Overview

This article identifies the leading suppliers of cold plates for electronics cooling solutions, capturing the attention of industry professionals. It highlights key companies, including:

- Gagner-Toomey Associates

- Boyd Corporation

- Kenfatech

It details their innovative technologies and market trends. These firms are recognized for their significant contributions to effective thermal management in high-performance applications such as electric vehicles and data centers. By showcasing their advancements, the article establishes their prominence in the industry, appealing to those seeking reliable solutions in thermal management.

Introduction

The demand for effective thermal management solutions is surging, driven by industries increasingly relying on advanced electronics, electric vehicles, and high-performance data centers. This article delves into seven leading cold plate suppliers who are revolutionizing cooling technologies, presenting innovative products specifically designed to meet the unique needs of engineers and manufacturers alike. As the market evolves, however, challenges such as rising material costs and supply chain disruptions arise. Which suppliers will rise to the occasion and lead the charge in this critical sector?

Gagner-Toomey Associates: Expert Sales Solutions in Electronics Cooling

Gagner-Toomey Associates stands out as a premier professional sales organization dedicated to empowering engineers within the electronics sector. By focusing on innovative temperature management solutions, they represent a wide range of manufacturers, guaranteeing clients access to state-of-the-art products tailored to their specific requirements. This unwavering commitment to excellence in not only positions Gagner-Toomey as a pivotal player in the electronics temperature control market but also establishes them as a trustworthy partner for engineers navigating the complexities of heat management.

Gagner-Toomey’s consultative approach, bolstered by advanced IT tools for opportunity tracking and sales reporting, significantly enhances their responsiveness and capability to meet customer needs effectively. Their strategic partnerships with industry leaders such as Delta and CONEC are essential in delivering efficient heat management strategies that adapt to the evolving demands of the sector. Furthermore, their brushless fan systems improve energy efficiency and reliability, utilizing considerably less power than conventional brushed devices, thus presenting a cost-effective solution for engineers.

Boyd Corporation: Pioneering Liquid Cold Plate Technologies

Boyd Corporation stands at the forefront of liquid cold surface technology, delivering solutions that excel in the efficient transfer of heat from high-load surfaces to advanced thermal management systems. Notably, their Hi-Contact tube liquid cold surfaces are engineered to enhance heat transfer by maximizing the contact area between liquid tubes and heat exchange surfaces. This innovative design significantly improves heat transfer efficiency, positioning these cold surfaces as the preferred choice for in both data centers and electric vehicles.

Recent advancements in liquid temperature regulation technologies have solidified Boyd’s status as a key player in the market. The escalating demand for efficient thermal management solutions underscores this trend. The electric vehicle battery thermal management market, projected to grow from approximately $1.2 billion in 2024 to around $3.5 billion by 2034, boasts a Compound Annual Growth Rate (CAGR) of 12.3% from 2025 to 2034. This growth trajectory is driven by the increasing need for efficient thermal systems in high-capacity batteries.

Boyd’s unwavering commitment to research and development ensures they remain at the cutting edge of temperature management technology, effectively catering to the evolving demands of the electronics sector and the needs of cold plate suppliers. Their comprehensive fabrication techniques and 100% leak-tested construction options enhance reliability and performance, establishing Boyd’s cold plate suppliers as indispensable components in modern cooling systems. The standard sizes of Boyd Hi-Contact tube liquid cold units—2-pass, 4-pass, and 6-pass models—are tailored to meet diverse application requirements. Case studies further demonstrate their capability in managing high-density heat loads, illustrating the critical role of liquid cooling systems in maintaining optimal operating temperatures for electronic components.

As the industry continues to evolve, Boyd’s Hi-Contact tube liquid cold components are set to play a pivotal role in shaping the future of heat management solutions. However, challenges such as supply chain disruptions and rising material costs loom over the market, necessitating ongoing innovation and adaptation.

Kenfatech: Custom Liquid Cold Plates for Diverse Applications

Kenfatech excels in the creation of tailored liquid cooling components, specifically designed to meet the unique heat management requirements across various industries. Their products utilize advanced materials and innovative manufacturing techniques, ensuring .

For instance, in the automotive sector, customized cooling systems are crucial for regulating the heat generated by electric vehicle batteries and power electronics. The EV liquid cooling market is projected to reach USD 5.9 billion by 2031, expanding at a CAGR of 11.2%. Notably, the Asia-Pacific region commands the largest market share due to high production volumes of electric vehicles.

