Overview

High power blowers are indispensable for electronics cooling, delivering significant advantages such as enhanced airflow, energy efficiency, and dependable operation. These factors collectively improve the performance and longevity of electronic components. This article underscores their versatility across diverse applications, including:

- Data centers

- Medical devices

It also highlights the escalating market demand fueled by the necessity for effective thermal management solutions in increasingly intricate electronic systems.

Introduction

High power blowers are transforming the landscape of electronic heat management, a vital aspect for ensuring optimal performance and longevity. These sophisticated cooling solutions not only improve airflow efficiency but also guarantee reliability across a wide range of applications, from data centers to medical devices.

However, as demands for energy efficiency and precise temperature control escalate, manufacturers face the pressing question: how can they fully harness the capabilities of these advanced technologies?

This article investigates the significant advantages of high power blowers, examining their pivotal role in enhancing electronic cooling and tackling the challenges inherent in contemporary thermal management.

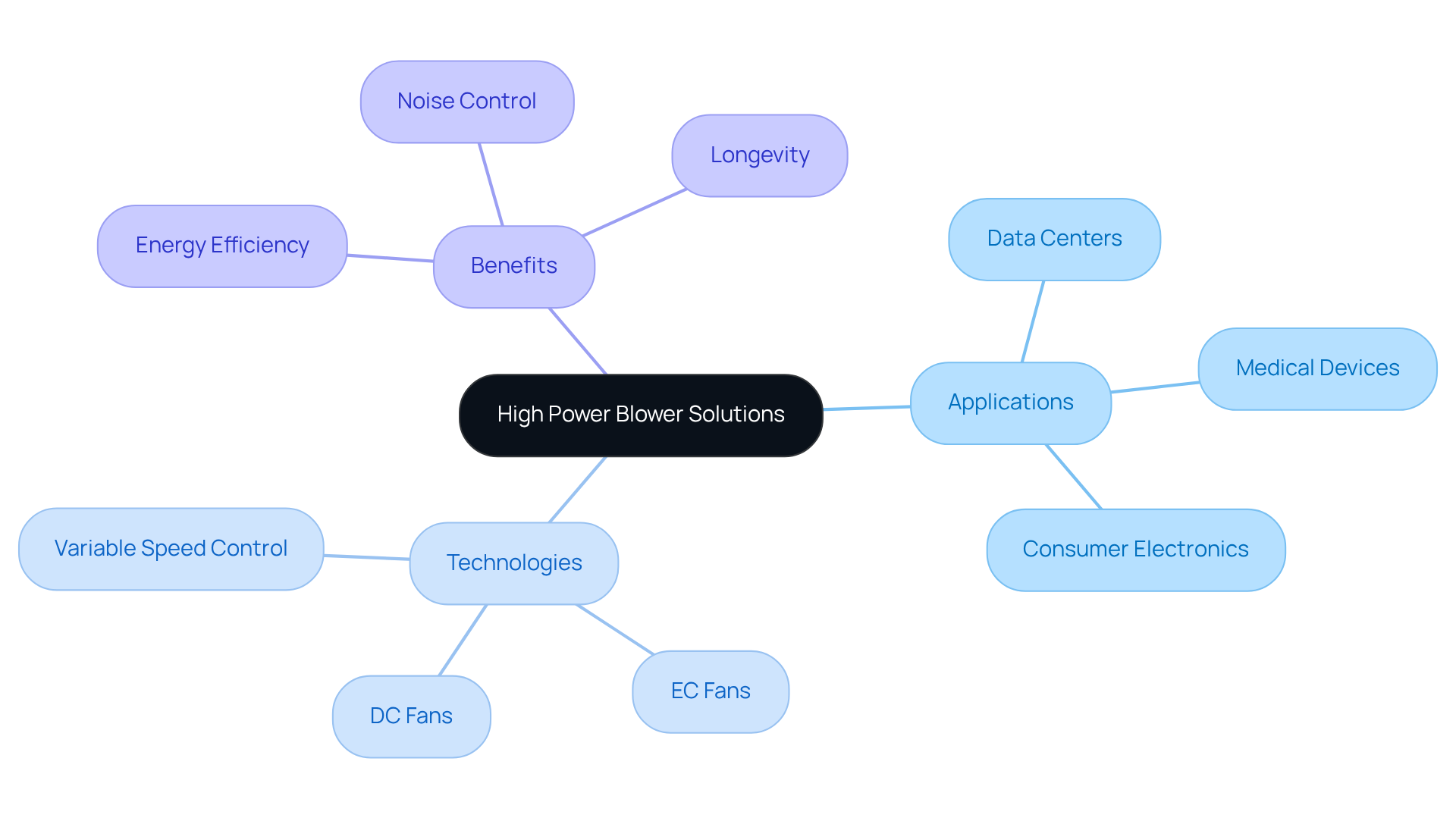

Gagner-Toomey Associates: Pioneering High Power Blower Solutions for Electronics Cooling

Gagner-Toomey Associates leads the electronics sector by providing solutions that include high power blower systems to effectively tackle intricate temperature regulation challenges. These fans are crucial for sustaining across a range of electronic applications, including data centers, medical devices, and consumer electronics. Statistics indicate that DC fans, celebrated for their energy efficiency and quiet operation, are widely employed in laptops, desktops, and gaming consoles, significantly enhancing performance and reliability. Moreover, DC fans are particularly well-suited for medical devices where low noise is imperative, demonstrating their versatility in sensitive environments.

Successful implementations of high power blowers have been observed in critical settings such as clean rooms and data centers, where stringent air quality management is vital. For example, the integration of Electronically Commutated (EC) fans has emerged as a transformative solution, delivering precise airflow control and energy savings that align with contemporary energy efficiency standards. The market for EC devices and fans is projected to grow at a CAGR of 7.8% from 2024 to 2032, indicating a rising demand for these technologies.

Advancements in blower technology persist, with innovations like variable speed control and compact designs addressing the escalating need for efficient temperature regulation solutions. Gagner-Toomey’s collaboration with leading manufacturers ensures that [engineers have access to cutting-edge tools](https://gagner-toomey.com/?p=8720) that not only meet but exceed the thermal requirements of high-power electronics. As T. Coyle highlighted, accurate load estimations are critical to ensure adequate temperature control is maintained without incurring excessive equipment costs or air velocity. As the industry shifts towards more sustainable practices, the significance of high power blowers in enhancing thermal management remains paramount, paving the way for future innovations in electronics temperature regulation. A rise of 18° in operating temperature halves the lifespan of electrical insulation, underscoring the importance of effective temperature management in prolonging equipment longevity.

