Overview

This article delves into the indispensable applications of air pressure blowers within the realm of electronics engineering. It underscores their vital roles in:

- Cooling

- Power management

- Timing accuracy

- Preservation of signal integrity

By illustrating how these blowers significantly enhance system efficiency, avert overheating, and elevate the performance of various electronic devices, the article demonstrates their crucial contribution to the optimization of engineering designs.

Introduction

The critical role of air pressure blowers in electronics engineering is paramount, providing essential solutions for cooling, power management, and maintaining signal integrity. This article explores ten vital applications of air pressure blowers, illustrating how these devices significantly enhance system efficiency and reliability across various electronic sectors. Yet, with a multitude of options available, how can engineers ascertain the most effective application of air pressure blowers in their designs? Investigating this question uncovers the transformative potential of these innovative tools in optimizing electronic performance.

Gagner-Toomey Associates: Innovative Air Pressure Solutions for Electronics Engineering

Gagner-Toomey Associates stands at the forefront of delivering advanced air pressure blower solutions specifically designed to address the unique challenges of electronics engineering. By focusing on critical domains such as cooling, power management, and interconnect technologies, the company empowers engineers with essential tools to optimize their designs effectively. Their commitment to surpassing customer expectations is reflected in their consultative approach, where they actively engage with clients to comprehend their distinct needs and provide customized solutions. This level of responsiveness is highly valued by clients across a variety of industries.

As Joseph, a Global Sales & Marketing Director at Delta Products Corp, remarks, ‘GTA has been the best rep in the North American fan business for many years.’ Such dedication to innovation, coupled with strategic collaborations with leading manufacturers, enables Gagner-Toomey to offer cutting-edge air pressure blowers that significantly enhance system efficiency and reliability.

David, a Senior Design Engineer at Juniper Networks, underscores, ‘It’s not only a pleasure dealing with GTA, it makes good business sense. I get correct information quickly, excellent products, courteous and proactive service, and competitive prices on state-of-the-art air movers from Delta Electronics.’

These robust customer relationships, along with advanced IT solutions, facilitate , positioning Gagner-Toomey as a leader in delivering solutions that meet the evolving demands of the industry. For engineers seeking to optimize their designs, leveraging Gagner-Toomey’s innovative air pressure blower solutions represents a transformative decision.

Regenerative Blowers: Enhancing Cooling Efficiency in Electronics Systems

Solenoid and rotary boost pumps are essential components in enhancing cooling efficiency within electronic systems. These pumps are meticulously engineered to deliver continuous airflow, making them ideal for applications that demand consistent cooling. By maintaining optimal temperatures, solenoid and rotary boost pumps effectively prevent overheating, thereby extending the lifespan of electronic components. Their operation is characterized by low noise levels and high efficiency, making them the preferred choice in environments where noise reduction is paramount.

Moreover, Gagner-Toomey Associates offers a comprehensive selection of solenoid pumps, including:

- Open frame

- Tubular

- Latching varieties

All adhering to automotive standards such as SAE and VDA. This commitment guarantees across diverse applications.

Air Pressure Blowers: Optimizing Power Management in Electronic Devices

Air pressure blowers play a crucial role in optimizing power management within electronic devices, significantly enhancing energy efficiency. By facilitating effective airflow, the air pressure blower regulates temperatures, which is essential in high-performance applications where power efficiency is paramount.

For example, DC fans, recognized for their low noise operation and compact design, are widely employed in laptops, desktops, and gaming consoles. They help maintain optimal temperatures, thereby preventing performance degradation due to heat buildup.

In data centers, air pressure blowers effectively cool routers, switches, and servers, ensuring a continuous supply of fresh air while consuming less power than conventional cooling methods. Industry specialists assert that integrating air pressure blowers can yield energy savings of up to 10%, making them indispensable in modern electronics design.

Their capacity to at sound levels of 72-73 dB(A) renders them suitable for sound-sensitive environments, such as hospitals and offices, where maintaining a low noise profile is critical. Furthermore, the advanced control systems in contemporary fans allow for real-time monitoring and adjustments, optimizing energy usage and enhancing overall system performance.

By leveraging air movement devices, engineers can develop products that not only meet stringent performance criteria but also comply with energy regulations, leading to more sustainable and efficient electronic solutions.