In telecommunications, Kenfatech’s solutions effectively dissipate heat in high-density environments, thereby enhancing system reliability. The organization’s commitment to quality is underscored by rigorous testing protocols provided by cold plate suppliers, including:

- Pressure holding assessments

- Flow resistance assessments

These ensure the reliability of cold components under high-pressure and high-temperature conditions. Furthermore, the increasing demand for cold plate suppliers in medical devices and healthcare applications highlights the adaptability of Kenfatech’s offerings.

By providing tailored approaches, Kenfatech not only addresses unique temperature control challenges but also positions itself as a dependable partner for engineers striving for efficiency and performance in their applications.

XD Thermal Technology: High-Performance Liquid Cold Plates

XD Thermal Technology is renowned for its high-performance liquid cooling components, essential for efficient temperature regulation in high-density electronics. Their products are engineered to manage significant heat loads, ensuring optimal performance in applications such as electric vehicles and data centers.

Notably, according to IDTechEx, cold plate suppliers in the refrigeration sector are projected to experience a growth rate of 16% CAGR until 2023, underscoring the increasing demand for effective temperature control within the industry. As Yulin Wang highlights, the rising power density of data center racks, driven by advancements in cloud computing and AI, necessitates sophisticated heat management strategies.

With a steadfast commitment to innovation, XD Thermal consistently enhances its product range to meet the evolving needs of contemporary electronics, establishing itself as a reliable choice for engineers seeking . Recent developments in heat management for electric vehicles further underscore the importance of XD Thermal’s offerings, as they adapt to the industry’s dynamic landscape and the growing need for effective heat solutions.

Furthermore, Intel’s introduction of a new cold component design that integrates cold elements directly into the package illustrates competitive advancements within the industry, further accentuating the relevance of XD Thermal’s innovations.

Case studies demonstrating the effectiveness of XD Thermal products in managing heat within electric vehicles reveal their practical applications and efficacy in real-world scenarios.

Wakefield Thermal: Comprehensive Liquid Cooling Solutions

Wakefield Thermal stands at the forefront of liquid refrigeration technology, offering a diverse range of solutions, including advanced cold plate suppliers that excel in heat management. These meticulously engineered products are designed to minimize heat resistance and optimize heat dissipation, rendering them particularly suitable for high-performance applications in the electronics sector. With an unwavering commitment to innovation and quality, Wakefield Thermal guarantees that its not only meet but surpass the rigorous demands of the industry. This dedication empowers engineers to adeptly address temperature-related challenges, thereby enhancing the reliability and efficiency of their designs.

The liquid cooling systems market, valued at $2.75 billion in 2020, is anticipated to surge to $12.99 billion by 2030, reflecting a compound annual growth rate of 17.1% from 2021 to 2030. Wakefield Thermal’s contributions are vital in meeting the evolving temperature control needs of modern electronics. As the market expands, the challenges brought about by the COVID-19 pandemic have further influenced growth dynamics, underscoring the importance of Wakefield’s innovative solutions.

Moreover, case studies demonstrating Wakefield Thermal’s effectiveness in high-performance applications highlight their ability to resolve complex thermal management issues, solidifying their status as one of the leading cold plate suppliers in the industry.

