Overview

The article underscores the significant advantages of 12V centrifugal fans for engineers, accentuating their essential role in optimizing temperature regulation, achieving energy savings, and facilitating versatile applications across diverse industries. This assertion is bolstered by in-depth discussions on their compact design, low power consumption, quiet operation, and durability. Collectively, these attributes enhance the performance and reliability of electronic systems, making them an indispensable choice for professionals in the field.

Introduction

The escalating demand for efficient cooling solutions within the electronics industry has catalyzed the advancement of technologies, notably 12V centrifugal fans. These compact yet potent devices empower engineers to significantly enhance the performance and longevity of diverse electronic applications by delivering optimal airflow and energy efficiency.

Nevertheless, with a multitude of options at their disposal, engineers are confronted with the challenge of identifying the most suitable fan to fulfill their specific requirements while judiciously balancing considerations such as:

- Noise

- Durability

- Ease of installation

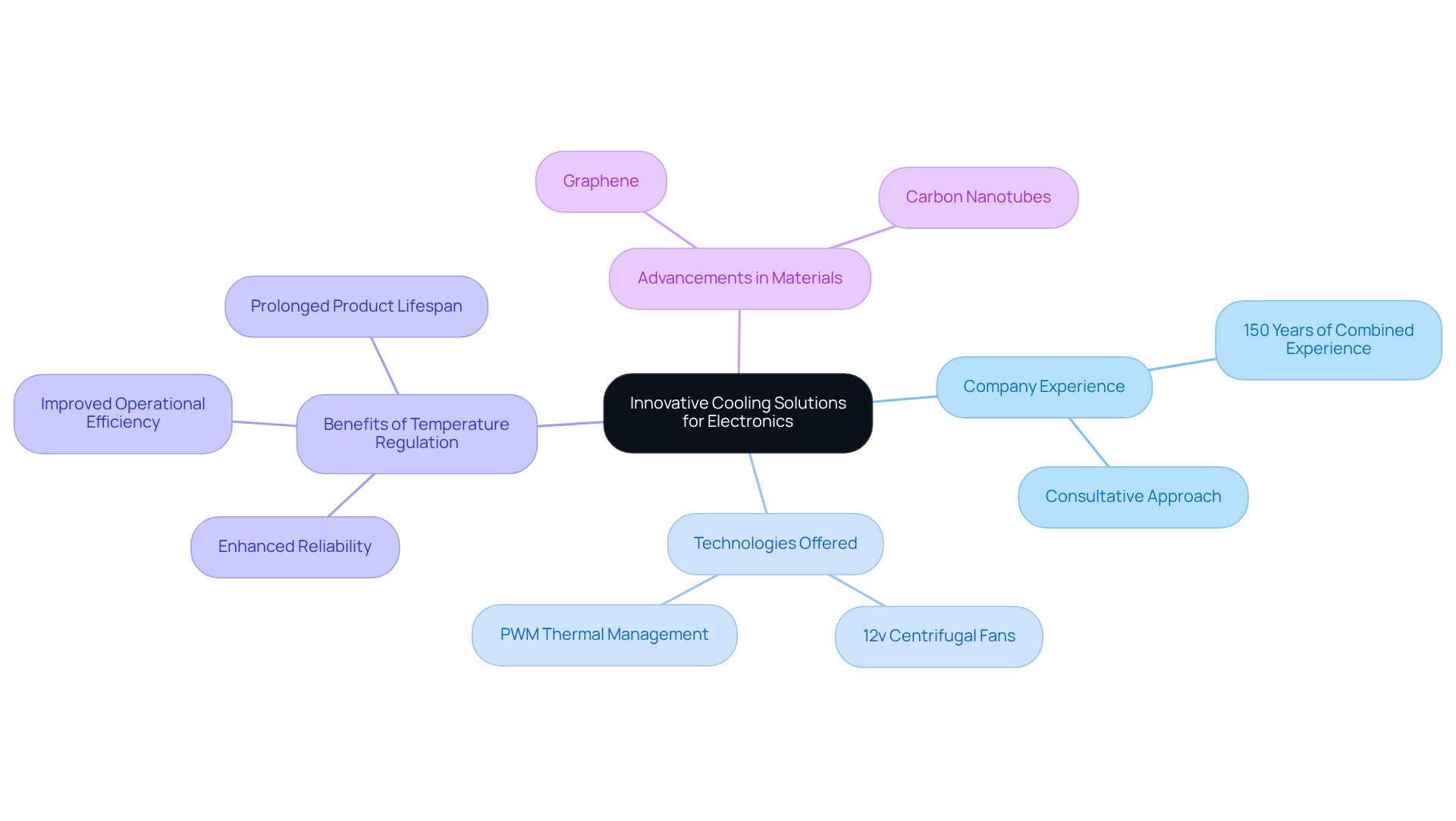

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Projects

Gagner-Toomey Associates stands at the forefront of specialized cooling solutions designed specifically for the electronics sector. With over 150 years of combined industry experience, our sales experts employ a that fortifies our partnerships with technical professionals.

By collaborating with a diverse array of manufacturers, including those specializing in PWM thermal management solutions, we equip engineers with access to cutting-edge technologies, such as 12v centrifugal fan devices. The 12v centrifugal fans play a critical role in regulating temperatures within electronic devices, thereby enhancing reliability and performance across various applications.

Research underscores that effective temperature regulation solutions can significantly prolong product lifespan and improve operational efficiency; for example, data centers utilizing PWM technology have reported efficiency enhancements in temperature management of up to 30%. This highlights the importance of selecting the appropriate temperature regulation technology tailored to specific applications.

