Overview

The article presents a compelling overview of the benefits associated with brushless fan technology in electronics. It emphasizes key advantages such as:

- Energy efficiency

- Reliability

- Quiet operation

- Compact design

- Versatility

- Ease of integration

- Advanced technology

- Cost-effectiveness

- Environmental benefits

Each of these points is substantiated with evidence and examples, illustrating how brushless fans significantly enhance performance and sustainability across various electronic applications. This positions brushless fans as the preferred choice for engineers and manufacturers who seek to optimize their designs.

Introduction

In the rapidly evolving electronics industry, effective thermal management is paramount for ensuring optimal performance and reliability. Gagner-Toomey Associates emerges as a leader in providing innovative cooling solutions specifically tailored to address the unique challenges engineers encounter.

By harnessing advanced technologies, particularly brushless fan systems, they are transforming the landscape of electronic cooling. These fans not only promise enhanced energy efficiency and longevity but also cater to the increasing demand for sustainable solutions.

As engineers navigate the complexities of modern design, Gagner-Toomey’s unwavering commitment to cutting-edge technology and exceptional customer support positions them as a vital partner in achieving superior results across diverse applications.

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Projects

Gagner-Toomey Associates excels in providing state-of-the-art temperature control solutions specifically designed for the electronics industry. By collaborating with a diverse range of manufacturers, including industry leaders like CONEC and Delta, they equip engineers with essential tools to address intricate thermal management challenges. Their focus on cutting-edge systems, particularly the use of brushless fans in fan mechanisms, underscores a commitment to enhancing product performance and dependability across various applications, from consumer electronics to industrial equipment.

Recent market evaluations indicate a growing demand for , with systems that utilize brushless fans leading the charge due to their efficiency and durability. For instance, market size data reveals significant growth in regions such as North America and Europe, underscoring the increasing adoption of these advanced systems.

Numerous projects have documented successful implementations of brushless fan technology, with insights from consumer behavior analysis indicating that engineers are increasingly favoring these energy-saving and effective solutions. As trends evolve in 2025, Gagner-Toomey remains at the forefront of cooling solutions, ensuring that engineers have access to the latest advancements that meet the dynamic needs of the electronics landscape.

Furthermore, Gagner-Toomey adopts a consultative approach, offering 24/7 chat support and direct call services for procuring sample reports, thereby providing engineers with valuable resources to enhance their projects.

Energy Efficiency: Reduce Power Consumption with Brushless Fans

The brushless fan models from Gagner-Toomey Associates are engineered for high energy efficiency, utilizing up to 70% less power compared to conventional brushed devices. This significant reduction in power consumption is achieved through advanced electronic commutation, which minimizes energy loss and facilitates variable speed control. As a result, manufacturers can significantly lower their energy bills while simultaneously contributing to a more sustainable environment. This efficiency is particularly beneficial in applications where brushless fans operate continuously, such as in data centers and HVAC systems.

Gagner-Toomey’s extensive product range includes:

- Brushless fan DC input Tube Axial units that range from 15 to 280mm

- from 15 to 225mm

This ensures optimal performance and reliability across various sectors. Furthermore, most models provide IP protection upon request, enhancing their adaptability for diverse industrial applications. By choosing Gagner-Toomey, businesses not only invest in cutting-edge technology but also commit to a sustainable future.