Dana Incorporated: Innovative Battery Cold Plates for EVs

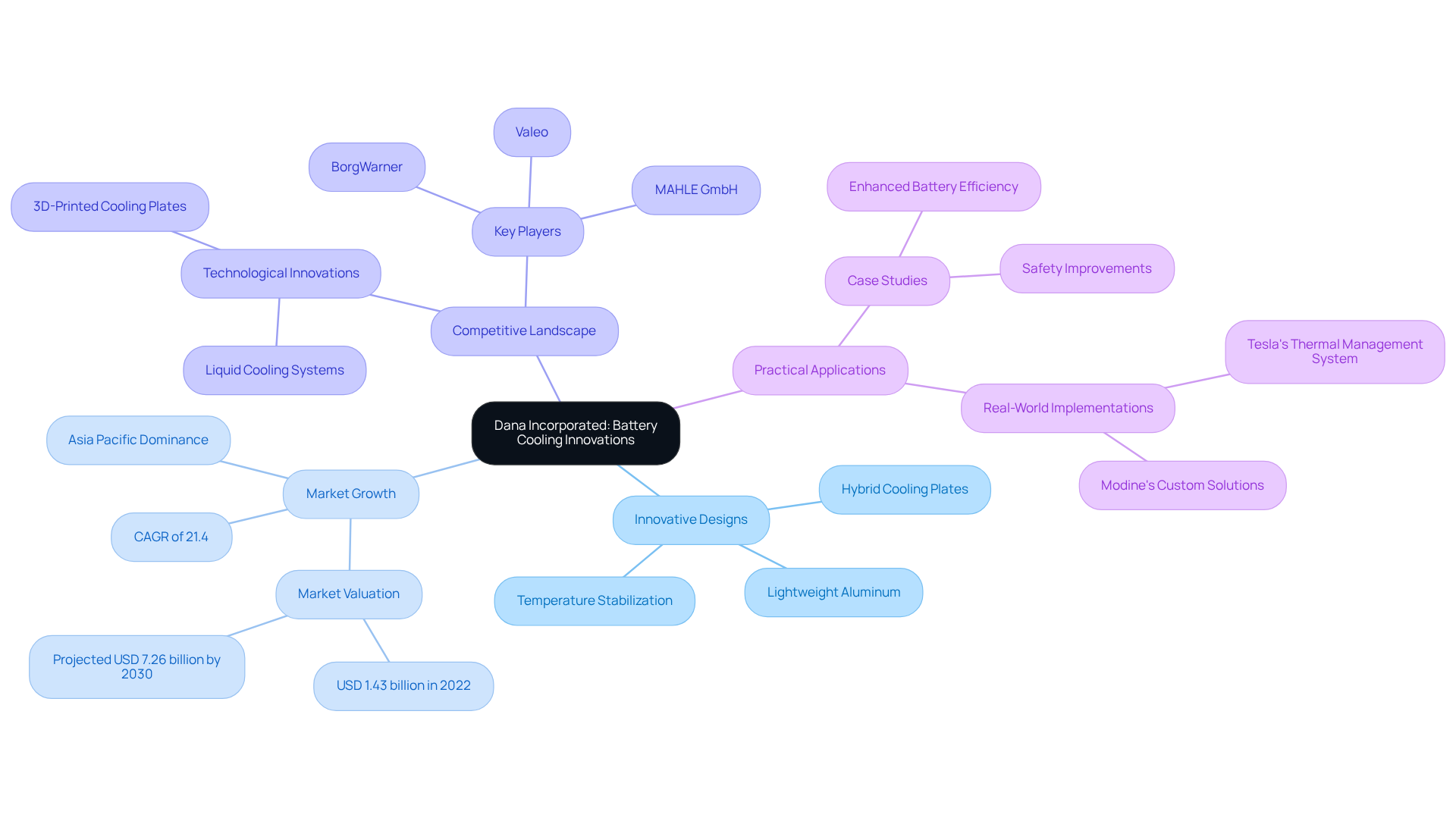

Dana Incorporated is at the forefront of developing innovative battery cooling components specifically designed for electric vehicles. Their lightweight aluminum designs effectively stabilize battery temperatures, ensuring both optimal performance and longevity.

The global electric vehicle battery thermal management system market was valued at USD 1.43 billion in 2022 and is projected to reach USD 7.26 billion by 2030, expanding at a compound annual growth rate (CAGR) of 21.4%. This remarkable growth underscores the critical importance of in the EV market, where Dana’s commitment to advancing heat management technologies positions them as a pivotal player.

Recent innovations, such as MAHLE GmbH’s introduction of 3D-printed temperature control plates, further illustrate the competitive landscape in heat management technologies. As noted by Valeo, “Effective thermal management systems are vital for the performance and safety of electric vehicles.”

Additionally, a case study on Dana’s thermal solutions revealed a significant enhancement in battery efficiency and safety in a leading EV model, showcasing the practical applications of their technology. As electric vehicles continue to gain traction, the necessity of effective cooling systems becomes increasingly apparent, with companies like Dana leading the charge in this essential development.

