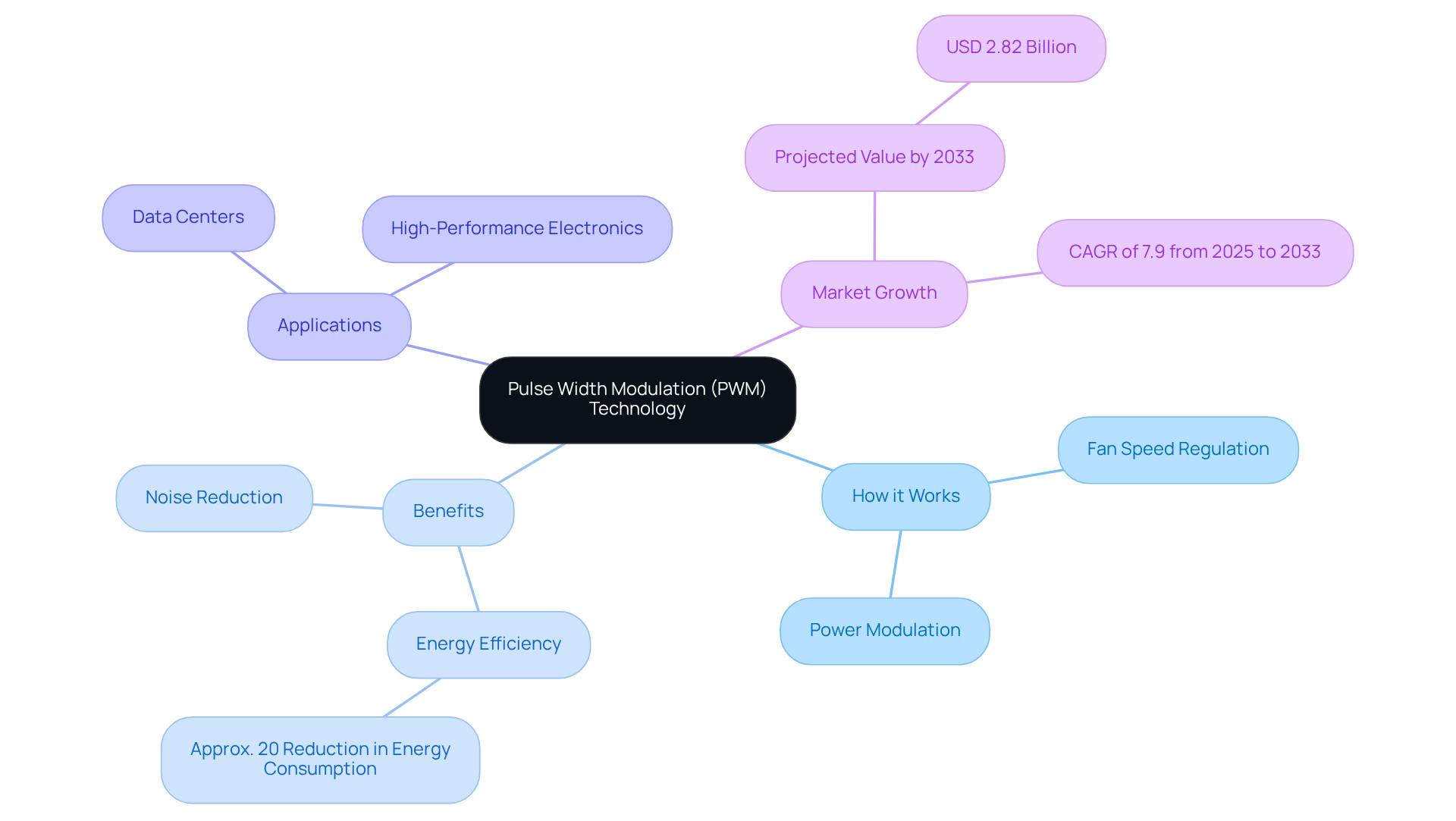

Pulse Width Modulation (PWM) is a sophisticated technique used by a fan PWM controller to regulate fan speed by varying the width of pulses within a digital signal. Unlike conventional devices that operate at a constant speed, the fan PWM controller empowers these units to according to real-time thermal requirements. This capability not only enhances energy efficiency—potentially reducing overall energy consumption by approximately 20%—but also minimizes noise levels, establishing the fan PWM controller as a preferred option in contemporary electronic cooling systems.

By rapidly switching power on and off, the fan PWM controller modulates the average power supplied to the fan, enabling precise control over its operation. This precision is particularly crucial in applications such as data centers and high-performance electronics, where a fan PWM controller is essential for effective temperature regulation, optimal performance, and longevity.

As highlighted by the Lawrence Berkeley National Laboratory, the adoption of fan PWM controller technology can yield significant energy savings, further emphasizing its importance in modern electronic applications. Moreover, the Electric Radiator Fan Controller PWM market is projected to grow to USD 2.82 billion by 2033, underscoring the increasing relevance of PWM technology within the industry.

2-Wire vs. 4-Wire PWM Fan Controllers: Key Differences Explained

The distinction between 2-wire and 4-wire PWM controller units is fundamentally rooted in their operational capabilities, particularly in the context of Gagner-Toomey Associates’ extensive range of cooling solutions, which includes DC input Tube Axial units and Centrifugal Blowers spanning from 15 to 280mm.