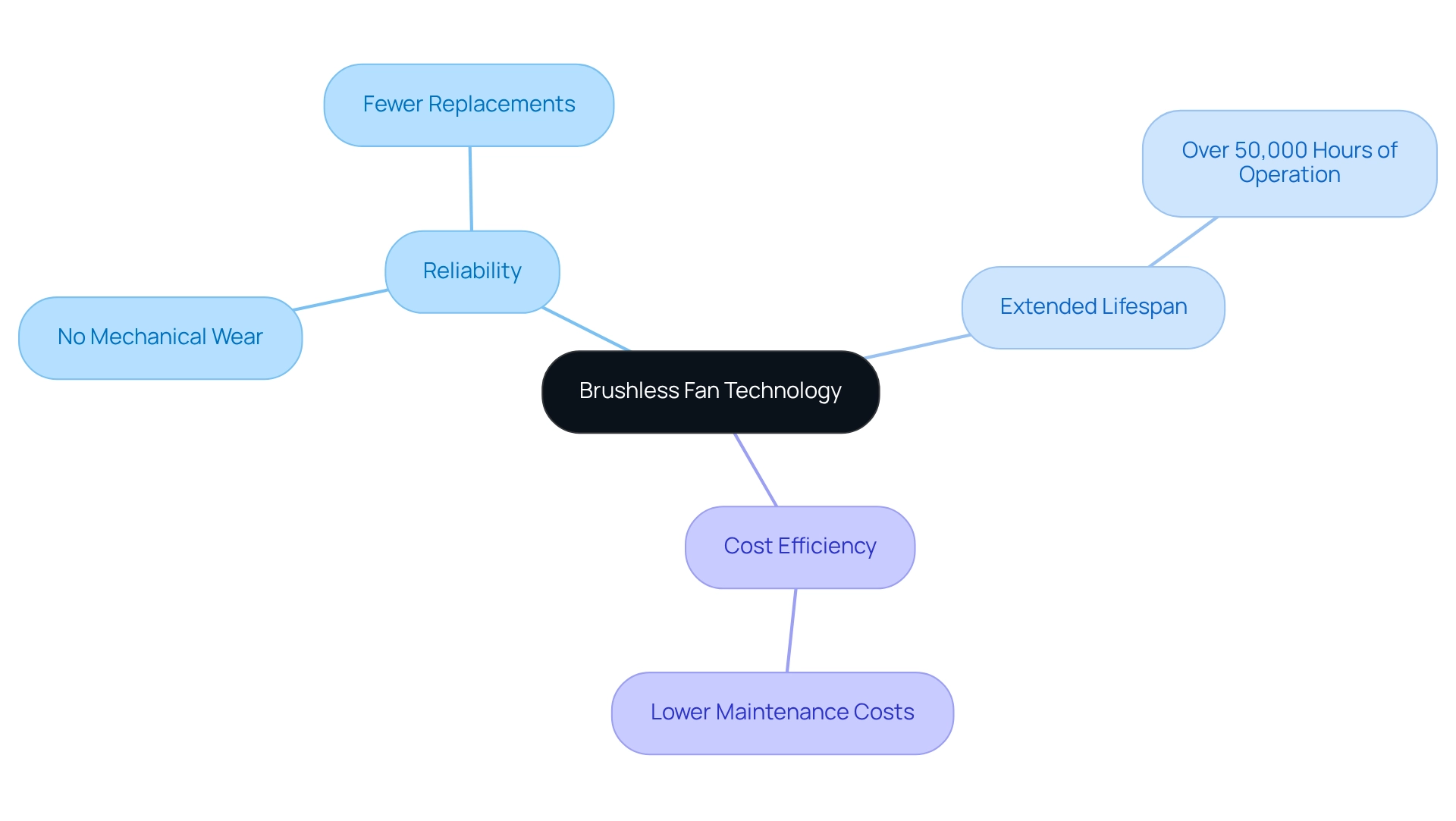

Reliability: Enhance System Longevity with Brushless Fan Technology

One of the most compelling advantages of using is its exceptional reliability. Unlike conventional devices that rely on brushes prone to wear over time, a brushless fan utilizes electronic commutation, effectively eliminating mechanical wear and tear. This innovation leads to a significantly extended lifespan, often surpassing 50,000 hours of operation. The enhanced dependability of brushless fans translates to fewer replacements and lower maintenance costs, making them an optimal choice for critical applications in electronics and industrial settings.

