Overview

The key benefits of 3-phase fans for electronics engineers are substantial. These fans offer:

- Enhanced energy efficiency

- Superior airflow

- Adaptability for various applications

- Low maintenance requirements

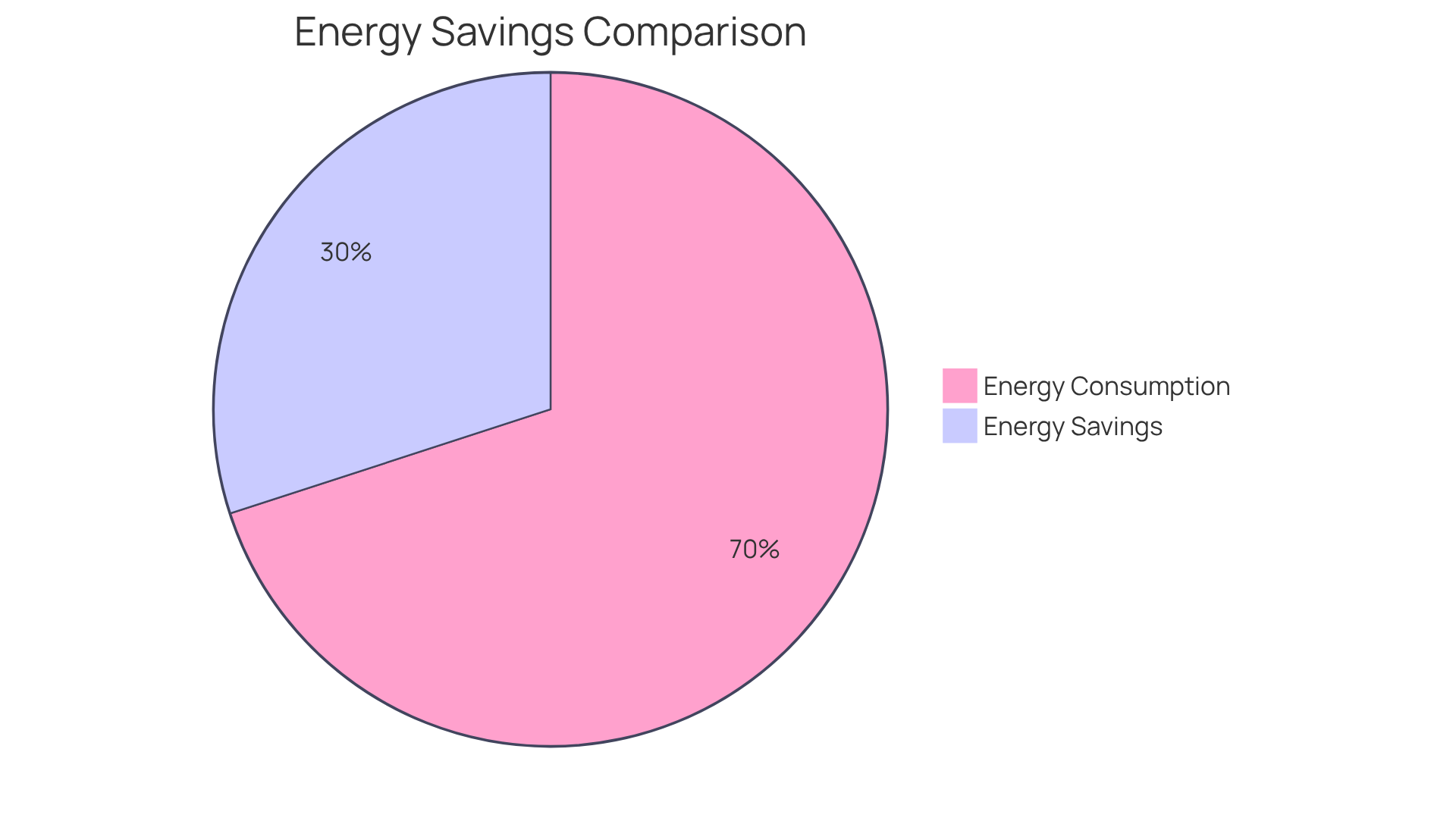

Notably, 3-phase fans can reduce power consumption by up to 30%, thereby providing improved cooling performance. Furthermore, their minimal upkeep makes them an optimal choice for engineers who are seeking reliable and cost-effective cooling solutions across diverse environments. By integrating these fans into their designs, engineers can significantly enhance system performance while reducing operational costs.

Introduction

The evolution of cooling technology has emerged as a critical focus for electronics engineers, particularly in light of the increasing demand for efficient thermal management solutions. Among these innovations, 3-phase fans distinguish themselves with remarkable advantages, including energy efficiency, enhanced performance, and versatility across a range of applications. However, with a plethora of options available, how can engineers ascertain whether 3-phase fans are the optimal choice for their specific needs? This article explores ten key benefits of 3-phase fans, offering insights designed to empower professionals in making informed decisions for their engineering projects.