2-wire devices regulate their speed by varying the voltage supplied, which inherently limits their control accuracy and can lead to increased noise levels. Conversely, 4-wire PWM devices, integral to Gagner-Toomey’s cutting-edge product line, utilize a fan PWM controller that employs a dedicated PWM signal for speed management, facilitating finer adjustments and significantly quieter operation.

The additional wire in 4-wire devices not only enables precise speed control but also provides real-time performance feedback, crucial for applications in electronics, automotive, and industrial sectors that demand high reliability and efficiency. Engineers have observed that the advantage of the fan PWM controller is that it makes it easier to start the fan and maintain low speeds, thereby enhancing both performance and longevity.

Recent advancements in fan PWM controller technology have further refined these systems, with numerous fan PWM controllers now capable of operating at frequencies exceeding 20 kHz, effectively reducing audible noise. Furthermore, 4-wire fans can function at speeds as low as 10% of their maximum capacity, demonstrating their versatility in cooling applications.

Market trends indicate a growing preference for 4-wire configurations, as they deliver superior performance in compact electronic devices, which are increasingly designed to manage higher heat outputs while minimizing noise. This transition underscores the importance of selecting the to optimize cooling efficiency and operational reliability, particularly with Gagner-Toomey’s advanced cooling technologies.

Applications of PWM Fan Controllers in Electronic Cooling Systems

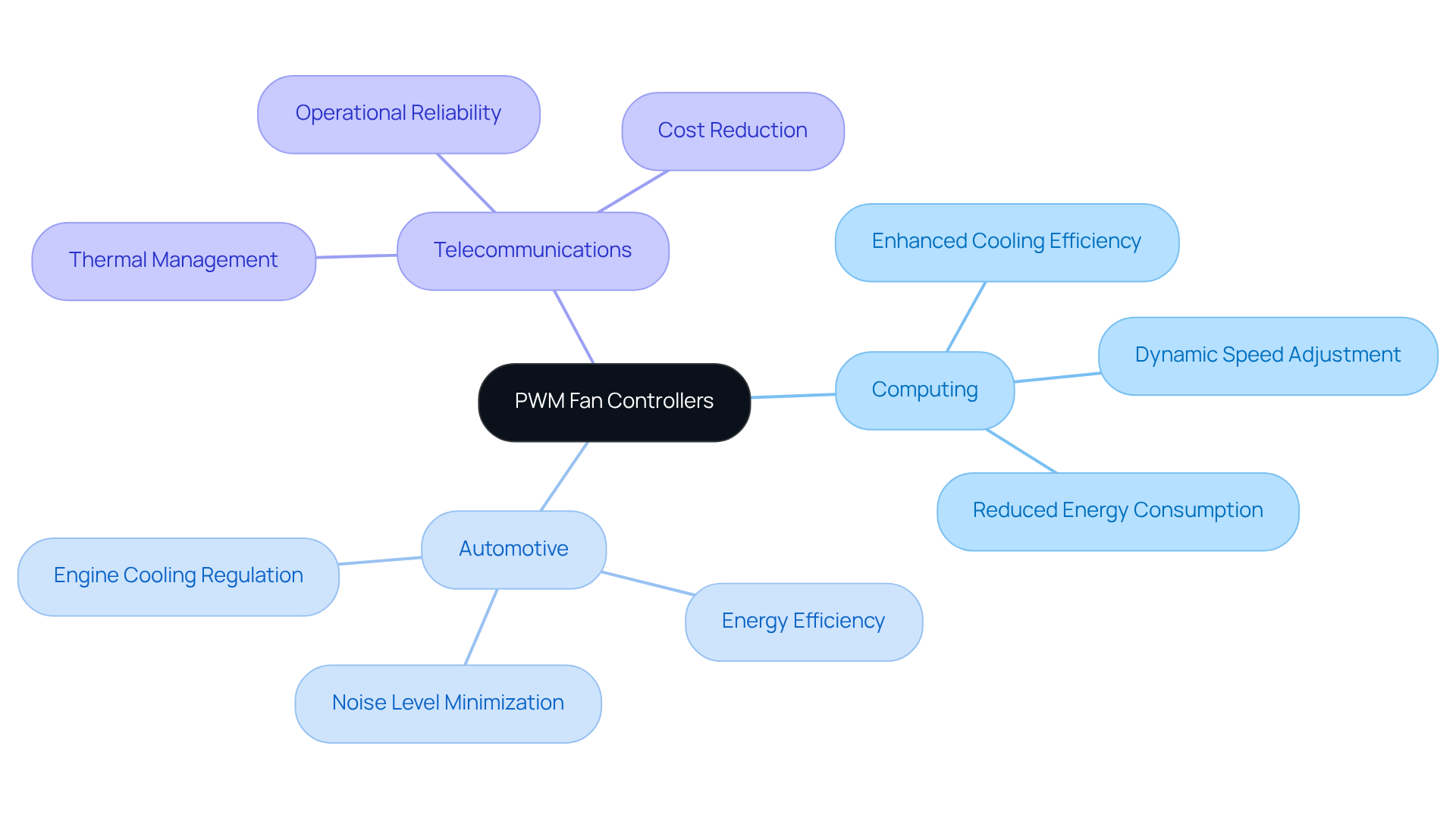

Fan PWM controllers serve as a cornerstone in electronic cooling solutions across diverse sectors, including computing, automotive, and telecommunications. In data centers, for example, the use of a fan PWM controller significantly enhances cooling efficiency by dynamically adjusting fan speeds in response to real-time temperature readings. This optimization not only improves performance but also leads to substantial . Similarly, in automotive applications, the fan PWM controller plays a crucial role in regulating engine cooling systems, ensuring optimal performance while minimizing noise levels. The adaptability of PWM technology positions it as an ideal choice for any application where effective thermal management is paramount.