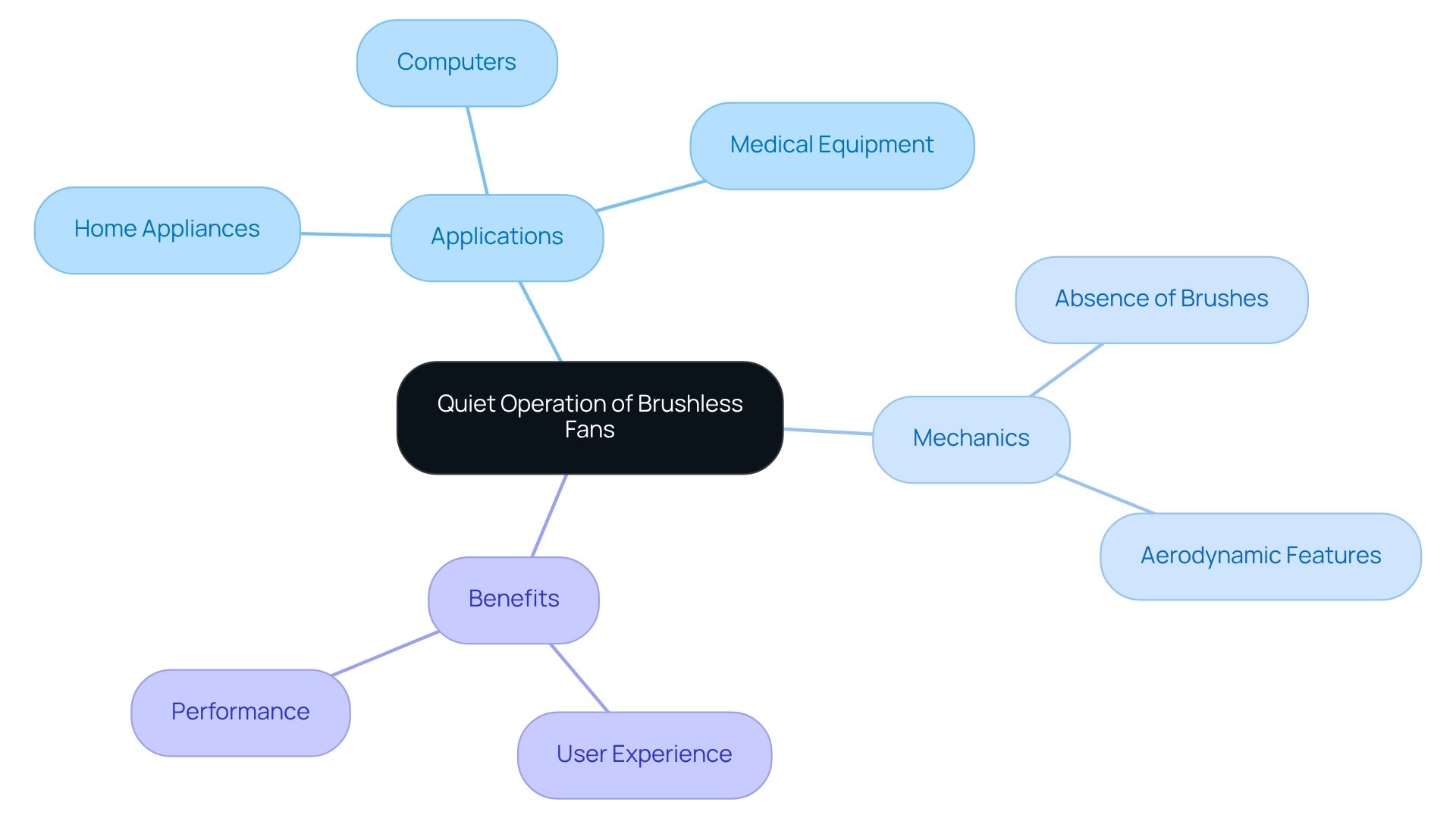

Quiet Operation: Minimize Noise Levels in Your Electronics Projects

Brushless fans are distinguished by , making them ideal for environments where minimizing noise levels is crucial, such as in home appliances, computers, and medical equipment. The absence of brushes significantly reduces friction, which is typically a primary source of noise in conventional devices. Moreover, many brushless fan devices are engineered with advanced aerodynamic features that further diminish operational noise. This design not only enhances user experience but also ensures that performance remains uncompromised.