Timing Applications: Utilizing Air Pressure Blowers for Precision in Electronics

Air pressure blowers play a pivotal role in timing processes, ensuring the precision necessary for optimal performance in electronic systems. By delivering consistent airflow, an air pressure blower stabilizes temperatures and minimizes variations, which is critical in functions such as clock generation and synchronization. Even slight timing deviations can result in substantial performance challenges, making reliability essential. Notably, research indicates that circuits utilizing an air pressure blower can achieve up to a 30% improvement in timing accuracy compared to those that do not.

Furthermore, the integration of solenoid and rotary boost pumps can enhance airflow management, with the air pressure blower providing a complementary solution that bolsters the precision of timing circuits. This underscores the importance of employing both air pressure blowers and to elevate precision and reliability in electronics.

RF Applications: Maintaining Signal Integrity with Air Pressure Blowers

Air pressure blowers play a critical role in preserving signal integrity in RF applications. By supplying regulated airflow, the air pressure blower effectively disperses the heat generated by RF components, which, if left unchecked, could lead to signal deterioration. Furthermore, they contribute to minimizing electromagnetic interference (EMI) by utilizing an air pressure blower to maintain components within optimal operating temperatures. This function is particularly vital in high-frequency environments where is essential for optimal performance.

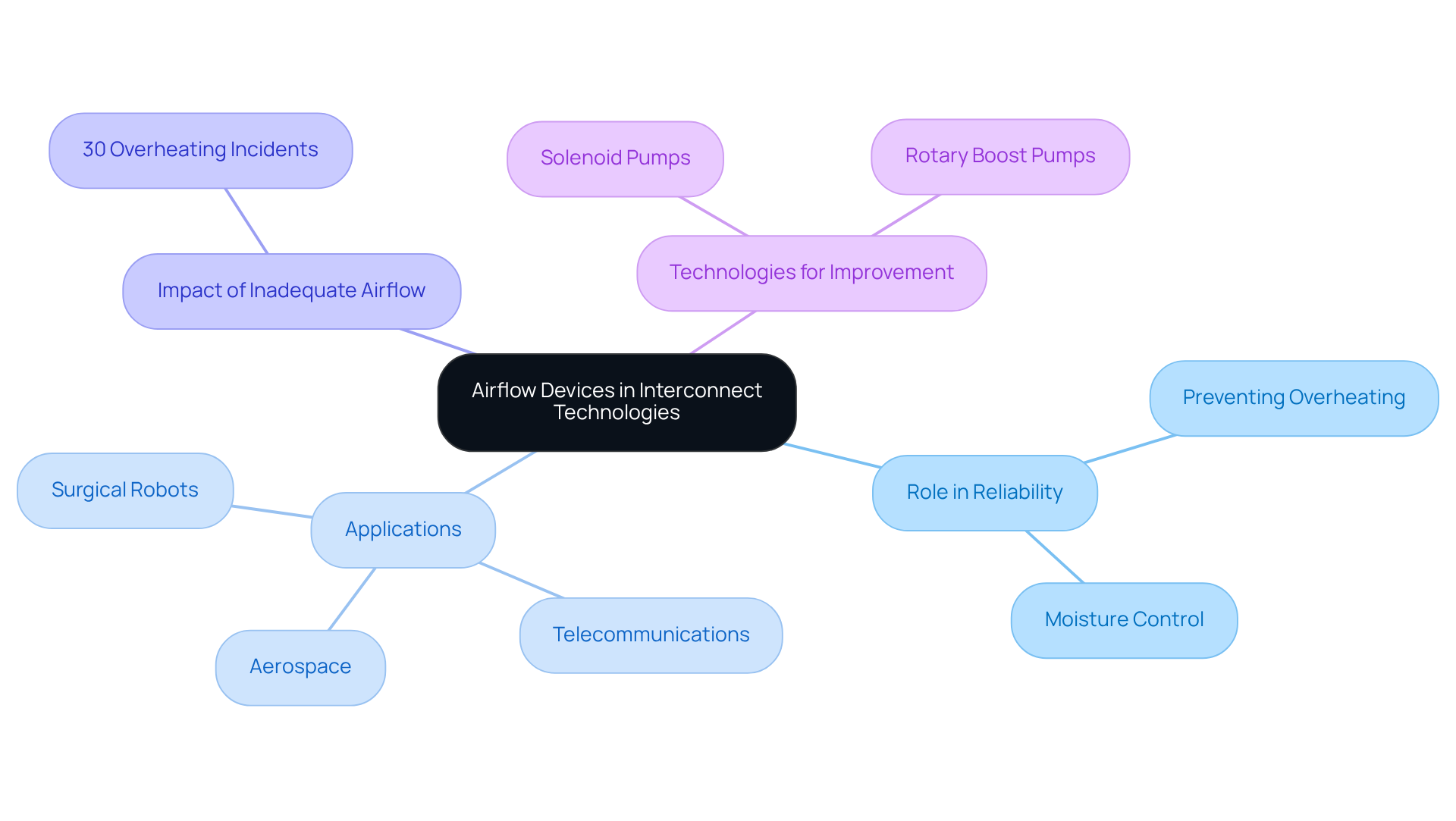

Interconnect Technologies: Ensuring Reliability with Air Pressure Blowers

Airflow devices, particularly the air pressure blower, and advanced pumping systems play a crucial role in maintaining optimal conditions for connectors and cables. These systems effectively prevent overheating and moisture accumulation, which can lead to connection failures. By providing consistent airflow, they significantly enhance the longevity and performance of interconnect systems, particularly in high-reliability applications such as aerospace and telecommunications.

For instance, the integration of compact fans in surgical robots illustrates how effective airflow management can elevate performance and safety in critical environments. Furthermore, studies indicate that inadequate airflow, which can be improved with an air pressure blower, is responsible for approximately 30% of overheating incidents in devices, underscoring the importance of air pumps in safeguarding system integrity.

To maximize effectiveness, engineers must regularly assess their airflow systems and consider implementing advanced technologies, such as:

- Solenoid pumps that operate up to 16 Bar

- Rotary boost pumps known for their low noise operation

These measures can help mitigate risks associated with overheating and moisture.