Benefits of PWM Fan Controllers: Efficiency and Performance Gains

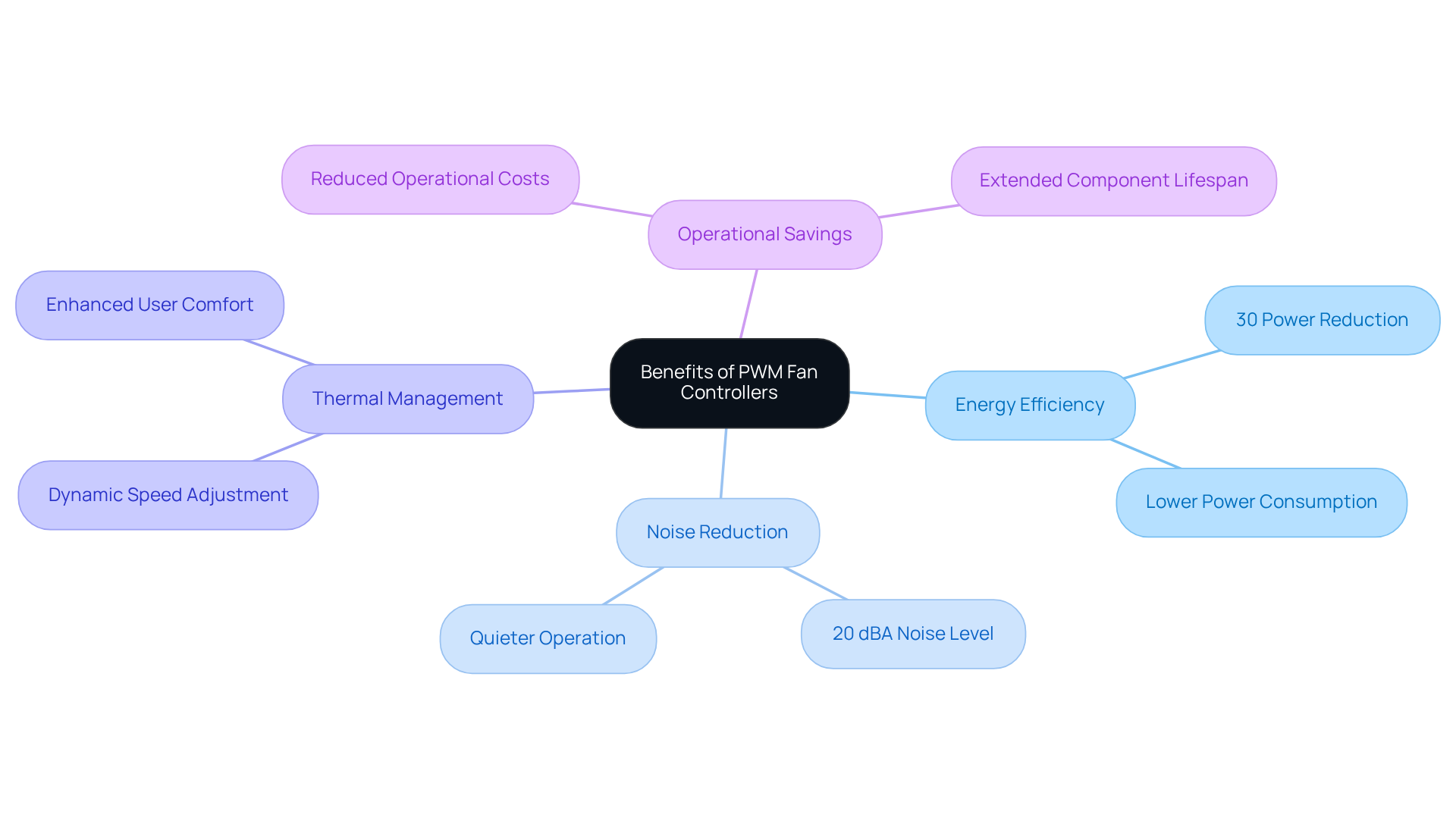

Fan PWM controllers present substantial advantages in energy efficiency, noise reduction, and thermal management. By dynamically adjusting fan speeds in response to real-time thermal conditions using a fan PWM controller, PWM technology effectively minimizes energy waste, leading to significant operational cost savings.

Research indicates that PWM units can achieve noise levels as low as 20 dBA, in contrast to conventional models that often exceed 30 dBA under similar conditions. This makes PWM technology particularly suitable for .

Engineers have observed that the capability of PWM fans to operate at lower speeds during reduced cooling demand not only enhances user comfort but also extends the lifespan of electronic components. Furthermore, the energy efficiency of PWM technology is underscored by findings suggesting it can reduce power usage by as much as 30% compared to traditional setups.

This combination of performance enhancements and operational savings positions the fan PWM controller as a preferred choice for engineers seeking reliable and effective cooling solutions in modern electronic systems.

Real-world applications, such as CPU coolers and high-performance gaming rigs, further illustrate the practical benefits of PWM technology. As Gagner-Toomey emphasizes, “Embracing PWM technology not only enhances performance but also contributes to a more sustainable future in electronics, establishing it as an indispensable tool for the challenges that lie ahead.