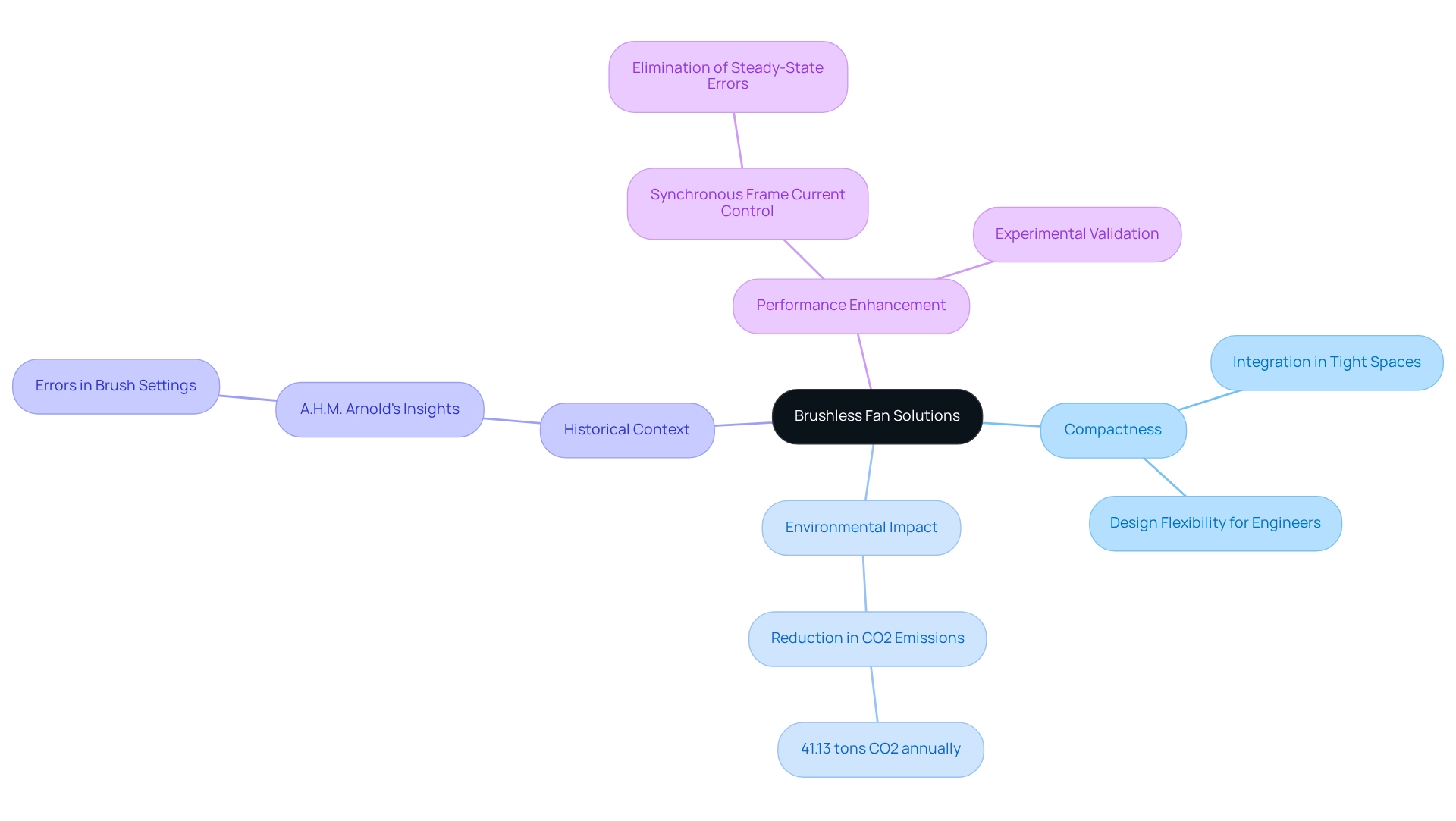

Compact Design: Optimize Space with Brushless Fan Solutions

Brushless units present a significant advantage in compactness compared to conventional brushed designs, making them particularly suitable for applications where space is limited. Their smaller dimensions allow for seamless integration into tight spaces within electronic devices such as laptops, gaming consoles, and compact industrial machinery. This optimization of space not only enhances design flexibility for engineers but also boosts the efficiency of temperature regulation systems.

For instance, employing motor-driven ventilators can lead to a reduction in the carbon footprint associated with traditional cooling methods, potentially decreasing emissions by as much as 41.13 tons of CO2 annually for conventional V-belt-driven air handling units. Moreover, experimental findings have confirmed that these devices sustain performance even in restricted environments, underscoring their effectiveness in promoting compact design solutions in electronics.

A.H.M. Arnold highlighted in the December 1926 Journal of the Institution of Electrical Engineers that understanding phenomena occurring during motor operation at synchronous speed, particularly concerning errors in brush settings, is essential for grasping motor performance. This historical context underscores the evolution of motor mechanisms, particularly highlighting brushless fan systems.

Additionally, insights from the case study ‘Start-up of Large Power Electric Motors with High Load Torque’ demonstrate that the proposed method for synchronous frame current control significantly enhances performance without steady-state errors, further validating the reliability of non-brushed ventilators in compact designs.

Engineers recognize that optimizing space by leveraging is vital for creating innovative products that address contemporary demands.