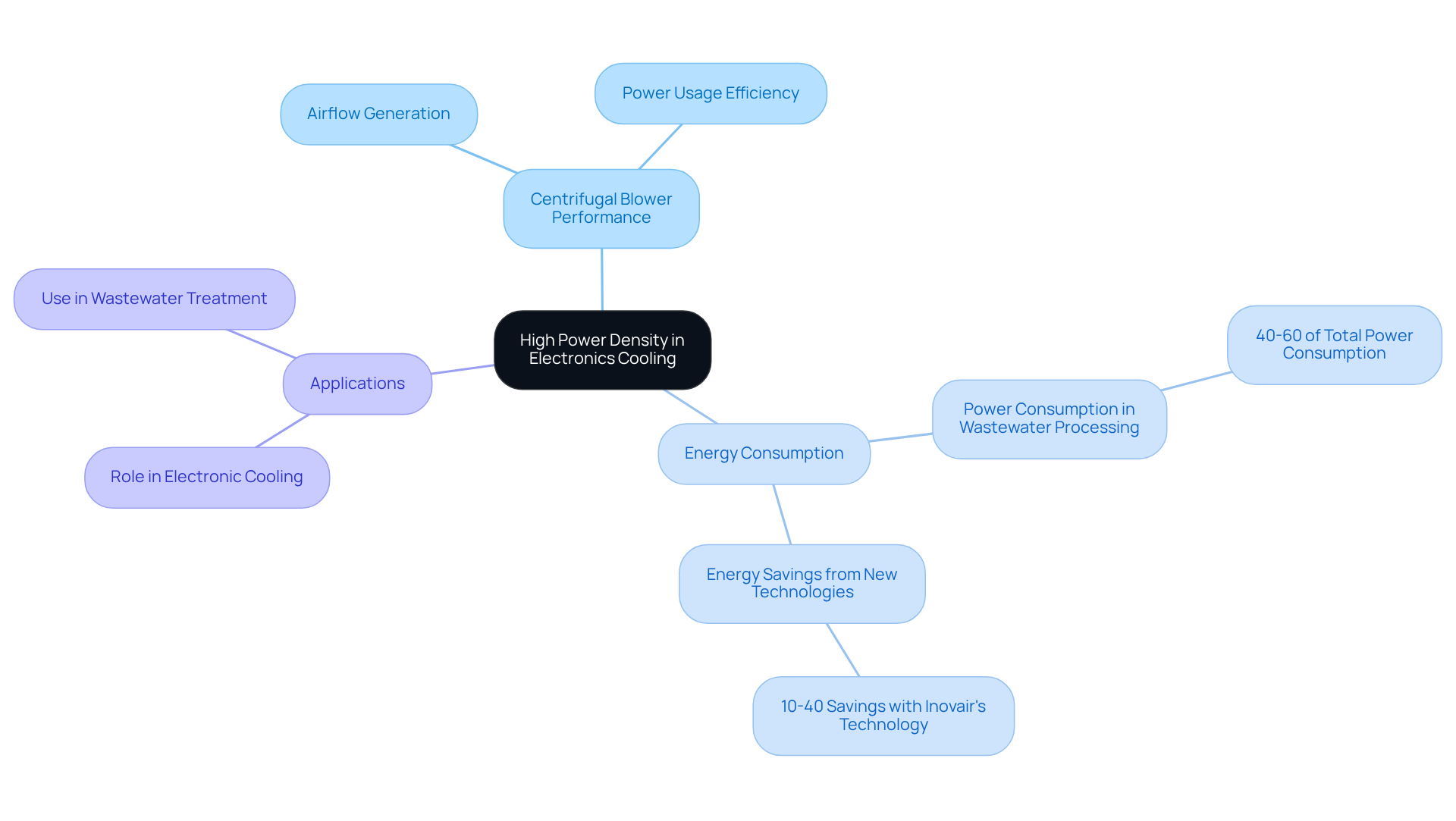

High Power Density: Maximizing Efficiency in Electronics Cooling with Centrifugal Blowers

Centrifugal fans are engineered to achieve high power blower performance, a crucial factor in improving cooling efficiency for electronic systems. These high power blowers generate substantial airflow while consuming minimal power, effectively maintaining optimal operating temperatures. This capability not only of electronic components but also addresses the challenges posed by space constraints in high-performance applications.

For instance, in wastewater processing facilities, centrifugal fans can account for 40-60% of total power consumption, underscoring their significance in power management, particularly considering that the water and wastewater sector consumes approximately 75 billion kilowatt hours of electricity annually.

Furthermore, advancements in ventilation technology, such as Inovair’s geared centrifugal fans, demonstrate energy savings of 10-40% compared to traditional setups, positioning them as an ideal choice for regulating electronics temperatures. The average energy consumption of centrifugal fans in electronic applications is significantly lower than that of positive displacement units, further reinforcing their efficiency.

As industries increasingly prioritize energy-saving solutions, the role of centrifugal fans in cooling applications continues to expand, driving innovation and enhancing efficiency in electronic devices.