As a leading sales firm in advanced electronics solutions, Gagner-Toomey Associates is committed to aiding professionals in achieving optimal thermal management. Our enduring relationships with customers and principals further amplify our capacity to deliver value.

Additionally, we investigate advancements in materials such as graphene and carbon nanotubes, which hold the potential to transform cooling efficiency, ensuring that engineers are equipped with the best tools for their projects.

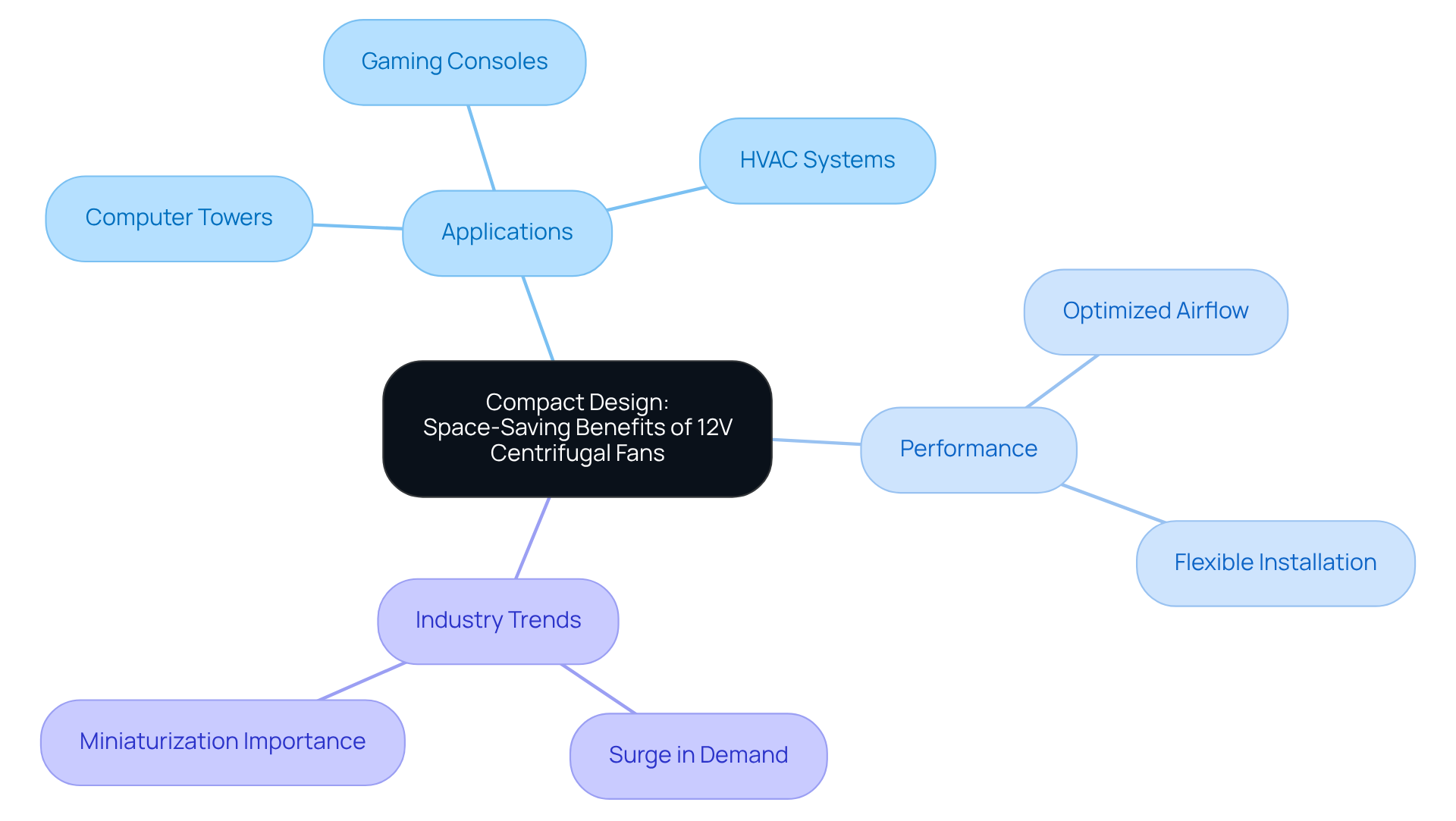

Compact Design: Space-Saving Benefits of 12V Centrifugal Fans

The 12v centrifugal fan designed by Gagner-Toomey Associates is expertly engineered with a compact footprint, making it exceptionally suited for applications where space is limited. Their small size does not compromise performance; rather, it facilitates flexible installation in confined areas, such as within enclosures or adjacent to other electronic components. This is crucial in contemporary electronics, where miniaturization is increasingly vital.

For instance, these fans are commonly employed in:

- Computer towers

- Gaming consoles

- HVAC systems

This optimizes airflow while preserving valuable design space. As highlighted by industry authorities, the incorporation of space-saving technologies is essential for improving efficiency and functionality in electronic temperature management solutions.

Gagner-Toomey Associates provides a wide range of DC input fans, varying from 15 to 225mm, with options for IP protection and low noise operation. Statistics indicate that the demand for compact cooling solutions has surged, reflecting a broader trend towards more efficient use of space in engineering designs. By utilizing the benefits of the 12v centrifugal fan from Gagner-Toomey Associates, engineers can effectively tackle thermal management challenges without compromising design integrity.