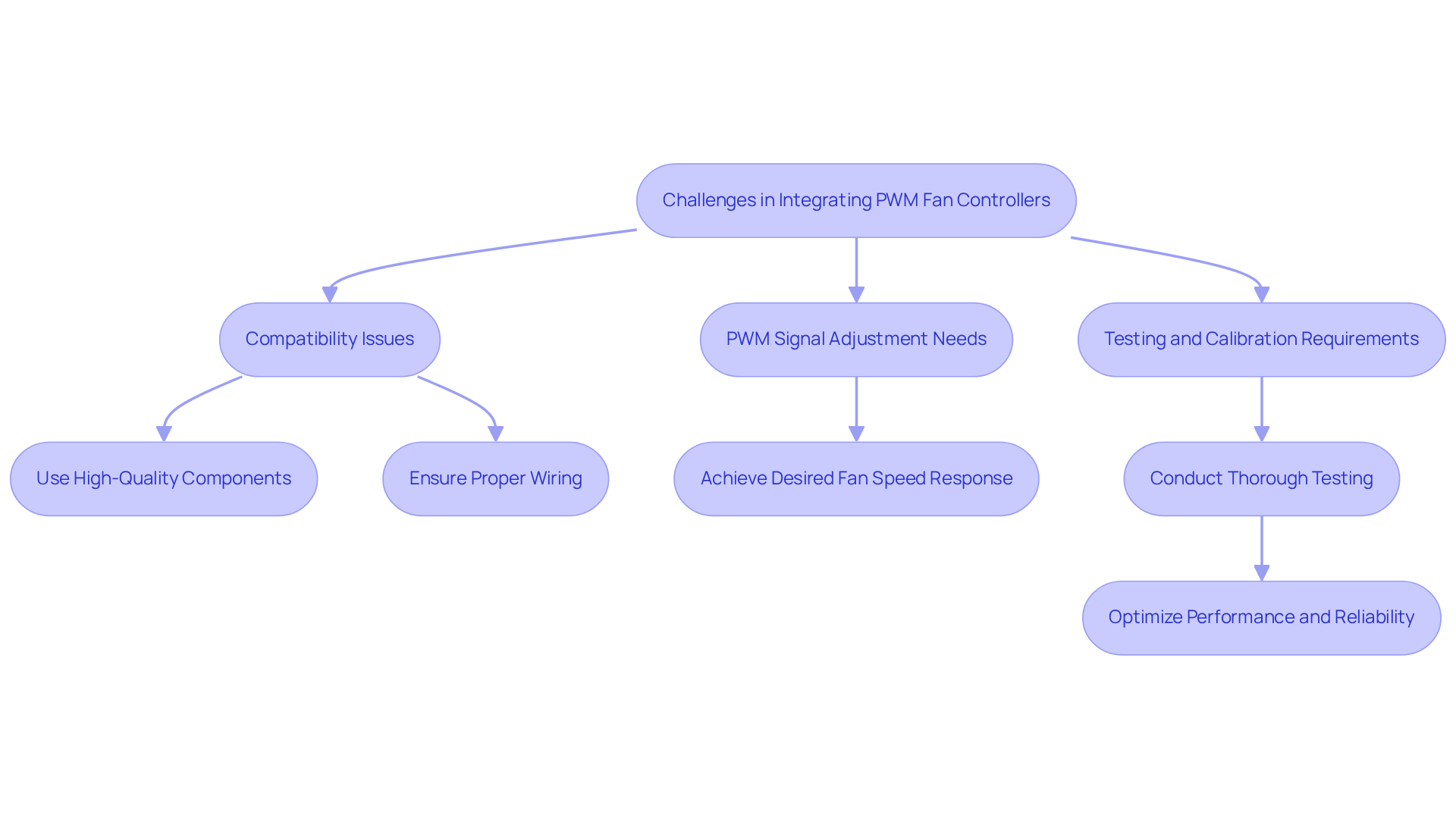

Challenges in Integrating PWM Fan Controllers: Common Issues and Solutions

Incorporating a fan PWM controller often presents several challenges, notably compatibility issues with existing setups and the necessity for precise PWM signal adjustments. Engineers frequently encounter difficulties in achieving the desired fan speed response, particularly when the fan PWM controller frequency is not tailored to the specific fan model. Statistics indicate that successful tuning of PWM signals can markedly enhance performance; many engineers report improved efficiency and responsiveness following meticulous calibration.

To address these challenges, it is essential to conduct during the design phase. Employing high-quality components and ensuring proper wiring can mitigate numerous common integration issues, thereby facilitating a more seamless implementation process.

As one engineer observed, tackling compatibility concerns early in the design phase can result in more effective thermal management and decreased energy consumption. By prioritizing these strategies, engineers can adeptly integrate fan PWM controllers into their systems, thereby optimizing both performance and reliability.