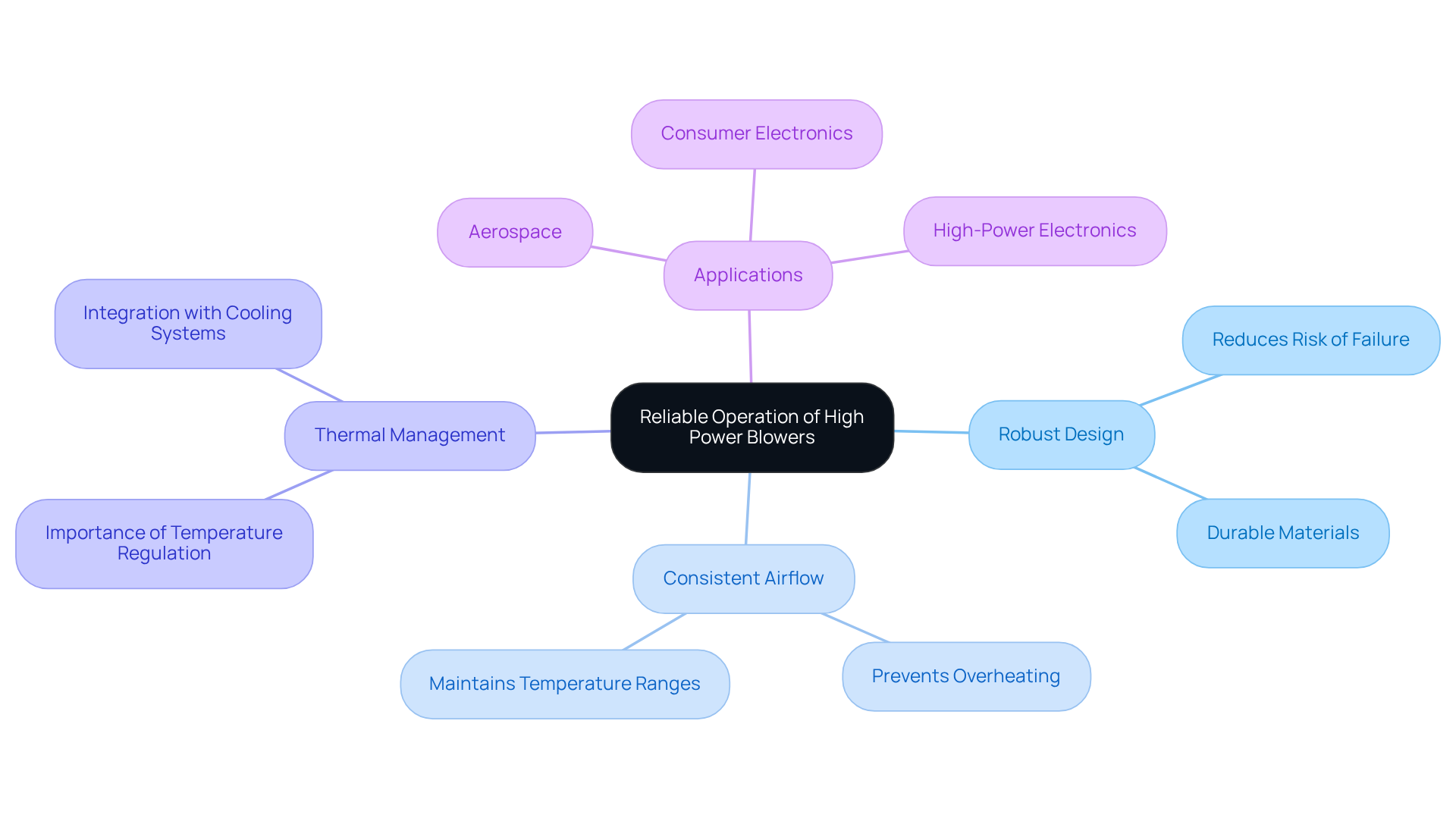

Reliable Operation: Ensuring Consistent Performance with High Power Blowers

High power blowers are meticulously engineered to deliver reliable operation, ensuring consistent performance even in the most demanding environments. Their robust design significantly reduces the risk of failure, which is vital for preserving the integrity of sensitive electronic components. By ensuring a consistent airflow, these devices effectively avoid overheating, enabling mechanisms to function within their designated temperature ranges. According to Yong Tang, “more than 50% of electronic component failures are caused by a thermal issue,” highlighting the necessity of effective temperature regulation solutions.

For instance, the IHS-PMP is considered a high-potential component for thermal management, demonstrating exceptional reliability in high-power electronics applications. This consistency is crucial for applications ranging from aerospace to consumer electronics, where is paramount.

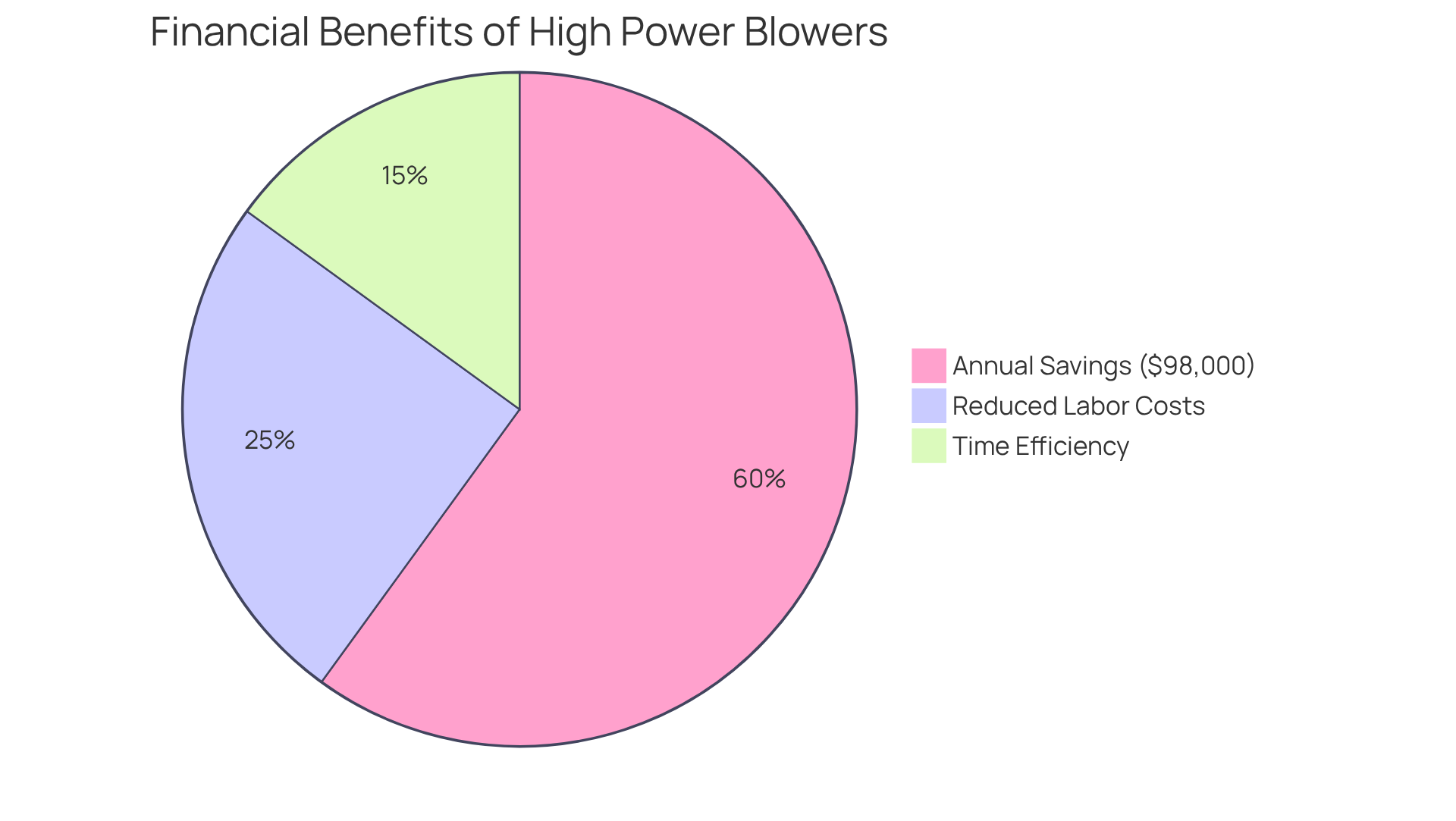

Simple Commissioning: Streamlining Installation of High Power Blowers in Electronics