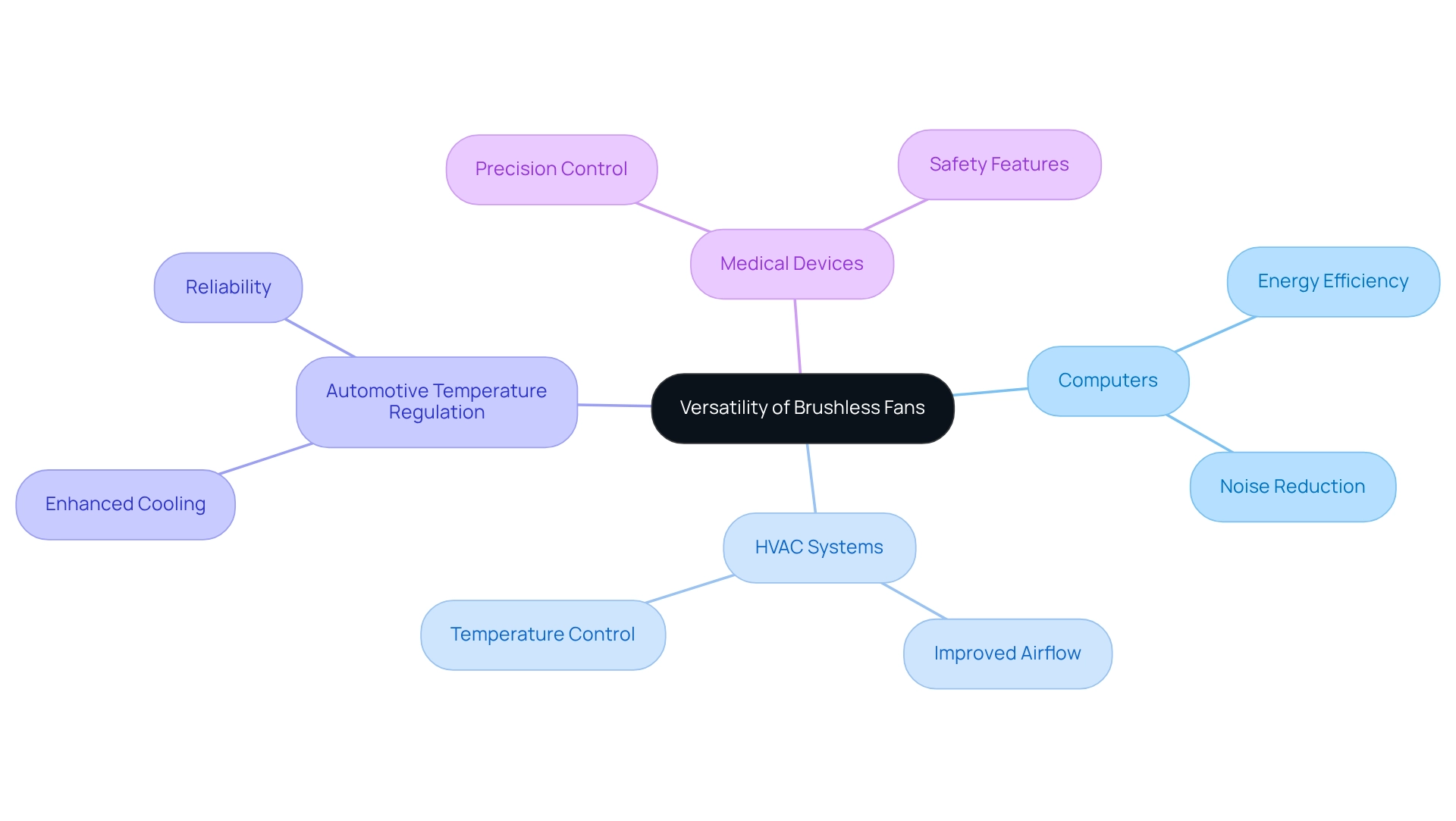

Versatility: Utilize Brushless Fans in Diverse Electronics Applications

The versatility of brushless fans is remarkable, as they find application across a broad spectrum of industries, from consumer electronics to industrial machinery. Brushless fans are commonly integrated into devices such as:

- Computers

- HVAC systems

- Automotive temperature regulation

- Medical devices

Their ability to operate efficiently in diverse settings positions them as a preferred choice for engineers who seek reliable temperature regulation solutions, such as brushless fan technology, in various projects. This adaptability not only addresses the but also significantly enhances their overall appeal.