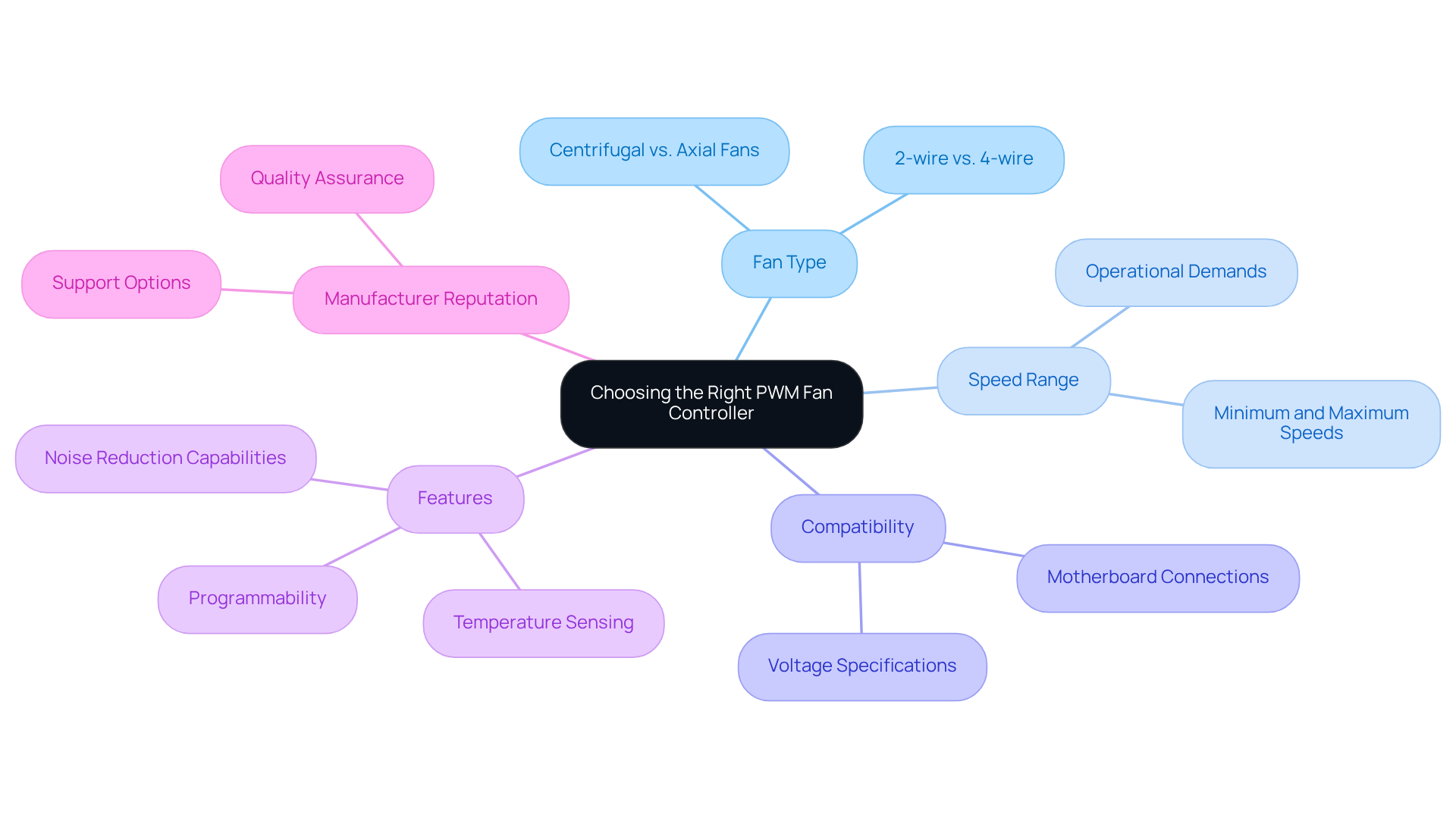

Choosing the Right PWM Fan Controller: Factors to Consider

Selecting the appropriate requires careful consideration of several critical factors. Engineers must first evaluate the type of fan in use, distinguishing between 2-wire and 4-wire configurations, as this distinction directly influences compatibility and control capabilities. Additionally, understanding the necessary speed range is vital; operators need to ensure that the regulator meets the specific operational demands of the application at hand. Compatibility with existing frameworks is crucial; confirming that the device can seamlessly connect with the motherboard or control unit is essential to avoid integration challenges. For instance, many engineers have encountered difficulties when using devices that do not align with the connector types or voltage specifications of their systems, leading to performance inefficiencies.

Moreover, it is imperative to assess the features of the device, such as the fan PWM controller, temperature sensing capabilities, and programmability, to guarantee alignment with project specifications. Advanced features can significantly enhance responsiveness and efficiency, particularly in high-performance environments. As one engineer aptly stated, “The adaptability of PWM devices is crucial for optimizing thermal management in dynamic applications.”

Finally, the reputation of the manufacturer and the availability of support options should not be underestimated, as these elements can profoundly impact the integration process and the long-term reliability of the cooling solution. Data indicates that systems equipped with well-matched fan PWM controllers can achieve up to a 30% improvement in temperature management efficiency, underscoring the importance of meticulous selection in achieving optimal performance.

