Overview

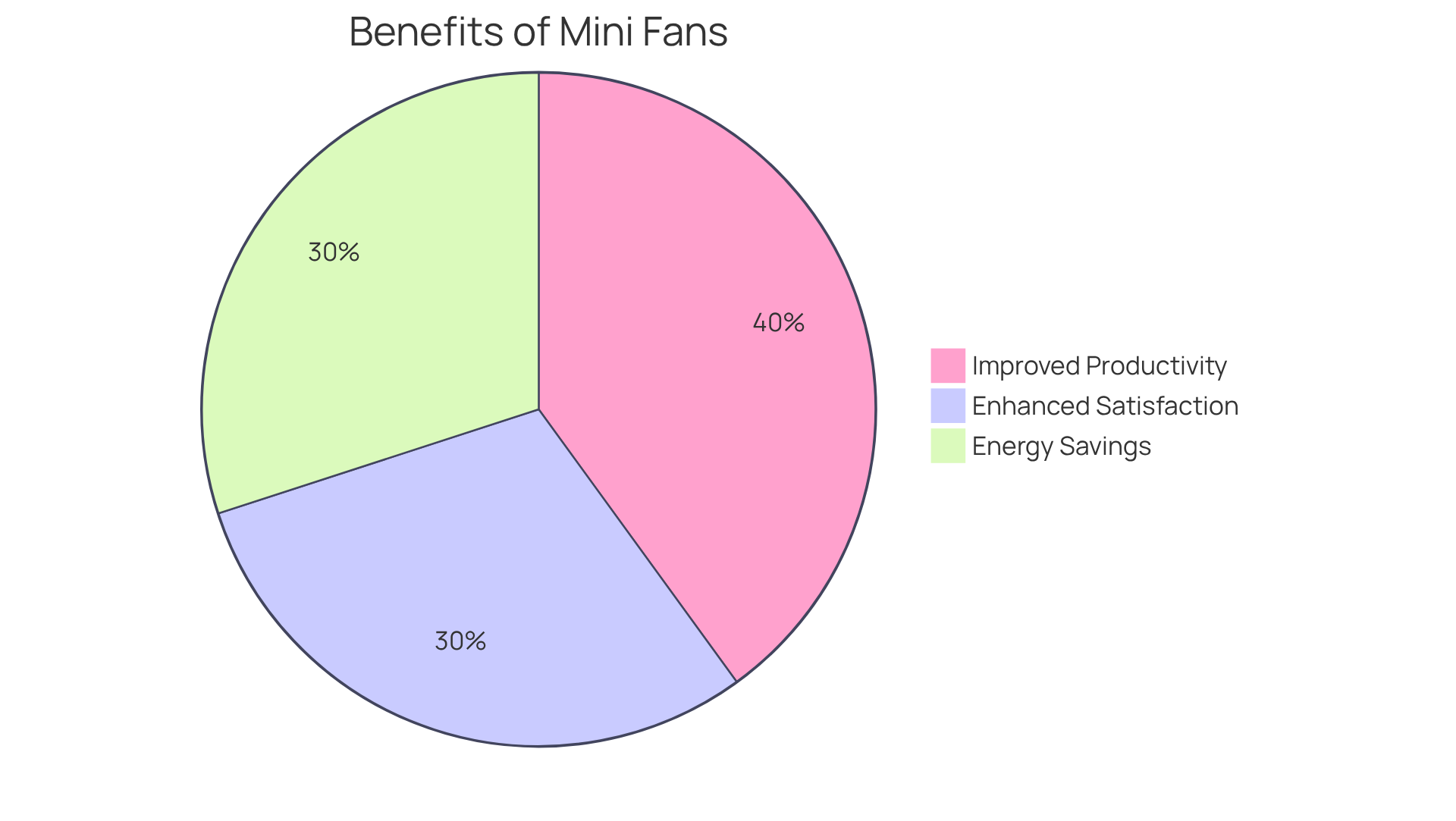

The advantages of mini industrial fans for electronics engineers are significant, encompassing enhanced cooling efficiency, energy savings, and improved workspace design. This article delineates how these fans not only optimize temperature regulation and minimize operational costs but also provide versatile applications and aesthetic appeal. Consequently, they emerge as indispensable tools within modern engineering environments, warranting consideration for integration into engineering practices.

Introduction

Mini industrial fans have emerged as essential tools for electronics engineers, presenting a multitude of benefits that enhance both performance and efficiency across various applications.

These compact devices not only optimize temperature management but also significantly improve air circulation, leading to energy savings and a more comfortable, productive workspace.

However, with a plethora of options available, engineers face the challenge of determining the best fan solutions tailored to their specific needs.

This article delves into ten compelling advantages of mini industrial fans, illustrating how these innovative cooling solutions can transform electronic environments.

Gagner-Toomey Associates: Innovative Mini Industrial Fan Solutions for Enhanced Cooling

Gagner-Toomey Associates stands at the forefront of innovative solutions with their mini industrial fan, adeptly enhancing temperature regulation for electronic systems. As the world’s largest producer of both standard and custom air-movers, Gagner-Toomey offers an extensive array of DC input tube axial devices and centrifugal blowers, ranging from 15 to 910mm, all optimized for peak performance, efficiency, and minimal noise.