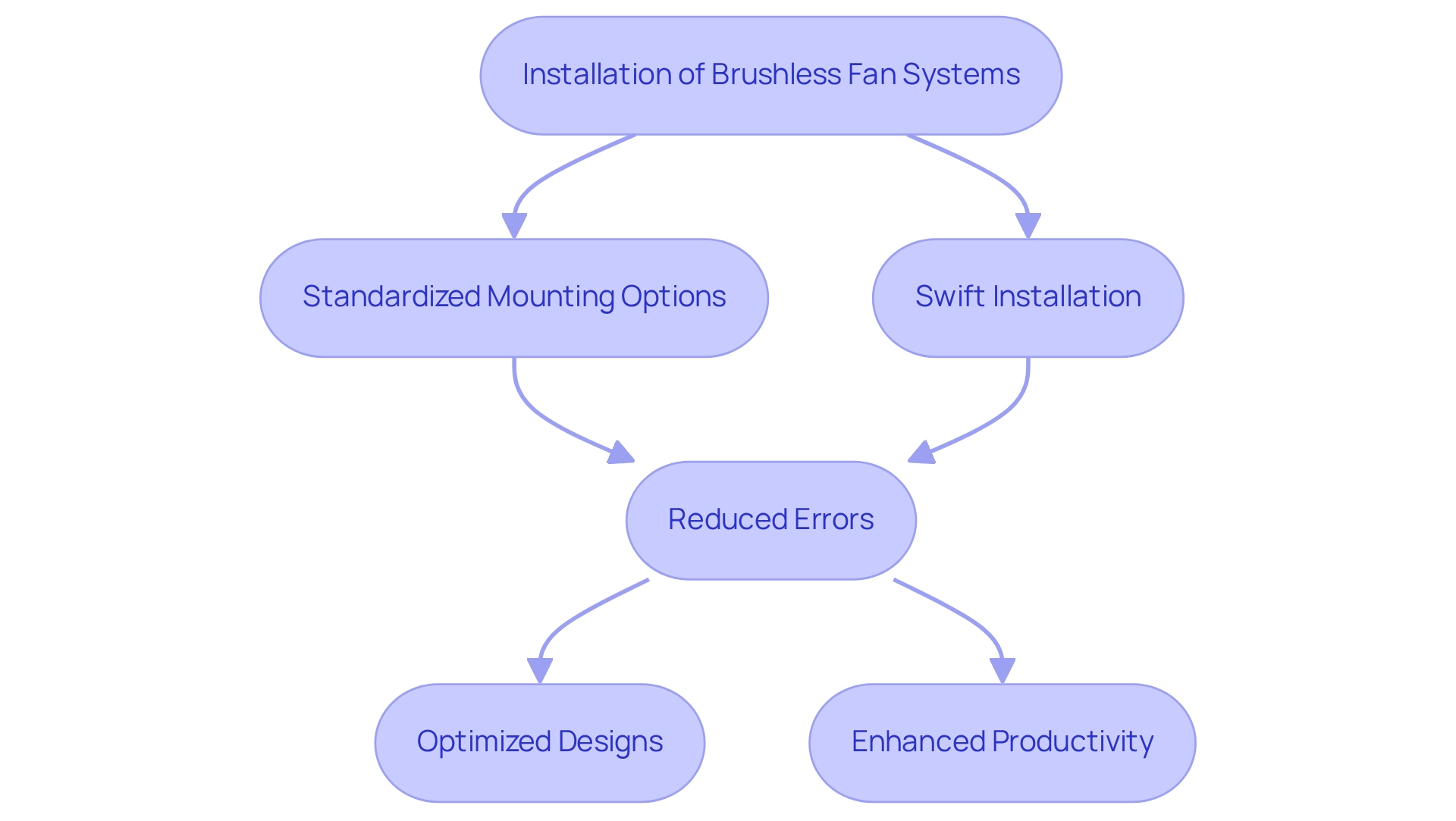

Ease of Integration: Simplify Installation with Brushless Fan Systems

offer a solution to the challenge of integrating cooling solutions into existing electronic setups. These systems are engineered with standardized mounting options and connectors, facilitating swift installation without necessitating extensive modifications. This streamlined integration not only curtails installation time but also significantly reduces the potential for errors during setup. Consequently, engineers can concentrate on optimizing their designs rather than expending excessive time on fan installation. This focus leads to more efficient project timelines, ultimately enhancing overall productivity.

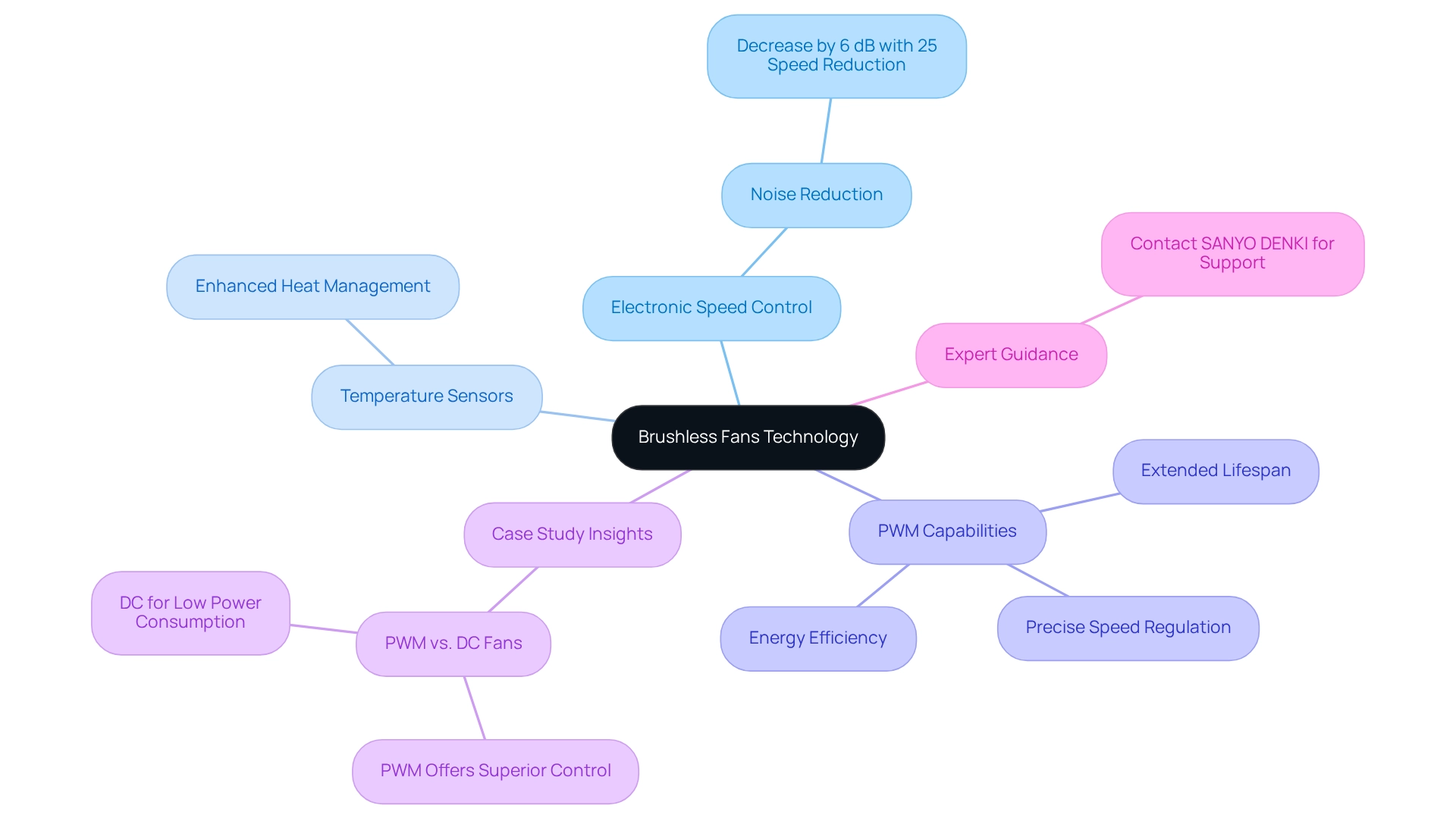

Advanced Technology: Leverage Cutting-Edge Features of Brushless Fans

At the forefront of thermal management, brushless fans incorporate advanced features that significantly enhance their performance and efficiency. Innovations such as electronic speed control, temperature sensors, and Pulse Width Modulation (PWM) capabilities facilitate precise adjustments tailored to the cooling needs of various systems. For instance, reducing fan speed by 25% can lead to of approximately 6 dB, demonstrating the impact of these advancements on user experience.