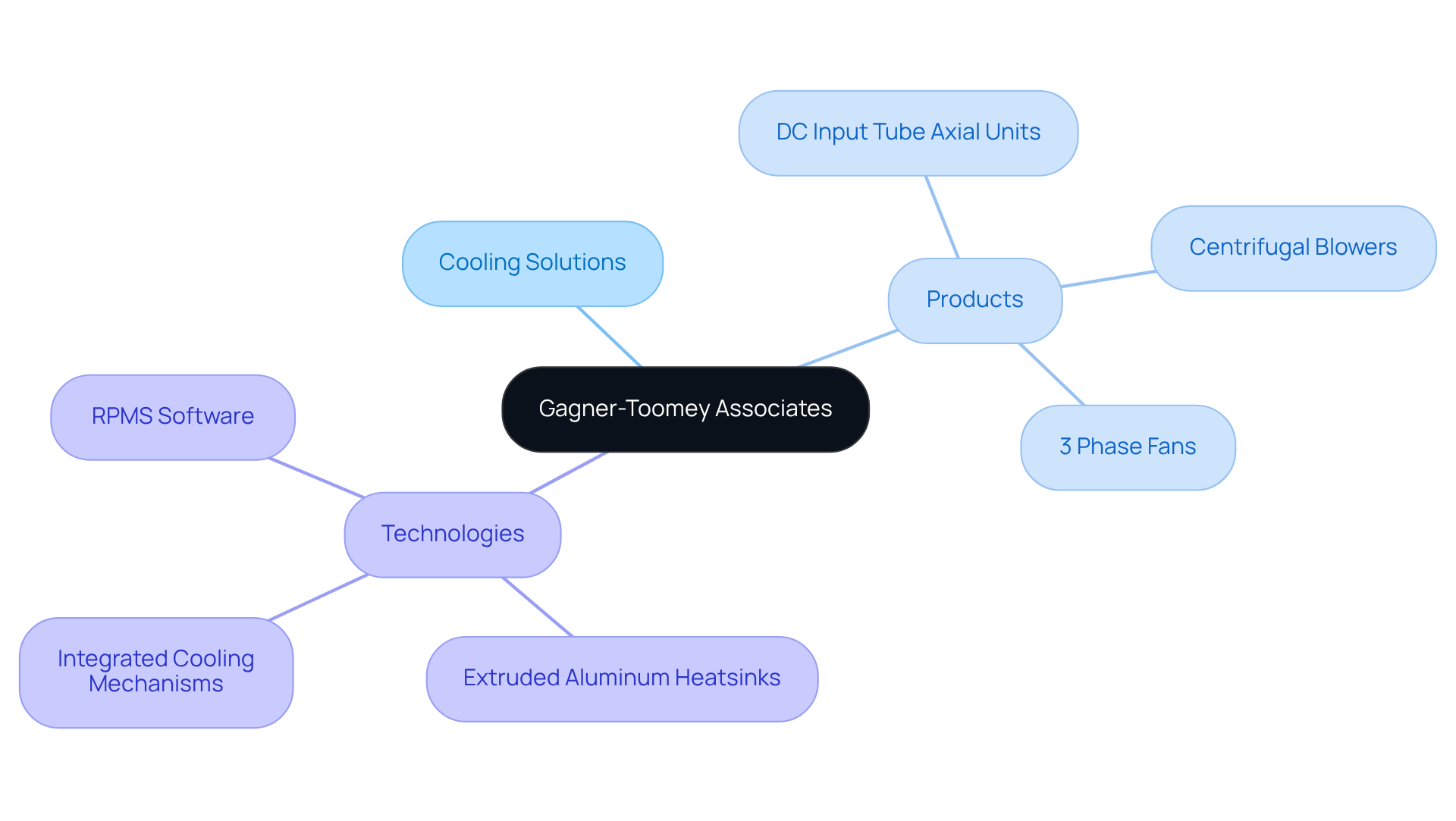

Gagner-Toomey Associates: Innovative Cooling Solutions for Engineering Projects

Gagner-Toomey Associates stands at the forefront of advanced temperature control solutions tailored specifically for the electronics sector. As the world’s largest producer of both standard and custom air-movers, they provide engineers with a comprehensive portfolio of products, including:

- DC input tube axial units

- Centrifugal blowers

All meticulously optimized for performance, efficiency, and low noise. Their unwavering commitment to innovation ensures that clients receive cutting-edge products, including:

Which are vital for effective temperature regulation across a multitude of applications. Furthermore, Gagner-Toomey’s extensive range of thermal management solutions, encompassing:

- Extruded aluminum heatsinks

- Integrated cooling mechanisms

Solidifies their position as a leader in the industry. By harnessing advanced technology and tools like RPMS software for opportunity tracking and sales management, Gagner-Toomey empowers engineers to develop high-performance electronic systems that meet the most stringent operational demands.

Energy Efficiency: Reduce Power Consumption with 3-Phase Fans

3-phase fans are engineered for superior efficiency compared to their single-phase counterparts, resulting in significant reductions in power consumption. By leveraging a balanced power supply, these devices deliver consistent performance while minimizing energy usage.

Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, offers a comprehensive range of DC input Tube Axial units and Centrifugal Blowers that are optimized for performance and low noise levels. This not only reduces operational costs but also contributes to a smaller carbon footprint, rendering them an optimal choice for environmentally conscious engineering projects.

Engineers can expect energy savings of up to 30% when integrating Gagner-Toomey’s 3 phase fan devices into their systems, thereby significantly enhancing the overall sustainability of their designs.