These devices are engineered with cutting-edge technology tailored to address the specific of various electronic components, thereby ensuring optimal performance and an extended lifespan. The company’s unwavering commitment to excellence is reflected in its diverse portfolio, which showcases advanced cooling technologies, including:

- Extruded aluminum heatsinks

- Copper-based heat sinks

- Integrated cooling solutions

Recent innovations in mini industrial fans feature enhanced blade designs and sound-insulating materials that not only boost airflow but also significantly reduce noise levels—an essential consideration for maintaining a conducive working environment.

Furthermore, the integration of smart and IoT technologies facilitates remote management and enhances energy efficiency, positioning these devices as vital components in modern electronic systems. Successful implementations of small-scale ventilation systems have demonstrated their efficacy in heat release management, ultimately leading to more reliable and efficient electronic devices.

Energy Efficiency: Reduce Power Consumption with Mini Industrial Fans

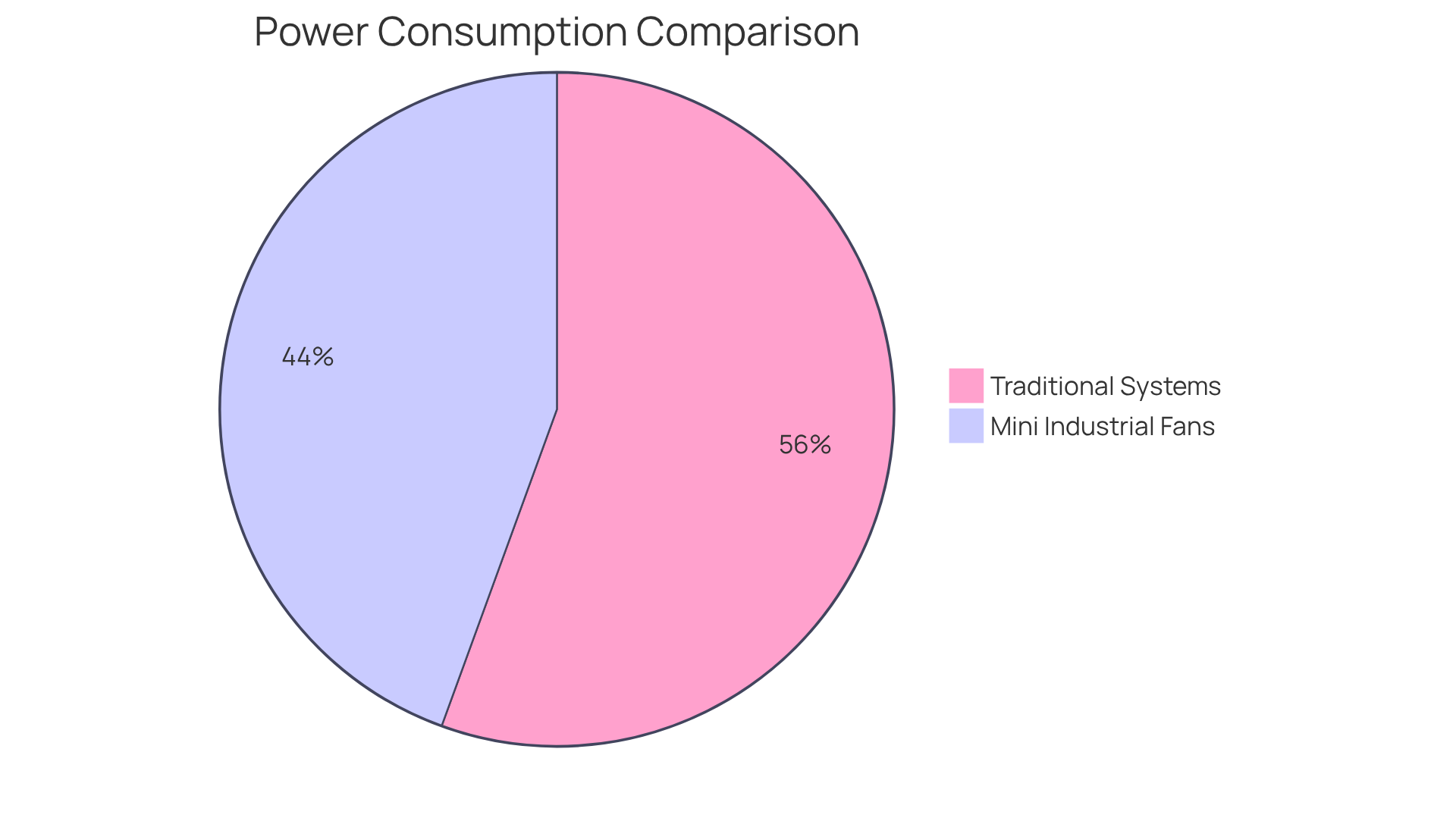

Compact commercial blowers represent a significant advancement in energy efficiency, often consuming up to 50% less power compared to traditional climate control systems. By leveraging advanced motor technologies and optimized airflow designs, these devices not only reduce operational expenses but also promote sustainable temperature management in electronic applications.

Engineers have noted that the integration of mini industrial fans enhances temperature regulation while aligning with the growing demand for energy-efficient technologies within the sector. Facilities utilizing these devices have reported average power consumption reductions ranging from approximately 30% to 50%, underscoring their effectiveness in minimizing energy use.

This transition towards more is essential as industries increasingly prioritize sustainability and cost-effectiveness in their operations.