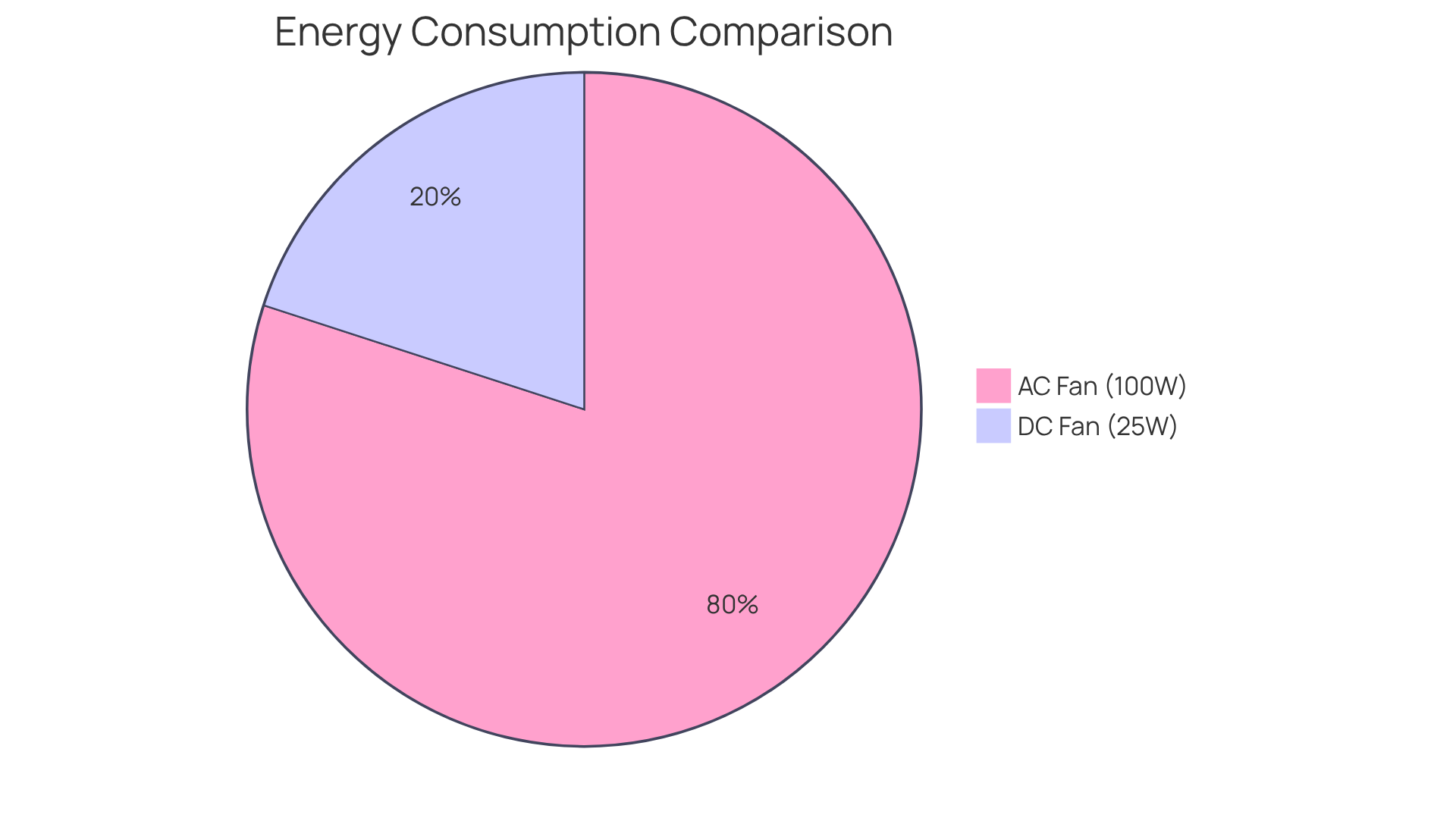

Energy Efficiency: Low Power Consumption of 12V Centrifugal Fans

A defining characteristic of the 12v centrifugal fan is its remarkably low power consumption. These devices are meticulously engineered to deliver substantial airflow while utilizing minimal energy, making them an ideal choice for projects focused on . By integrating these devices into their systems, engineers can significantly reduce overall power requirements, resulting in lower operational expenses and a reduced carbon footprint. Notably, DC enthusiasts consume up to 70% less energy than conventional AC units, which is particularly advantageous in battery-operated devices, where extending battery life is crucial. For instance, a 25-watt DC fan can achieve the same airflow output as a 100-watt AC fan, illustrating a significant reduction in energy usage. Furthermore, the average lifespan of a 12v centrifugal fan is approximately 40,000 hours, which enhances reliability and minimizes replacement costs over time. As Sam Pelonis observes, ‘DC enthusiasts are broadly seen as the most effective kind of devices,’ underscoring the integration of low power consumption technologies in electronic temperature regulation solutions that enhance performance and promote sustainable practices in engineering.

Versatile Applications: Utilizing 12V Centrifugal Fans Across Industries

The 12v centrifugal fan plays a critical role across various sectors, including automotive, telecommunications, consumer electronics, IoT, robotics, and medical applications. Gagner-Toomey Associates has established itself as a leader in delivering innovative solutions tailored to the specific temperature control needs of these diverse industries. Their expertise in mechanical, thermal, and system engineering ensures that these devices deliver reliable temperature regulation for a wide array of equipment, ranging from computer systems to HVAC units.

As one satisfied customer remarked, “Gagner-Toomey Associates has been instrumental in optimizing our cooling solutions, enhancing both performance and efficiency.”

Engineers can creatively customize these devices, including the 12v centrifugal fan, to meet the unique demands of their projects, solidifying its role as a staple in modern engineering solutions. This adaptability, reinforced by Gagner-Toomey Associates’ unwavering commitment to excellence, cements their status as a within the industry.