The integration of PWM systems allows for more accurate speed regulation without the risk of stalling, making it particularly effective in managing heat dissipation in devices like laptops. A case study comparing PWM and DC devices reveals that while DC models are frequently employed for low power consumption, PWM models provide superior control, ensuring optimal temperature management across diverse thermal loads.

Moreover, the latest innovations in brushless fan technology for 2025 are designed to enhance energy efficiency and minimize component wear, ultimately extending the lifespan of the brushless fans. By harnessing these cutting-edge features, engineers can achieve improved performance in their electronic designs, ensuring reliability and efficiency in their applications.

As Daren Perez articulates, “Dimensional analysis can be used to illustrate the dramatic effect lowering can have on the flow rate, noise, and power.” This insight underscores the importance of understanding fan dynamics in electronic thermal management solutions.

For technical support and quotes on innovative cooling solutions, engineers are encouraged to reach out to experienced providers who prioritize the significance of customization and expert guidance in selecting the appropriate fan technology.

Cost-Effectiveness: Achieve Performance Without Breaking the Bank

While typically incur a higher initial purchase cost than conventional models, their long-term cost efficiency is compelling. These devices deliver significant energy savings, leading to reduced operational expenses over time. Their design minimizes maintenance requirements, further lowering overall costs. Additionally, the extended lifespan of motorized devices results in fewer replacements, enhancing their value proposition for manufacturers. The combination of durability, longevity, and versatility positions these motors as a premier choice in the marketplace.

For those balancing performance with budget considerations, investing in solutions featuring a brushless fan is a strategic choice that promises substantial long-term savings. Recent data reveals that the total cost of ownership for motorized ventilators is markedly lower than that of conventional alternatives, making them an attractive option within the electronics sector.

According to the M18™ Brushless 18” Fan FAQ Insights, the brushless fan features a design that incorporates dual power options and multiple speed settings, augmenting its practicality and reliability for professional applications. Milwaukee Tool underscores that for professionals in search of a dependable, high-performance brushless fan, the M18™ Brushless 18” Fan is a prudent investment, providing unparalleled performance and durability where it is most needed.