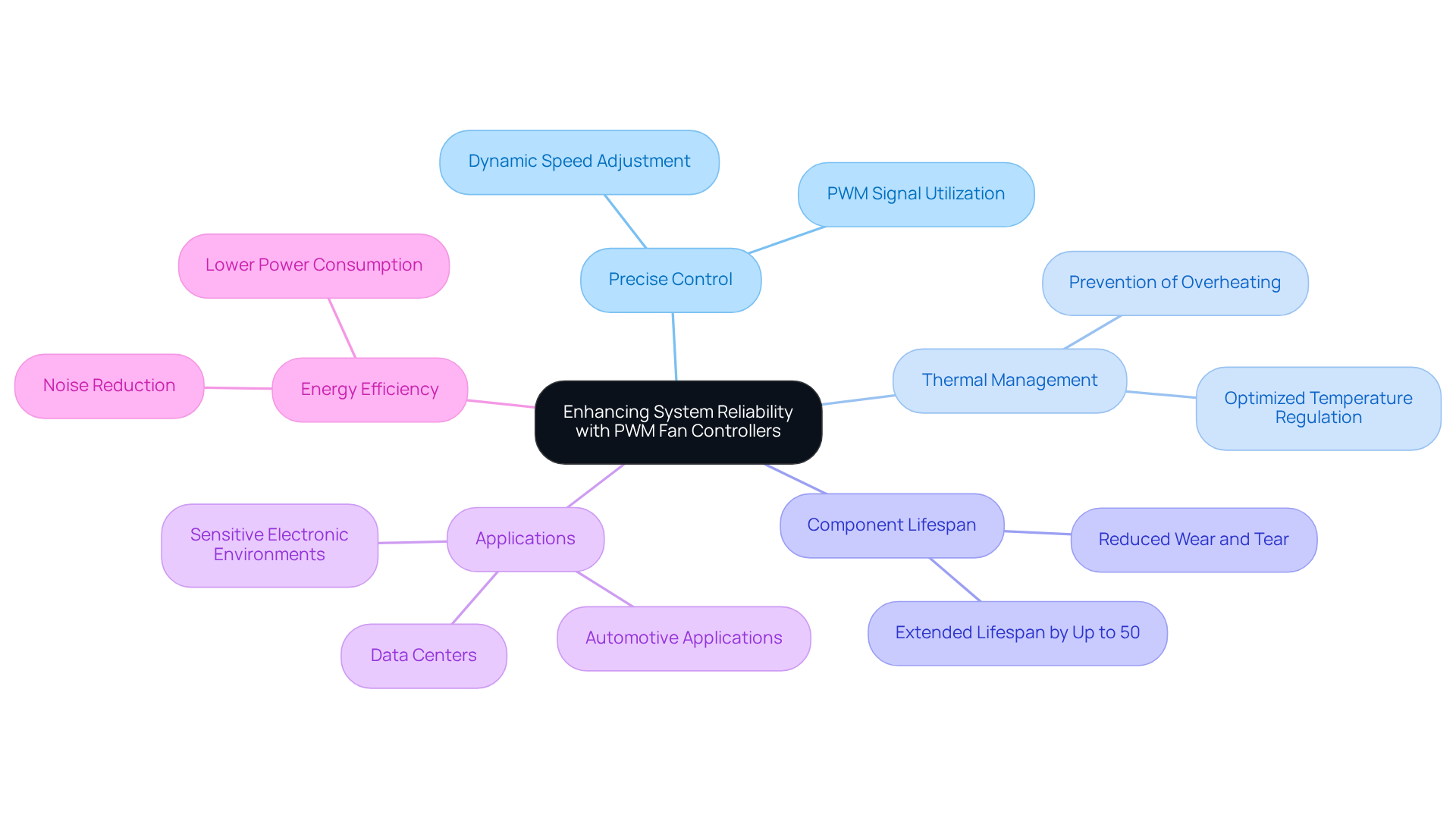

Enhancing System Reliability with PWM Fan Controllers

The fan PWM controller significantly enhances reliability by delivering , which is crucial for maintaining optimal thermal conditions. By dynamically adjusting fan speeds using a fan PWM controller in response to temperature fluctuations, these controllers adeptly prevent overheating, ensuring that electronic components operate within safe limits. This proactive thermal management strategy not only extends the lifespan of components—potentially by up to 50%, as demonstrated in the case study ‘Maximize Energy Efficiency in Electronic Systems’—but also mitigates the risk of failures.

In environments such as data centers, where thermal stability is critical, the fan PWM controller utilizing PWM technology has proven indispensable in sustaining operational efficiency and reliability. Engineers have emphasized that the versatility of fan PWM controllers outperforms traditional cooling systems, particularly in high-reliability contexts such as automotive applications and sensitive electronic environments.

As the significance of effective thermal management in electronics continues to escalate in 2025, the integration of PWM technology into contemporary designs becomes increasingly imperative.