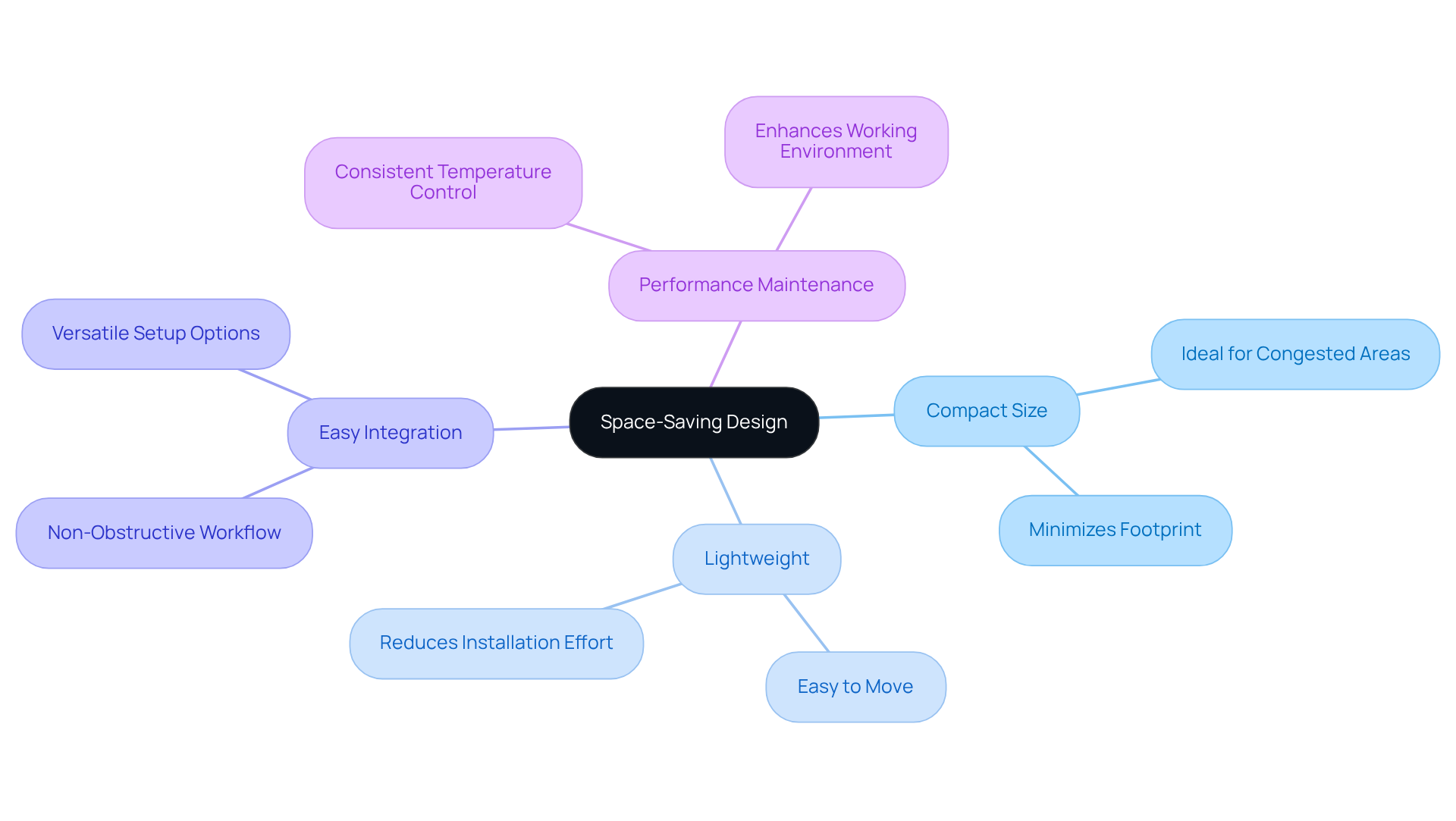

Space-Saving Design: Maximize Workspace with Compact Mini Industrial Fans

Mini industrial fans are specifically designed to be compact and lightweight, which makes them particularly well-suited for environments where space is at a premium. Their small footprint enables engineers to seamlessly integrate the mini industrial fan into various setups without sacrificing performance. This , which incorporates a mini industrial fan, proves especially advantageous in congested work areas, ensuring that temperature control methods do not obstruct workflow or accessibility. By prioritizing both functionality and practicality, these fans deliver optimal solutions for maintaining a conducive working environment.