Future Market Insights: Trends and Insights in Cold Plates Market

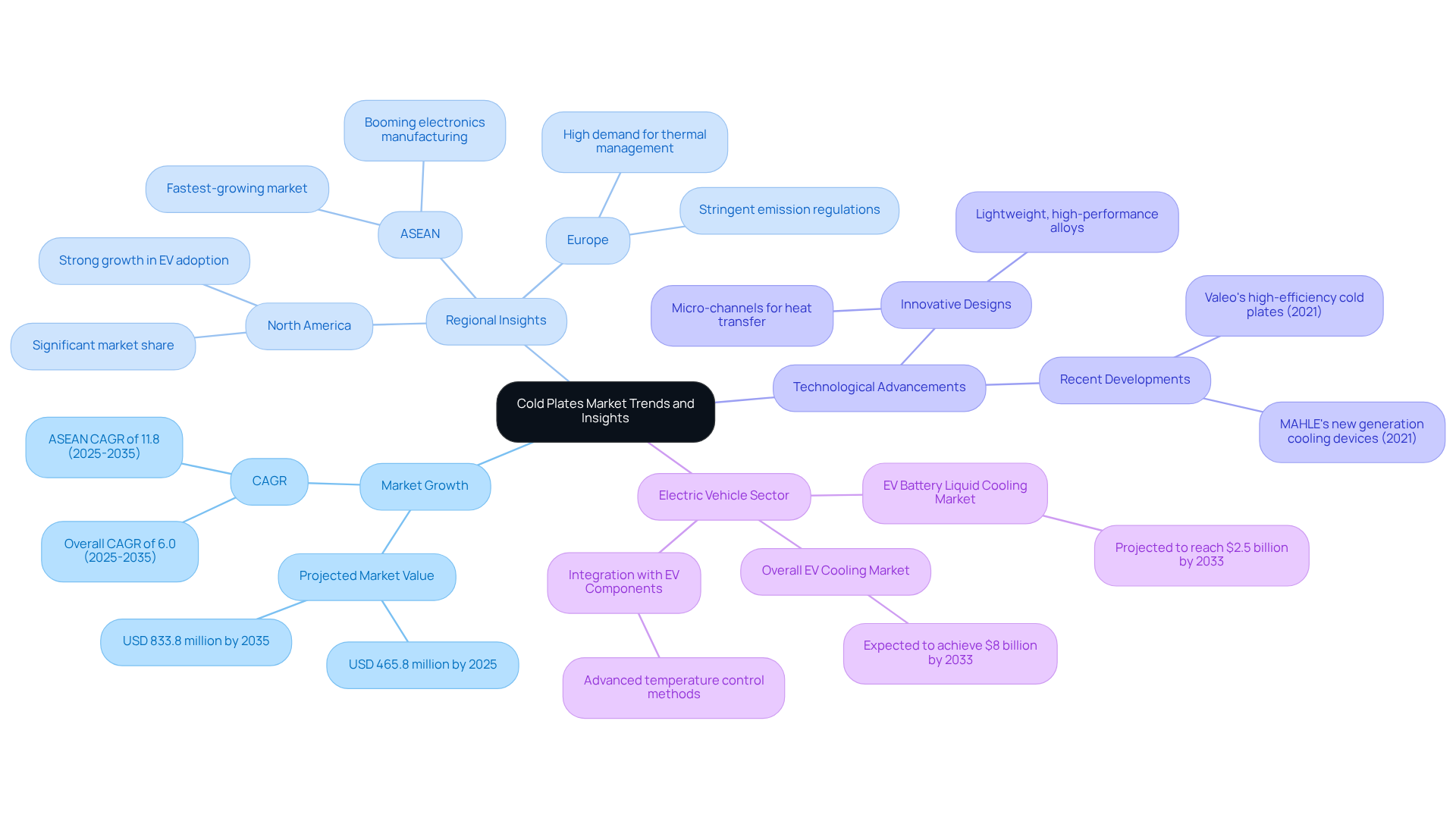

The chilly dishes market is poised for substantial expansion, driven by several critical factors. A primary catalyst is the increasing demand for efficient thermal management solutions in high-power electronics, electric vehicles, and data centers. Projections indicate that the market will reach approximately USD 465.8 million by 2025, with expectations to grow to around USD 833.8 million by 2035, reflecting a compound annual growth rate (CAGR) of 6.0% through 2035. Notably, the ASEAN region is emerging as a significant player, with a projected CAGR of 11.8% from 2025 to 2035, fueled by the booming electronics manufacturing and electric vehicle production sectors.

Recent advancements in cold surface materials and technologies are also reshaping the market landscape. Manufacturers are actively exploring lightweight, high-performance alloys and innovative designs, such as micro-channels, to enhance heat transfer efficiency. For instance, in 2021, MAHLE introduced a new generation of high-efficiency cooling devices, exemplifying the trend toward innovation within the sector.

The electric vehicle sector holds particular significance, with the projected to reach $2.5 billion by 2033, and the overall EV cooling market expected to achieve $8 billion by the same year, driven by the rising demand for high-performance vehicles. Industry analysts underscore that the integration of cold surfaces with other EV components represents a significant developing trend, further underscoring the importance of advanced temperature control methods.

As the market evolves, understanding these trends and predictions will be crucial for cold plate suppliers and manufacturers aiming to remain competitive and seize new opportunities in the cold components sector.