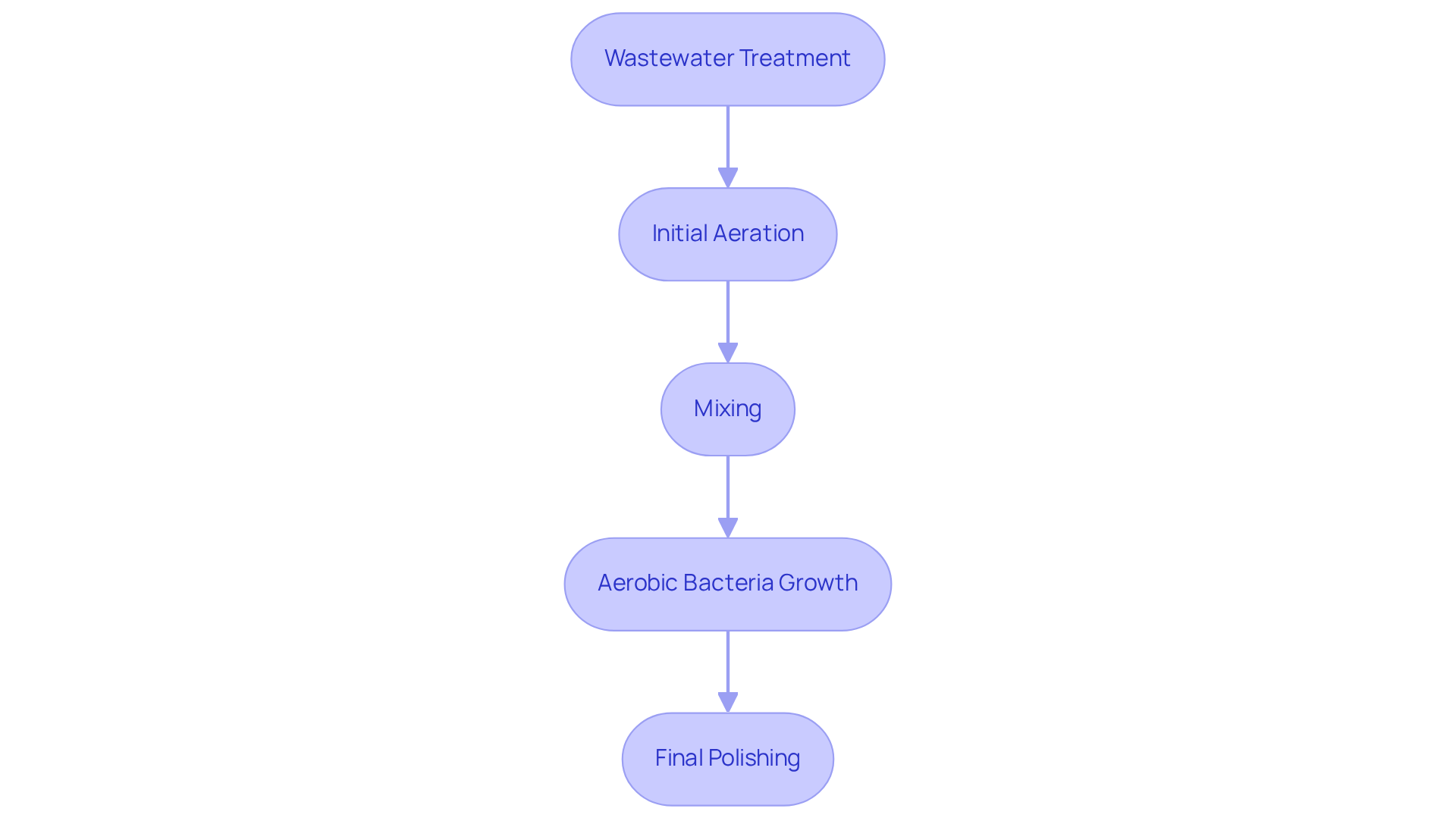

Waste Water Treatment: Versatile Applications of Air Pressure Blowers

Air pressure blowers play a crucial role in wastewater treatment processes, facilitating both aeration and mixing. By introducing air into treatment tanks with an air pressure blower, these devices stimulate the growth of aerobic bacteria, which are essential for breaking down organic material. Their adaptability allows for application across various treatment stages, from initial aeration to final polishing. This versatility makes them indispensable for maintaining water quality and ensuring compliance with environmental regulations.