High power blowers are distinguished by their straightforward commissioning process, facilitating seamless integration into existing systems with minimal disruption. This efficient setup not only conserves valuable time but also , making high power blowers a compelling choice for engineers who want to enhance cooling efficiency without necessitating extensive modifications.

For instance, the Victor Valley Wastewater Reclamation Authority (VVWRA) experienced a notable reduction in energy consumption and operational costs after upgrading to high-speed turbo fans, resulting in annual savings of approximately $98,000. Moreover, the typical payback period for ongoing commissioning projects is reported to be just 1.5 years, according to broader industry data, underscoring the financial benefits associated with these strategies.

By implementing high power blowers, facilities can achieve substantial cost savings while simultaneously improving overall performance.

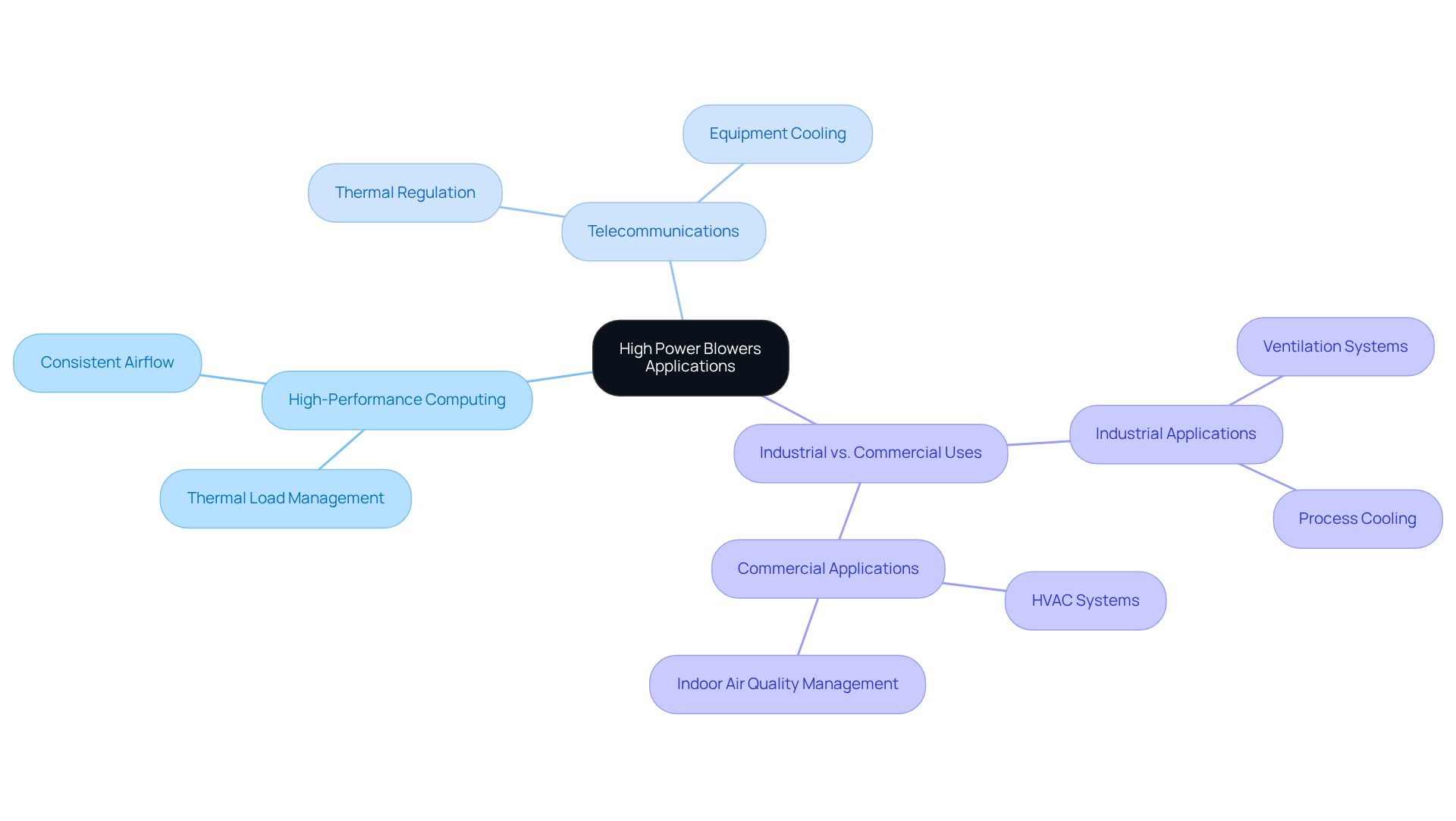

Versatile Applications: Utilizing High Power Blowers Across Electronics Cooling Needs

High power blowers are adaptable instruments essential for addressing various electronics temperature management requirements. These fans are pivotal in regulating high-performance computing systems and controlling thermal loads in telecommunications devices. Their versatility allows them to seamlessly adjust to different environments and specific needs. With the capability to deliver , high power blowers are suitable for both industrial and commercial applications, thereby ensuring optimal performance across diverse settings.