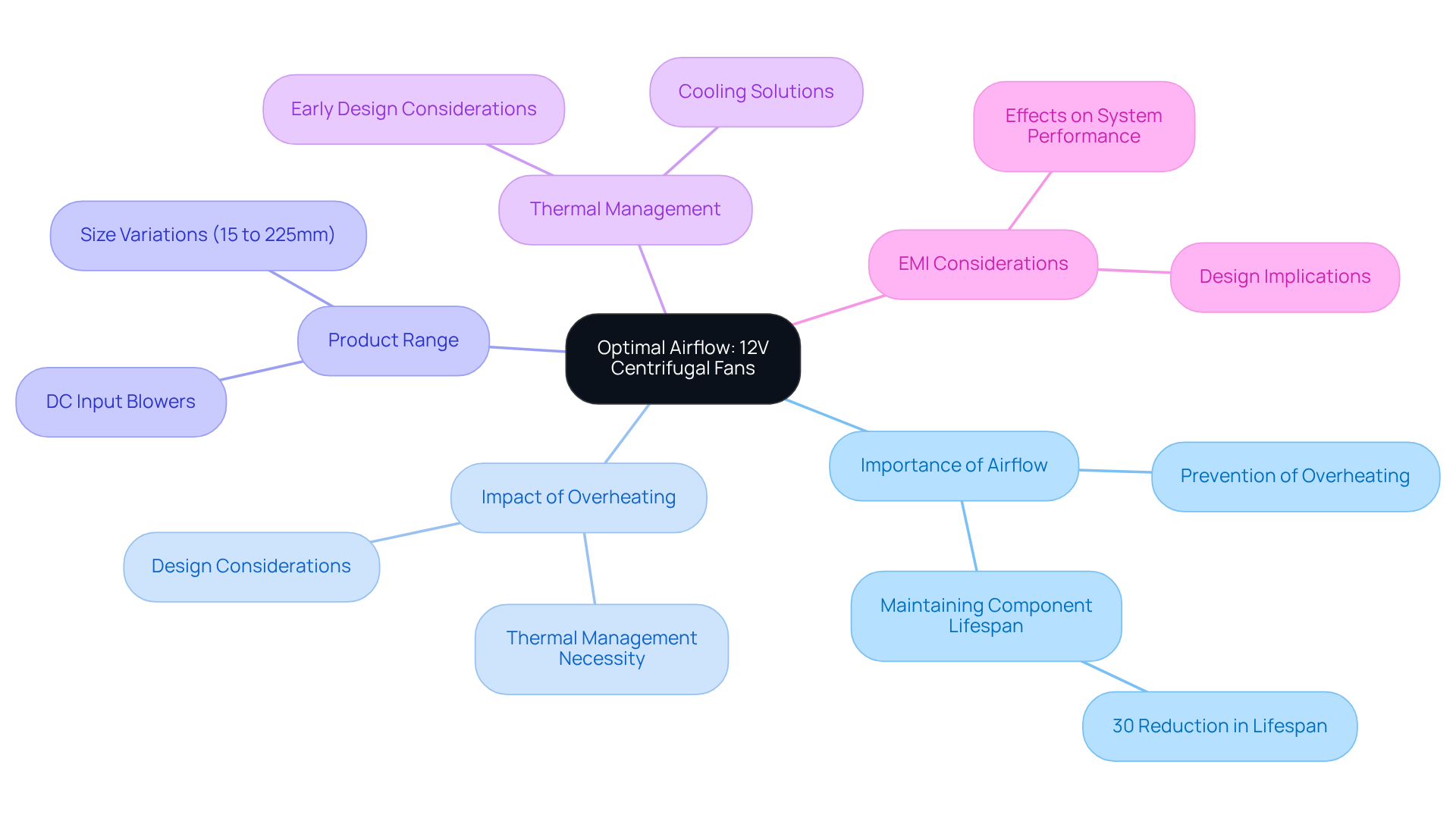

Optimal Airflow: Meeting Cooling Needs with 12V Centrifugal Fans

The 12V centrifugal fan from Gagner-Toomey Associates is engineered to deliver optimal airflow, which is crucial for maintaining electronic components within safe operating temperatures. By efficiently circulating air through systems, the 12V centrifugal fan effectively dissipates the heat generated by high-performance components, thereby preventing overheating and potential failures.

Overheating issues present a significant concern in electronics, with studies indicating that improper thermal management can lead to a 30% reduction in component lifespan. It is imperative for professionals to consider thermal management early in the design process for systems that generate heat.

Gagner-Toomey’s extensive product range features DC input blowers, including a 12V centrifugal fan that varies from 15 to 225mm, ensuring that professionals can depend on the performance specifications of these devices to select the appropriate model for their cooling needs, thus maintaining efficiency and reliability under diverse operating conditions.

As Ryan Smoot aptly noted, ‘Any component or system that generates operational heat which can negatively affect its performance must be cooled.’ This statement underscores the necessity for in electronic systems, highlighting the importance of the 12V centrifugal fan in contemporary engineering.

Furthermore, engineers should be cognizant of the electromagnetic interference (EMI) effects stemming from fan designs, which can influence system performance in sensitive applications. Gagner-Toomey’s rotating blowers are frequently employed in applications such as AC condensers and heat exchange units, showcasing their versatility in addressing thermal challenges.