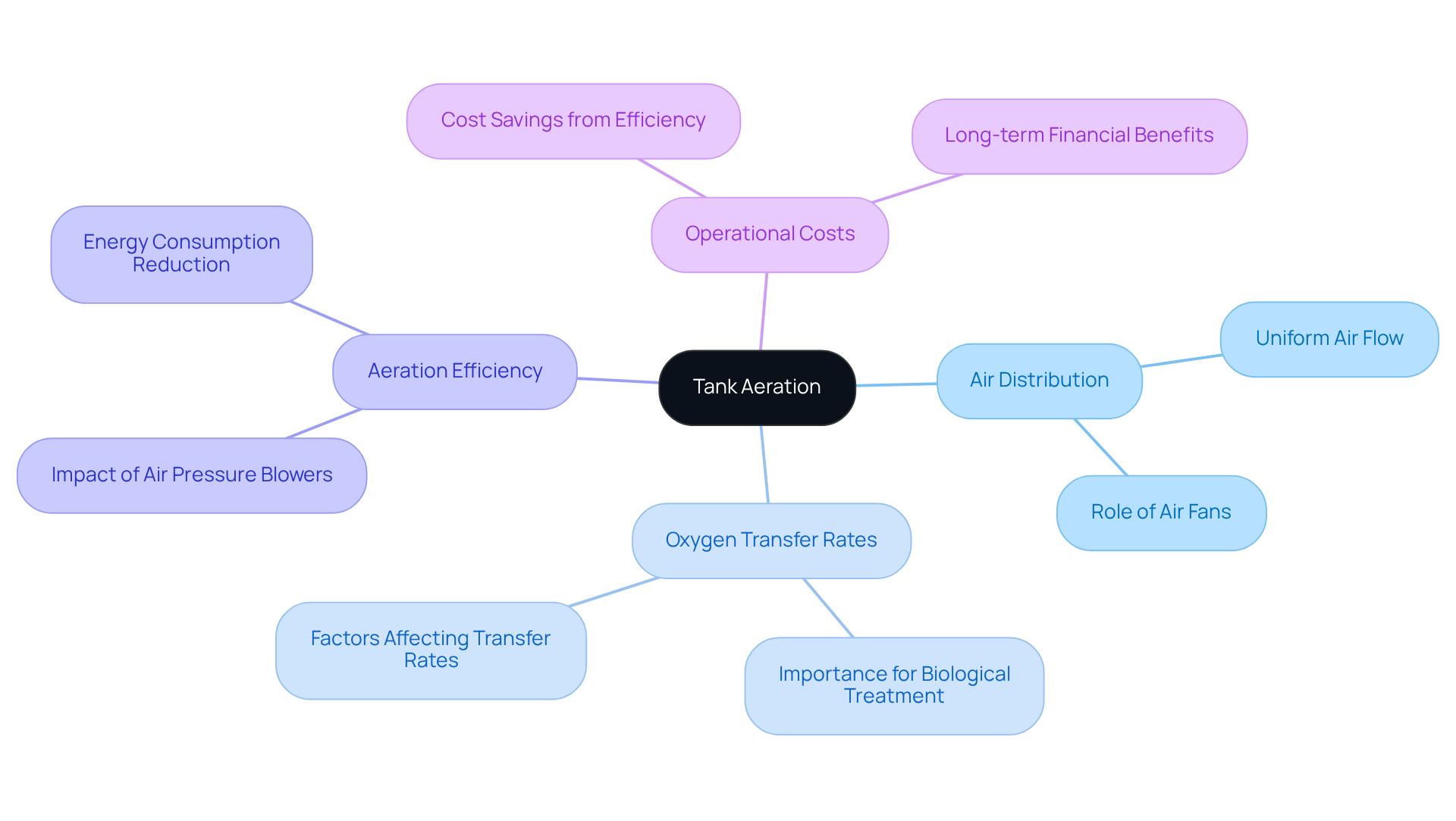

Tank Aeration: Enhancing Process Efficiency with Air Pressure Blowers

In the realm of tank aeration, air fans play a pivotal role in enhancing process efficiency by ensuring a uniform distribution of air throughout the tank. This uniformity is vital as it promotes , which are essential for effective biological treatment processes. These devices, such as the air pressure blower, significantly improve aeration efficiency, contributing to reduced energy consumption and lower operational costs. Consequently, they emerge as a critical asset in both industrial and municipal wastewater treatment plants.