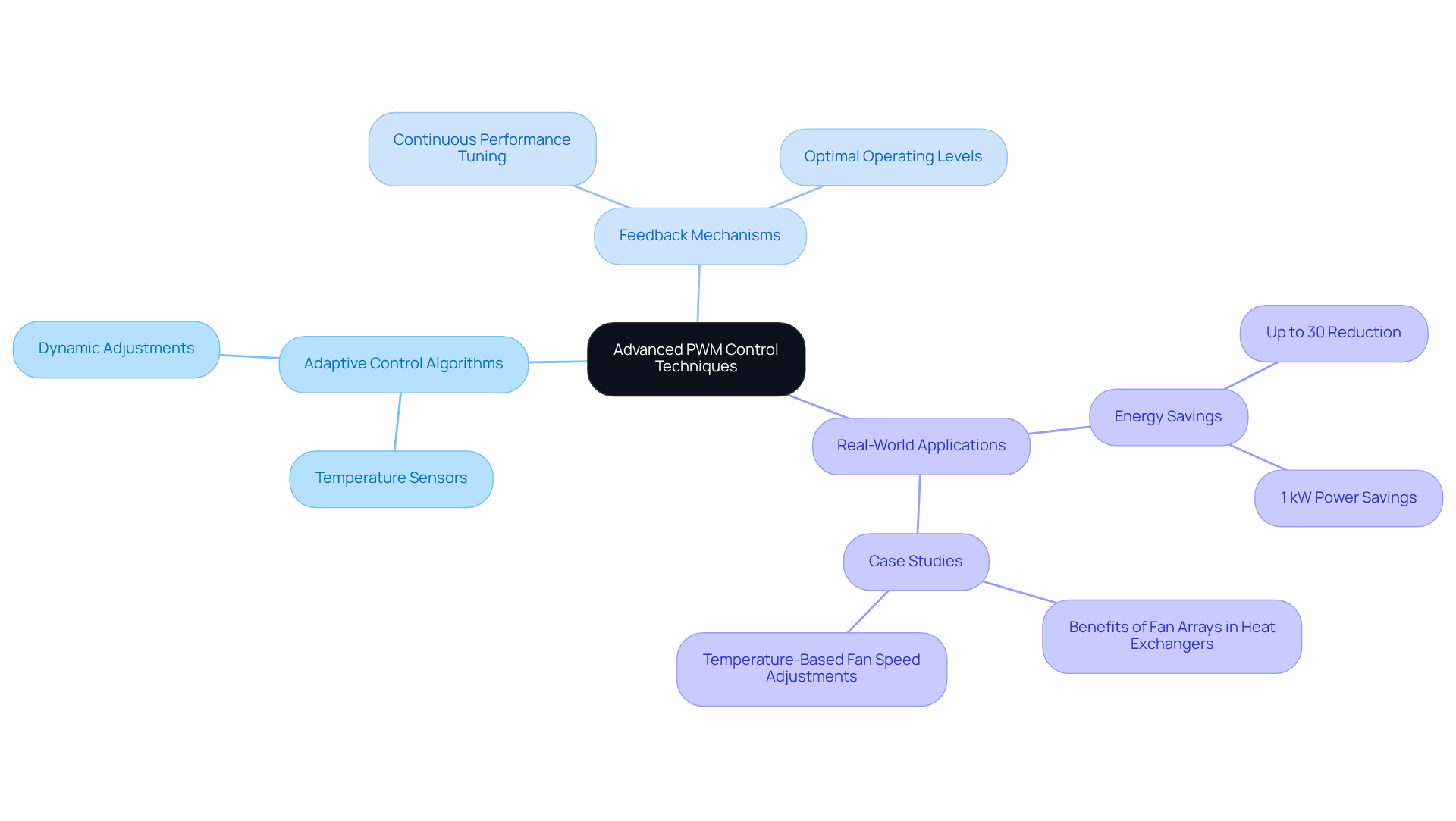

Advanced PWM Control Techniques for Optimizing Fan Performance

Advanced control techniques in the fan PWM controller, particularly adaptive control algorithms and feedback mechanisms, are essential for optimizing fan performance. By employing algorithms that adjust based on operational behavior, engineers can achieve precise modifications in fan speed, ensuring cooling is applied exactly when necessary.

For instance, integrating temperature sensors with real-time monitoring tools facilitates dynamic adjustments that respond to actual thermal conditions, significantly enhancing efficiency. Real-world applications have illustrated that these advanced techniques can yield energy savings of up to 30%, as evidenced by a case study focused on temperature-based fan speed adjustments.

Moreover, feedback mechanisms within the fan PWM controller enable continuous performance tuning, ensuring that systems operate at optimal levels under varying conditions. This comprehensive approach not only maximizes airflow but also , making it crucial for contemporary electronic cooling solutions.

Additionally, the potential for power consumption savings of 1 kW with the new method highlights the effectiveness of these advanced control strategies, particularly in scenarios characterized by moderate to low volume flow rates and/or high pressure levels. As noted by Daniel Conrad, the redundancy of fan arrays and the capacity to dynamically resize them by selectively powering down fans further bolster energy efficiency.