Noise Management: Quiet Operation of 12V Centrifugal Fans

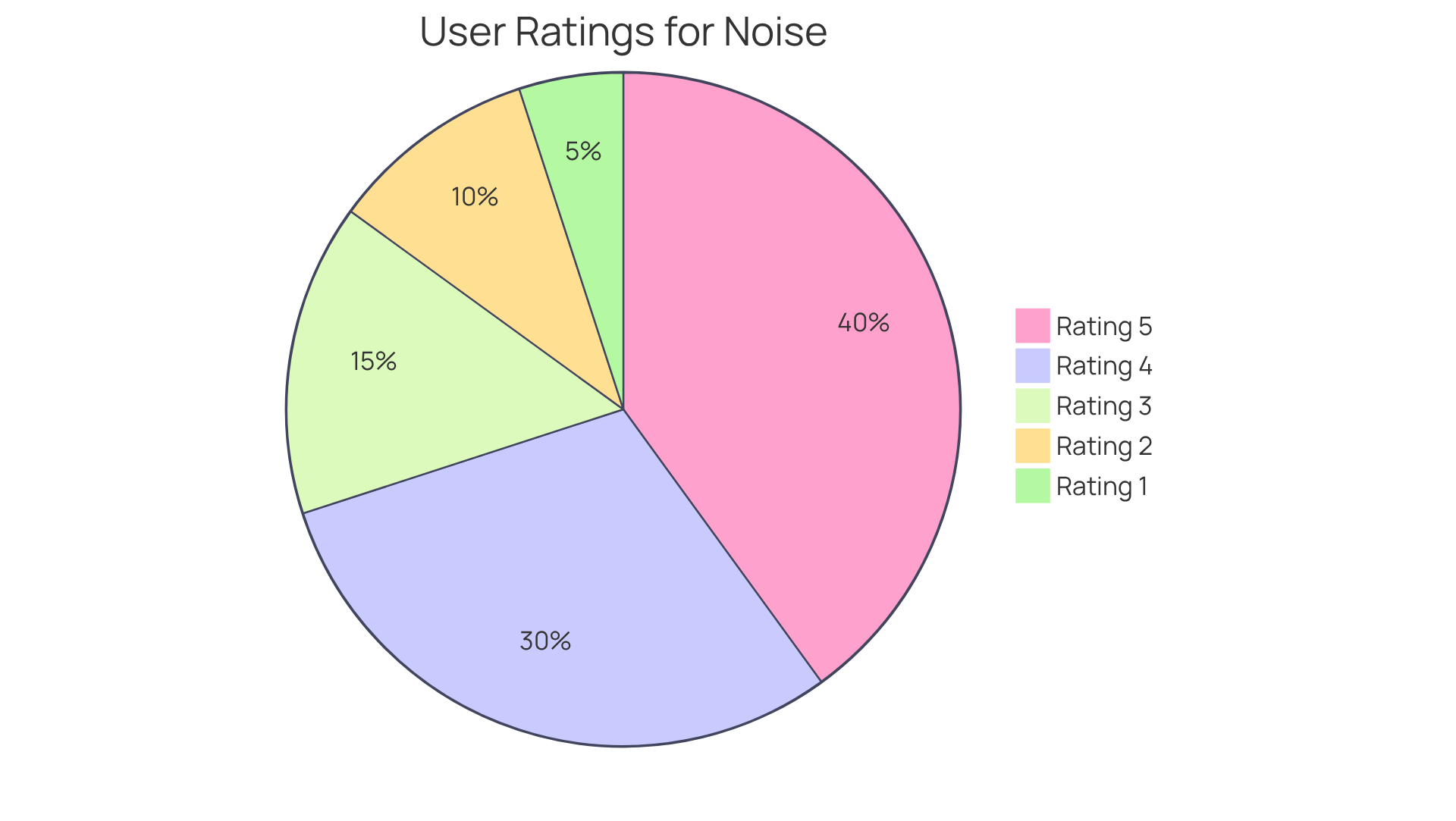

One of the standout characteristics of the 12v centrifugal fan is its remarkable silent performance, making it ideal for environments where noise management is paramount. These devices are meticulously engineered to minimize both vibration and noise levels, thereby ensuring their suitability for residential applications, office equipment, and other sensitive settings.

Engineers have the option to select from a variety of models with specific noise ratings, allowing them to adhere to industry standards while enhancing user comfort. Studies show that noise sensitivity in office environments can significantly affect productivity, with many employees reporting that excessive noise levels disrupt their focus. User ratings for noise levels in such settings average 4.5 out of 5, highlighting the critical importance of .

By integrating advanced motor designs and optimized airflow paths, these devices not only foster a tranquil atmosphere but also support the overall well-being of users. Consequently, the 12v centrifugal fan emerges as an exceptional choice for a diverse range of applications, from household uses to essential office environments.