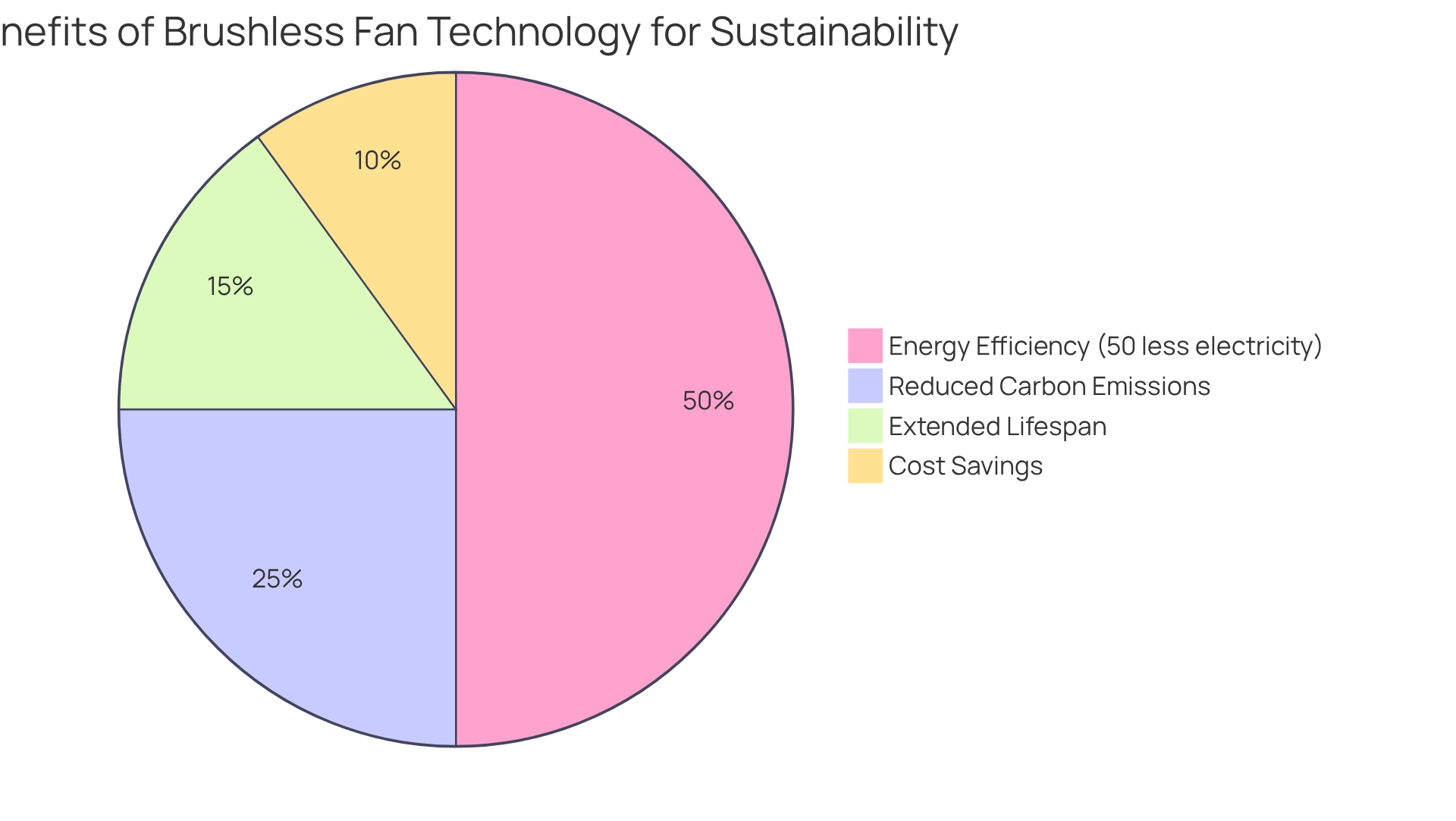

Environmental Benefits: Promote Sustainability with Brushless Fan Usage

The incorporation of brushless fan technology significantly aids global sustainability initiatives by improving energy efficiency and reducing carbon emissions. BLDC units can utilize up to 50% less electricity compared to conventional models, directly decreasing the demand for power and thereby reducing from energy production.

Furthermore, the design of frictionless blowers eliminates friction and wear, resulting in an extended lifespan and decreased maintenance requirements. This longevity not only minimizes waste but also leads to substantial long-term cost savings for manufacturers and consumers alike.

As highlighted in the case study titled ‘Long Lifespan of BLDC Fans,’ this design contributes to lower resource consumption and environmental impact. For organizations committed to environmental stewardship, adopting brushless fan technology represents a strategic move towards a more sustainable future.

As Mingletec aptly states, ‘By embracing brushless fans, we can contribute to a greener and more energy-efficient future.’ This alignment with eco-friendly practices supports broader sustainability initiatives in the electronics industry.

Conclusion

Gagner-Toomey Associates emerges as a pioneering force in the electronics industry, particularly in thermal management. Their innovative brushless fan systems not only enhance energy efficiency and reliability but also address the urgent demand for sustainable cooling solutions. By collaborating with leading manufacturers and leveraging advanced technologies, Gagner-Toomey equips engineers with the essential tools to tackle complex thermal challenges across a diverse range of applications.

The advantages of brushless fan technology are extensive. These fans consume significantly less power, ensuring reduced operational costs while promoting environmental sustainability. Their reliability extends product lifespans and minimizes maintenance needs, establishing them as a cost-effective choice in both consumer and industrial sectors. Moreover, their quiet operation and compact design facilitate seamless integration into various electronic devices, enhancing user experience without compromising performance.

As the electronics landscape evolves, Gagner-Toomey remains steadfast in providing cutting-edge solutions that meet the dynamic needs of engineers. With a focus on advanced features and ease of integration, their brushless fan systems are not only versatile but also essential for modern electronic designs. Embracing these technologies enables manufacturers to achieve optimal performance while contributing to a more sustainable future. By choosing Gagner-Toomey Associates, engineers can confidently navigate the complexities of thermal management, paving the way for innovative and reliable electronic projects.

Frequently Asked Questions

What types of temperature control solutions does Gagner-Toomey Associates provide?

Gagner-Toomey Associates offers state-of-the-art temperature control solutions specifically designed for the electronics industry, focusing on advanced thermal management systems that utilize brushless fans.

Who are some of the manufacturers Gagner-Toomey collaborates with?

Gagner-Toomey collaborates with a diverse range of manufacturers, including industry leaders like CONEC and Delta.

What are the benefits of using brushless fans in thermal management?

Brushless fans are known for their efficiency and durability, utilizing up to 70% less power than conventional brushed devices, leading to lower energy consumption and costs.

In which applications are brushless fans particularly beneficial?

Brushless fans are especially beneficial in applications where they operate continuously, such as in data centers and HVAC systems.

What product range does Gagner-Toomey offer for brushless fans?

Gagner-Toomey’s product range includes Brushless fan DC input Tube Axial units ranging from 15 to 280mm and Brushless fan Centrifugal Blowers from 15 to 225mm.

How does Gagner-Toomey ensure the reliability of their brushless fans?

The reliability of Gagner-Toomey’s brushless fans is enhanced through electronic commutation, which eliminates mechanical wear and tear, leading to a lifespan often surpassing 50,000 hours.

What support does Gagner-Toomey provide to engineers?

Gagner-Toomey adopts a consultative approach, providing 24/7 chat support and direct call services for procuring sample reports to assist engineers with their projects.

How is the market for thermal management solutions evolving?

Recent market evaluations indicate a growing demand for sophisticated thermal management solutions, particularly those utilizing brushless fans, with notable growth in regions like North America and Europe.