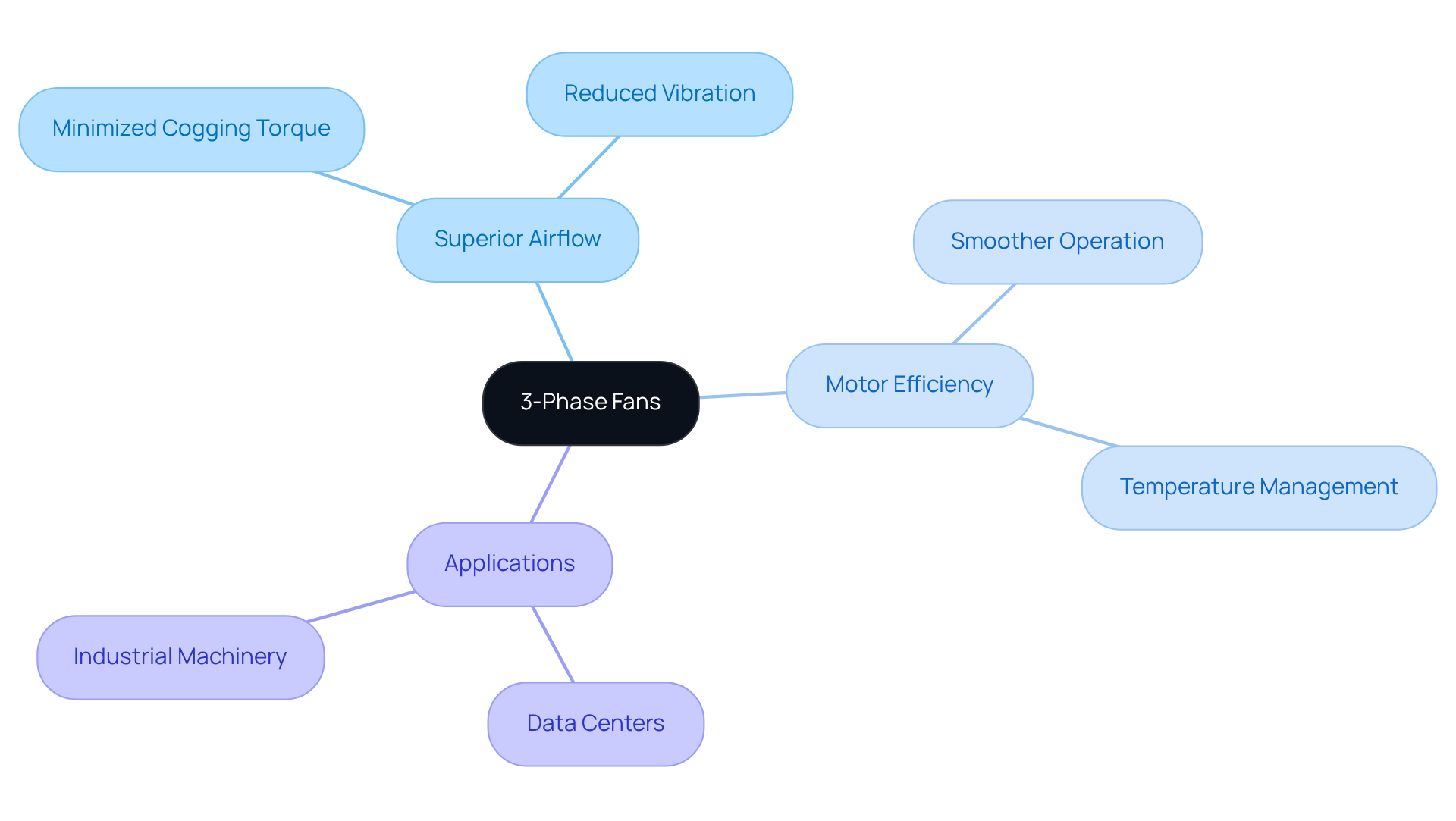

Enhanced Performance: Achieve Superior Airflow with 3-Phase Fans

A standout characteristic of a 3 phase fan is its superior capacity to produce airflow compared to single-phase models. This advantage stems from a more that minimizes cogging torque and vibration, resulting in smoother operation. The enhanced airflow not only improves temperature management but also ensures that electronic components maintain optimal operating temperatures, thereby extending their lifespan.

Engineers can leverage this performance advantage in various applications, from data centers to industrial machinery, where a 3 phase fan is critical for effective thermal management. By understanding these benefits, professionals can make informed decisions that enhance operational efficiency and equipment longevity.