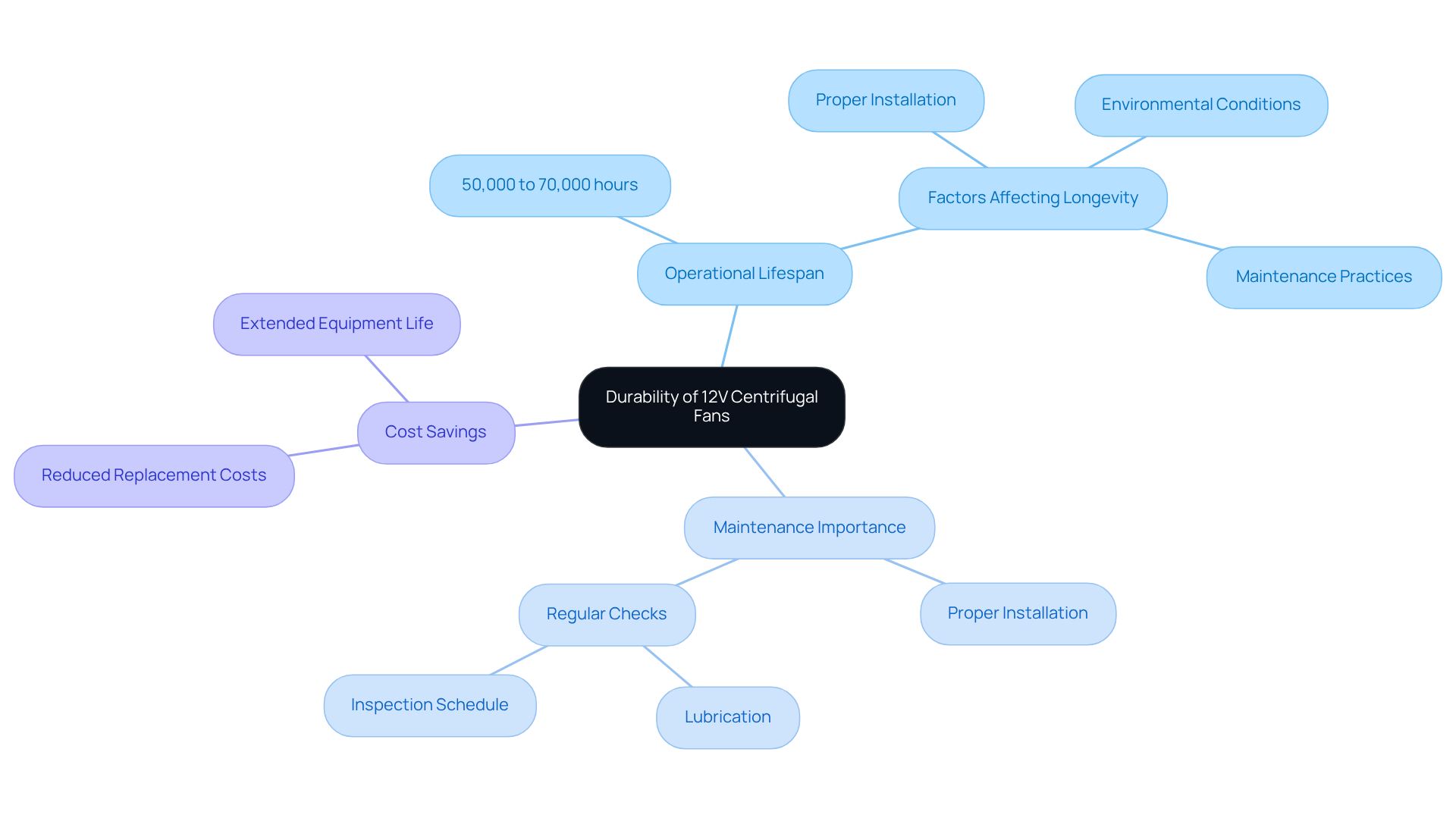

Durability: Long-Lasting Performance of 12V Centrifugal Fans

Gagner-Toomey Associates’ 12v centrifugal fan is engineered for exceptional durability, featuring robust construction and high-quality materials that ensure remarkable longevity. These devices are adept at withstanding harsh operating conditions, making them ideal for both industrial applications and consumer products.

Typically, centrifugal blowers offer an ranging from 50,000 to 70,000 hours, depending on usage and maintenance practices, providing a clear perspective on their longevity in practical terms. Engineers can confidently incorporate the 12v centrifugal fan into their designs, knowing they are investing in reliable temperature regulation solutions that minimize the need for maintenance and replacements.

Industry experts emphasize that proper installation and regular maintenance of a 12v centrifugal fan can significantly extend the operational lifespan of these devices, underscoring the importance of selecting high-quality cooling solutions from Gagner-Toomey Associates. This enhanced longevity not only boosts performance but also leads to substantial cost savings over time.