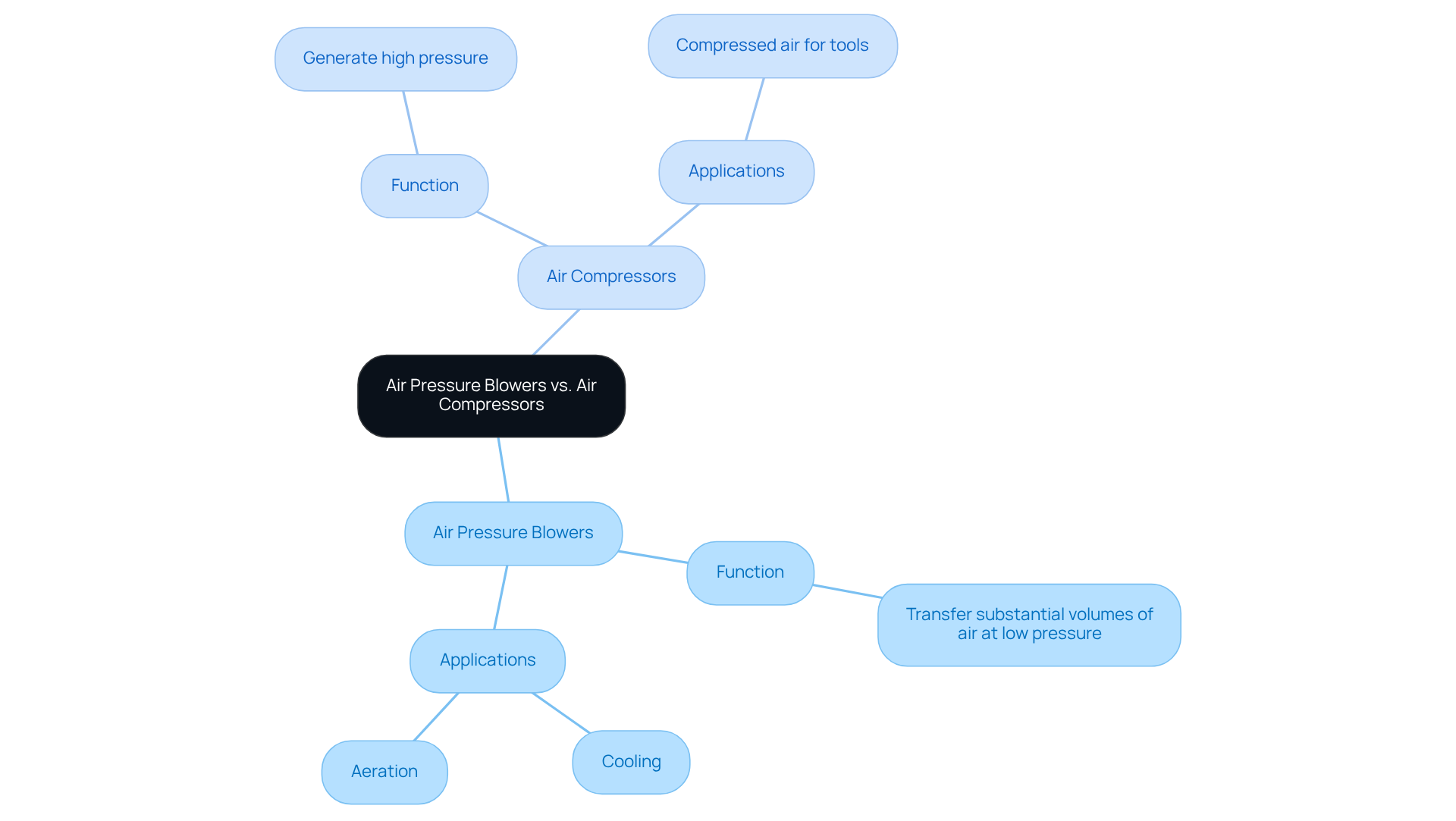

Air Pressure Blowers vs. Air Compressors: Choosing the Right Solution for Electronics

When selecting between air fans and air compressors, understanding their is essential.

- Air pressure blowers are specifically designed to transfer substantial volumes of air at low pressure, making them ideal for applications that require consistent airflow, such as cooling and aeration.

- Conversely, air compressors generate high pressure and are more suitable for applications that necessitate compressed air for tools or pneumatic systems.

Engineers must assess their specific requirements to determine which solution aligns best with their needs.

Debunking Myths: Understanding Industrial Air Blowers in Electronics Engineering

Numerous myths surround industrial air devices in electronics engineering, often leading to significant misunderstandings. A prevalent misconception is that all fans are identical, which overlooks critical distinctions in design and application. Additionally, many believe the air pressure blower is suitable solely for low-pressure scenarios; however, contemporary models are engineered to perform effectively at elevated pressures as well. By debunking these myths, engineers can gain a deeper appreciation for the capabilities of the air pressure blower, ultimately enabling them to make more informed decisions in their designs.

Conclusion

Gagner-Toomey Associates has firmly established itself as a leader in delivering innovative air pressure blower solutions specifically tailored for the electronics engineering sector. By addressing critical needs such as cooling, power management, and enhancing the reliability of interconnect technologies, these solutions empower engineers to optimize their designs and ensure efficient performance across various applications.

This article has explored the multifaceted applications of air pressure blowers, highlighting their essential roles in:

- Cooling electronic systems

- Optimizing power management

- Improving timing accuracy

- Maintaining signal integrity in RF applications

- Enhancing the reliability of interconnect technologies

Moreover, the versatility of these blowers extends to wastewater treatment processes, where they facilitate aeration and mixing, demonstrating their broad utility across different industries.