Air Curtain Principle: Enhancing Cooling Efficiency with Centrifugal Blowers

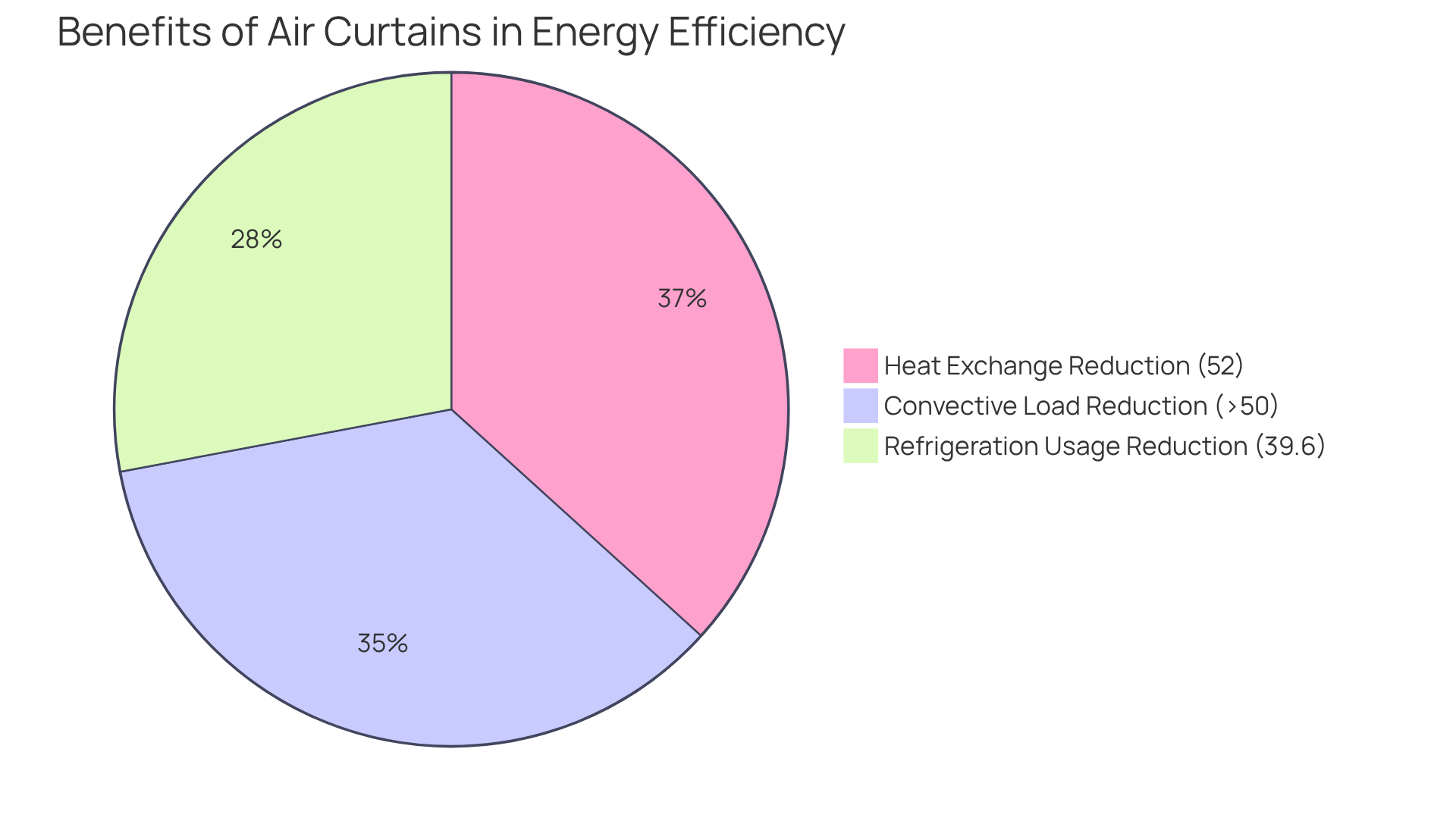

The air curtain principle is pivotal in enhancing temperature control, especially when integrated with centrifugal fans. By creating a barrier of air, the high power blowers effectively isolate heated areas from cooler environments, which is crucial for managing thermal loads. This separation not only improves temperature management but also leads to substantial resource savings by decreasing reliance on additional systems such as high power blowers for temperature control.

Research indicates that air curtains can reduce refrigeration usage by 39.6% compared to sliding doors, and a 50% air curtain coverage ratio can diminish heat exchange by over 52%, significantly boosting efficiency across various applications. Furthermore, the implementation of air curtains in large public buildings has shown a reduction in convective loads exceeding 50% when optimal configurations are applied.

Additionally, air curtains can sustain a temperature difference of up to 3 °C between zones, further enhancing their effectiveness in thermal load management. This technology not only improves cooling efficiency but also promotes a more , particularly in an industry where building energy consumption represents 40% of primary energy usage.