Heatraplates: Advanced Battery Cooling Solutions

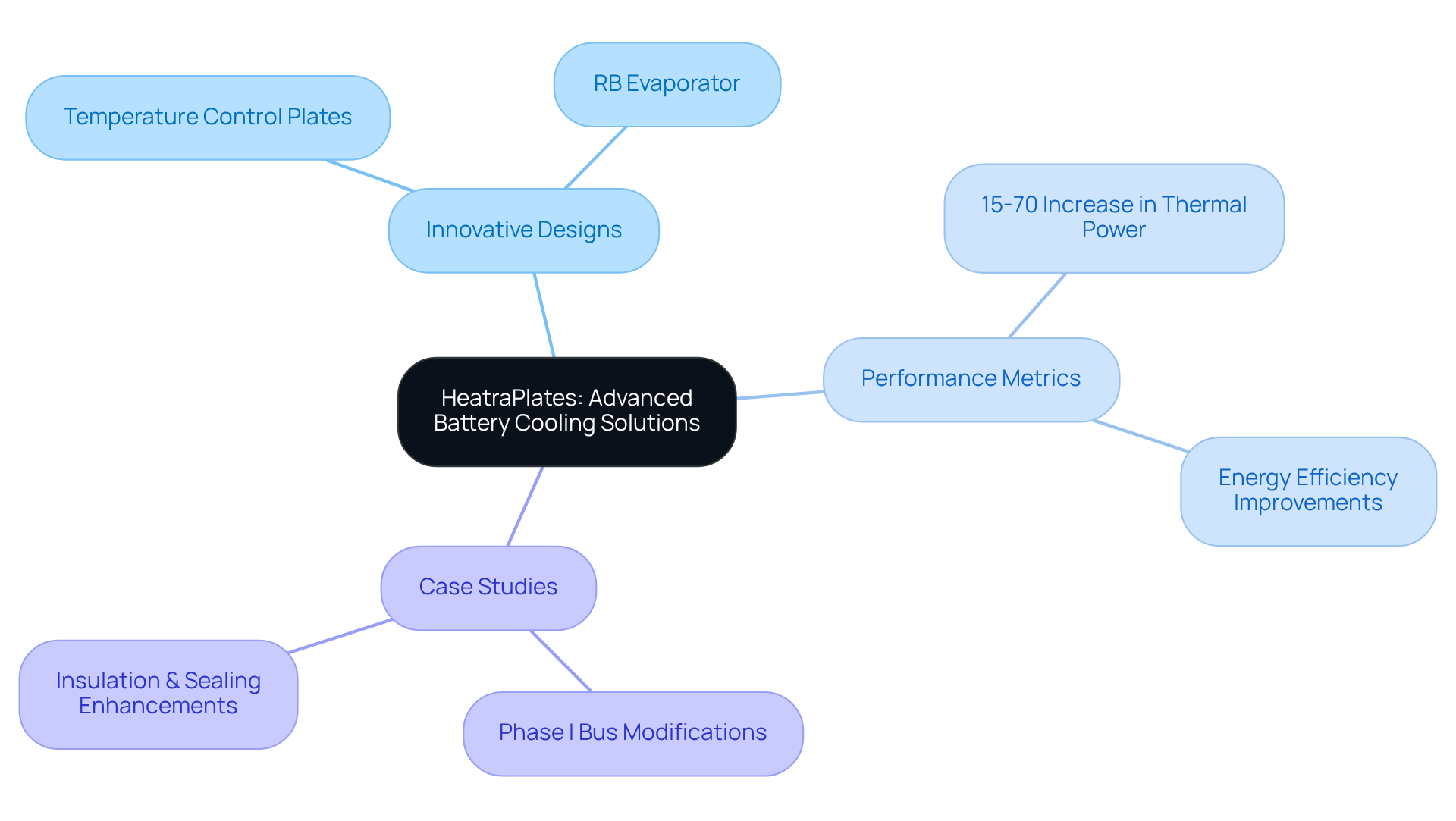

HeatraPlates stands out as a premier producer of advanced battery temperature regulation solutions, leveraging innovative designs that significantly enhance heat management in electric vehicles and energy storage systems. Their meticulously engineered ensure uniform heat distribution, a critical factor in minimizing degradation and boosting overall system efficiency.

Recent advancements in battery thermal management underscore that effective temperature regulation can yield performance metrics showing a remarkable 15 to 70% increase in thermal power compared to conventional systems, largely attributed to the superior efficiency of the RB evaporator.

Furthermore, case studies demonstrate that uniform temperature distribution not only extends battery life but also markedly improves energy efficiency, as illustrated by the Phase I Bus Modifications and Performance Testing, which showcased the effectiveness of insulation and sealing enhancements.

Consequently, HeatraPlates emerges as an invaluable partner for engineers tackling the complex temperature control challenges inherent in modern battery applications.