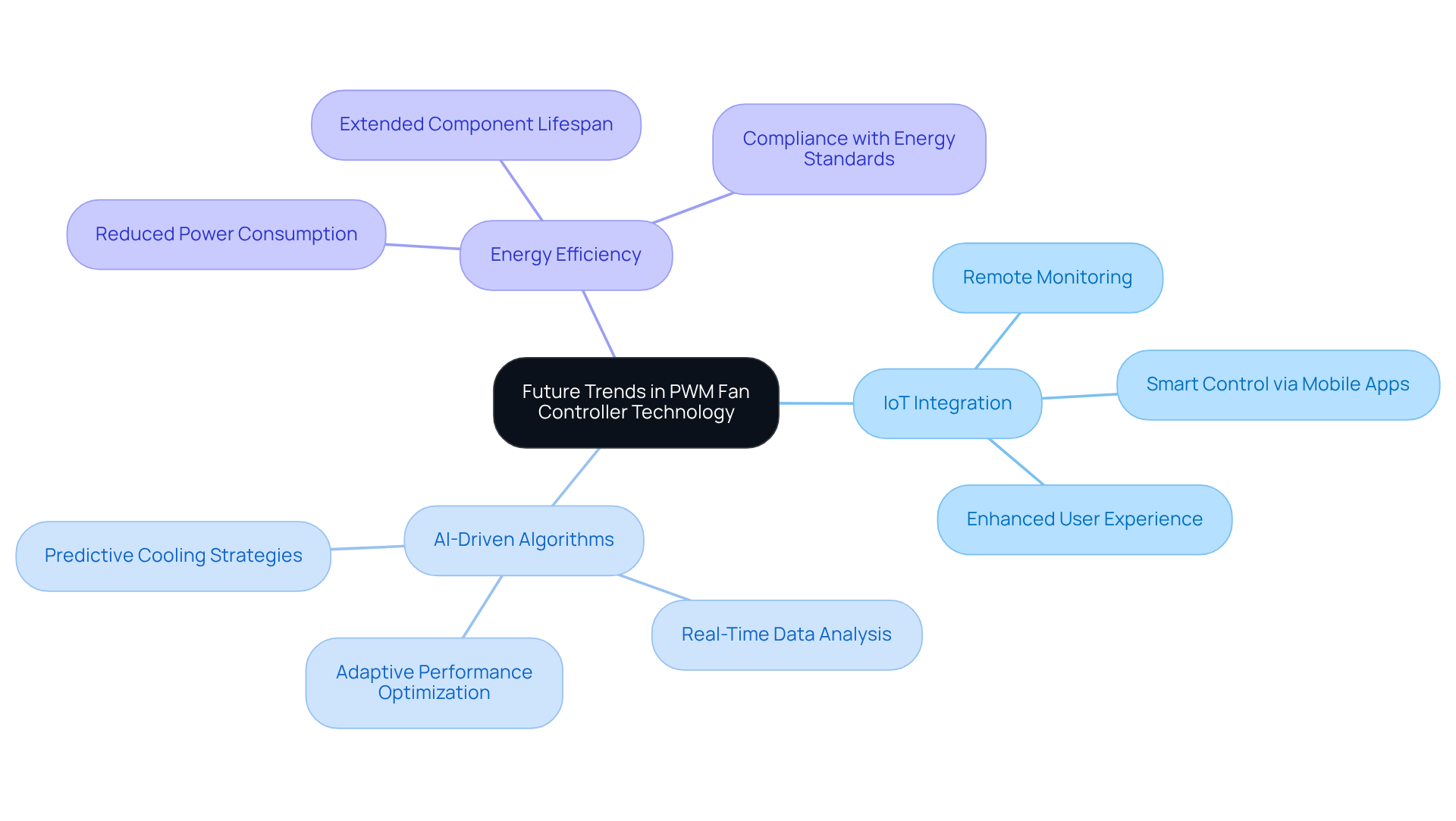

Future Trends in PWM Fan Controller Technology: What Engineers Should Expect

The future of fan PWM controller technology is set to undergo significant advancements, driven by the escalating demand for and smart technologies. Notably, emerging trends encompass the integration of IoT capabilities, which facilitate remote monitoring and control of fan units. Furthermore, advancements in AI-driven algorithms will empower more sophisticated predictive cooling strategies, optimizing performance based on historical data and real-time conditions. As the electronics industry continues to evolve, engineers can anticipate that the fan PWM controller will play a central role in enhancing system efficiency, reliability, and overall performance.

Conclusion

The exploration of fan PWM controllers underscores their pivotal role in contemporary electronic systems, highlighting their importance in enhancing efficiency and performance. By harnessing advanced Pulse Width Modulation technology, engineers can exercise precise control over fan speeds, resulting in significant energy savings and noise reduction. This capability not only optimizes thermal management but also prolongs the lifespan of electronic components, rendering PWM controllers an essential tool for engineers navigating the complexities of today’s cooling demands.

Key insights include:

- The distinctions between 2-wire and 4-wire PWM controllers

- Their diverse applications across sectors such as data centers and automotive systems

- The challenges engineers encounter during integration

The benefits of adopting PWM technology are evident, with data demonstrating enhancements in energy efficiency and operational reliability. Furthermore, emerging trends indicate a growing integration of IoT and AI technologies, promising even greater advancements in cooling solutions.

As the electronics industry continues to evolve, the necessity of selecting the appropriate PWM fan controller cannot be overstated. Engineers are urged to remain informed about the latest trends and advancements in PWM technology to ensure that their systems not only meet current demands but also anticipate future challenges. Embracing these innovations will be crucial in fostering a more sustainable and efficient electronic landscape, ultimately shaping the future of thermal management.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leading provider of fan PWM controller solutions, specializing in innovative cooling technologies that enhance efficiency and performance in electronic applications.

How is the global market for programmable PWM controllers expected to change in the coming years?

The global programmable PWM controllers market is projected to grow from USD 1.25 billion in 2024 to USD 2.75 billion by 2033.

What advancements in PWM technology has Gagner-Toomey Associates integrated into their products?

Gagner-Toomey Associates has integrated advancements such as AI and IoT for intelligent control into their PWM technology, ensuring they provide cutting-edge solutions for thermal management.

What is Pulse Width Modulation (PWM) and how does it work in fan controllers?

Pulse Width Modulation (PWM) is a technique used to regulate fan speed by varying the width of pulses in a digital signal, allowing fans to adjust their RPM based on real-time thermal requirements, enhancing energy efficiency and minimizing noise levels.

What energy savings can be achieved by adopting fan PWM controller technology?

The adoption of fan PWM controller technology can potentially reduce overall energy consumption by approximately 20%.

What are the key differences between 2-wire and 4-wire PWM fan controllers?

2-wire PWM controllers regulate speed by varying voltage, which limits control accuracy and increases noise. In contrast, 4-wire PWM controllers use a dedicated PWM signal for precise speed management, resulting in finer adjustments and quieter operation.

What are the advantages of using 4-wire PWM fan controllers?

4-wire PWM fan controllers enable precise speed control, provide real-time performance feedback, and can operate at speeds as low as 10% of their maximum capacity, enhancing performance and longevity.

Why is there a growing preference for 4-wire PWM fan controllers in the market?

There is a growing preference for 4-wire configurations due to their superior performance in compact electronic devices, which manage higher heat outputs while minimizing noise levels.