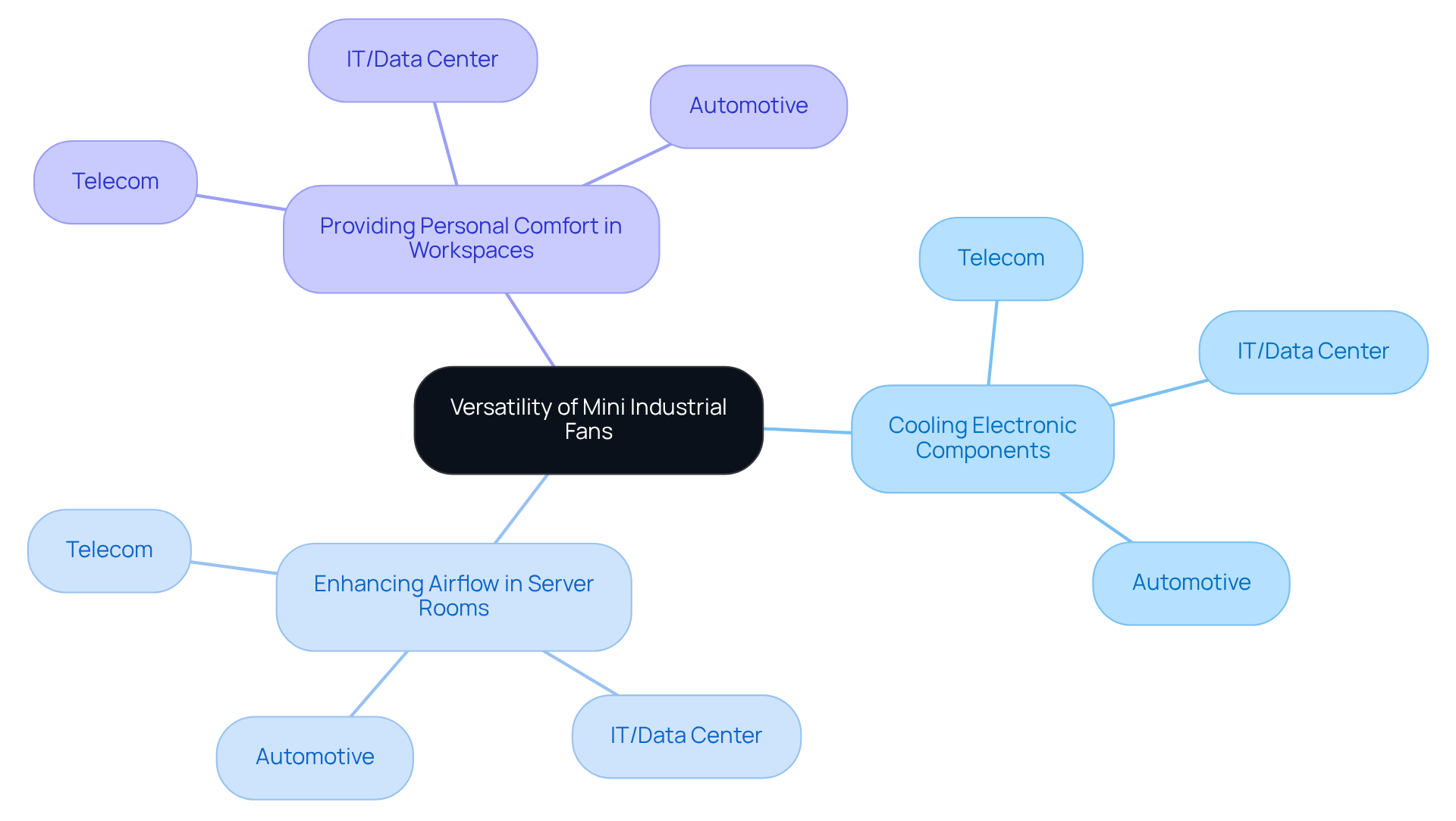

Versatility: Use Mini Industrial Fans in Various Workspace Applications

Mini industrial fans are remarkably versatile, adept at addressing a wide array of applications, such as:

- Cooling electronic components

- Enhancing airflow in server rooms

- Providing personal comfort in workspaces

‘Gagner-Toomey Associates‘ expertise in delivering innovative solutions has positioned these devices as essential tools for engineers. A notable example comes from a customer in the Telecom industry, who observed that these fans significantly improved equipment reliability during peak usage. Their adaptability facilitates customized cooling solutions that align with specific project requirements across various sectors, including:

- Telecom

- IT/Data Center

- Automotive

This inherent versatility empowers engineers to effectively tackle the unique challenges presented by their projects.