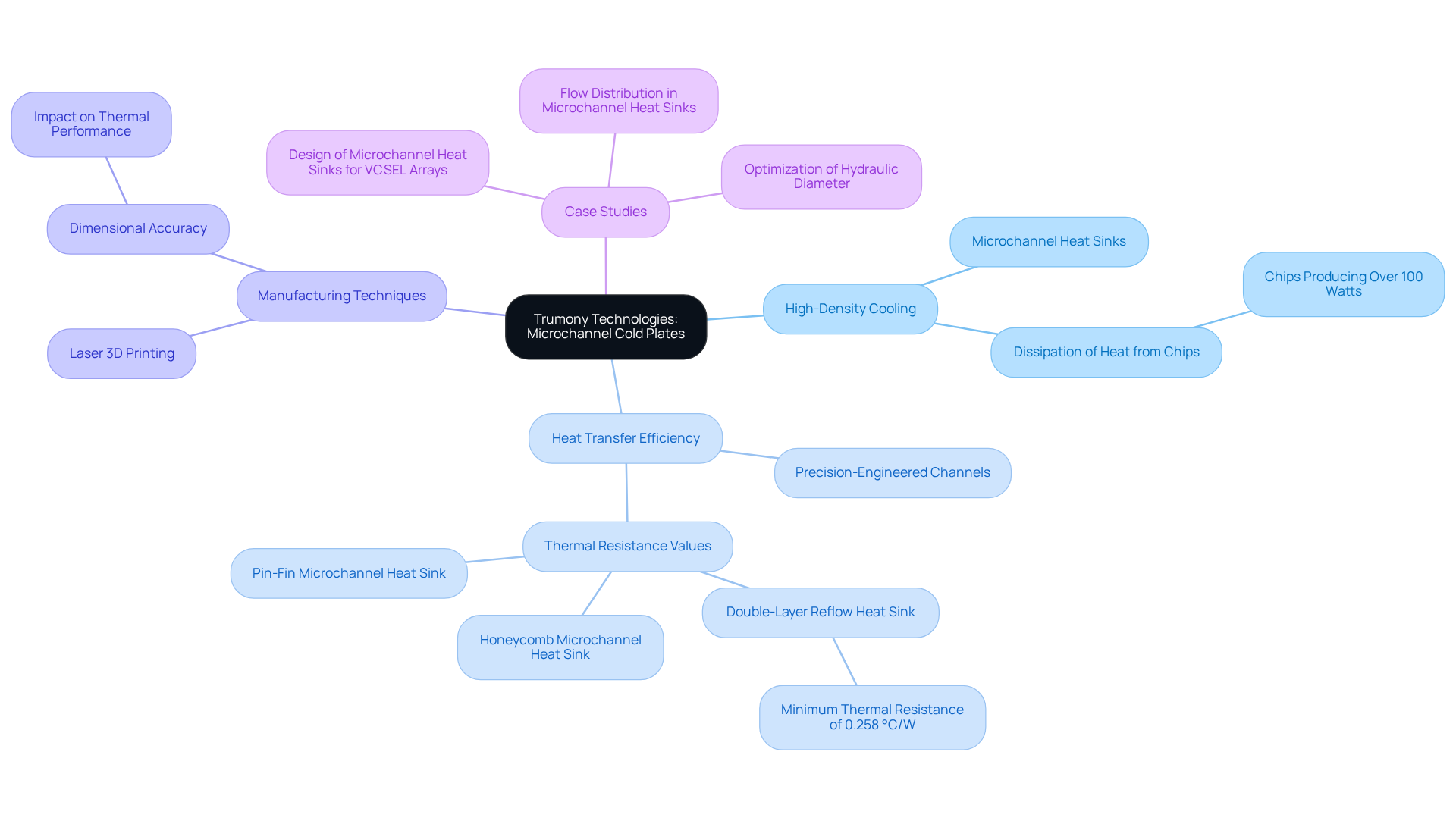

Trumony Technologies: Microchannel Cold Plates for High-Density Cooling

Trumony Technologies stands at the forefront of developing microchannel cold plates, establishing itself among the top specifically designed for high-density cooling applications in electronics. Their innovative designs utilize precision-engineered channels that significantly enhance heat transfer efficiency, making them ideal for compact, high-performance systems.

Recent advancements reveal that microchannel heat sinks can effectively dissipate heat from chips producing over 100 watts, with the double-layer reflow microchannel heat sink achieving a remarkable minimum temperature resistance of 0.258 °C/W under specific design parameters.

By leveraging advanced manufacturing techniques such as laser 3D printing technology, Trumony delivers reliable solutions that not only manage heat effectively but also ensure optimal performance.

Case studies demonstrate that dual inlet designs improve flow distribution and reduce temperature gradients, further enhancing thermal performance.