Additional Applications: Leveraging High Power Blowers in Air Lock Systems

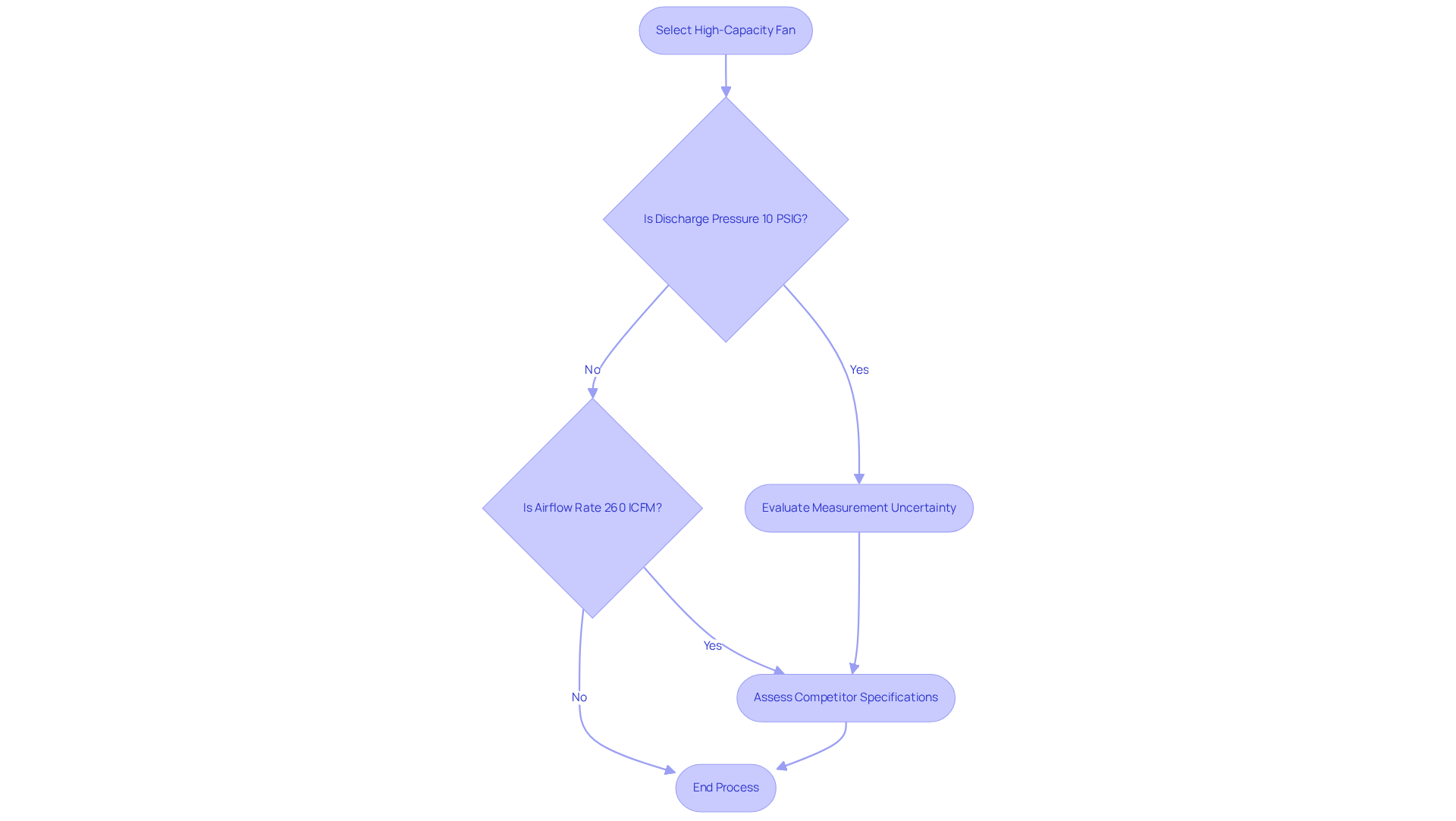

High-capacity fans are integral to air lock mechanisms, where precise airflow regulation is essential for maintaining controlled environments. These systems benefit from the consistent and provided by high-capacity fans, which help prevent contamination and uphold the integrity of sensitive processes.

For example, in applications that require a discharge pressure of 10 PSIG and an airflow rate of 260 ICFM, a high power blower can effectively manage the necessary conditions to optimize performance. Furthermore, the measurement uncertainty for volume flow in these setups is as low as 0.15%, ensuring precision in adhering to operational standards.

As Tom Jenkins, President of JenTech Inc., notes, “The curve is essential to assess fan performance,” highlighting the importance of understanding how discharge pressure influences power consumption.

As we approach 2025, the demand for efficient airflow management in air lock systems is increasingly significant, underscoring the need for advanced fan technologies. Engineers are also urged to critically evaluate competitor specifications concerning energy consumption, ensuring they select the most efficient options available, including both lobe-type and screw-type positive displacement devices.

Forward-Curved Blades: Optimizing Airflow for Enhanced Cooling Performance

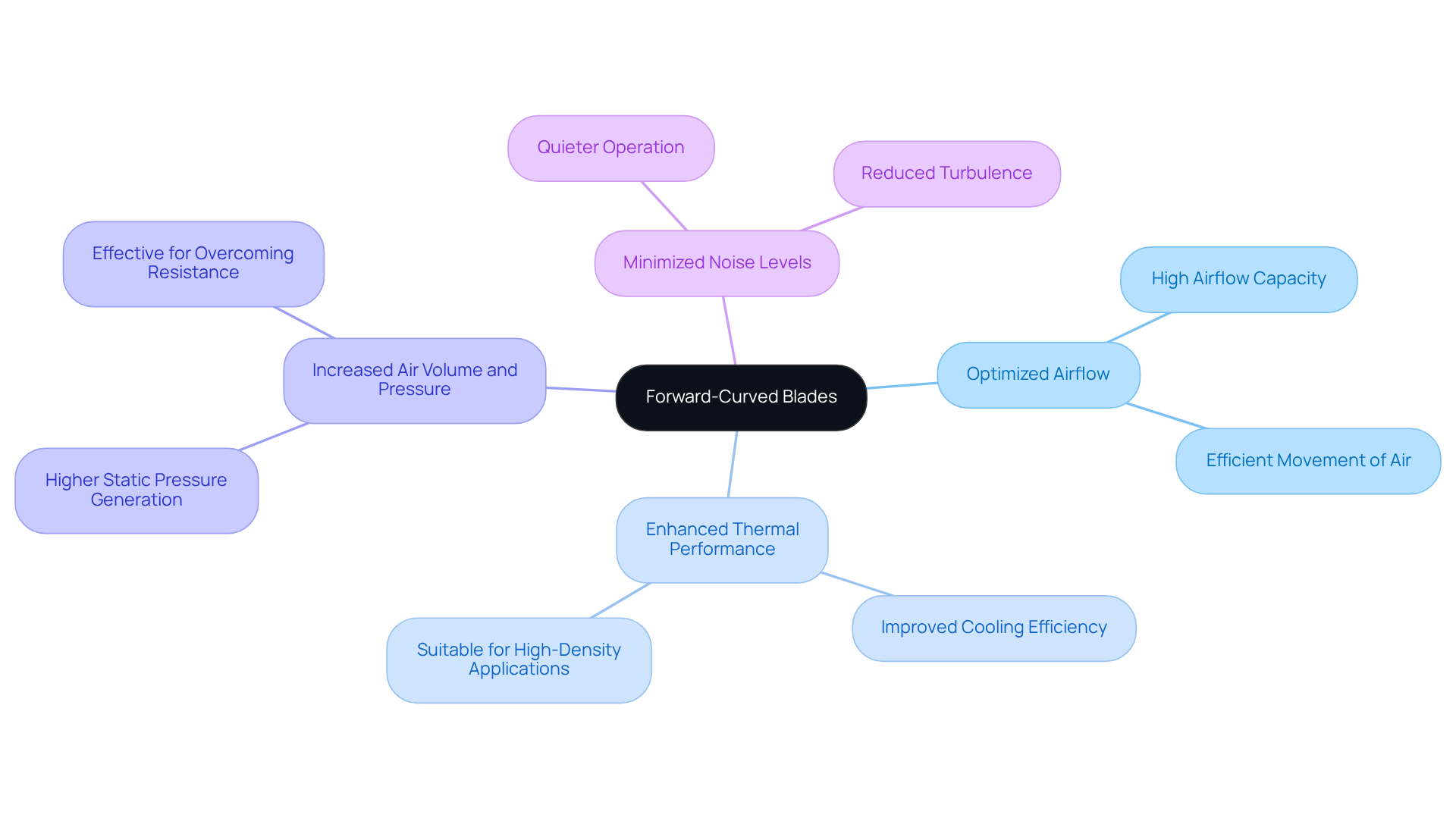

Forward-curved blades represent a pivotal feature in many high-power fans, as they optimize airflow to enhance thermal performance. This innovative design facilitates , which are critical for effective cooling in high-density electronic applications. By maximizing airflow while concurrently minimizing noise levels, forward-curved blades not only contribute to a more efficient operation but also ensure a quieter environment. Consequently, these blades have emerged as the preferred choice for engineers seeking reliable and effective cooling solutions.