Improved Air Circulation: Enhance Comfort with Mini Industrial Fans

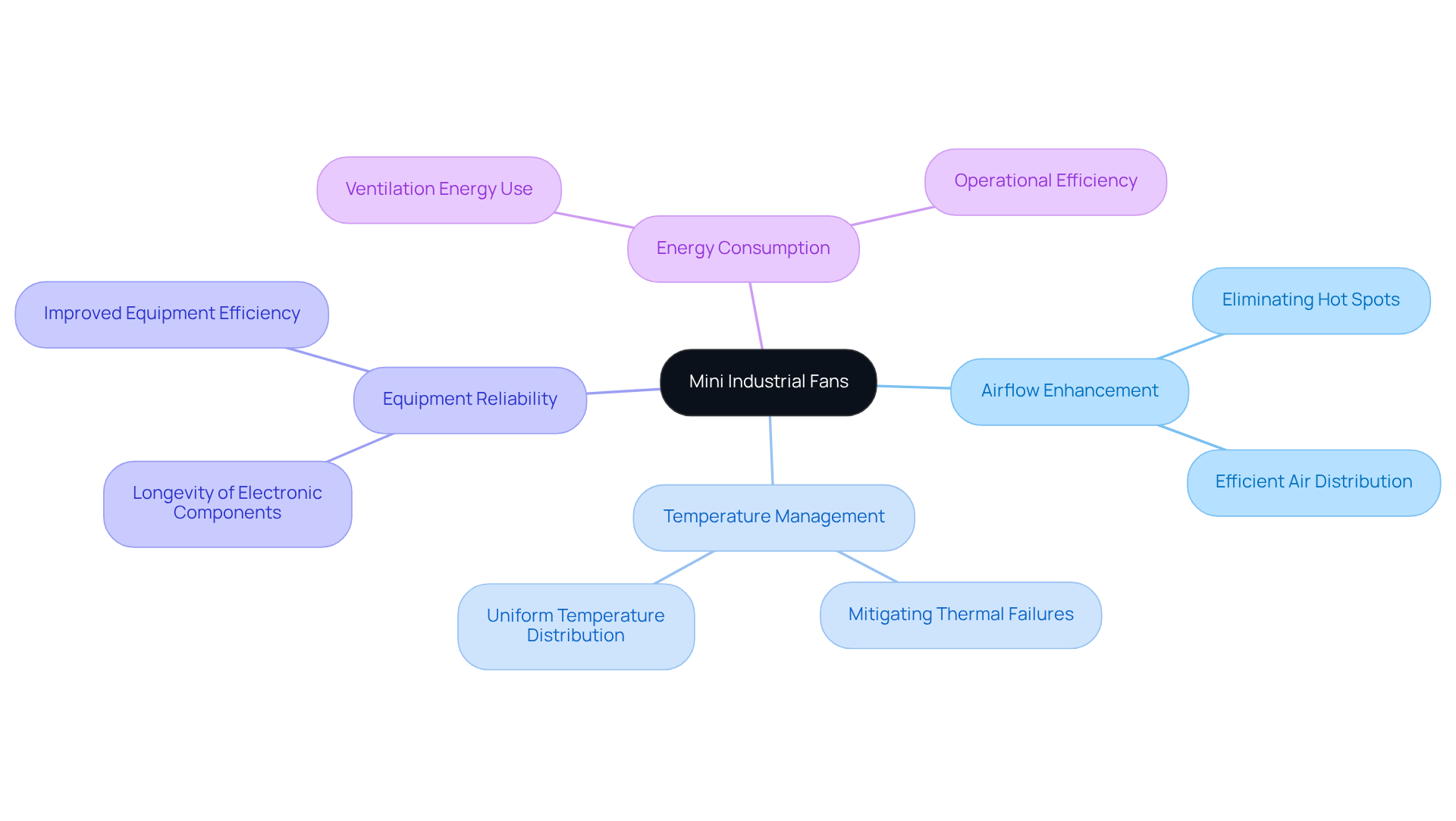

Mini industrial fans are essential for enhancing airflow, which is a critical factor in maintaining a comfortable working environment. By efficiently distributing cool air throughout the workspace, the mini industrial fan effectively eliminates hot spots, ensuring that every area receives sufficient airflow. This is particularly important in electronic environments, where overheating can lead to equipment failure and diminished performance.

Engineers emphasize that maintaining optimal temperatures is crucial for the longevity and reliability of electronic components. For example, studies reveal that proper air circulation can significantly mitigate the risk of thermal-related failures, thereby improving overall equipment efficiency. Moreover, in workplaces densely populated with electronic devices, a mini industrial fan facilitates a more uniform temperature distribution, fostering a healthier and more productive atmosphere.

Research indicates that ventilation energy consumption constitutes a substantial portion of the total energy use in large educational buildings, highlighting the necessity of effective air circulation in electronic settings. The integration of mini industrial fans not only enhances comfort but also contributes to the operational efficiency of electronic systems, making them an indispensable resource for professionals in the field.

As one technician aptly noted, ‘Maintaining optimal temperatures is not just about comfort; it’s about ensuring the reliability of our systems.’ To fully leverage the , specialists must consider factors such as size, airflow capacity, and noise levels to select the most appropriate options for their specific electronic environments.