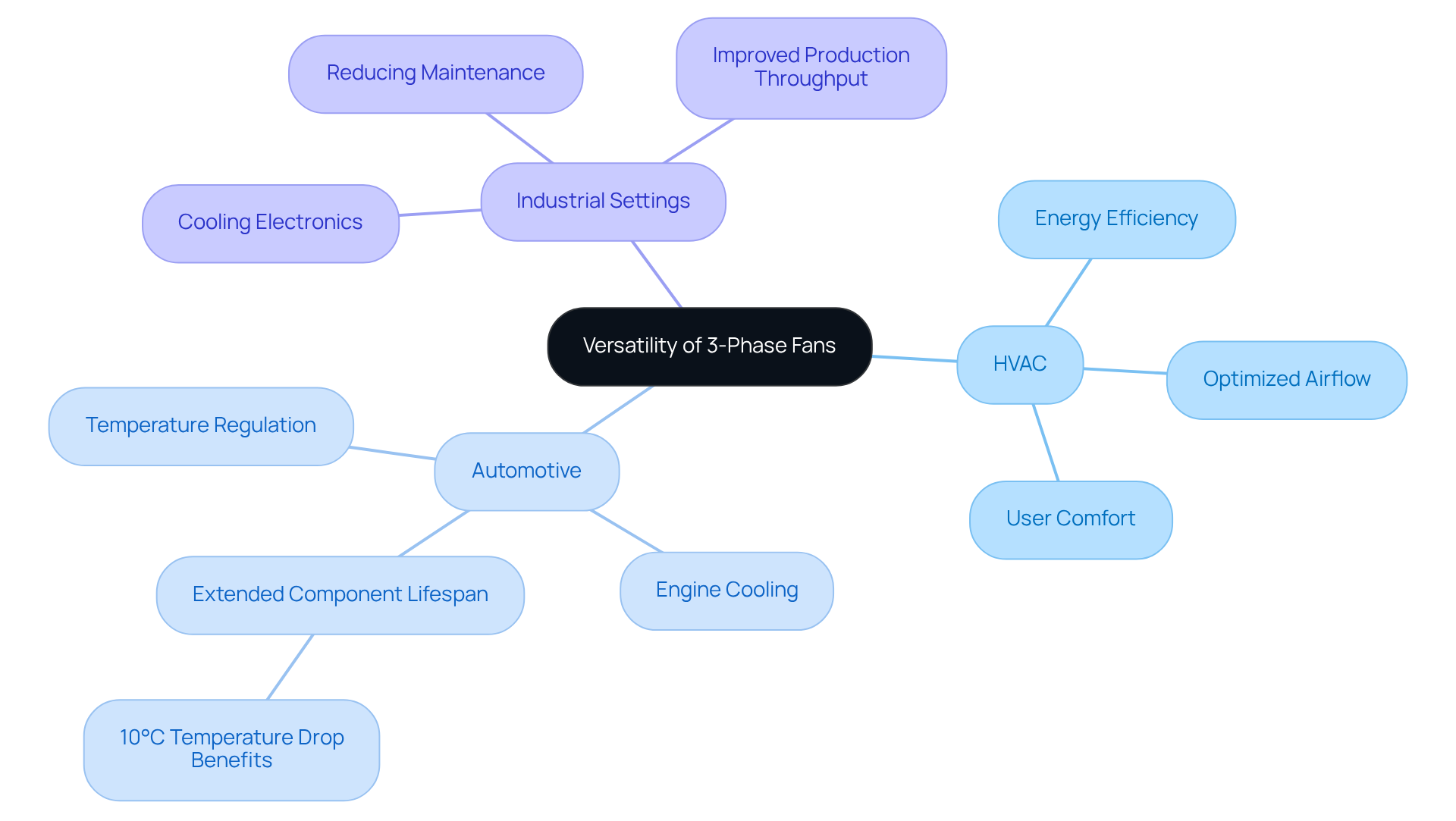

Versatility: Adapt 3-Phase Fans for Multiple Engineering Applications

3 phase fans exhibit remarkable adaptability, making them ideal for a wide array of engineering applications. Their design facilitates the efficient cooling of electronic components in high-performance computing environments while also providing effective ventilation in industrial settings. This versatility is crucial in key sectors such as HVAC and automotive, where a 3 phase fan enhances both .

In HVAC systems, the 3 phase fan optimizes airflow and temperature control, thereby contributing to energy efficiency and user comfort. In automotive applications, they play a vital role in regulating engine temperatures and maintaining optimal operating conditions. Notably, a mere 10°C reduction in temperature can double the lifespan of aluminum electrolytic capacitors, underscoring the significance of effective temperature management solutions.

The ability of a 3 phase fan to operate efficiently across diverse environments ensures that engineers can depend on it for consistent performance, regardless of the specific application. As Johann Tang, a product specialist, asserts, ‘In industrial automation, cooling devices are utilized to cool electronics so that equipment can last longer.’ Their extensive application highlights their critical role in contemporary engineering solutions, including telecommunications.

Durability: Benefit from Long-Lasting Performance of 3-Phase Fans

3 phase fan units are engineered for exceptional durability, often surpassing the lifespan of single-phase models due to their robust construction and efficient motor design. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, utilizes high-quality materials and advanced manufacturing techniques to ensure these devices can withstand harsh operating conditions, making them ideal for industrial applications.

With proper maintenance, or more, significantly minimizing the frequency of replacements and the associated costs. This durability not only bolsters the reliability of cooling systems, including the 3 phase fan, but also enhances overall project efficiency, underscoring Gagner-Toomey’s commitment to delivering innovative cooling solutions for electronics and beyond.