The significance of air pressure blowers in electronics engineering cannot be overstated. As technology continues to evolve, leveraging these advanced solutions will be crucial for engineers aiming to enhance system performance, energy efficiency, and overall reliability. By understanding the distinct functions and applications of air pressure blowers, professionals can make informed decisions that ultimately lead to superior designs and sustainable practices in the ever-changing landscape of electronics engineering.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for delivering advanced air pressure blower solutions tailored for electronics engineering, focusing on cooling, power management, and interconnect technologies.

How does Gagner-Toomey Associates engage with its clients?

The company employs a consultative approach, actively engaging with clients to understand their unique needs and provide customized solutions.

What do clients say about Gagner-Toomey Associates?

Clients, such as Joseph from Delta Products Corp and David from Juniper Networks, praise Gagner-Toomey for their quick information, excellent products, courteous service, and competitive pricing.

What types of pumps does Gagner-Toomey Associates offer for cooling efficiency?

Gagner-Toomey offers a comprehensive selection of solenoid pumps, including open frame, tubular, and latching varieties, all adhering to automotive standards like SAE and VDA.

What is the role of air pressure blowers in electronic devices?

Air pressure blowers optimize power management by regulating temperatures and enhancing energy efficiency, which is crucial in high-performance applications.

How do air pressure blowers contribute to energy savings?

Integrating air pressure blowers can yield energy savings of up to 10% in modern electronics design by consuming less power than conventional cooling methods.

What are the noise levels of air pressure blowers offered by Gagner-Toomey?

The air pressure blowers operate quietly at sound levels of 72-73 dB(A), making them suitable for sound-sensitive environments like hospitals and offices.

What benefits do advanced control systems in contemporary fans provide?

Advanced control systems allow for real-time monitoring and adjustments, optimizing energy usage and enhancing overall system performance.