Cost-Effectiveness: Save Money with Affordable Mini Industrial Fans

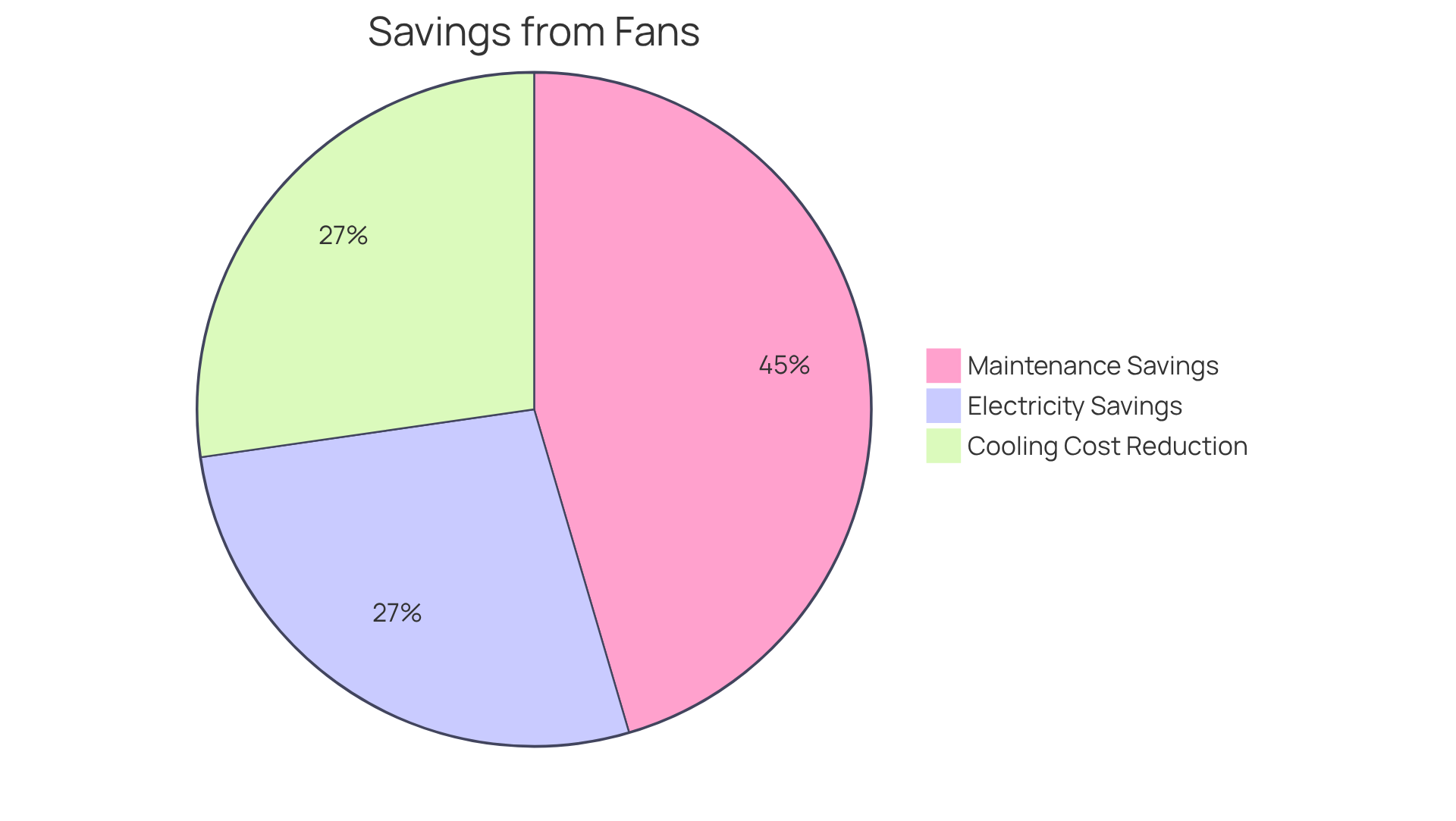

Small commercial ventilators present a highly economical solution for temperature regulation, offering engineers significant reductions in both initial expenditures and ongoing operational costs. Their energy-efficient designs can , as upgrading to more efficient devices can similarly decrease power costs by 10-20% each year. The robust construction of these ventilators minimizes maintenance expenses, often resulting in a payback period of just 12 to 24 months.

For instance, a case study highlighted that the installation of new commercial ceiling ventilators in a large warehouse resulted in a 15% reduction in cooling costs, demonstrating their efficiency in practical applications. Industry leaders emphasize that these devices not only enhance energy efficiency but also contribute to improved climate control, making them a compelling choice for any engineering project.

By opting for compact commercial blowers, professionals can achieve substantial operational savings while ensuring reliable performance.