As engineers face increasing challenges in heat management, Trumony’s innovative approach positions them as a leader among cold plate suppliers, providing efficient refrigeration solutions for modern electronic devices.

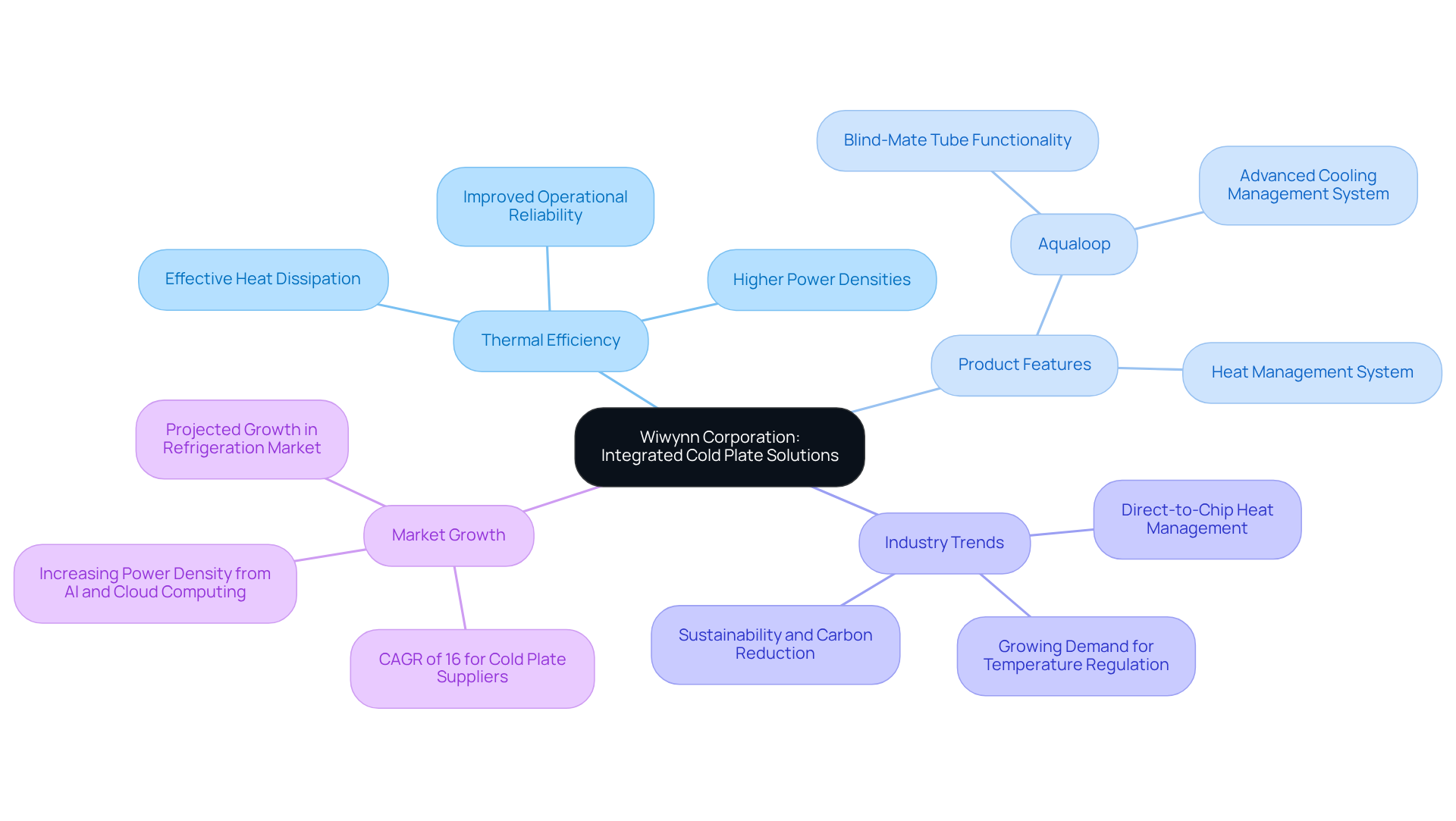

Wiwynn Corporation: Integrated Cold Plate Solutions for Data Centers

Wiwynn Corporation specializes in integrated cold plate systems provided by cold plate suppliers, designed specifically for data centers, significantly enhancing thermal efficiency and overall performance. Their innovative designs facilitate effective heat dissipation, allowing for higher power densities and improved operational reliability.

For instance, Wiwynn’s Aqualoop offering features blind-mate tube functionalities alongside a sophisticated heat management system, underscoring their commitment to addressing the thermal management challenges faced by modern data centers. With the growing demand for effective temperature regulation technologies, Wiwynn’s focus on sustainability and carbon reduction positions them as a pivotal player in the industry.