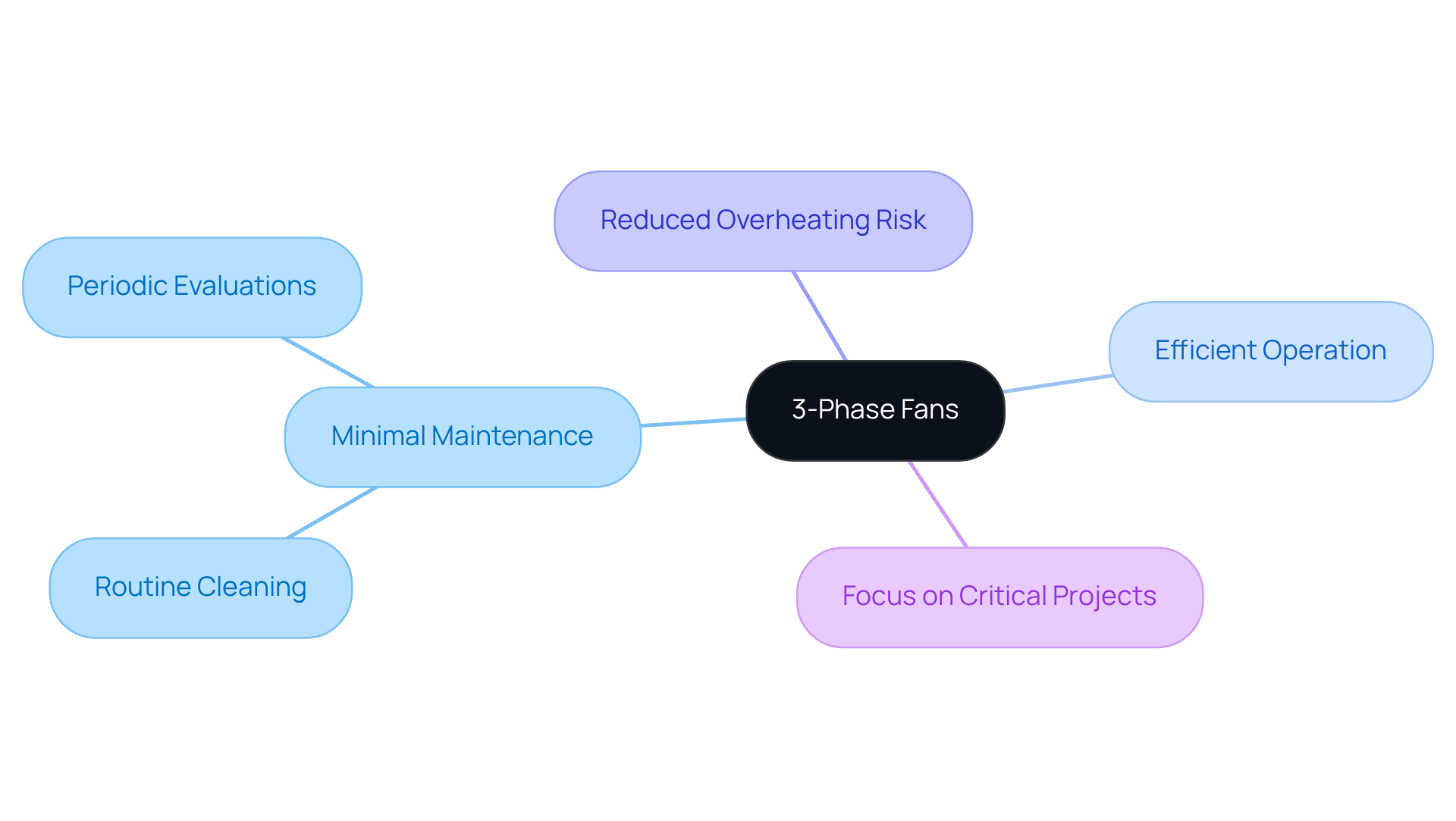

Low Maintenance: Simplify Upkeep with 3-Phase Fans

One of the primary advantages of a 3 phase fan lies in its minimal maintenance requirements. Unlike conventional models that often necessitate regular upkeep due to wear and tear, the 3 phase fan units are designed for with minimal intervention. Their advanced motor design significantly reduces the [risk of overheating and mechanical failure](https://gagner-toomey.com/?p=8862), enabling engineers to concentrate on other critical project elements. Typically, routine cleaning and periodic evaluations suffice to keep these devices functioning effectively, making them an ideal choice for busy engineering environments.