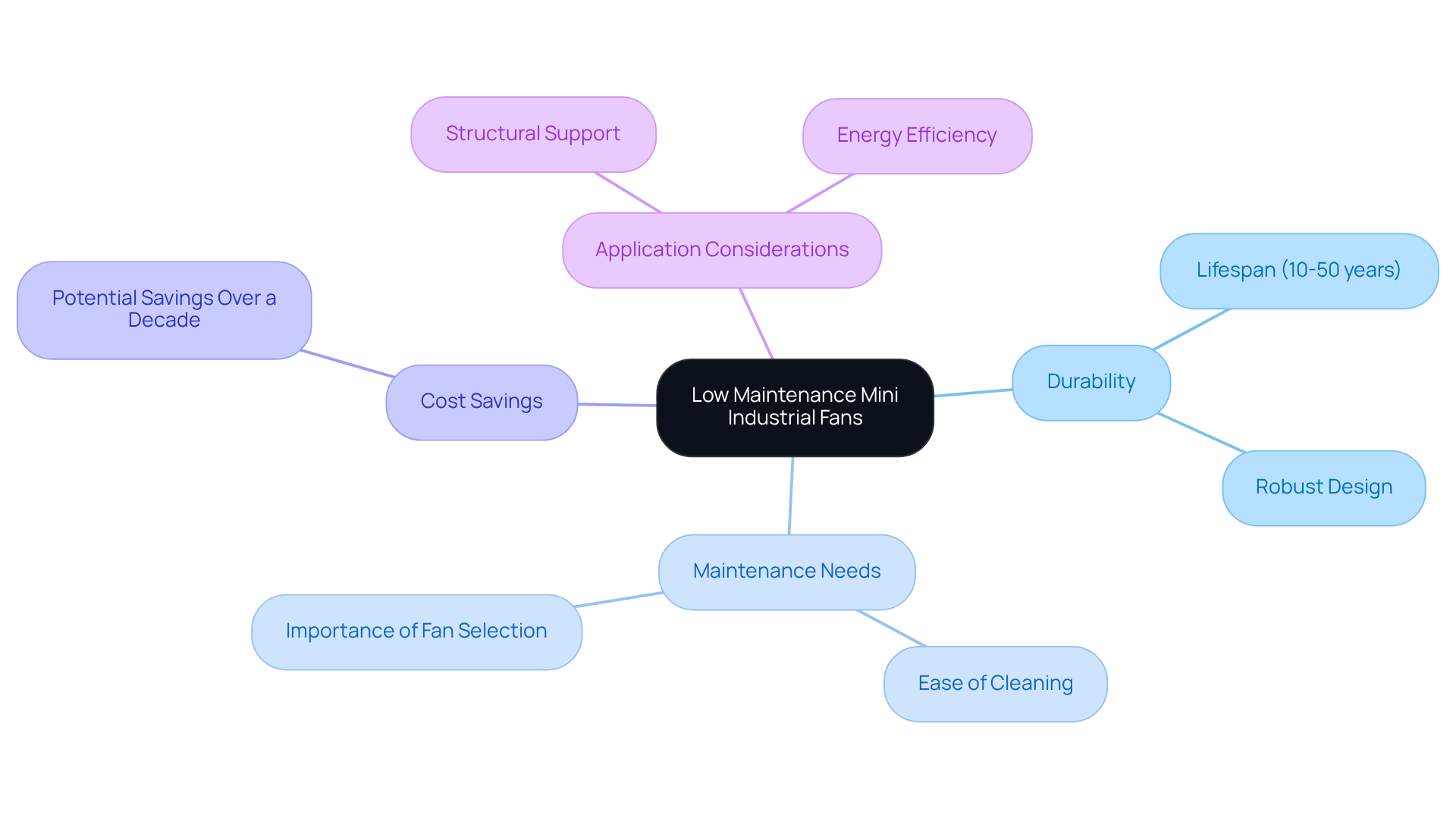

Low Maintenance: Enjoy Hassle-Free Operation with Mini Industrial Fans

Compact commercial blowers are engineered for minimal maintenance, enabling engineers to concentrate on their projects without the burden of routine care. Numerous models feature easy-to-clean designs and robust components that withstand rigorous use, making them particularly suitable for demanding environments.

The typical lifespan of commercial fans ranges from 10 to 25 years, with high-quality fans capable of lasting up to 50 years under optimal conditions. This reliability guarantees that cooling solutions remain effective over time, significantly diminishing the likelihood of expensive repairs or replacements.

Engineers consistently stress the importance of selecting the appropriate fan for specific applications, as “choosing the correct fan necessitates thorough evaluation of your specific application needs, quality standards, proper installation requirements, and structural support.”

In high-temperature or dusty environments, regular maintenance becomes crucial; however, the investment in durable, energy-efficient units proves worthwhile, often resulting in savings exceeding $10,000 in energy costs over a decade, particularly for models intended for continuous use with a 10% efficiency enhancement.

Ultimately, the durability and seamless operation of compact machines position them as an intelligent choice for electronics specialists in search of .

Noise Reduction: Create a Quieter Workspace with Mini Industrial Fans

Small commercial blowers are specifically engineered for silent operation, making them an exceptional choice for environments where maintaining minimal noise levels is essential. By employing advanced motor technologies and innovative blade designs, these devices significantly reduce operational noise, enabling engineers to create a tranquil workspace conducive to concentration. This characteristic is particularly beneficial in laboratories and offices, where distractions can .

Industry experts emphasize that a quieter environment not only enhances focus but also contributes to overall employee satisfaction. For instance, a factory manager reported that after implementing an overhead fan system, employees experienced a consistent cool breeze throughout the facility, greatly improving comfort and reducing noise levels. Furthermore, statistics indicate that monthly energy consumption decreased by 15% following the transition to this system, underscoring the efficiency advantages of silent devices.

By prioritizing silent performance and utilizing premium bearings that minimize friction and extend operational lifespan, mini industrial fans ensure that engineers can work effectively without the disruptive noises typically associated with conventional cooling methods.