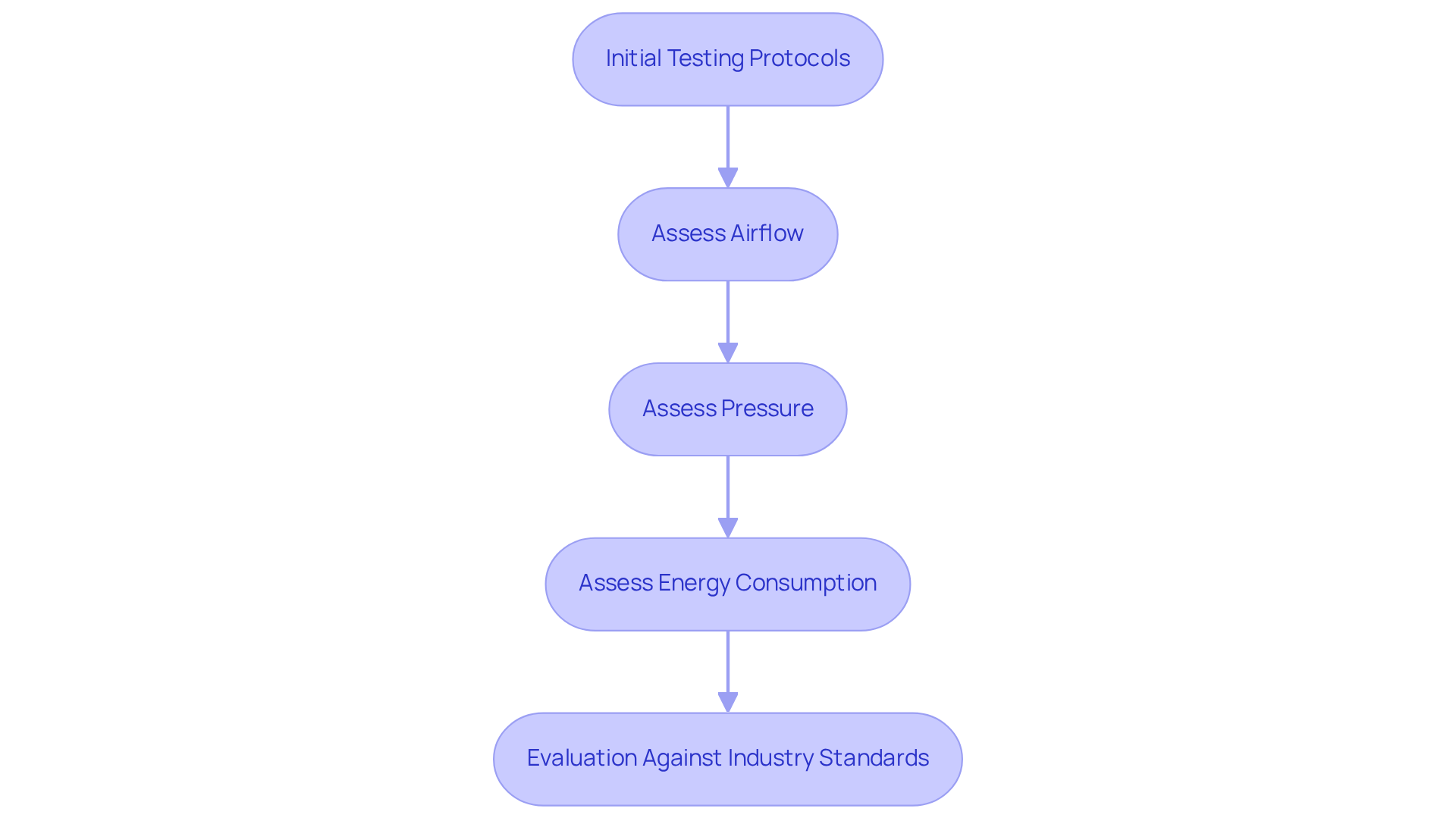

Testing and Evaluation: Ensuring Performance Reliability of High Power Blowers

Testing and evaluation are critical components in ensuring the of high power blowers. Comprehensive testing protocols meticulously assess airflow, pressure, and energy consumption, equipping engineers with essential data for informed decision-making. By adhering to rigorous industry standards, manufacturers can guarantee that their devices fulfill the required performance criteria, thereby enabling engineers to confidently depend on their ventilation solutions.