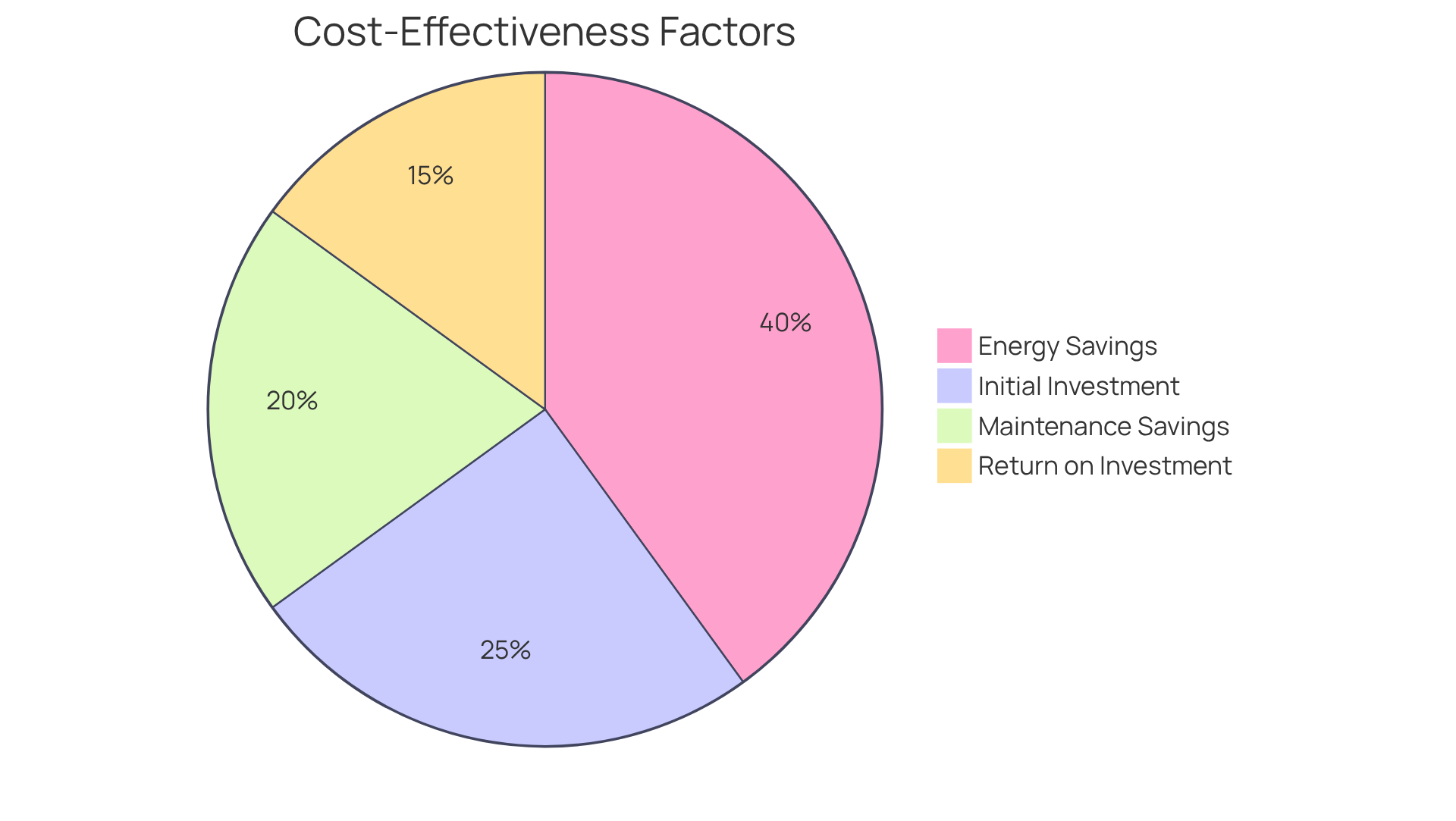

Cost-Effectiveness: Save Money with 3-Phase Fan Technology

While the initial investment in three-phase motors may surpass that of single-phase units, the potential for significant is undeniable. The superior energy efficiency of tri-phase systems translates to lower electricity costs, and their durability coupled with minimal maintenance needs further reduces operational expenses. Engineers can expect a return on investment within a few years, positioning the 3 phase fan as a financially prudent choice for projects that demand reliable cooling solutions. This cost-effectiveness proves especially advantageous in large-scale applications, where energy consumption can profoundly affect the bottom line.

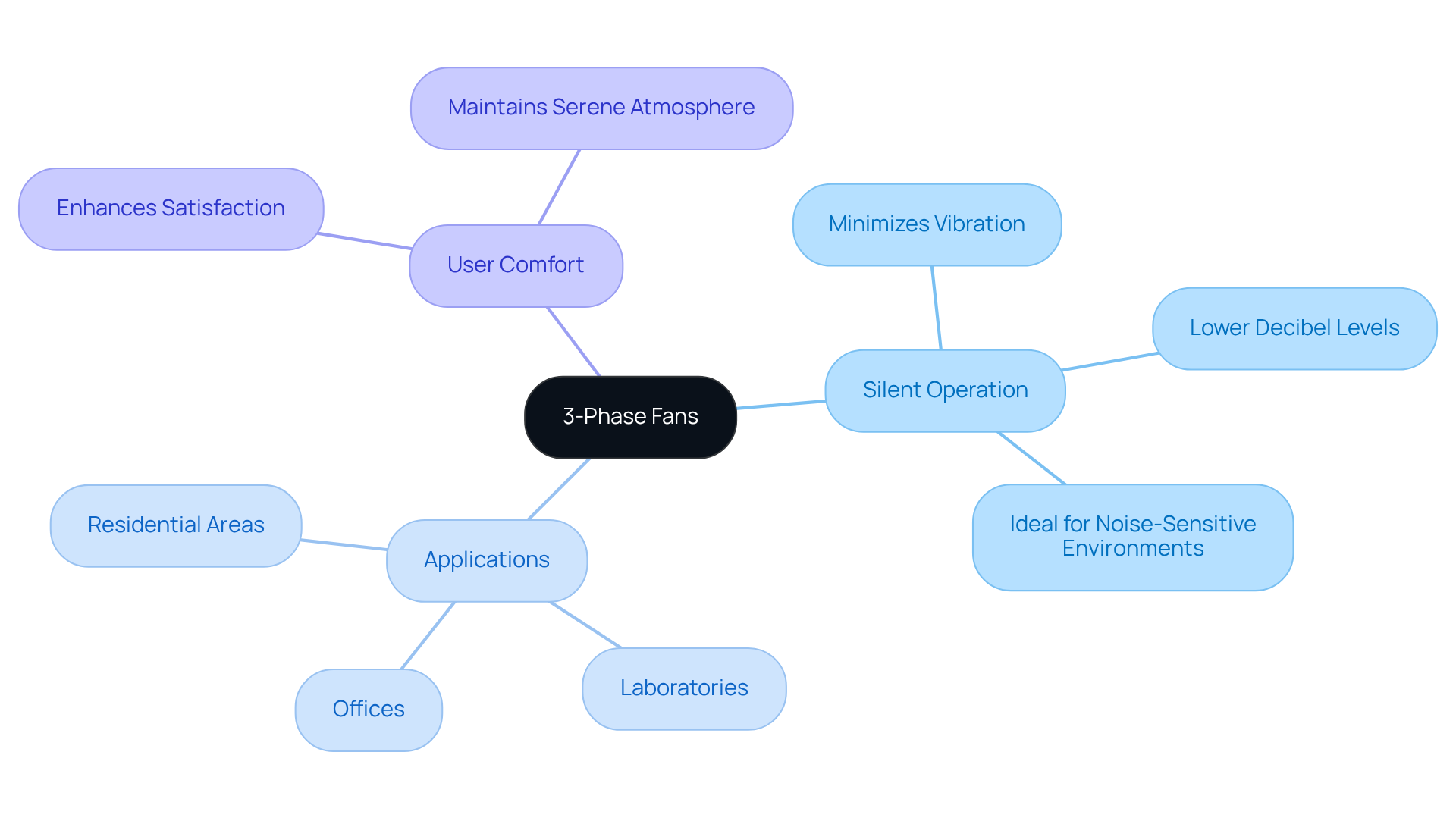

Quiet Operation: Enjoy Silent Performance with 3-Phase Fans

3 phase fans are esteemed for their silent operation, making them ideal for noise-sensitive environments such as offices, laboratories, and residential areas. Their advanced motor design significantly minimizes vibration and noise, allowing these devices to operate at lower decibel levels compared to traditional models. Engineers can effectively implement 3 phase fans in scenarios where maintaining a serene atmosphere is crucial, ensuring that temperature control systems do not disrupt the workplace environment. This capability , establishing the 3 phase fan as a preferred choice across various settings.