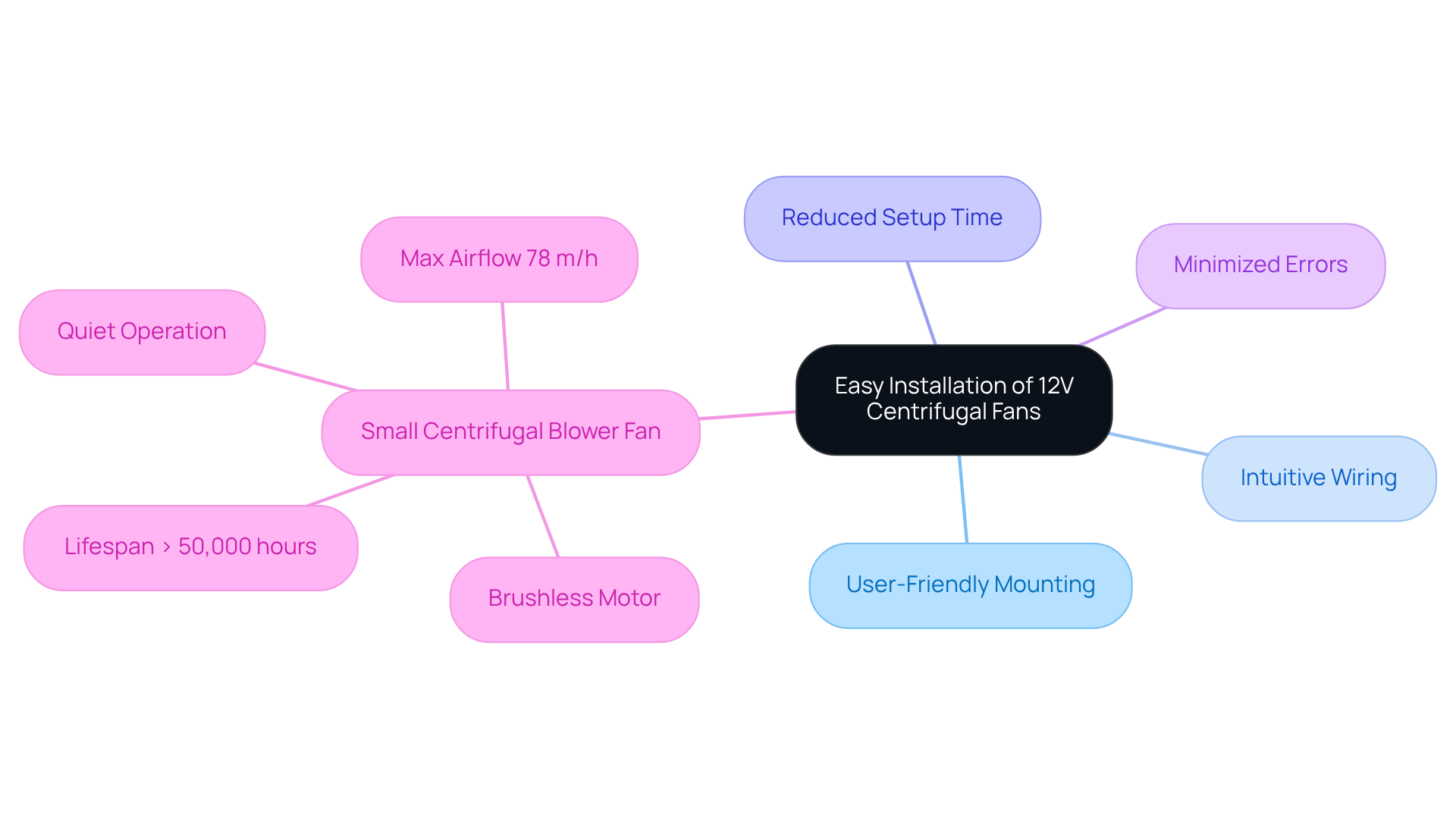

Easy Installation: Simplifying Setup with 12V Centrifugal Fans

12v centrifugal fans are engineered for effortless installation, featuring user-friendly mounting options and intuitive wiring configurations. This design simplicity not only allows professionals to seamlessly incorporate these devices into their projects but also significantly reduces setup time and minimizes the risk of errors. By selecting fans that prioritize ease of installation, designers can concentrate on other critical elements of their projects, thereby enhancing overall project efficiency.

For instance, the Small Centrifugal Blower Fan showcases a brushless motor and operates quietly, making it suitable for a range of applications, from cooling systems to ventilation. With a lifespan exceeding 50,000 hours and a at 0 kPa pressure, this fan exemplifies how streamlined installation can enhance functionality in confined spaces. Ultimately, the ease of installation of the 12v centrifugal fan not only accelerates project timelines but also fosters innovation, enabling engineers to allocate resources more effectively.