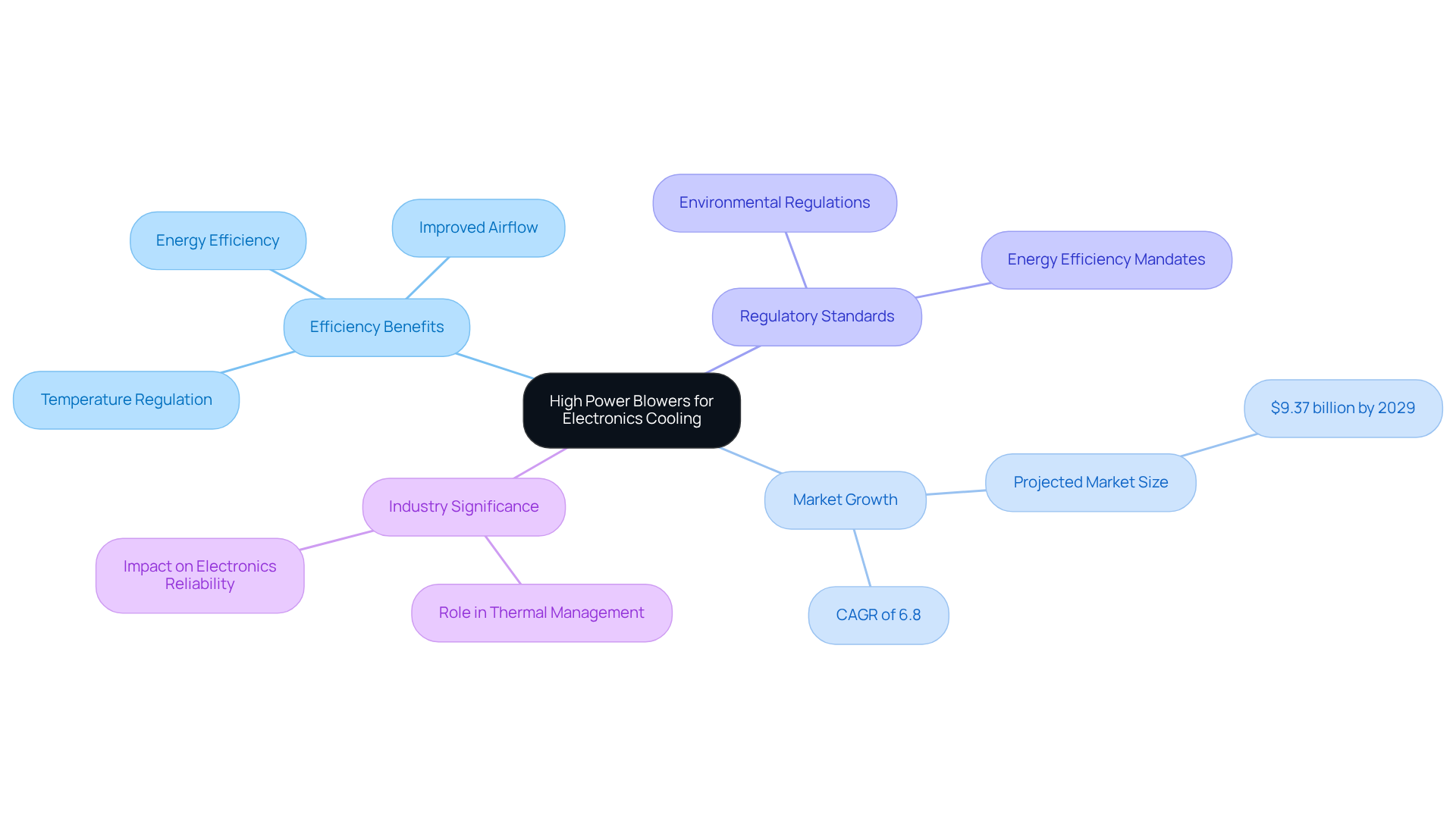

Comprehensive Advantages: Why High Power Blowers Are Essential for Electronics Cooling

High power blowers are essential for effective electronics temperature management, providing a range of benefits that enhance performance and reliability. These devices not only improve efficiency but also ensure dependable operation across various applications, making them crucial for modern electronic systems. Their innovative designs, characterized by forward-curved blades and the air curtain principle, significantly boost airflow and temperature regulation. For instance, the integration of high-speed fans in data centers has revolutionized thermal management, facilitating optimal cooling of densely packed equipment.

The global fans and ventilation market is projected to reach $9.37 billion by 2029, with a compound annual growth rate (CAGR) of 6.8%. This growth signifies an increasing demand for these devices, driven by the escalating complexity of electronic equipment and the need for . Furthermore, regulatory standards and energy efficiency mandates are intensifying the demand for high-performance fans, underscoring their importance in maintaining optimal operating conditions.

As industry specialists emphasize, ‘The significance of high-speed fans for contemporary electronic systems cannot be overstated, as they play a crucial role in ensuring effective thermal management and compliance with environmental regulations.’ As the electronics industry continues to advance, the necessity of high power blowers becomes increasingly apparent, establishing them as a cornerstone of effective cooling strategies.

Conclusion

High power blowers are indispensable for the efficient cooling of electronic systems, ensuring optimal performance and longevity across various applications. Their advanced designs and technologies not only tackle the intricate thermal management demands of modern electronics but also contribute significantly to energy savings and operational reliability.

This article has highlighted the key benefits of high power blowers, including their high power density, reliable operation, and versatility in diverse environments. The integration of centrifugal fans, innovative air curtain principles, and the use of forward-curved blades represent essential advancements that enhance airflow and cooling efficiency. Moreover, the substantial cost savings and reduced energy consumption associated with these systems further emphasize their critical role in contemporary electronic applications.

As industries continue to evolve and the demand for efficient cooling solutions escalates, the importance of high power blowers cannot be overstated. Embracing these technologies transcends merely enhancing performance; it reflects a commitment to sustainability and energy efficiency. Engineers and decision-makers are urged to consider the adoption of high power blowers in their systems, ensuring they remain at the forefront of innovation in electronics cooling.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for providing high power blower systems that address complex temperature regulation challenges in the electronics sector.

What applications benefit from high power blower systems?

High power blower systems are used in various electronic applications, including data centers, medical devices, and consumer electronics, to maintain optimal airflow and cooling.

Why are DC fans popular in electronics?

DC fans are celebrated for their energy efficiency and quiet operation, making them ideal for use in laptops, desktops, and gaming consoles, thereby enhancing performance and reliability.

How do high power blowers contribute to air quality management?

High power blowers are successfully implemented in critical environments like clean rooms and data centers, where effective air quality management is essential.

What are Electronically Commutated (EC) fans, and why are they significant?

EC fans provide precise airflow control and energy savings, aligning with modern energy efficiency standards. Their market is projected to grow at a CAGR of 7.8% from 2024 to 2032.

What advancements are being made in blower technology?

Innovations such as variable speed control and compact designs are being developed to meet the increasing demand for efficient temperature regulation solutions.

How does temperature management affect electronic component longevity?

A rise of 18° in operating temperature can halve the lifespan of electrical insulation, highlighting the importance of effective temperature management in prolonging equipment life.

What is the role of centrifugal fans in electronics cooling?

Centrifugal fans are designed for high power blower performance, generating significant airflow while consuming minimal power, which helps maintain optimal operating temperatures.

How do centrifugal fans impact power consumption in wastewater processing?

In wastewater processing facilities, centrifugal fans can account for 40-60% of total power consumption, emphasizing their importance in power management.

What energy savings can be achieved with advanced ventilation technologies?

Technologies like Inovair’s geared centrifugal fans can demonstrate energy savings of 10-40% compared to traditional setups, making them an excellent choice for regulating electronics temperatures.

What is the importance of reliable operation in high power blowers?

High power blowers are engineered for reliable operation, reducing the risk of failure and ensuring consistent airflow to prevent overheating of sensitive electronic components.

What percentage of electronic component failures are caused by thermal issues?

More than 50% of electronic component failures are attributed to thermal issues, underscoring the need for effective temperature regulation solutions.