Recent trends indicate that cold surface heat dissipation, also known as direct-to-chip heat management, is emerging as the leading solution in data centers, driven by increasing power densities from advancements such as AI and cloud computing. This transition highlights the critical importance of temperature regulation efficiency in data center operations, as it directly impacts energy consumption and operational costs.

Industry projections suggest that cold plate suppliers will experience significant growth in the refrigeration market, with an expected compound annual growth rate (CAGR) of 16% over the next decade. Wiwynn’s contributions to this sector are not merely innovative; they are essential for the .

At the forthcoming OCP Global Summit, Wiwynn will present its latest cooling solutions, further reinforcing its position as a leader in the industry.

Conclusion

The landscape of electronics cooling solutions is undergoing rapid evolution, characterized by a diverse array of leading cold plate suppliers responding to the burgeoning demand for efficient thermal management. This article underscores the pivotal contributions of companies such as Gagner-Toomey Associates, Boyd Corporation, Kenfatech, and others, each delivering unique innovations and tailored solutions that cater to the specific needs of various industries. By emphasizing advanced technologies and customer-centric approaches, these suppliers are enhancing the performance of electronic devices while ensuring sustainability and reliability in their operations.

Key insights reveal the critical importance of adapting to market trends, particularly the increasing demand for liquid cooling technologies in electric vehicles and data centers. Companies like XD Thermal Technology and Wakefield Thermal are at the forefront of these advancements, leveraging innovative designs and materials to optimize heat transfer efficiency. The projected growth of the cold plates market further underscores the necessity for continuous innovation and strategic partnerships among suppliers to remain competitive and address future challenges.

As the electronics industry continues to expand, the significance of effective temperature control solutions remains paramount. Stakeholders are urged to stay informed about market trends and technological advancements to fully leverage the offerings of these leading cold plate suppliers. By embracing innovative cooling solutions, engineers and manufacturers can significantly enhance the performance and longevity of their products, ultimately driving success in an increasingly competitive landscape.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is a professional sales organization specializing in innovative temperature management solutions for the electronics sector. They represent various manufacturers, ensuring clients have access to state-of-the-art products tailored to their needs.

How does Gagner-Toomey Associates enhance customer service?

They utilize a consultative approach supported by advanced IT tools for opportunity tracking and sales reporting, which improves their responsiveness and ability to meet customer needs effectively.

Who are some of the strategic partners of Gagner-Toomey Associates?

Gagner-Toomey Associates has strategic partnerships with industry leaders such as Delta and CONEC, which help them deliver efficient heat management strategies.

What advantages do Gagner-Toomey’s brushless fan systems offer?

Their brushless fan systems improve energy efficiency and reliability, using significantly less power than conventional brushed devices, making them a cost-effective solution for engineers.

What is Boyd Corporation’s specialty in thermal management?

Boyd Corporation specializes in liquid cold plate technologies that efficiently transfer heat from high-load surfaces to advanced thermal management systems, particularly in data centers and electric vehicles.

What are Hi-Contact tube liquid cold surfaces?

These are specially engineered surfaces by Boyd Corporation designed to enhance heat transfer by maximizing the contact area between liquid tubes and heat exchange surfaces, improving heat transfer efficiency.

What is the projected growth of the electric vehicle battery thermal management market?

The market is projected to grow from approximately $1.2 billion in 2024 to around $3.5 billion by 2034, with a Compound Annual Growth Rate (CAGR) of 12.3% from 2025 to 2034.

How does Boyd Corporation ensure the reliability of their cold plate products?

Boyd Corporation employs comprehensive fabrication techniques and offers 100% leak-tested construction options, enhancing the reliability and performance of their cold plate suppliers.

What unique features does Kenfatech provide in their liquid cooling components?

Kenfatech creates tailored liquid cooling components designed for various industries, utilizing advanced materials and innovative manufacturing techniques to ensure optimal thermal performance.

What is the projected market size for the EV liquid cooling market by 2031?

The EV liquid cooling market is projected to reach USD 5.9 billion by 2031, with a CAGR of 11.2%.

How does Kenfatech ensure the reliability of their cooling solutions?

Kenfatech conducts rigorous testing protocols, including pressure holding assessments and flow resistance assessments, to ensure the reliability of their cold components under high-pressure and high-temperature conditions.

In which sectors does Kenfatech’s cooling solutions find applications?

Kenfatech’s solutions are utilized in various sectors, including automotive for electric vehicle batteries, telecommunications for high-density environments, and medical devices for healthcare applications.