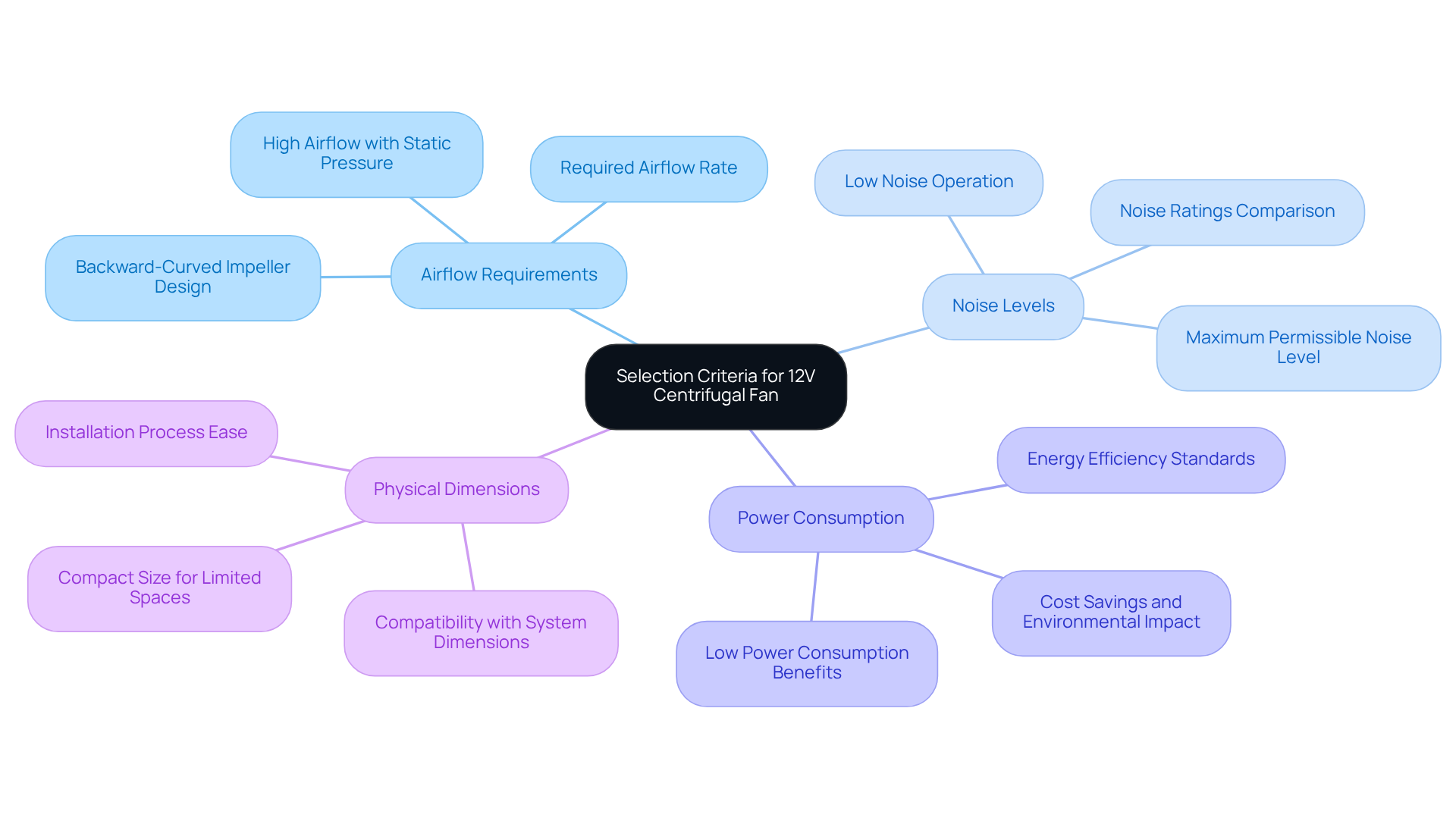

Selection Criteria: Choosing the Right 12V Centrifugal Fan for Your Project

Choosing the right 12v centrifugal fan requires careful consideration of several critical criteria. Engineers must prioritize:

- Airflow requirements

- Noise levels

- Power consumption

- Physical dimensions

to ensure optimal performance. Understanding the specific application and environmental conditions is crucial, as these factors significantly influence . Performance curves and manufacturer specifications serve as vital resources, empowering professionals to make informed decisions aligned with their project’s temperature needs.

Recent statistics reveal that professionals frequently cite airflow capacity and energy efficiency as paramount selection criteria for the 12v centrifugal fan, underscoring the importance of these elements in achieving reliable and effective cooling solutions. By adhering to these guidelines, engineers can enhance the performance and longevity of their designs, ultimately leading to more successful project outcomes.

Where to Buy: Sourcing Quality 12V Centrifugal Fans for Your Needs

Engineers seeking to acquire a 12v centrifugal fan should explore a range of sourcing options, including:

- Specialized electronics distributors

- Online marketplaces

- Direct purchases from manufacturers

The procurement process for these fans necessitates a thorough evaluation of suppliers based on:

- Reliability

- Quality

- Delivery timelines

In this context, Gagner-Toomey Associates plays a pivotal role by connecting professionals with reputable manufacturers, thereby ensuring access to high-quality products that meet specific project requirements. By leveraging established relationships within the industry, professionals can optimize their procurement processes, enhancing efficiency and ensuring the timely delivery of essential components. Recent trends reveal a growing preference for , as engineers increasingly prioritize responsive service and flexible delivery options in their sourcing strategies.

Conclusion

The advantages of 12V centrifugal fans are substantial, establishing them as an essential component for engineers dedicated to optimizing thermal management in electronic applications. These fans not only facilitate effective cooling but also enhance the overall performance and reliability of various devices. Their compact design, energy efficiency, versatility across industries, and user-friendly installation make them a preferred choice for modern engineering solutions.

Key insights from the article underscore how 12V centrifugal fans excel in critical areas such as:

- Space-saving capabilities

- Low power consumption

- Durability

These fans are meticulously engineered to provide optimal airflow while minimizing noise, ensuring they meet the diverse needs of applications ranging from consumer electronics to industrial systems. By understanding the selection criteria and sourcing options, engineers can make informed decisions that lead to successful project outcomes.

Ultimately, embracing the benefits of 12V centrifugal fans can lead to significant improvements in:

- Product lifespan

- Operational efficiency

- User satisfaction

As the demand for innovative cooling solutions continues to grow, exploring the offerings from trusted suppliers like Gagner-Toomey Associates becomes imperative. By investing in high-quality cooling technologies, engineers can not only enhance their projects but also contribute to more sustainable practices in the electronics industry.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates specializes in innovative cooling solutions specifically designed for the electronics sector, leveraging over 150 years of combined industry experience.

How does Gagner-Toomey Associates support engineers in their projects?

The company employs a consultative approach and collaborates with various manufacturers to provide engineers access to advanced technologies, such as PWM thermal management solutions and 12v centrifugal fan devices.

What role do 12v centrifugal fans play in electronics?

12v centrifugal fans are critical for regulating temperatures within electronic devices, enhancing reliability and performance across various applications.

What benefits do effective temperature regulation solutions provide?

Effective temperature regulation can significantly prolong product lifespan and improve operational efficiency, with data centers using PWM technology reporting efficiency enhancements of up to 30%.

What are the design benefits of the 12v centrifugal fans offered by Gagner-Toomey Associates?

The 12v centrifugal fans have a compact design that allows for flexible installation in confined spaces, making them suitable for applications like computer towers, gaming consoles, and HVAC systems.

What is the significance of space-saving technologies in electronics?

Space-saving technologies are essential for improving efficiency and functionality in electronic temperature management solutions, especially as miniaturization becomes increasingly vital in modern designs.

What are the energy efficiency benefits of 12v centrifugal fans?

These fans have low power consumption, using up to 70% less energy than conventional AC units, which is advantageous for battery-operated devices and helps reduce operational expenses and carbon footprints.

How long do 12v centrifugal fans typically last?

The average lifespan of a 12v centrifugal fan is approximately 40,000 hours, enhancing reliability and minimizing replacement costs over time.