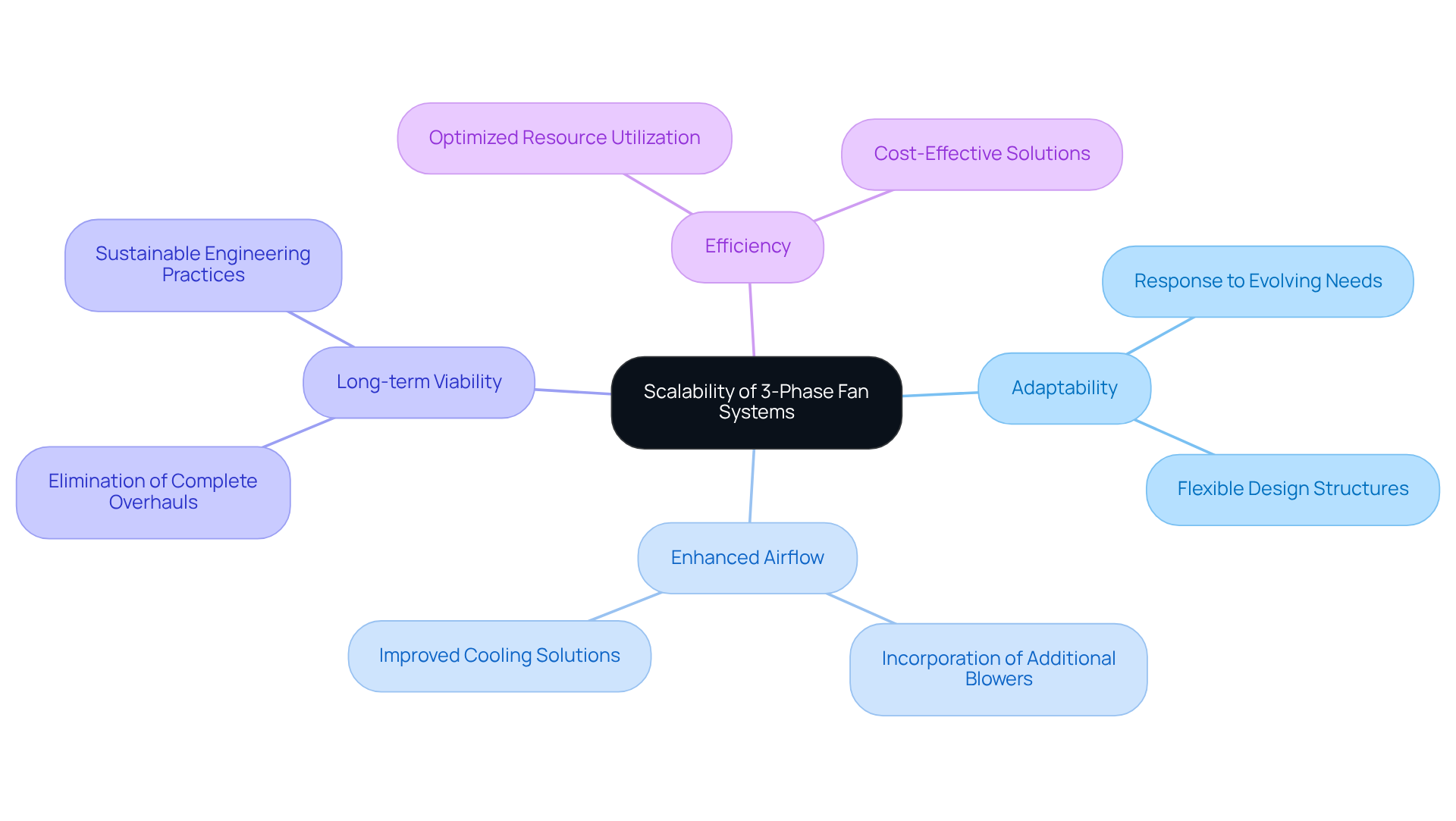

Scalability: Easily Scale Up with 3-Phase Fan Systems

The setups of the 3 phase fan capture attention with their outstanding scalability, enabling engineers to broaden their cooling solutions effortlessly as project requirements increase. This technology allows for the incorporation of additional blowers to enhance airflow or the integration of extra components into existing setups, providing the for responding to evolving needs. Such scalability proves particularly advantageous in industries where production levels fluctuate or where new technologies are continuously integrated. Engineers can confidently design structures that evolve over time, eliminating the need for complete overhauls and ensuring long-term viability and efficiency.