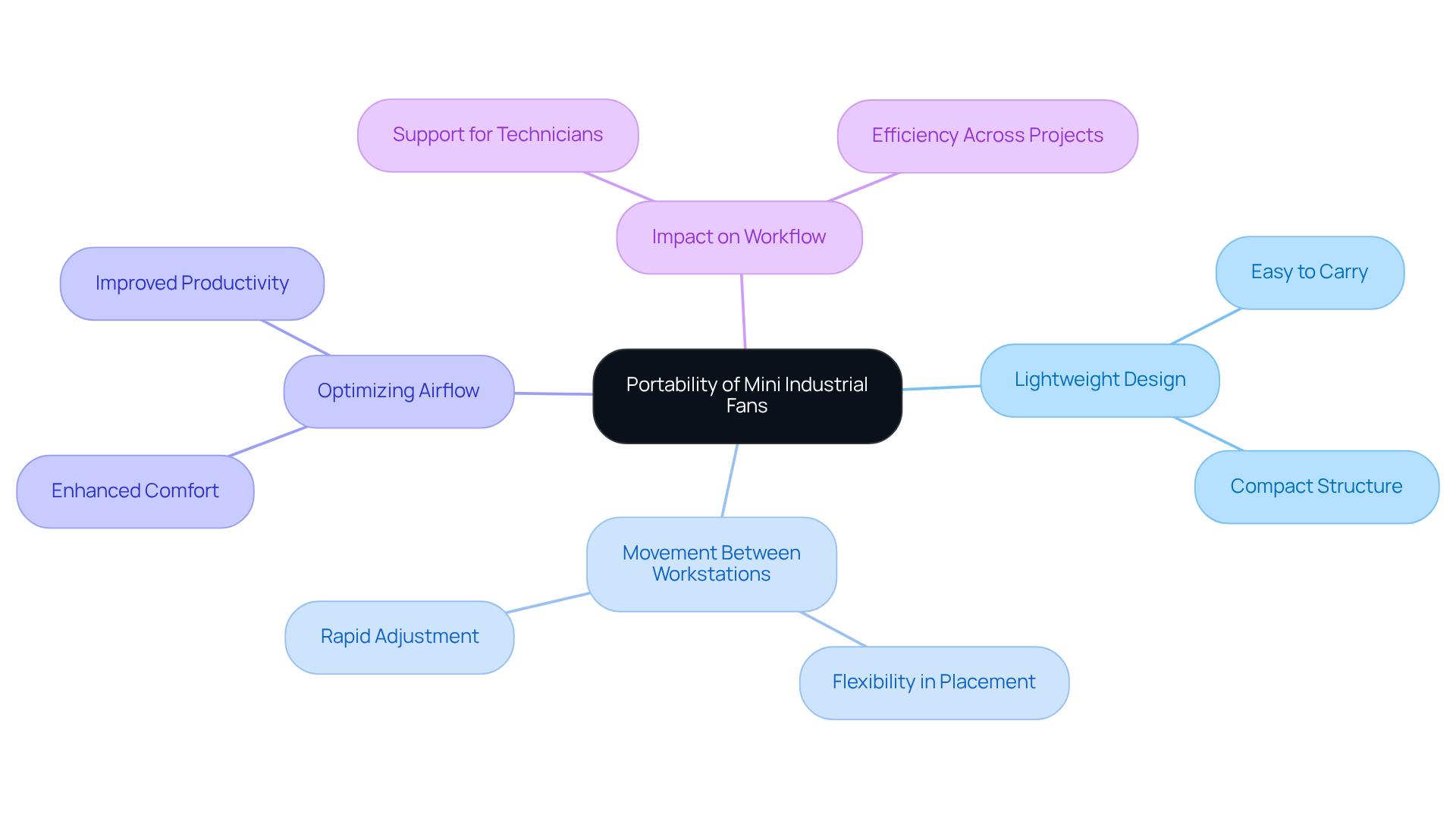

Portability: Easily Move Mini Industrial Fans to Where They’re Needed

Mini industrial fans are engineered with a lightweight and compact structure, rendering them exceptionally portable. This design allows engineers to move the mini industrial fan effortlessly between various workstations or adjust its placement to . Such flexibility proves invaluable in dynamic environments where project requirements frequently evolve.

For example, in engineering projects with fluctuating cooling needs, the capacity to rapidly adjust a mini industrial fan significantly enhances comfort and productivity. A technician aptly noted, ‘The ease of movement allows for better management of thermal conditions, ultimately leading to improved project outcomes.’

Furthermore, a case study examining the implementation of small mechanical ventilators in a manufacturing setting demonstrated that their adaptability not only supported technicians in their immediate tasks but also fostered a more efficient workflow across diverse project locations.

Aesthetic Appeal: Enhance Workspace Design with Stylish Mini Industrial Fans

Compact mechanical blowers serve as both practical ventilation solutions and stylish design elements, available in a diverse array of contemporary styles that can seamlessly enhance any workspace. Their sleek designs not only elevate the visual appeal of offices and laboratories but also foster a professional atmosphere.

Research reveals that well-designed workspaces can significantly boost productivity; notably, 37% of employees in open-plan offices report that their environment adversely affects their efficiency. By selecting mini industrial fans that enhance their office decor, engineers can cultivate an inviting and effective workspace.

Designers emphasize the importance of merging style with functionality, noting that appropriate temperature regulation solutions can enhance the overall atmosphere while ensuring optimal performance. This deliberate design approach not only addresses the practical needs of cooling but also nurtures a more .

Conclusion

Mini industrial fans stand as a transformative solution for electronics engineers, delivering numerous advantages that elevate cooling efficiency and operational effectiveness. These compact devices not only optimize temperature regulation but also integrate seamlessly into diverse workspaces, equipping engineers with essential tools to ensure the reliability and longevity of electronic components.

This article has highlighted key benefits of mini industrial fans, such as:

- Energy efficiency

- Space-saving design

- Versatility across applications

- Improved air circulation

- Cost-effectiveness

- Low maintenance requirements

- Noise reduction

- Portability

- Aesthetic appeal

Each aspect contributes to a more productive and comfortable working environment, demonstrating how these fans address the evolving demands of modern engineering projects.

The importance of adopting mini industrial fans cannot be overstated. As industries increasingly prioritize energy efficiency and sustainability, these devices become essential components in achieving optimal cooling solutions. By leveraging the advantages of mini industrial fans, engineers can enhance project outcomes, reduce operational costs, and create workspaces that are both functional and visually appealing. Embracing this innovative technology represents a significant step toward fostering a more efficient and comfortable environment in the realm of electronics engineering.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for being the world’s largest producer of both standard and custom air-movers, specializing in innovative mini industrial fan solutions that enhance temperature regulation for electronic systems.

What types of cooling technologies does Gagner-Toomey offer?

Gagner-Toomey offers a diverse portfolio that includes extruded aluminum heatsinks, copper-based heat sinks, and integrated cooling solutions.

How do mini industrial fans enhance performance and efficiency?

Mini industrial fans are engineered with advanced technology to meet specific temperature management needs of electronic components, ensuring optimal performance, extended lifespan, and minimal noise.

What are the recent innovations in mini industrial fans?

Recent innovations include enhanced blade designs and sound-insulating materials, which improve airflow and significantly reduce noise levels.

How do mini industrial fans integrate with modern technology?

The integration of smart and IoT technologies allows for remote management and enhances energy efficiency, making these fans vital components in modern electronic systems.

What are the energy efficiency benefits of mini industrial fans?

Mini industrial fans can consume up to 50% less power compared to traditional climate control systems, reducing operational expenses and promoting sustainable temperature management.

What power consumption reductions have facilities reported using mini industrial fans?

Facilities utilizing mini industrial fans have reported average power consumption reductions ranging from approximately 30% to 50%.

How do mini industrial fans accommodate space limitations?

Mini industrial fans are designed to be compact and lightweight, making them suitable for environments with limited space, allowing for seamless integration without sacrificing performance.

Why is the space-saving design of mini industrial fans advantageous?

The space-efficient design ensures that temperature control methods do not obstruct workflow or accessibility in congested work areas, delivering optimal solutions for maintaining a conducive working environment.