Advanced Technology: Leverage Cutting-Edge Features of 3-Phase Fans

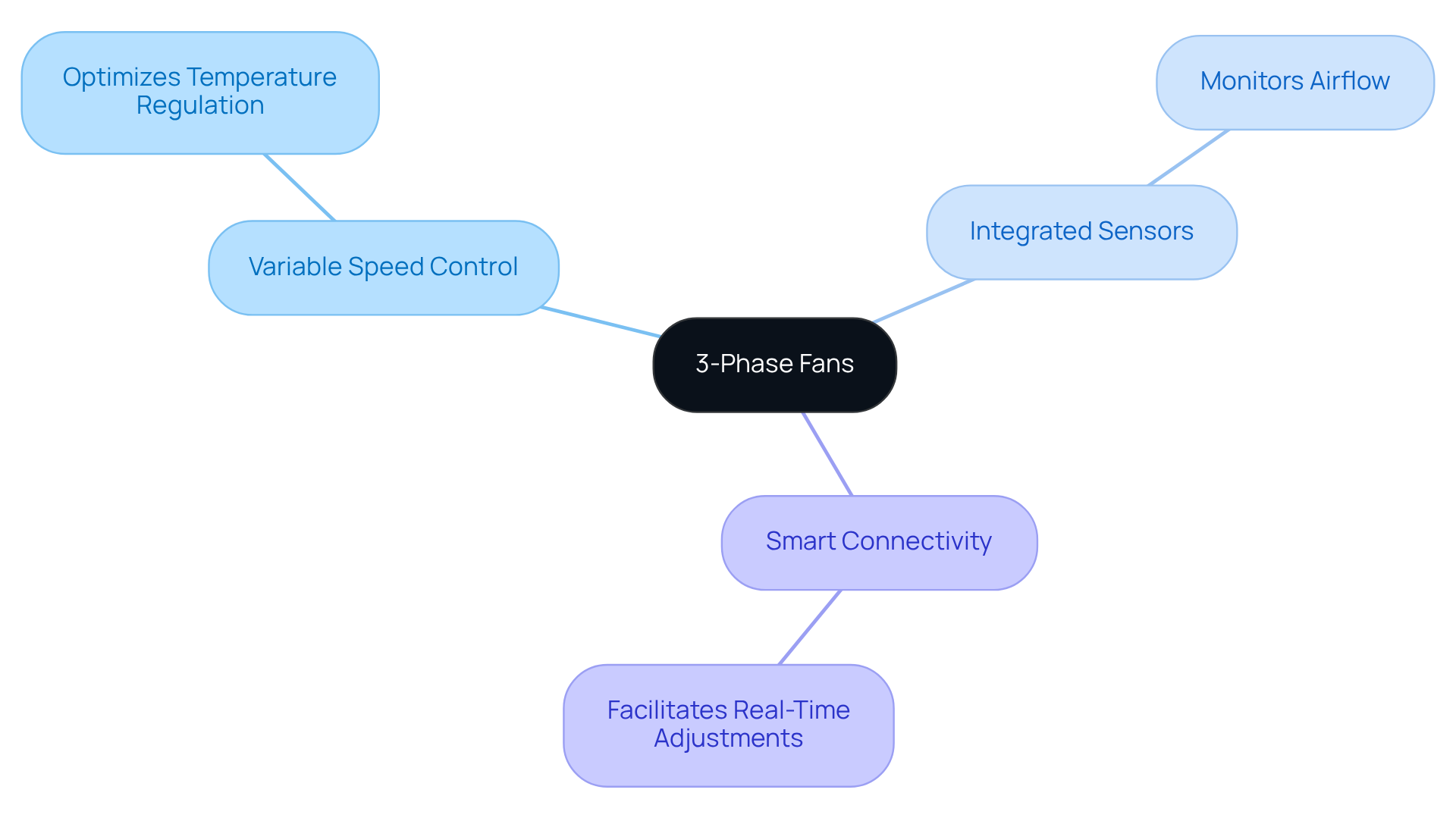

The 3 phase fan integrates advanced technologies that significantly enhance performance and efficiency. With features such as variable speed control, integrated sensors for monitoring airflow, and smart connectivity options, engineers can dynamically optimize their . These innovations not only elevate operational efficiency but also facilitate real-time adjustments based on environmental conditions. By leveraging these cutting-edge capabilities, engineers can ensure their cooling solutions are not only effective but also in alignment with the latest industry standards and technological advancements.

Conclusion

The advantages of 3 phase fans extend far beyond mere cooling; they signify a substantial advancement in engineering solutions for electronics. Their energy efficiency, enhanced performance, and versatility render them indispensable tools for engineers intent on optimizing thermal management across diverse applications. With Gagner-Toomey Associates at the forefront of innovative cooling technologies, the integration of these fans into electronic systems not only fulfills operational demands but also aligns with sustainability objectives.

Key insights reveal the considerable energy savings achievable with 3 phase fans, estimated at up to 30%, alongside their superior airflow capabilities, which contribute to prolonged component lifespans. Moreover, the durability and low maintenance requirements of these fans diminish long-term operational costs, while their quiet operation ensures deployment in noise-sensitive environments without compromise. The scalability of 3 phase fan systems facilitates adaptability as project needs evolve, establishing them as a prudent investment for future-proof engineering designs.

In conclusion, embracing 3 phase fans represents a strategic decision for engineers aiming to enhance the performance and reliability of their projects. As industries increasingly prioritize energy efficiency and sustainability, the adoption of these advanced cooling solutions will not only drive operational excellence but also cultivate a commitment to environmental stewardship. Engineers are encouraged to explore the full potential of 3 phase fans, leveraging their innovative features to create cutting-edge, efficient, and reliable electronic systems that withstand the test of time.

Frequently Asked Questions

What products does Gagner-Toomey Associates offer for temperature control solutions?

Gagner-Toomey Associates offers a comprehensive portfolio of products including DC input tube axial units, centrifugal blowers, and 3 phase fans, all optimized for performance, efficiency, and low noise.

How do 3-phase fans compare to single-phase fans in terms of energy efficiency?

3-phase fans are engineered for superior efficiency, resulting in significant reductions in power consumption. They can provide energy savings of up to 30% compared to single-phase fans, making them an optimal choice for environmentally conscious engineering projects.

What are the benefits of using 3-phase fans in engineering projects?

The benefits of using 3-phase fans include superior airflow production, enhanced temperature management, reduced operational costs, and a smaller carbon footprint. They help maintain optimal operating temperatures for electronic components, thereby extending their lifespan.

What additional thermal management solutions does Gagner-Toomey provide?

In addition to fans, Gagner-Toomey provides thermal management solutions including extruded aluminum heatsinks and integrated cooling mechanisms.

How does Gagner-Toomey support engineers in developing high-performance electronic systems?

Gagner-Toomey empowers engineers by harnessing advanced technology and tools like RPMS software for opportunity tracking and sales management, enabling the development of high-performance electronic systems that meet stringent operational demands.